Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Ackuretta FreeShape 120

- Page 2 FreeShape 120, Alpha 3D, the Alpha 3D logo, Omega 3D, the Omega 3D logo, Ackuretta, and the Ackuretta logo are all trademarks of Ackuretta Technologies Pvt. Ltd. Products or company names mentioned herein besides Ackuretta-branded products are regis- tered trademarks of their owners.

- Page 3 Resin Safety Resins provided by Ackuretta are non-carcinogenic acrylic-based photopolymer liquids that give off a light odor. These resins may cause skin, eyes and respiratory system irritation, and skin sensitivities or allergic reactions by skin contact.

- Page 4 Resin Protective Gear The hands are the most likely affected area when handling resins. Wear rubber, nitrile, polyvinyl Gloves chloride, or other chemical-resistant gloves. While using air compressors or due to usage or handling, resin may splash into the eyes. Wear protective Eye Protection goggles, safety glasses with side shields, or a face shield.

- Page 5 Disposal Resins provided by Ackuretta are not readily biodegradable. Releasing these resins into the environment may be illegal according to the regulations in the usage area. * Properly dispose of resins in accordance with all applicable federal, state, and local regulations.

-

Page 6: Table Of Contents

Contents About the FreeShape 120 Specifications Features Machine Overview Package Contents Machine Console Interface Web Console Interface Getting Started Unboxing Your Machine What You Need Setup Environment Calibrating Your Build Platform Connecting to Your LAN or Wi-Fi Network Printing Design Your 3D Model... -

Page 7: About The Freeshape 120

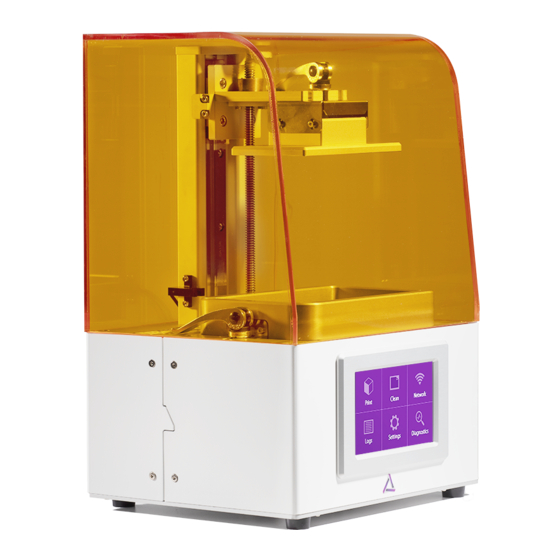

Resin-based 3D printing has advanced in several stages, starting from laser-based SLA machines to much faster DLP printers. Ackuretta brings its technical expertise into the next stage of printing with the FreeShape 120, a desktop LCD printer that delivers high-resolution, smooth surface prints at a price point that is ideal for the entry-level market. -

Page 8: Machine Overview

Machine Overview Front Left Side Right Side Hood Console Back Side Build platform Guideway Power port Power USB ports switch Serial number sticker Ethernet/LAN port FreeShape 120 Manual... -

Page 9: Package Contents

FreeShape 120 Machine Console Interface When you turn on your FreeShape 120, the machine will spend a few seconds loading, and then will arrive on the home screen. The home screen has the following functions: Set up your build platform or check that your light engine is working correctly. -

Page 10: Web Console Interface

Web Console Interface Access the web console by connecting your FreeShape 120 to a network, either using an Ethernet cable or over Wi-Fi. The web console has the following functions: The Print screen is the home screen for the web console. You upload print files from your computer to the Printer Memory and start prints from there. -

Page 11: Getting Started

Getting Started After you receive your FreeShape 120 printer, you will need to do a little bit of work to get your printer up-and-running. This section describes all of the setup you need to do for your machine, so you can go from package to printing as soon as possible. -

Page 12: What You Need

This section outlines the items that you need to acquire in addition to the items shipped with the printer. A. Computer In order to run the Alpha 3D or Omega 3D print software, you will need a computer that meets the following minimum requirements. FreeShape 120 Manual... - Page 13 C. Cleaning alcohol – isopropyl alcohol (99% solution) or ethyl alcohol (95% solution) D. Resin – the FreeShape 120 is tested with all Ackuretta Qura- resins, but you may use any 405 nm resin E. Knife or scraper – to remove prints from the build platform F.

-

Page 14: Setup Environment

4. Calibrating Your Build Platform Adjust the fit of your FreeShape 120 build platform when you first open your machine. If you do not calibrate your build platform, your prints may be uneven, or you may encounter print failures. After calibrating once for the machine, you do not need to calibrate your build platform again, unless you use it on a different FreeShape 120, or unless you purchase a new build platform. - Page 15 Your FreeShape 120 comes with a build platform attached. If you remove your build platform, attach your build platform securely before calibrating. Turn your build platform so the hole in the top of the platform is facing toward the printer.

