Table of Contents

Advertisement

Safety Instructions

& Operator's Manual for

REAR ENGINE RIDING MOWER

SERIES 18

MODELS

281318BE

301318BE

3314518BVE

331518KVE

MODEL

NUMBER

EXPLANATION

CUTTING WIDTH

ENGINE HP

SERIES DESIGNATION

I 33114sl 1 8I B I v I E I

I

I

ENGINE OPTIONS

ENGINE TYPE

ENGINE MODEL

28 -28" Cutting Deck

13 - 13.0 HP Engine

30 - 30" Cutting Deck

145 - 14.5 HP Engine

33 -33" Cutting Deck

15 - 15.0 HP Engine

18 - Series Designation

B - Briggs Engine

V - Over Head

K - Kohler Engine

Valve

E - Electric Start

Thank you for buying a SNAPPER Product!

Before operating your machine, read this manual carefully and pay

particular attention to the "IMPORTANT

SAFETY INSTRUCTIONS"

on Pages 2 & 3. Remember that all power

equipment

can be dangerous

if used improperly.

Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

SNAPPER, McDonough,

GA., 30253

U.S.A.

COPYRIGHT

© 1999

SNAPPER

INC.

ALL RIGHTS RESERVED

MANUAL No. 4-7008 (REV. 1, 8/20/99)

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Snapper SERIES 18 281318BE

- Page 1 30 - 30" Cutting Deck 145 - 14.5 HP Engine 33 -33" Cutting Deck 15 - 15.0 HP Engine Thank you for buying a SNAPPER Product! particular attention to the "IMPORTANT equipment can be dangerous accordance with the operating instructions and common sense!

-

Page 2: Safety Instructions

SAFETY INSTRUCTIONS If you have any questions pertaining to your machine which your dealer call or write the Customer Service Department at SNAPPER, McDonough, PROTECTION (Continued From Previous Column) STAY ALERT for holes and other hidden hazards. -

Page 3: Operation

14. Have repair SNAPPER dealer at least once a year and have the dealer install any new safety devices. 15. Use only genuine SNAPPER maintained. SLOWLY CAUTION... -

Page 4: Table Of Contents

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS TABLE OF CONTENTS SECTION 1 - FAMILIARIZATION SECTION 2 - OPERATING INSTRUCTIONS Pre-start Checklist ... Operator's Seat Adjustment ... Starting & Stopping Engine, Blade & Wheel Drive ... Starting & Stopping Mower Blades ... Starting &... -

Page 5: Important Safety Instructions

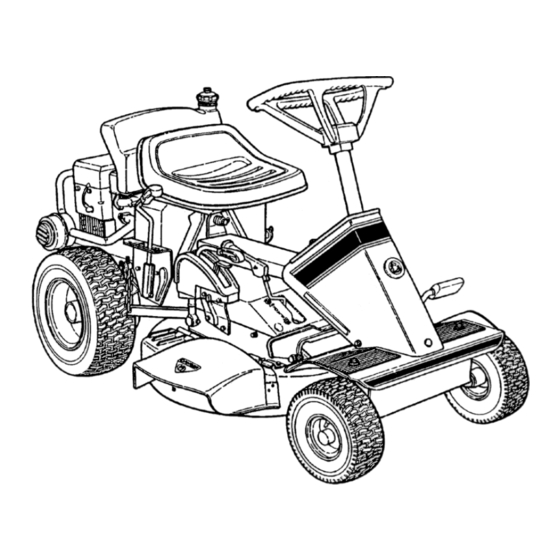

FUEL VENT FILLER BLADE LEVER BLADE PEDALS FIGURE 1.1 1.2 NOMENCLATURE The nomenclature essential parts of the SNAPPER Rear Engine Rider. It is procedures recommended SAFETY become thoroughly components, SAFETY operating. Specific details involving the engine are found in the separate engine owner's manual. -

Page 6: Section 2 - Operating

Section 2 - OPERATING PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 2.1.1. Check tires and add or release air as needed to bring pressure to 12 psi in front and 12 psi in rear tires. -

Page 7: Starting & Stopping Engine, Blade & Wheel Drive

Section 2 - OPERATING STARTING & OPERATION 2.3.1. ENGINE (ELECTRIC START) IMPORTANT: When the ignition key is turned to "START", the engine will turn over, but will not start unless the Clutch/Brake pedal is pressed all the way down, the Blade Lever is in the "OFF" position (See Figure 2.5). -

