Table of Contents

Advertisement

How to Use This Manual

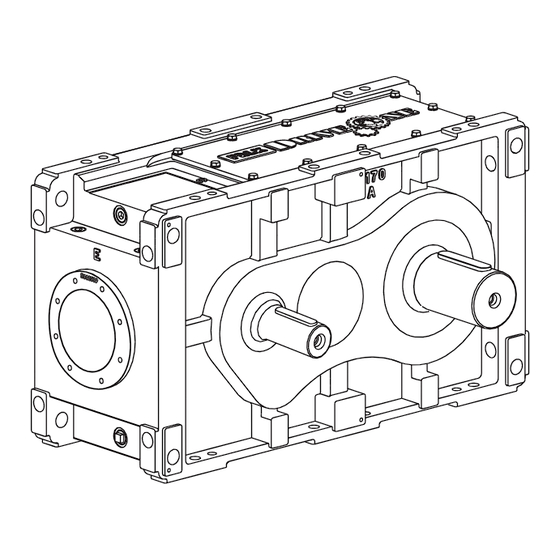

This manual provides detailed instructions on installation

and maintenance of parallel shaft Type DH, DV and right

angle Type DB, DX gear drives. Use the table of contents

below to locate required information.

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND

TROUBLE-FREE SERVICE OF YOUR FALK GEAR

DRIVE.

Table of Contents

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Shaft Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tightening Torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lubrication Recommendations. . . . . . . . . . . . . . . . . . . . 6-9

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Stored and Inactive Gear Drives . . . . . . . . . . . . . . . . . . . 11

APPENDIX

Adjustable Torque Arm Installation . . . . . . . . . . . 13

Rod End Adj. Torque Arm Installation . . . . . . 14-15

Swing Base Installation . . . . . . . . . . . . . . . . . . . . 16

Alignment Free Assembly & Installation. . . . . 17-20

Electric Fan Installation & Maintenance . . . . . 21-22

Cooling Tubes Installation & Maintenance . . . 23-25

Thrust Plate & Fastener Usage . . . . . . . . . . . . . . 26

Directions For Inverting Drives DH2 & DB3 . . . . . 27

Introduction

Credit for long service and dependable operation of a

gear drive is often given to the engineers who designed it,

or the craftsmen who constructed it, or the sales engineer

who recommended the type and size. Ultimate credit

belongs to the mechanic on the job who worked to make

the foundation rigid and level, who accurately aligned the

shafts and carefully installed the accessories, and who

made sure that the drive received regular lubrication. The

details of this important job are the subject of this manual.

NAMEPLATE - Operate Falk gear drives only at power,

speed and ratio shown on the nameplate. Before changing

any one of these, submit complete nameplate data and

new application conditions to the Factory for correct oil

level, parts, and application approval.

DISASSEMBLY AND ASSEMBLY - Disassembly &

assembly instructions and parts guides are available from

the Factory or Rexnord representatives. When requesting

information, please give complete data from the nameplate

on the gear drive: model, M.O. number, date, rpm, and ratio.

WARNING: Consult applicable local and national safety

codes for proper guarding of rotating members. Lock out

power source and remove all external loads from drive

before servicing drive or accessories.

Warranty

Rexnord Industries, LLC (the "Company") warrants that

Drive One gear drives (I) conform to Company's published

specifications, and (II) are free from defects of material for

three years from the date of shipment.

Company does not warrant any non-Company branded

products or components (manufacturer's warranty applies)

or any defects in, damage to, or failure of products caused

by: (I) dynamic vibrations imposed by the drive system in

which such products are installed unless the nature of such

vibrations has been defined and accepted in writing by

Company as a condition of operation; (II) failure to provide

suitable installation environment; (III) use for purposes other

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

Telephone: 414-342-3131 Fax: 414-937-4359

e-mail: info@rexnord.com web: www.rexnord.com

™

Falk

Drive One

®

Enclosed Gear Drives

•

Type D Series

Sizes M1130 thru M1210

than those for which designed, or other abuse or misuse;

(IV) unauthorized attachments, modifications or disassembly,

or (V) mishandling during shipping.

Installation Instructions

The following instructions apply to standard Falk Type DH,

DB, DV & DX drives. If a drive is furnished with special

features, refer to the supplementary instructions shipped

with the drive.

WELDING - Do not weld on the gear drive or accessories

without prior approval from the Factory. Welding on the

drive may cause distortion of the housing or damage to the

bearings and gear teeth. Welding without prior approval

could void the warranty.

NOTE: Drives equipped with cooling fans may require

removal of shroud when installing foundation fasteners.

EFFECTS OF SOLAR ENERGY - If the gear drive

operates in the sun at ambient temperatures over 38°C

(100°F), then special measures should be taken to protect

the drive from solar energy. This protection can consist

of a canopy over the drive or reflective paint on the drive.

If neither is possible, a heat exchanger or other cooling

device may be required to prevent the sump temperature

from exceeding the allowable maximum.

MOUNTING POSITION - Standard mounting positions

for types DH & DB are with the input and output shafts

horizontal and for DV & DX with the output shafts vertical

Allowable mounting angles for standard oil levels are:

DH & DB

Consult the Factory for other angles.

If a gear drive is ordered for non-standard mounting

positions, refer to the instructions provided with the drive

for oil levels and bearing lubrication. If it is necessary to

mount the gear drive in a different position from which it

was ordered, refer to the Factory for required changes to

provide proper lubrication.

