Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ABB Totalflow microFLO G4

- Page 2 Translated versions, in any other language, shall be maintained as accurately as possible. Should any discrepancies exist, the US English version will be considered final. ABB is not liable for any errors and omissions in the translated materials.

-

Page 3: Basic Installation

Basic Installation Step 1 Unpacking and Inspection The µFLO and RTD are shipped separately in specially designed shipping cartons that contain all of the relevant parts needed for installation. Carefully remove the items from each carton. Inspect for damage or missing or incorrect parts. Step 2 Mounting the Unit There are multiple ways to mount the unit. - Page 4 2) Screw the 2” by 40” mounting pipe into the saddle. Vertically align. Upon alignment, tighten the mounting pipe into the saddle. 3) Position the µFLO on the 2” mounting pipe. Secure in place with associated hardware. Position the µFLO high enough to allow slope from the externally mounted manifold to the tap valves.

- Page 5 Step 3 Installing and Wiring the RTD RTD kits are available through ABB Totalflow. If the user orders the RTD but provides their own thermowell, the U-length must be provided. Various sizes of thermowells are available from ABB Totalflow, but the U-length or insertion depth is required.

-

Page 6: Supplying Power

Reinstall the terminal block with the wires attached. Secure the cable to the meter run pipe with the plastic tie-wraps. Do not wrap the cable around the meter run pipe. Supplying Power The user has two powering options with the µFLO : Battery/Solar or External. - Page 7 Step 5 Solar Panel The solar panel is designed for outdoor mounting on a 2” extension pipe and is installed on the upper end of the µFLO 40” mounting pipe. The solar panel must be mounted within 12 feet of the µFLO .

- Page 8 to pins 1 & 2. Reinstall the terminal block with the wires attached. Secure the cable to the extension pipe and the mounting pipe cable with plastic tie-wraps. Step 6 External Power to the µFLO Board (9-30 Vdc) Note: Electrical wiring must be installed according to requirements for the area classification.

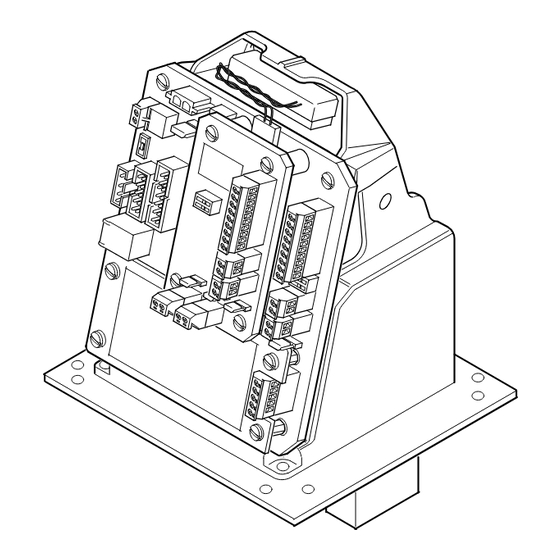

- Page 9 Step 8 µFLO Board, Pinouts and Communication The following represents the µFLO board and designated pinouts.

- Page 10 Table 1 Com1 J10 RS-232 RS-485 RS-422 Pin 1 VBATT VBATT VBATT Pin 2 Ground (GND) Ground (GND) Ground (GND) Pin 3 Switched (SW VBATT) Switched (SW VBATT) Switched (SW VBATT) Pin 4 Operate (OPER) Operate (OPER) Operate (OPER) Pin 5 Remote Request to Send Remote Request to Send (RRTS)

-

Page 11: General Information

General Information The following information pertains to the communication between the µFLO and the host (typically WinCCU). To communicate with the host, the µFLO uses the remote communications port (COM 1) that can function as RS-232 or RS-485. After installation of the µFLO , and with the communications path complete, the user needs to enter the appropriate communication parameters. -

Page 12: Standard Displays

Standard Displays The single tube µFLO comes from the factory with a set of default displays. By default, each display item remains on the display for five (5) seconds. The user has the ability to change this default to zero (item not displayed) or any value from 1 to 255 seconds. - Page 13 Indicator Description System Low Lithium Battery Alarm: When LL (low lithium) is displayed, the lithium battery voltage is below 2.5 Vdc. A new lithium battery measures approximately 3.6 Vdc. Low Charger: Displayed if the µFLO battery charging voltage is (+) 0.4 Vdc or is less than or equal to the battery voltage.

-

Page 14: Communication Troubleshooting

Terminal mode, and type: 0.0.0=COLD. The unit should initate a cold start and begin scrolling. If this does not occur, it may be necessary to call an ABB Totalflow representative for additional assistance. Refer to the telephone number on the back of this guide. - Page 15 Note: The user may not see the “ ” symbol flashing where baud rates are set higher than 2400. The user may need to set the baud rate to 1200 to see if the port is active and then set it back to the preferred baud rate.

- Page 16 ABB Inc. Totalflow Products 7051 Industrial Blvd. Bartlesville, Oklahoma 74006 Tel: USA (800) 442-3097 International 001-918-338-4880...

Need help?

Do you have a question about the Totalflow microFLO G4 and is the answer not in the manual?

Questions and answers