Page 8: Starting & Operation

Section 2 - OPERATING STARTING & OPERATION 2.3.1. ENGINE (ELECTRIC START) (Continued) 8. Should the battery be too weak to start the engine, Refer to Section "ENGINE (MANUAL START)" to manually start the electric start engines. 9. On Model 331418BVE, the engine is equipped with a fuel shut-off solenoid. -

Page 9: Starting & Stopping Mower Blades

3 seconds, the blade brake must be adjusted. Refer to Section "BLADE ADJUSTMENT" for adjustment procedures or return machine an authorized SNAPPER adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted properly. - Page 10 3 seconds, the blade brake must be adjusted. Refer to Section "BLADE ADJUSTMENT" for adjustment procedures or return machine an authorized SNAPPER adjustment. DO NOT CONTINUE to operate machine until blade brake adjusted properly.

-

Page 11: 2.5. Cutting Height Adjustment

Section 2 - OPERATING STOPPING - ENGINE, WHEEL DRIVE, BLADE 2.4.4. PARK BRAKE 1. Engage park brake by pushing clutch/brake pedal "DOWN" and moving the park brake lever to the "ON" position. While holding the park brake lever "ON", release clutch/brake pedal See Figure 2.16. -

Page 12: Section 3 - Maintenance

Fuel Filler Cap and vent must be closed securely to prevent fuel spillage. INTRODUCTION To retain the quality of the Rear Engine Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer assistance. For the correct part or information for a particular Rear Engine Riding Mower, always mention the model and serial number. -

Page 13: 3.2.4. Check Blade Drive Belt

REMOVE If the blade seconds "BLADE SNAPPER dealer for assistance. 3.2.6. Check machine brake for proper function. park brake. Push machine. Rear tires should skid. Drive machine forward and apply brake. Machine should come to a complete stop in less than 5 ft. -

Page 14: Lubrication - Grease Fittings

Section 3- MAINTENANCE 3.2.8. LUBRICATION - GREASE FITTINGS The following components Rider are equipped with grease require periodic lubrication. Purpose grease (NLGI No.2) with a grease gun. Front Wheel Bearings. "FRONT WHEEL BEARINGS - LUBRICATION". Rear Axle Bearing. Refer to Section "REAR AXLE BEARING - LUBRICATION". -

Page 15: Rear Axle Bearing - Lubrication

WARNING maintenance or blades running. wires away from spark are HOT. Avoid serious look lubricant of the chain case. If no lubricant is add SNAPPER transmission grease See Figure 3.9. AXLE BOOTS FIGURE 3.9 Check "MAINTENANCE SCHEDULE" Stop plugs. internal... -

Page 16: Service - Annually

Replace worn or damaged genuine SNAPPER replacement from an authorized SNAPPER dealer. 3.5.1. All bushings and pivot areas. 3.5.2. Check both front wheel king pins. 3.5.3. Transmission shift lever and detent. 3.5.4. Clutch disc. -

Page 17: Section 4 - Adjustments

However, if there is difficulty adjustments and repairs, it is recommended these repairs be made by an authorized SNAPPER dealer. WARNING Once blade is disengaged it should come to a stop in 3 seconds or less. If the blade continues to rotate after 3 seconds the blade brake must be adjusted. -

Page 18: Mower Deck Adjustment (Side To Side Levelness)

Section 4 - ADJUSTMENTS WARNING DO NOT attempt adjustments, service or repairs with the engine engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. -

Page 19: 4.2.4. Cutting Height Adjustment

If problems are experienced, contact your Snapper dealer for repair. & REPAIR 4.3.1 Test the wheel brake on a dry concrete surface. maintenance, When properly adjusted, the Rear Engine Rider will running. -

Page 20: Wheel Brake Adjustment

Section 4 - ADJUSTMENTS WARNING DO NOT attempt adjustments, service or repairs with the engine engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. -

Page 21: Mower Blade Replacement

Section 4 - ADJUSTMENTS WARNING DO NOT attempt adjustments, service or repairs with the engine engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. -

Page 22: Mower Drive Belt Removal/Replacement

Section 4 - ADJUSTMENTS WARNING DO NOT attempt adjustments, service or repairs with the engine engine. STOP blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. -

