Advertisement

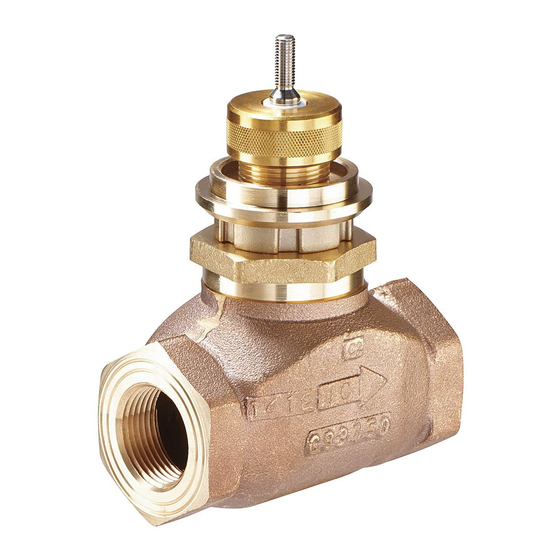

VG7000 Series Bronze Control Valves

Installation Instructions

VG7000

Applications

VG7000 Series Bronze Control Valves are primarily

designed to regulate the flow of water and steam in

response to the demand of a controller in Heating,

Ventilating, and Air Conditioning (HVAC) systems.

Contact the local Johnson Controls® representative for

compatibility concerns before using the VG7000 Series

Bronze Control Valves Technical Specifications table at

the end of this document.

These installation instructions conform to the relevant

and valid European Norm (EN) safety standards, as

well as the current laws and regulations of the

European Union. Qualified personnel are required for

the proper application of these installation instructions.

Qualified personnel are trained in the installation,

mounting, commissioning, operation, and servicing of

pneumatically and electrically actuated VG7000 Series

Bronze Control Valves; they include trainers and

instructors who have the following responsibilities:

•

ensure adherence to regional and international

ordinances and requirements

•

teach safety standards

•

enforce adequate facility safety and protective

operation

•

instruct first aid

Location of Valve Data

Each VG7000 Series Bronze Control Valve shipped

from the factory includes a brass tag chained to the

valve bonnet. The tag features technical data about the

valve, including:

•

code number of the valve

•

flow coefficient Cv of the valve

•

maximum allowable fluid temperature of the

controlled media

•

manufacturing date code of the valve (as

illustrated in Figure 1)

Refer to the

VG7000 Series Bronze Control Valves Installation Instructions

*1410786RevM*

14-1078-6 Rev. M

Release Issued December 2018

QuickLIT website

for the most up-to-date version of this document.

M

y

Manufacturing Facility

Figure 1:

Manufacturing Date Code

Installation

IMPORTANT: The VG7000 Series Bronze Control

Valves are intended to control saturated steam, hot

water, and chilled water flow under normal

equipment operating conditions. Where failure or

malfunction of the VG7000 Series Valve could lead

to personal injury or property damage to the

controlled equipment or other property, additional

precautions must be designed into the control

system. Incorporate and maintain other devices,

such as supervisory or alarm systems or safety or

limit controls, intended to warn of or protect against

failure or malfunction of the VG7000 Series Valve.

Pre-installation Details

Before installing a VG7000 Series Bronze Control

Valves, note the following:

•

Be sure to mount the valve in an upright position, in

a conveniently accessible location.

•

Protect the electric actuator from dripping water

that could enter the actuator housing and damage

the mechanism or motor.

•

Do not cover the actuator with insulating material.

•

Allow sufficient clearance to remove the actuator

(see Figure 2, Table 1, and Table 2).

•

Pipe the valve with the flow in the direction of the

arrow on the valve body, so that the plug seats

against the flow.

•

Wire all electrically actuated valve assemblies in

accordance with applicable electrical code

requirements. Input lines to the actuator must be

wired correctly for the valve to move in the proper

direction.

1

Part No. 14-1078-6, Rev. M

y

w

w

Week

Year

Advertisement

Table of Contents

Summary of Contents for Johnson Controls VG7000 Series

- Page 1 European Union. Qualified personnel are required for equipment operating conditions. Where failure or the proper application of these installation instructions. malfunction of the VG7000 Series Valve could lead Qualified personnel are trained in the installation, to personal injury or property damage to the...

- Page 2 1-3/4 (44) 2-9/16 (65) 1-1/4 (DN32) 4-23/32 (119) 1-11/32 (34) 2 (51) 2-25/32 (70) 1-1/2 (DN40) 5-1/8 (130) 2-5/32 (55) 2-3/4 (70) 3-3/8 (85) 2 (DN50) 5-29/32 (150) 2-1/8 (53) 2-27/32 (72) 3-3/4 (95) VG7000 Series Bronze Control Valves Installation Instructions...

- Page 3 Dimension C is the overall height above the centerline of the valve body, and dimension D is the clearance required for actuator removal (as illustrated in Figure 2). An extended bonnet comes as standard equipment on VG7000 Series Bronze Control Valves with stainless steel trim, to allow for higher fluid temperatures (100 psig [690 kPa] saturated steam at 338°F [170°C]).

- Page 4 Two-Way N.O./PDTC Union Angle Valve Dimensions (See Table 4.) Table 4: Two-Way N.O./PDTC Union Angle Valve Dimensions, in. (mm) Valve Size, in. (DN) 1/2 (DN15) N.O./PDTC 1-23/32 (44) 2-21/32 (68) 1-7/8 (48) 3/4 (DN20) N.O./PDTC 1-9/16 (40) 3-3/32 (79) 2-1/8 (54) VG7000 Series Bronze Control Valves Installation Instructions...

- Page 5 Repair Information (LIT-977140) for a list of repair parts and reconditioning kits available. For a replacement valve, contact the If the VG7000 Series Bronze Control Valve fails to nearest Johnson Controls representative. operate within its specifications, refer to the VG7000...

- Page 6 Pre-servicing Details Before servicing a VG7000 Series Bronze Control Valve, isolate or disconnect the pneumatic supply or electrical power to the actuator and note the following: Risk of Property Damage. Do not apply power to the system before checking all wiring connections.

-

Page 7: Technical Specifications

Technical Specifications VG7000 Series Bronze Control Valves (Part 1 of 2 ) Hot Water, Chilled Water, 50/50 Glycol Solutions, or Steam for HVAC Service Systems (Fluid Group 1 According to 67/548/EEC) Valve Body Size/Cv (kv) 1/2 in. 0.73 (0.63), 1.8 (1.6), and 4.6 (4.0) 3/4 in. - Page 8 The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications, consult the local Johnson Controls office. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products.

Need help?

Do you have a question about the VG7000 Series and is the answer not in the manual?

Questions and answers