FOUNDATION, GENERAL - To facilitate oil drainage,

elevate the gear drive

foundation above the

surrounding floor level. If

desired, replace the drive oil

drain plug with a valve, but

provide a guard to protect the

valve from accidental opening or breakage.

When an outboard bearing is used, mount drive and

outboard bearing on a continuous foundation or bedplate,

and dowel both in place.

•

Owners Manual

(Page 1 of 27)

Type DH

Type DV

Bridge

Slope

0° Up & 4° Down

± 1.5°

(PN 2124650)

Supersedes 04-11

Type DB

Type DX

168-050

January 2019

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rexnord Falk Drive One DH

-

Page 1: Table Of Contents

Company as a condition of operation; (II) failure to provide and dowel both in place. suitable installation environment; (III) use for purposes other 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 2 Re-shim bedplate and recheck high-speed coupling alignment. If necessary, realign motor. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11...

- Page 3 0.008 8.8478 8.8688 7.4920 7.5000 or pipe wrench to tighten the bushing nut to the 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 04-11...

- Page 4 (user supplied). To use, remove remove the backstop. Find the torque to apply to the 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 5: Shaft Connections

Illustrated ® Check with feelers. shaft and select the removal bolts from the table above. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 04-11... -

Page 6: Tightening Torques

If rotations are correct, complete pumps for special lubrication considerations or external alignment and assembly of coupling. cooling. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11... -

Page 7: Lubrication Recommendations

Valvoline AW ISO 220 Valvoline AW ISO 320 ..† Minimum viscosity index of 90. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 8 ★ Minimum viscosity index of 130. Consult lubricant supplier/manufacturer for maximum operating temperature. † Minimum viscosity index of 120. ‡ EP lubricant (contains sulphur phosphorus). 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 9: Preventive Maintenance

4. If drive is equipped with a torque arm, check for free movement. removed. A grease that meets USDA “H1” classification is suitable for food processing applications. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 10 GREASE-LUBRICATED SEALS — Depending on the PLUG FITTING frequency and degree of contamination (at least every 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 11: Stored And Inactive Gear Drives

M1160 & M1170 M1180 & M1190 M1200 & M1210 ★ Product of Daubert Chemical Company, Chicago, IL. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 12 (Page 12 of 27) Type D Series Sizes M1130 thru M1210 THIS PAGE INTENTIONALLY LEFT BLANK 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 13: Appendix A: Adjustable Torque Arm Installation

168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... -

Page 14: Appendix B: Rod End Adj. Torque Arm Installation

Bushing, shrink disc or rigid coupling connection. maintenance or at least every six months. See Table 11 for approved greases. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 January 2019 (PN 2124650) Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11... - Page 15 MOUNTING HARDWARE BRACKET ROD END HEADS ROD END HEADS (SUPPLIED BY CUSTOMER) PARALLEL NOT PARALLEL 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 04-11...

-

Page 16: Appendix C: Swing Base Installation

Refer to the coupling manufacturer’s manual for specific instructions. Bolt down the motor to the torque specified in Table 4, page 6. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com... -

Page 17: Appendix D: Alignment Free Assembly & Installation

Measurements must be taken to accurately position the motor half of the coupling hub on the motor 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 18 NUT SIDE OR DRIVE FOOT ON BUSHING EXTENSION SIDE NUT SIDE OR EXTENSION SIDE Figure 6 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

- Page 19 Assemble fan cowling with expanded metal guard to back of fan shroud/plates on same fasteners. Mount fan shroud assembly to mounting rails. The cowling may require 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com...

- Page 20 MOUNTING BRACKET HARDWARE (SUPPLIED BY CUSTOMER) Figure 3 SECTON A-A SPACER LIFT POINTS Figure 4 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 21: Appendix E: Electric Fan Installation & Maintenance

6. Use liquid tight electrical fittings and conduit. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 22 Verify proper fan rotation, resulting in air flow directed at the adjacent face of the gear drive. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

-

Page 23: Appendix F: Cooling Tubes Installation & Maintenance

Cooling tube connections are cadmium-plated mild assemblies and record location of assemblies for steel with “Buna-N” seal rings. reinstallation purposes. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com... - Page 24 No. 114 (.625 I.D. x .812 O.D. x .094 W) Buna-N seal rings if replacements are required. TIGHTEN NUT UNTIL FLUSH Figure 5 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com...

- Page 25 Female Elbow (Lenz 450-10) Tubing (.625 O.D.) Female Connector (Lenz 250-10) 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 04-11...

-

Page 26: Appendix G: Thrust Plate & Fastener Usage

AUXILIARY RELEASE SYSTEM - USER-PROVIDED WHEN REQUIRED LOOSEN BUSHING NUT AND REMOVE NUT RETAINING RING BEFORE USING ADD FLAT WASHERS AT BACKING BOLT IF NEEDED 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 (PN 2124650) January 2019 Telephone: 414-342-3131 Fax: 414-937-4359 Supersedes 04-11 e-mail: info@rexnord.com web: www.rexnord.com... -

Page 27: Appendix H: Directions For Inverting Drives Dh2 & Db3

THE SOCKET HEAD PLUGS FROM 4A TO 4B. BE SURE TO LOCATE THE DIPSTICK ON THE OPPOSITE SIDE FROM THE LOW-SPEED GEAR TO AVOID INTERFERENCE. 168-050 Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200 Telephone: 414-342-3131 Fax: 414-937-4359 (PN 2124650) January 2019 e-mail: info@rexnord.com web: www.rexnord.com...

Need help?

Do you have a question about the Falk Drive One DH and is the answer not in the manual?

Questions and answers