Page 23: Battery Cover

Section 4 - ADJUSTMENTS WARNING DO NOT attempt adjustments, service or repairs with the engine engine. Stop blade. Engage parking brake. Remove key. Remove spark plug wire from spark plug and secure away from plug. Engine and components are HOT. Avoid serious burns, allow all parts to cool before working on machine. - Page 24 Section 4 - ADJUSTMENTS WARNING The electrolyte (acid) produces a highly explosive gas. Keep all sparks, flame and fire away from area when charging battery or when handling battery. Electrolyte (acid) is a highly corrosive liquid. Wear eye protection. Wash affected areas immediately after having eye or skin contact with electrolyte (acid).

-

Page 25: Rear Engine Rider Accessories

State of Charge 100% Charged w/Sulfate Stop 100% Charged 75% Charged 50% Charged 25% Charged 0% Charged SNAPPER PART NO. DESCRIPTION 6-0517 ..Wheel Weight (8" Wheels) ... All Rear Engine Riders 6-0601 ..Smooth Start Clutch ... 6-0697 ... -

Page 26: Troubleshooting

Contact authorized SNAPPER dealer. Engage park brake. Replace with new 20 AMP fuse. 7. Contact authorized SNAPPER dealer. 8. Turn ignition switch to the START position. 9. Charge or replace with new battery. 10. Clean and connect battery cables. If broken, replace with new battery cables. -

Page 27: Troubleshooting

TROUBLESHOOTING PROBABLE CAUSE CORRECTIVE ACTION Replace drive disc. Adjust rubber drive disc. Replace with SNAPPER tapered bolt & nut. Contact authorized SNAPPER dealer. Contact authorized SNAPPER dealer. Move lever to the "ON" position. Adjust or replace mower belt. Sharpen or replace cutting blade. -

Page 28: Maintenance Schedule

SUBJECT SERVICE TO BE PERFORMED Check Oil Level Engine Engine Initial Oil Change Engine Periodic Oil Change Air Pre-Cleaner Service Sponge Pre- Cleaner Element Air Cleaner Replace Element Spark Plug Replace Plugs Fuel Filter Replace Filter Clean Shrouds & Fins Engine Cooling System Battery... -

Page 29: Maintenance/Replacement Parts

MAINTENANCE/REPLACEMENT MAINTENANCE Engine Speed Control (Briggs Engine) Engine Speed Control (Kohler Engine) Clutch/Brake Cable Brake Cable 28" Cutter Blade IStandard - Not Air Lift Compatible) 28" Cutter Blade (Standard - Air Lift Compatible) 28" Cutter Blade IMulchin_) 28" Cutter Blade (Ninja - Quad Edge) 30"... -

Page 30: Warranty

For three (3) years from purchase date for the original purchaser's residential, non-commercial any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both. -

Page 31: Primary Maintenance

PRIMARY MAINTENANCE can protect it! Snapper uses the best avail- able engines and components In their products in order to provide long, satisfactory service. However, proper care is essential In _" prolonging engine life. Dirt Is your engine's enemy number 11... - Page 32 Because of its working environ- ment, the air available to your Snapper engine Is " heavily saturated with air- borne dirt particles. As the dirt particles are stopped, they build up and begin to clog the outside of the filter.

- Page 33 PRIMARY MAINTENANCE Generally, wash foam-type filters In a dlshwashlng detergent and water solution. Rinse and wring dry, then saturate with oil and squeeze out excess. Failure to re-oil this type filter will ruin the engine. Clean paper elements by tapping lightly.

-

Page 34: Primary Maintenance

2-cycle engine fuel, be sure the containers are clearly marked to avoid mix-up. Snapper 2-cycle engines require a 32 to 1 mixture of gasoline and BIA certified TC-W oil such as Snapper's 2-cycle engine o11. Many of the 2-cycle engine oils on the... - Page 35 SERVICE NOTES...

- Page 36 Safety Instructions & Operator's Manual for REAR ENGINE RIDING MOWER SERIES 18 Snapper products are built using engines that meet or exceed all applicable emissions requirements date manufactured. The labels on those engines contain very important emissions safety warnings. Read, Understand, manual, and on the machine, engine and attachments.

Need help?

Do you have a question about the SERIES 18 281318BE and is the answer not in the manual?

Questions and answers