Table of Contents

Advertisement

www.factorycat.com

1711 South Street

Racine, WI 53404 (USA)

(800) 634-4060 | (+001) 262-681-3583

© 2018 RPS Corporation

Operating Instructions (EN)

Scan With Phone for more Information

Read these Instructions before

using the machine.

Read these Safety Messages

before using the machine.

FC-MICRO-HD-OP-EN

V18.234

Advertisement

Table of Contents

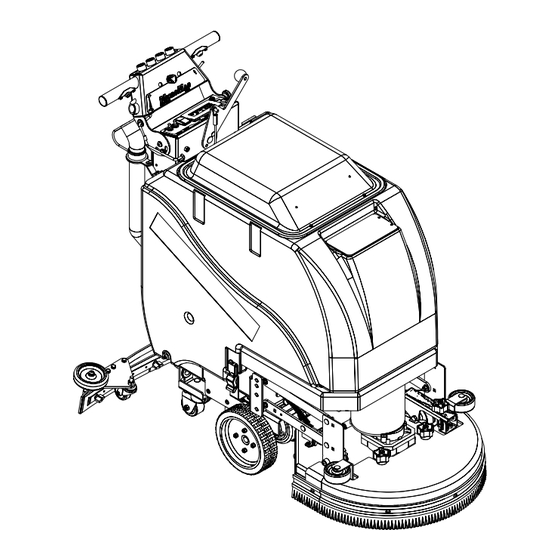

Summary of Contents for FactoryCat MICRO-HD

- Page 1 Read these Instructions before using the machine. Read these Safety Messages before using the machine. Scan With Phone for more Information www.factorycat.com 1711 South Street Racine, WI 53404 (USA) (800) 634-4060 | (+001) 262-681-3583 V18.234 © 2018 RPS Corporation FC-MICRO-HD-OP-EN...

-

Page 2: Introduction

The serial number of your machine is located on the lower half of the control panel of the machine. SERIAL NUMBER AS OUR POLICY IS ONE OF CONSTANT IMPROVEMENT - ALL INFORMATION AND SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE. - 2 - FC-MICRO-HD-OP-EN... -

Page 3: Table Of Contents

Remove Squeegee Common Wear Parts Round Disk Brushes: Adjust Squeegee Round Disk Pads: Cylindrical Brushes: Remove From Battery Charger Squeegee Blade Kits & Complete Squeegee Assemblies: Transportation - Forward P&G Controller Common Error Codes Transportation - Reverse FC-MICRO-HD-OP-EN - 3 -... -

Page 4: Safety Messages

An open fl ame or spark can cause this gas not use fl ammable materials in Tank or pick up. to explode. Serious personal injury or property damage could occur. Only charge the Batteries in this machine in a well ventilated area. - 4 - FC-MICRO-HD-OP-EN... - Page 5 Do not operate this machine if any parts have been controller. damaged or removed. CAUTION To avoid damage to the electronic control components of this machine, Do not store this machine outdoors. Do not pressure wash this machine. FC-MICRO-HD-OP-EN - 5 -...

-

Page 6: Safety Labels

DANGER SAFETY LABELS Read and obey all Safety Labels on your MICRO-HD Floor Scrubber. If you have questions about these labels, ask your supervisor. These images indicate where on the MICRO-HD Safety Labels are located. If ever the labels become illegible, worn off, or torn, promptly report it to your supervisor and replace it. -

Page 7: Lcd Screen

10. VACUUM HOUR METER - Indicates total hours the vacuum motor has been used 11. DIAGNOSTIC CODE - Displays diagnostic code which helps troubleshoot issues 12. ERROR WARNING SYMBOL - Indicates when there has been a diagnostic code error FC-MICRO-HD-OP-EN - 7 -... -

Page 8: Operation Controls

OPERATION CONTROLS - 8 - FC-MICRO-HD-OP-EN... -

Page 9: Touch Screen (Optional)

8. ACTIVE SYSTEM MACHINE DISPLAY - Indicates which systems of the equipment currently has power 9. OPERATION MODE SELECTOR - Cycle through and select which operation mode you would like to work in FC-MICRO-HD-OP-EN - 9 -... -

Page 10: Touch Screen Symbols (Optional)

Double Scrub Vacuum Only Solution Setting Down Pressure Setting Transport Motor Scrub Deck Motor(s) Working Active Inactive Working Active Inactive Solution Pump Vacuum Motor Working Active Inactive Working Active Inactive Setup Hour Meters Zone Lock Locked Unlocked - 10 - FC-MICRO-HD-OP-EN... -

Page 11: Touch Screen Zone Operation (Optional)

The zone you are working in is highlighted as indication. In Figure 1. the zone selected is Zone 1. SUDS SUDS Figure 2. shows Zone 3 “locked out” by the indicator lock icon. #1 NAME SUDS SUDS FC-MICRO-HD-OP-EN - 11 -... -

Page 12: Touch Screen Zone Progamming (Optional)

Alternatively you can lock the Zone out from this screen. To alter the name of a Zone, simply click on the black name box and a full keyboard will appear as Figure 4. shows. - 12 - FC-MICRO-HD-OP-EN... -