- Page 16 While holding the platform down, tighten the 4 hex screws. Interchange tightening the left side and right side of the platform to ensure that the platform stays flat during the tightening. Press OK. The build platform moves back up. FreeShape 120 Manual...

-

Page 17: Connecting To Your Lan Or Wi-Fi Network

Connect to a Wi-Fi network or LAN so that you can access the printer and start up prints from your internet browser. The FreeShape 120 arrives with a Wi-Fi dongle attached to one of the USB ports. If you want to connect to your Wi-Fi network, ensure that your dongle is connected before starting this process. - Page 18 OK. If the connection is successful, the network will display “Connected” next to its network name. H. Once connected, the machine console will display 2 different IP addresses: Top IP address: Wi-Fi connection Bottom IP address: LAN connection FreeShape 120 Manual...

-

Page 19: Design Your 3D Model

FreeShape 120 Printing After you set up your FreeShape 120, the next step is to get your first print up and running. This section describes the basic process for getting your printer ready and starting up a print. The topics covered in this section are as follows: 1. -

Page 20: Make Your Print File

2. Make Your Print File Ackuretta provides a variety of different software solutions to match your industry or application. Import your STL or other design file into your Ackuretta software, support your print, and use the built-in slicer to make your print file. -

Page 21: Attach Your Vat

• Supported input file types: .stl, .fbx, .blend, .obj, .dfx 3. Attach Your Vat Your FreeShape 120 comes with a vat or resin tank attached. If you remove your vat and need to reattach it, do the following: A. Place the empty vat on the LCD panel, so the metal grooves on the sides line up with the handle holes. -

Page 22: Fill Your Vat With Resin

If any resin is in the vat, stir the resin with a rubber spatula. Then shake your resin bottle for at least 2 minutes so that the resin is thoroughly mixed. A. After shaking, slowly pour resin into the vat. FreeShape 120 Manual... -

Page 23: Attach Your Build Platform

6. Print Using a USB Device There are two ways of starting a print on the FreeShape 120: • Attach a USB device with the print file to the printer, and then use the printer console to start the print •... - Page 24 C. On the FILES screen, press USB. Note: On the Files screen, all previous prints you have uploaded to the FreeShape 120 are available, as well as a few default print files from Ackuretta. D. Find and press the file that you wish to print.

- Page 25 Press Print to begin your print. Note: If your resin profile is incorrect, press Profile to change your resin settings. If you are using an Ackuretta resin profile from Alpha 3D or Omega 3D, your resin profile will be automatically set from the software.

-

Page 26: Print Over A Lan Or Wi-Fi Network

Connecting to Your LAN or Wi-Fi Network. A. Type the IP address on your FreeShape 120 into an internet browser using a computer or mobile device on the same network. The FreeShape 120 web console opens. B. Go to the Print screen. - Page 27 files. E. Browse for your print file and click Open. The FreeShape 120 only supports files in IBF or SBF format. For more information about software and file types, Make Your Print File.

-

Page 28: Print Options

While the machine is printing, you can pause or stop the print at any time from the printer console or the web console. FreeShape 120 Console Options • Print Status View the print information, and access the other print options from the Print Status screen. - Page 29 The printer will completely stop its print so you can clean the platform and begin printing a new print. cannot undo this action. After you press Cancel Print, the printer will finish printing its current layer. When the printer has completely stopped, the build platform will move back to the top. FreeShape 120 Manual...

-

Page 30: Remove Your Print From The Printer

FreeShape 120 Finishing Your Print After the FreeShape 120 finishes your print, the print still requires some preparation before it is ready for polishing, casting, or applying to a machine or a patient. The order of the process is variable, as most steps can be done before or in between others. Generally, the process is as follows: 1. -

Page 31: Finishing Your Print

Typically, you will need to do the following steps multiple times: A. Spray your print liberally with cleaning alcohol to rinse off residual material. Ackuretta recommends using ethyl alcohol (95% solution) or isopropyl alcohol (99% solution). -

Page 32: Separate Your Print From The Build Platform

If you have an ultrasonic cleaner or cleaning bath available, you may soak the print to make cleaning easier. Usually you should do this after separating the print from the build platform. C. Submerge the print into a bath of cleaning alcohol or an ultrasonic cleaner. For most prints, Ackuretta recommends soaking for about 2 minutes. -

Page 33: Cut Off Supports

After printing, cleaning, and drying, place your print in a UV oven for final curing. The Ackuretta UV oven is tested and certified for all Qura- resins. Dreve, Keystone, and other resin suppliers may have preferred UV ovens to use with their materials. See your resin supplier for details about which UV ovens they recommend that you use. -

Page 34: Configuring Your Printer

file in order to perform important system or print diagnostics. To obtain your log file: 1. Attach your USB device to a USB port on the rear side of the FreeShape 120. 2. Go to FreeShape 120 web console, and click Save log to USB device. - Page 35 1. Go to FreeShape 120 web page, and click Set Timezone Offset. • Toggle either + or - to set if your time zone is before or after UTC 0:00.

