Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

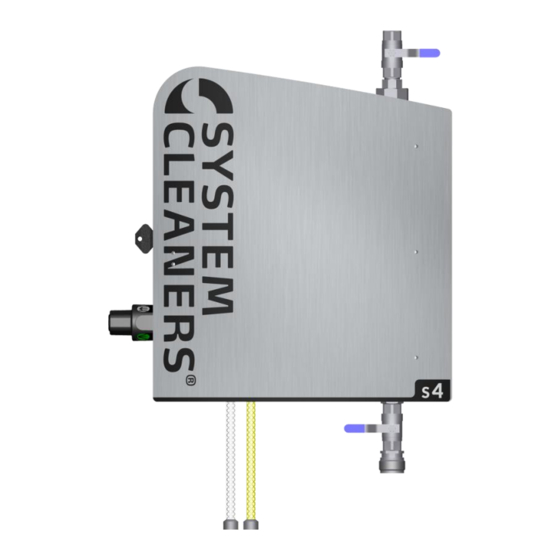

Summary of Contents for System Cleaners S4

- Page 1 MANUAL Version 3 (02.207. EN)

-

Page 2: Proper Use

System Cleaners A/S cannot be held liable for consequential damage resulting from improper use of the equipment. Proper use includes the following: ... -

Page 3: Declaration Of Conformity

The type plate is located on a fixed part of the system. Declaration of conformity We declare that this product is in conformity with the following directives: 2006/42/EC Directive on Machinery Per Kjøller Development Manager Version 5 (05.2018. EN) (S4) Page 3 of 52... - Page 4 Using a satellite it is possible for one operator to rinse, foam or disinfect (depending on model). Description Inlet air Inlet water Air regulator Injector system Suction tube chemical Dosing valve chemical Function selector Outlet Version 5 (05.2018. EN) (S4) Page 4 of 52...

- Page 5 Trolley Description Trolley Inlet water Injector system Inlet air Air regulator Dosing valve chemical Outlet Outlet Suction tube chemical Allen key Version 5 (05.2018. EN) (S4) Page 5 of 52...

-

Page 6: Installation

In order to facilitate maintenance of the equipment, it is recommended to fit a shut-off valve in the pipelines immediately at the connections for water. Pipe supports Always use pipe supports designed for the pipe size and material and maximum working pressure and temperature. Version 5 (05.2018. EN) (S4) Page 6 of 52... - Page 7 Local specifications may require disinfection of the wetted parts like internals of pipes and pumps before use to avoid contamination of newly cleaned surfaces. Dosing Adjust the dosing according to the chemical supplier’s recommendations. Always calibrate and, if required, document the dosing on a regular basis. Version 5 (05.2018. EN) (S4) Page 7 of 52...

-

Page 8: Operation

The system must not be used together with solvents or volatile liquids that pose a health risk or are inflammable. In the event that the system is used with non-approved soaps, chemicals or solvents, System Cleaners A/S disclaims all liability. -

Page 9: Maintenance

Chemical residues compromises the function of the injector and flushing with warm water after each use is required to maintain trouble free operation. Depending on the water quality it may be necessary to de-scale the water side of the injector on a regular basis following the chemical supplier’s guidelines. Version 5 (05.2018. EN) (S4) Page 9 of 52... -

Page 10: Troubleshooting

Water pressure is too low Make sure that the water supply is as described in the technical specifications Air pressure too low Increase air pressure Non-original foam nozzle fitted Replace with original white foam nozzle Version 5 (05.2018. EN) (S4) Page 10 of 52... -

Page 11: Spare Parts

SPARE PARTS Cabinet Version 5 (05.2018. EN) (S4) Page 11 of 52... - Page 12 Injector system Version 5 (05.2018. EN) (S4) Page 12 of 52...

- Page 13 42-600038 Hinge for door 300 mm AISI 304 42-600039 Hinge for satellite AISI 304 43-100080-01 Wall bracket for satellite 46-400301 Housing 300mm S4 AISI 304 55-100040 Air hose 8mm black PA12 72-000030 Nut for lock Nylon 72-000040 Lock with hook...

- Page 14 Function F Version 5 (05.2018. EN) (S4) Page 14 of 52...

- Page 15 Function F D Version 5 (05.2018. EN) (S4) Page 15 of 52...

- Page 16 Function F F Version 5 (05.2018. EN) (S4) Page 16 of 52...

- Page 17 Function F F D Version 5 (05.2018. EN) (S4) Page 17 of 52...

- Page 18 Function F F F Version 5 (05.2018. EN) (S4) Page 18 of 52...

- Page 19 Function PF Version 5 (05.2018. EN) (S4) Page 19 of 52...

- Page 20 Function PF PD Version 5 (05.2018. EN) (S4) Page 20 of 52...

- Page 21 Function PF PF Version 5 (05.2018. EN) (S4) Page 21 of 52...

- Page 22 Function PF PF PD Version 5 (05.2018. EN) (S4) Page 22 of 52...

- Page 23 Function PF PF PF Version 5 (05.2018. EN) (S4) Page 23 of 52...

- Page 24 Function PF D Version 5 (05.2018. EN) (S4) Page 24 of 52...

- Page 25 Function PF F Version 5 (05.2018. EN) (S4) Page 25 of 52...

- Page 26 Function PF F D Version 5 (05.2018. EN) (S4) Page 26 of 52...

- Page 27 Function PF PF D Version 5 (05.2018. EN) (S4) Page 27 of 52...

- Page 28 Function PF PF F Version 5 (05.2018. EN) (S4) Page 28 of 52...

