Snapper Z-Mow / 150Z Operator's Manual

Snapper rider operator's manual

Hide thumbs

Also See for Z-Mow / 150Z:

- Operator's manual (44 pages) ,

- Operator's manual (33 pages) ,

- Operator's manual (44 pages)

Summary of Contents for Snapper Z-Mow / 150Z

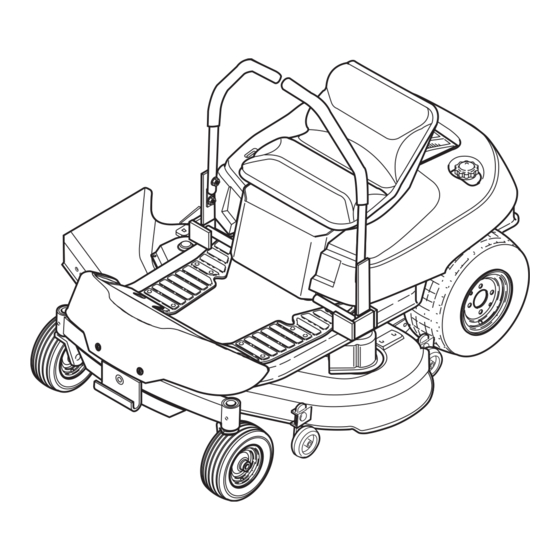

- Page 1 OPERATOR’S MANUAL Z-Mow / 150Z Series Mfg. No. Description 2690611 Z-Mow, 18.5HP & 42” Mower (CE) 2690612 150Z, 18.5HP & 42” Mower (CE) 1733615 Revision 00 Rev. Date 11/2006 TP 100-4413-00-ZT-SN...

-

Page 3: Table Of Contents

TABLE OF CONTENTS Safety Rules & Information...3 Identification Numbers...6 Pre-Operation...7 Operation...8 Maintenance...15 Service & Adjustments ...24 Storage ...28 Troubleshooting...29 Specifications ...31 NOTE: In this manual, “left” and “right” are referred to as seen from the operating position. -

Page 4: General Operation

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment. This mowing deck is capable of amputating hands and feet and throwing objects. The triangle in text signifies important cautions or warnings which must be followed. -

Page 5: Slope Operation

SLOPE OPERATION Slopes are a major factor related to loss-of-control and tip- over accidents, which can result in severe injury or death. Operation on all slopes requires extra caution. If you cannot back up the slope or if you feel uneasy on it, do not operate on it. -

Page 6: Service And Maintenance

SERVICE AND MAINTENANCE Safe Handling of Gasoline 1. Extinguish all cigarettes, cigars, pipes, and other sources of ignition. 2. Use only approved gasoline containers. 3. Never remove the gas cap or add fuel with the engine running. Allow the engine to cool before refueling. 4. -

Page 7: Safety & Operation Decals

SAFETY & OPERATION DECALS This unit has been designed and manufactured to pro- vide you with the safety and reliability you would expect from an industry leader in outdoor power equipment manufacturing. Although reading this manual and the safety instructions it contains will provide you with the necessary basic knowledge to operate this equipment safely and effec- tively, we have placed several safety labels on the unit to... -

Page 8: Identification Numbers

J. Sound Pressure at Operator’s Position in Decibels ** K. Vibration at the Steering Wheel * L. Vibration at the Seat * This unit complies with European Harmonized Lawn Mower Standard EN 836, European Machinery Directive 98/37/EC, and European EMC Directive 89/336/EC... -

Page 9: Pre-Operation

Read The Operator’s Manual • Read the operator’s manual. You should always read and follow the instructions in the operator’s manual. Proper care, performance tips, and safety information is located in this important document. Always Check the Oil Level • Check the engine oil level. The engine in your tractor has been shipped, from the factory, already filled with oil for use during the engine break-in period. -

Page 10: Control Functions

Left Ground Speed & Parking Brake Lever Fuel Tank Ground Speed Levers - Ground Speed Levers - DRIVE Positons PARK Positons CONTROL FUNCTIONS The information below briefly describes the function of individual controls. Starting, stopping, driving, and mowing require the combined use of several controls applied in specific sequences. To learn what combination and sequence of controls to use for various tasks please read the entire section. -