- Page 36 For information about how to update the FreeShape 120 firmware, see Machine ID The unique ID for this FreeShape 120. This is not the same as the serial number, which is affixed to the back side of the printer. FreeShape 120 Manual...

-

Page 37: Upgrade Settings

Storage Used The Diplo has 16 GB of on-board storage. About 2 GB of that storage is dedicated to the FreeShape 120 firmware and is inaccessible. If your storage is nearly full, go to Print > Printer Memory to remove some print files. - Page 38 1. Ensure that you are connected to an internet-enabled network. Turn off firewalls and antivirus if necessary. 2. Click Upgrade firmware online. 3. The machine will check for an update from the Ackuretta server, and if one is found, an update screen will appear. FreeShape 120 Manual...

-

Page 39: Material Settings

The FreeShape 120 printer stores settings for all Ackuretta materials. You can modify or add materials from here. If you upload a print file using an Ackuretta resin in Alpha 3D or Omega 3D, the FreeShape 120 automatically detects the resin profile and prints using the settings stored in the printer. If you use the “Resin Test” profile in Alpha 3D, or any non-Ackuretta resin in Omega 3D, you will additionally need to set a material setting on the FreeShape 120. - Page 40 The amount of time each layer will be cured. This is the most important parameter for a material. • Buffer Layers * Instead of curing all First Layers at the same rate, if you add any Buffer Layers, the FreeShape 120 will gradual- ly reduce curing between the first layers until reaching the normal layers.

- Page 41 Immediately after printing a layer, the guideway will move at this speed for a distance equal to the Slow Peel Height. After that, it will increase based on the Z-Axis Peel Speed. Ackuretta recommends using a value of half of the Z-Axis Peel Speed.

-

Page 42: Maintaining Your Printer

Do not use any metal tools in the vat because metal tools may damage the vat surface. This includes knives, scrapers and tweezers. A. Remove the build platform from the FreeShape 120. B. On the Home screen press Files. C. Select the file: Clean_Vat_2k.ack D. -

Page 43: Using Clean Vat From The Web Console

Using Clean Vat from the Web Console Alternatively, you may start the clean vat process through your web browser. A. Connect to the web console by inputting the FreeShape 120 IP address. For more information, Connecting to Your LAN or Wi-Fi Network. -

Page 44: Replacing The Lcd Panel

Replacing the LCD Panel The FreeShape 120 LCD panel encounters some wear over time. Eventually, pixels on the LCD panel will go dark, and some areas of the panel will not cure as thoroughly as other areas. - Page 45 Do not remove the screws holding the back panel. It is not necessary for this operation. D. Pull the front casing outward from the machine. E. Before completely removing the front casing, unplug the UI console cable by moving the connector from side to side. FreeShape 120 Manual...

- Page 46 G. Pull the LCD wiring off of the circuit board. H. Remove the electrical tape from around the LCD screen. I. Use your fingernail or the head of a screwdriver to lift the corner of the LCD panel, and lift the panel out of the machine. FreeShape 120 Manual...

- Page 47 L. Push the LCD wiring into the connector. M. Flip the connector back upward to hold the wiring. N. Attach strips of electric tape over the sides of the LCD panel. Press down on the electrical tape to remove any air pockets. FreeShape 120 Manual...

- Page 48 Tip: Clean off any dust or debris with an air blower and microfiber tissues. P. Reattach the cable to the UI board before connecting the front casing to the FreeShape 120. Q. Attach and tighten the front casing screws FreeShape 120 Manual...

-

Page 49: Replacing The Vat Film

If the film on your vat becomes damaged, then you may need to replace it. Cloudiness or tears on the vat surface require replacement, but small bumps do not. Prepare these tools before you start to replace the FreeShape 120 vat film: 1. Vat to replace film on 2. - Page 50 Use the screwdriver to assist in removing the plate. D. Remove the old vat film. The screwdriver may also be useful here. Note: Clean any resin that may have remained between the vat film and the frame. FreeShape 120 Manual...

- Page 51 • Attach screws through those 4 holdes to tighten the film to the frame. G. Poke holes in the vat film at the screw holes on the 4 corners of the frame. H. Attach screws through those 4 holes. FreeShape 120 Manual...

- Page 52 I. Poke holes and attach screws in the remaining holes. J. Tighten all screws so that the vat film is very tight. K. Cut off the excess film with a utility knife. Your vat is now ready for printing. FreeShape 120 Manual...

- Page 53 4F, No. 322, Neihu Road Section 1, Neihu District, Taipei 11493, Taiwan www.ackuretta.com sales@ackuretta.com...

Need help?

Do you have a question about the FreeShape 120 and is the answer not in the manual?

Questions and answers