- Page 29 Function PF PD D Version 5 (05.2018. EN) (S4) Page 29 of 52...

- Page 30 Function PF PD F Version 5 (05.2018. EN) (S4) Page 30 of 52...

- Page 31 Separate D-injector Version 5 (05.2018. EN) (S4) Page 31 of 52...

- Page 32 Separate F-injector Version 5 (05.2018. EN) (S4) Page 32 of 52...

- Page 33 PD F 20-304002 Handle, F 20-304003 Handle, F D 20-304004 Handle, F F 20-304005 Handle, F F D F F D 20-304006 Handle, F F F F F F 20-304007 Handle, PF Version 5 (05.2018. EN) (S4) Page 33 of 52...

- Page 34 Hose nipple M12x7,5 AISI 316 55-600016 Hose nipple 1/4"x7,5 AISI 316 55-700091 Hose 1/4"x285 SS 15-010120 Air fitting 6x6 elbow Plastic 15-010041 Air fiting 6/4/4 Y Plastic 15-010111 Air fitting 6/6/6 (T-piece) Plastic Version 5 (05.2018. EN) (S4) Page 34 of 52...

- Page 35 Injector pre-diluted Version 5 (05.2018. EN) (S4) Page 35 of 52...

- Page 36 Injector concentrated Version 5 (05.2018. EN) (S4) Page 36 of 52...

- Page 37 Water nozzle ø1,8 AISI 316 15-50 bar 27-200100 Water nozzle ø2,5 mm AISI 316 3-8 bar 55-100030 Air hose 6mm green PA12 55-110080 Air hose ø4mm black PA12 69-400100 Label Quickguide Version 5 (05.2018. EN) (S4) Page 37 of 52...

- Page 38 Trolley Version 5 (05.2018. EN) (S4) Page 38 of 52...

- Page 39 Allen screw M8x12 08-300804 Toothed disk ø8 49-100012 Wheel with lock ø125mm Rubber/Plastic/AISI 304 08-800850 Screw M12x30 countersunk head (hexagon) 97-100340 Allen key 5mm Steel 04-000092 Plastic knob ø25mm White PP Version 5 (05.2018. EN) (S4) Page 39 of 52...

- Page 40 Cabinet - Trolley Version 5 (05.2018. EN) (S4) Page 40 of 52...

- Page 41 Injector system - Trolley Version 5 (05.2018. EN) (S4) Page 41 of 52...

- Page 42 Separate D-injector – Trolley Version 5 (05.2018. EN) (S4) Page 42 of 52...

- Page 43 Separate F-injector – Trolley Version 5 (05.2018. EN) (S4) Page 43 of 52...

- Page 44 27-200020 Water nozzle ø1,8 AISI 316 SEP D 15-40 bar 27-200100 Water nozzle ø2,5 mm AISI 316 SEP D 3-8 bar 27-200020 Water nozzle ø1,8 AISI 316 SEP F 15-40 bar Version 5 (05.2018. EN) (S4) Page 44 of 52...

- Page 45 42-600038 Hinge for door 300 mm AISI 304 42-600039 Hinge for satellite AISI 304 43-100080-01 Wall bracket for satellite 46-400301 Housing 300mm S4 AISI 304 48-100072 Trolley for Satellite Station AISI 304 55-100030 Air hose 6mm green PA12 55-100040 Air hose 8mm black...

- Page 46 Rinse nozzle System 15/30 BR 15-50 bar 53-502000 Foam nozzle System 50/200 BR 52-160300 Disinfection nozzle 60/30 KS 53-010402 Rinse pipe 660mm 10/40 BR 3-15 bar 53-015303 Rinse pipe 660mm 15/30 BR 15-50 bar Version 5 (05.2018. EN) (S4) Page 46 of 52...

-

Page 47: Recommended Spare Parts

Recommended spare parts Pos. Material Part no. Description 20-400054 Dosing valve pre-diluted AISI 316/Viton 20-400056 Dosing valve concentrated AISI 316/Viton 20-200175 Non-return valve DN 20 PPO-GF/EPDM 20-000283 Ball valve 1/2" with actuator Version 5 (05.2018. EN) (S4) Page 47 of 52... - Page 48 Technical specifications wall Version 5 (05.2018. EN) (S4) Page 48 of 52...

- Page 49 Technical specifications Trolley Version 5 (05.2018. EN) (S4) Page 49 of 52...

- Page 50 Water pressure 3-8 bar / 44-116 psi 3/4”, 10-15 m / 33-49 ft Water pressure 15-40 bar / 44-580 psi 1/2”, 10-35 m / 33-115 ft Dimensions Weight 10 kg / 22 lbs Version 5 (05.2018. EN) (S4) Page 50 of 52...

- Page 51 Water pressure 3-8 bar / 44-116 psi 3/4”, 10-15 m / 33-49 ft Water pressure 15-40 bar / 44-580 psi 1/2”, 10-35 m / 33-115 ft Dimensions Weight 30 kg / 66 lbs Version 5 (05.2018. EN) (S4) Page 51 of 52...

- Page 52 System Cleaners A/S Halkjærvej 17 DK-9200 Aalborg SV Denmark Tel.: +45 96 34 04 04 Fax.: +45 98 79 19 42 info@systemcleaners.com www.systemcleaners.com Please note: We reserve the right to make alterations to the technical specifications without notice. Version 5 (05.2018. EN)

Need help?

Do you have a question about the S4 and is the answer not in the manual?

Questions and answers

Plate s4 how dimension

The dimensions of the System Cleaners S4 plate are not provided in the available context.

This answer is automatically generated