Subscribe to Our Youtube Channel

Summary of Contents for CNC4PC C10D

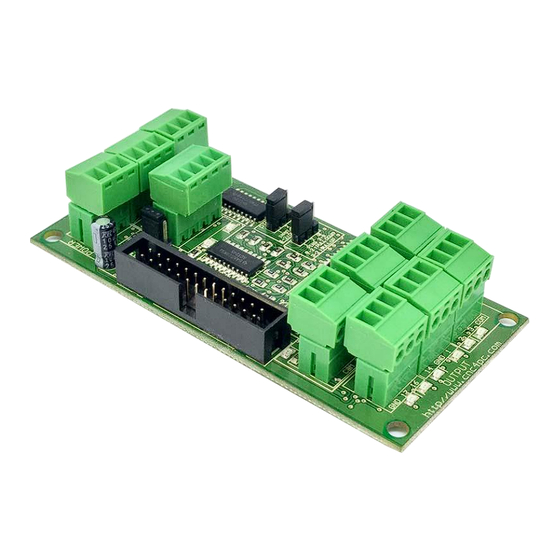

- Page 1 USER’S MANUAL VER.1 C10D- PARALLEL PORT INTERFACE CARD BOARD Rev. 1 MARCH 2018 User’s Manual Page i...

-

Page 2: Table Of Contents

USER'S MANUAL TABLE OF CONTENTS Contents Page # OVERVIEW ........................iii FEATURES ........................iii SPECIFICATIONS ......................1 BOARD DESCRIPTION ....................1 SPECIFICATIONS ......................2 Power Requirements ....................2 POWER TERMINAL ....................... 2 Enable pin........................3 LED INDICATOR ......................3 CONFIGURATION JUMPERS .................. -

Page 3: Overview

OVERVIEW This card uses the popular circuits found in the C10 with high power buffers that provide very stable signals but in an industrial format to make it easy to implement control boxes. This version of the C10 can be easily mounted on control boxes using DIN rails and can also accommodate ribbon cables or DB25 connectors. -

Page 4: Specifications

SPECIFICATIONS DIGITAL INPUT SPECIFICATIONS On-state voltage range 2 to 5V DC Maximum off-state voltage 0.8V Maximum operation frequency 4 MHz Typical signal delay 10nS DIGITAL OUTPUT SPECIFICATIONS Maximum output voltage 5VDC Typical output current 50mA Maximum off-state voltage 0.44 V Maximum operation frequency 4 MHz Typical signal delay... -

Page 5: Specifications

SPECIFICATIONS Power Requirements Regulated +5VDC@ 500mA is required to power this board. WARNING Check the polarity and voltage of the external power source and connect the 5VDC and GND. Overvoltage or reverse-polarity power applied to these terminals can cause damage to the board, and/or the power source. POWER TERMINAL User’s Manual Page 2... -

Page 6: Enable Pin

ENABLE BREAKOUT BOARD Enable pin. The card must be provided with a 5VDC signal to enable operation. This feature has been added to externally control the status of the outputs. An external switch or a Safety Charge Pump can be added to provide the enabling signal. When the enable signal is not present, output signals sent high impedance state. -

Page 7: Configuration Jumpers

CONFIGURATION JUMPERS Using the COM configuration jumper The COM terminal can be +5vdc or GND. 1-2: COM= GND 2-3: COM= +5VDC Using the Pins 2-9 direction jumper There is a jumper to select the pins 2-9 direction. 1-2: OUTPUTS 2-3: INPUTS User’s Manual Page 4... -

Page 8: Using The Pull-Up Or Pull-Down Selection Jumper For Pins 2-9

Using the Pull-up or Pull-down selection jumper for pins 2-9. Jumper allows to change the input configuration for 2-9. a. If a pin is pulled down, then it needs a high to make it change states. b. If a pin is pulled up, then it is a ground what will make it change states. 1-2: PULL-DOWN 2-3: PULL-UP Using the Pull-up or Pull-down selection jumper for pins 10, 11,... -

Page 9: Functional Block Diagrams

10.0 FUNCTIONAL BLOCK DIAGRAMS 10.1 Bidirectional pins simplified block diagram Fig. 1 Simplified functional block diagram for the 2-9 pins. A Pull-up or Pull-down selection jumper allows selecting the configuration for the all bidirectional pins (2-9) when they are set as inputs. 10.2 Dedicated Inputs simplified block diagram Fig. -

Page 10: Wiring Diagrams

11.0 WIRING DIAGRAMS While this board supports only TTL +5VDC signals, different kind of sensors, switches using different voltages can be connected using the diagrams that follow: Note. This board has two possible inputs banks, (bidirectional pins: 2-9) and (dedicated inputs: pins 10, 11, 12, 13 and 15), and all the inputs of the same bank have the same configuration. -

Page 11: Connecting In Parallel Npn Sensors

11.3 Connecting in parallel NPN sensors. Fig. 5 Wiring diagram to connect in parallel NPN open collector proximity sensors. Connecting NPN open collector proximity sensor with the C10D R1 Value (12V) R1 Value (24V) Approx. 10KΩ Approx. 25KΩ Fig. 6 Wiring diagram to connect NPN proximity sensors with internal pull up resistor. - Page 12 Some NPN proximity sensors have an internal pull-up resistor (R1). It is necessary to know its value in order to safety connect the sensor with the BOB. Follow this recommendation: Connecting NPN open collector proximity sensor with the C10D (R1+R2) Value (12V) (R1+R2) Value (24V) Approx. 10KΩ...

-

Page 13: Connecting Pnp Sensors

11.4 Connecting PNP sensors. Fig. 7 Wiring diagram to connect PNP proximity sensors Connecting PNP proximity sensor with the C10D R Value (12V) R Value (24V) Approx. 10KΩ Approx. 25KΩ User’s Manual Page 10... -

Page 14: Dimensions

12.0 DIMENSIONS All dimensions are in Millimeters. Fixing holes (4mm). DISCLAIMER Use caution. CNC machines can be dangerous machines. Neither DUNCAN USA, LLC nor Arturo Duncan are liable for any accidents resulting from the improper use of these devices. This product is not a fail-safe device and it should not be used in life support systems or in other devices where its failure or possible erratic operation could cause property damage, bodily injury or loss of life.

Need help?

Do you have a question about the C10D and is the answer not in the manual?

Questions and answers