Page 11: General Operating Safety

Mower Height of Cut Adjustment To adjust cutting height, rotate the turn crank clockwise to raise the mower deck and counterclockwise to lower the mower deck. Ignition Switch The ignition switch starts and stops the engine; it has three positions: Stops the engine and shuts off the electrical system. -

Page 12: Checks Before Starting

CHECKS BEFORE STARTING • Check that the crankcase oil is filled to full mark on dipstick. • Fill the fuel tank with fresh fuel. FUEL RECOMMENDATIONS For daily operation: Use only unleaded gasoline with a pump sticker octane rating of 87 or higher. Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by volume) is approved as a fuel. -

Page 13: Emergency Stopping

EMERGENCY STOPPING In the event of an emergency the engine can be stopped by simply turning the ignition switch to STOP. Use this method only in emergency situations. For normal engine shut down follow the procedure given in STOPPING THE RIDER AND ENGINE. -

Page 14: Driving Practice

DRIVING PRACTICE - BASIC DRIVING WARNING: Never operate on slopes greater than 17.6% (10°). See SLOPE OPERATION in the safety section. Zero turn riders operate differently from other four- wheeled vehicles. The drive wheels are also your steer- ing wheels. If you cannot drive the unit on a hill, you will not be able to steer the unit on it. -

Page 15: Advanced Driving

Practice Turning Around a Corner While traveling forward allow one handle to gradually return back toward neutral. Practice several times before mowing. NOTE: To prevent damaging your lawn by pivoting direct- ly on the tire tread, it is best to keep both wheels going at least slightly forward. -

Page 16: Removing The Mower Deck

MOWER DECK REMOVAL & INSTALLATION NOTE: Perform mower removal and installation on a hard, level surface such as a concrete floor. WARNING Engage parking brake, disengage PTO, stop engine and remove key before attempting to install or remove the mower. Removing the Mower Deck 1. -

Page 17: Maintenance Schedule

MAINTENANCE SCHEDULE The following schedules should be followed for normal care of your rider and mower. RIDER MAINTENANCE, All Models Clean Debris from Rider and Engine Compartment * Clean Debris from Engine Cooling Areas & Air Filter * Check Tire Pressure Lubricate Rider &... -

Page 18: Check Tire Pressure

Rider Maintenance Items CLEAN DEBRIS FROM RIDER AND ENGINE COMPARTMENT Service Interval: Before each use. CAUTION: If debris is not removed from the engine compartment and other hot surfaces, it creates a fire hazard. Before starting the unit at the beginning of the mowing session, remove any grass clippings, dirt, leaves, or other debris from the unit. - Page 19 LUBRICATION Service Interval: 25 hours. Lubricate the unit at the locations shown in Figures 15 through 17 as well as the following lubrication points. Grease: • front wheel grease fittings • front wheel bushings • mower pivots • mower arbors Use grease fittings when present.

- Page 20 CLEAN DECK & CHECK / REPLACE MOWER BLADES Service Interval: 25 hours or as required. WARNING For your personal safety, do not handle the sharp mower blades with bare hands. Careless or improper handling of blades may result in serious injury.

-

Page 21: Cleaning The Battery And Cables

CLEANING THE BATTERY AND CABLES WARNING Be careful when handling the battery. Avoid spilling electrolyte. Keep flames and sparks away from the battery. When removing or installing battery cables, disconnect the negative cable FIRST and reconnect it LAST. If not done in this order, the positive terminal can be shorted to the frame by a tool. -

Page 22: Check/Adjust Pto Clutch

CHECK / ADJUST PTO CLUTCH WARNING To avoid serious injury, perform adjustments only with engine stopped, key removed and tractor on level ground. Service Interval: 200 Hours. The PTO clutch is engaged and disengaged by the PTO switch. The clutch powers and brakes the mower blades. Check the PTO clutch adjustment every 200 hours of operation. -

Page 23: Check Engine Oil Level

CHECK ENGINE OIL LEVEL Service Interval: Before each use, and every 8 hours. 1. Turn the engine off, and set the parking brake to PARK. 2. Clean the area around the dip stick (C, Figure 25). 3. Remove the dip stick (C) and clean it with a paper towel. -

