Advertisement

Table of Contents

- 1 Safety Symbols

- 2 Preparation and Installation

- 3 Principle of Operation

- 4 Specifications

- 5 Troubleshooting

- 6 Testing and Adjusting

- 7 Piston Pump

- 8 Control Group

- 9 Rotating Group

- 10 Drive Shaft Group

- 11 Parts List

- 12 Service Kits

- 13 After Sales Services

- 14 Spare Parts Availability

- Download this manual

OILGEAR TYPE "PVG" PUMPS -

-048/-065/-075 (SERIES F1U)

PURPOSE OF INSTRUCTIONS

These instructions will simplify the installation,

operation, maintenance and troubleshooting of

Oilgear type "PVG" pumps.

REFERENCE MATERIAL

Fluid Recommendations .....................................................................................Bulletin 90000

Contamination Evaluation Guide.........................................................................Bulletin 90004

Filtration Recommendations ...............................................................................Bulletin 90007

Piping Information ...............................................................................................Bulletin 90011

Installation of Vertically Mounted Axial Piston Units ...........................................Bulletin 90014

PVG Open Loop Pumps, Sales........................................................................ Bulletin 47019-I

Pump Control Instructions, Series F1U

"P-1NN" Single Pressure Compensator ............................................................Bulletin 947651

"P-1NN/F" Single Pressure Compensator w/Load Sense .................................Bulletin 947652

"P-1NN/H" Single Pressure Compensator w/H.P. Limiter ....................................Bulletin 947653

"P-1NN/G" Horsepower Limiter w/Load Sense .................................................Bulletin 947654

"P-2" Dual Pressure Compensator....................................................................Bulletin 947655

"P-C" Single Pressure - Soft Start.....................................................................Bulletin 947656

"P-A" or "P-B" Electronic Pressure Compensator .......................Bulletins 947556 and 947657

"P-CNN/H" Single Pressure - Soft Start w/H.P. Limiter ...............Bulletins 947558 and 947658

"P-2NN/H" Dual Pressure Compensator w/H.P. Limiter ..............Bulletins 947559 and 947659

"V-S25" Electro Hydraulic Servo Valve..............................................................Bulletin 947560

"V-M20" Electro Hydraulic Servo Valve .............................................................Bulletin 947561

November 2009

Bulletin 947023

SERVICE INSTRUCTIONS

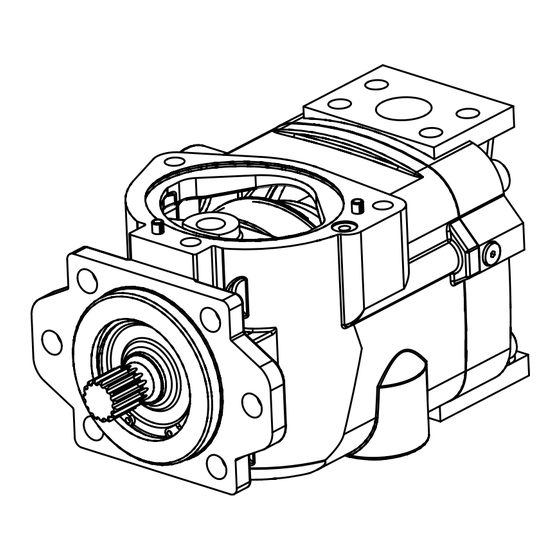

Figure 1. Typical Oilgear "PVG" Open Loop Pump

THE OILGEAR COMPANY

2300 South 51st Street

Milwaukee, Wisconsin 53219

THE OILGEAR COMPANY

OILG0457

Become familiar with the construction, principle of

operation and characteristics of your pump to help

you attain satisfactory performance, reduce shut-

down and increase the pump's service life. Some

pumps have been modified from those described in

this bulletin and other changes may be made

without notice.

www.oilgear.com

Bulletin 947023

1

Bulletin 947023

Advertisement

Table of Contents

Need help?

Do you have a question about the F1U Series and is the answer not in the manual?

Questions and answers