Page 13: Battery Setup

Batteries are a possible environmental hazard. Consult your Battery supplier for safe disposal methods. NOTICE Orientation of Batteries is critical for cables to reach. Ensure proper torque values when installing batteries. (Between 8 - 12 ft/lbs) 24 VOLTS FC-MICRO-HD-OP-EN - 13 -... -

Page 14: Remove Squeegee

REMOVE SQUEEGEE - 14 - FC-MICRO-HD-OP-EN... -

Page 15: Adjust Squeegee

ADJUST SQUEEGEE FC-MICRO-HD-OP-EN - 15 -... -

Page 16: Remove From Battery Charger

REMOVE FROM BATTERY CHARGER Please refer to OEM Charger Operating Instructions for more information. - 16 - FC-MICRO-HD-OP-EN... -

Page 17: Transportation - Forward

TRANSPORTATION - FORWARD ½ SPEED FC-MICRO-HD-OP-EN - 17 -... -

Page 18: Transportation - Reverse

TRANSPORTATION - REVERSE - 18 - FC-MICRO-HD-OP-EN... -

Page 19: Fill Solution Tank

Tank or pick up. Water temperature must not exceed 130˚F/54˚C • Do NOT use high-percentage Bleach mixture < 10 Gal. ( 38 l ) < 10 Gal. ( 38 l ) < 130°F / 54°C < 130°F / 54°C FC-MICRO-HD-OP-EN - 19 -... -

Page 20: Operation - Scrubbing

OPERATION - SCRUBBING ½ SPEED - 20 - FC-MICRO-HD-OP-EN... -

Page 21: Draining Recovery Tank

WASTE WATER DRAINS ONLY! DRAINING RECOVERY TANK WASTE WATER DRAINS ONLY! FC-MICRO-HD-OP-EN - 21 -... -

Page 22: Draining Solution Tank

WASTE WATER DRAINS ONLY! DRAINING SOLUTION TANK WASTE WATER DRAINS ONLY! - 22 - FC-MICRO-HD-OP-EN... -

Page 23: Flushing Recovery Tank

FLUSHING RECOVERY TANK FC-MICRO-HD-OP-EN - 23 -... -

Page 24: Clean Drain Saver

CLEAN DRAIN SAVER - 24 - FC-MICRO-HD-OP-EN... -

Page 25: Clean Cylindrical Hopper

CLEAN CYLINDRICAL HOPPER FC-MICRO-HD-OP-EN - 25 -... -

Page 26: Clean Vac Box System

CLEAN VAC BOX SYSTEM - 26 - FC-MICRO-HD-OP-EN... -

Page 27: Remove Disk Brushes

REMOVE DISK BRUSHES Rotate after 25 hrs FC-MICRO-HD-OP-EN - 27 -... -

Page 28: Remove Cylindrical Brushes

REMOVE CYLINDRICAL BRUSHES Rotate after 25 hrs - 28 - FC-MICRO-HD-OP-EN... -

Page 29: Charge Batteries

CHARGE BATTERIES Please refer to OEM Charger Operating Instructions for more information. FC-MICRO-HD-OP-EN - 29 -... -

Page 30: Battery Chargers

Please refer to OEM Charger Operating Instructions for more information. Onboard / AGM / International Chargers: AC Power: 80-270VAC / 50-60Hz DC Power OUT: 24VDC / 27A Please refer to OEM Charger Operating Instructions for more information. - 30 - FC-MICRO-HD-OP-EN... -

Page 31: Common Wear Parts

Provides best wear and tear resistance. Not LINATEX designed for use with harsh chemicals. Provides best resistance when dealing with harsh URETHANE chemicals, oils, fuels, etc. Provides best drying preformance on rough/grouted fl oor types by sealing over irregularities. Short life. FC-MICRO-HD-OP-EN - 31 -... - Page 32 Squeegee blade kits include (1) Rear Blade, (1) Front Squeegee Assemblies (complete) listed above all come Blade, and (2) Caster Wheels with hardware. with Linatex blades. NOTICE Size is stamped into the top of the painted steel squeegee body on all squeegee's. - 32 - FC-MICRO-HD-OP-EN...

-

Page 33: P&G Controller Common Error Codes

P&G CONTROLLER COMMON ERROR CODES Below are common diagnostic codes and some typical causes / remedies. If the information provided in the "Correction" section does not cure the code, seek technical support from your local authorized RPS Corporation distributor. Diagnostic Code Cause Correction 1501 Parking brake is released or the parking brake coil... - Page 34 BLANK THIS PAGE WAS INTENTIONALLY LEFT BLANK...

- Page 35 BLANK THIS PAGE WAS INTENTIONALLY LEFT BLANK...

- Page 36 1711 South Street Racine, WI 53404 www.factorycat.com Tel. US: 800-634-4060 Tel. Int: (001) 262-681-3583 © RPS Corporation 2018...

Need help?

Do you have a question about the MICRO-HD and is the answer not in the manual?

Questions and answers