Page 24: Air Filter Removal & Installation

AIR FILTER & PRE-CLEANER Service Interval: Pre-Cleaner: Every 25 hours or as required. Air Filter: Every 50 hours or as required. Replacement Interval: Pre-Cleaner: As required. Air Filter: Every 200 hours or once per season. Air Filter Removal & Installation 1. -

Page 25: Replace Spark Plug

Pre-Cleaner Service NOTE: Replace a worn or damaged pre-cleaner. 1. Figure 28. Wash the pre-cleaner in liquid detergent and water. 2. Squeeze the pre-cleaner dry and saturate with engine oil. Remove all excess oil by squeezing the pre-cleaner in an absorbent cloth. Air Filter Service NOTE: Replace a worn or damaged air filter. -

Page 26: Service & Adjustments

SERVICE & ADJUSTMENTS GROUND SPEED CONTROL LEVER ADJUSTMENT The control levers have three adjustments: To Adjust Control Lever Height: Pull the levers in across the operator’s lap to their DRIVE positions. Loosen the mount bolts (D, Figure 30) and raise or lower the levers to the desired position. -

Page 27: Cutting Height Adjustment

CUTTING HEIGHT ADJUSTMENT Turn the cutting height adjustment crank (A, Figure 31) clockwise to raise the mower deck and counterclockwise to lower it. If the crank is difficult to turn, thoroughly clean and lubricate it. PTO CLUTCH ADJUSTMENT See CHECK / ADJUST PTO CLUTCH in the Maintenance Section. -

Page 28: Mower Deck Leveling Adjustments

MOWER DECK LEVELING ADJUSTMENTS WARNING Before checking mower, shut off PTO and engine. Allow all moving parts to stop. Remove ignition key, then disconnect the spark plug wire and fasten it away from the spark plug. Side to Side Leveling If the cut is uneven, the mower may need leveling. -

Page 29: Mower Belt Replacement

Figure 36. Orient Blades Front-to-Back Front To Back Leveling If the cut is uneven, the mower may need leveling. Unequal or improper tire pressure may also cause an uneven cut. See CHECK TIRE PRESSURE. 1. Turn the blades front-to-back as shown in Figure 36. Measure the distance from the ground to front tip of center blade, and from ground to rear tips of left hand and right hand blades (Figures 36). -

Page 30: Storage

STORAGE Before you store your unit for the off-season, read the Maintenance and Storage instructions in the Safety Rules section, then perform the following steps: • Disengage the PTO, set the ground speed control levers to PARK, & remove the key. •... -

Page 31: Troubleshooting The Rider

While normal care and regular maintenance will extend the life of your equipment, prolonged or constant use may eventually require that service be performed to allow it to continue operat- ing properly. The troubleshooting guide below lists the most common problems, their causes and remedies. If you prefer, all of these procedures can be performed for you by an authorized dealer. -

Page 32: Troubleshooting The Mower

Engine runs, but Transmission release levers in PUSH rider will not positions. drive. Drive belt slips. Belt is broken. Parking brake is not fully released. Rider drive belt Pulleys or belt greasy or oily. slips. Belt stretched or worn. Parking brake Parking brake is incorrectly adjusted. -

Page 33: Specifications

NOTE: Specifications are correct at time of printing and are subject to change without notice. * The power ratings for an individual engine model are initially developed by starting with SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque Rating Procedure) (Revision 2002–05). Given both the wide array of products on which our engines are placed, and the variety of environmental issues applicable to operating the equipment, it may be that the engine you have purchased will not develop the rated horsepower when used in a piece of power equipment (actual “on–site”... - Page 36 Port Washington, WI 53074-0997 www.SimplicityMfg.com P R O D U C T S 535 Macon Street McDonough, GA 30253 www.Snapper.com Briggs & Stratton Yard Power Products Group Copyright © 2006 Briggs & Stratton Corporation Milwaukee, WI USA. All Rights Reserved...

Need help?

Do you have a question about the Z-Mow / 150Z and is the answer not in the manual?

Questions and answers