Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ingun MA 2x09 Series

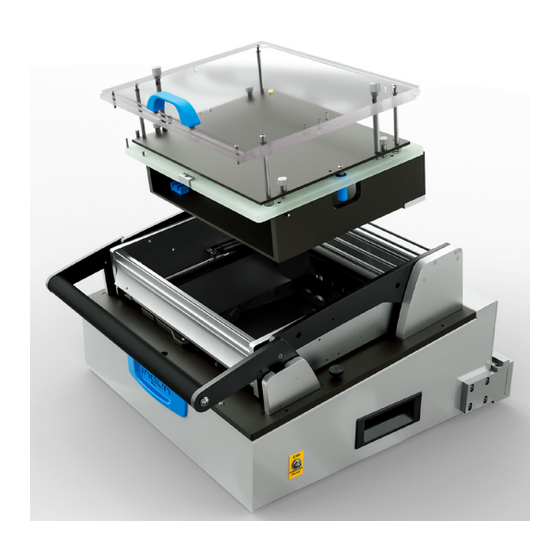

- Page 1 Technical manual Manual Test Fixture MA xxxx with ATS MAxx...

-

Page 2: Table Of Contents

Check locking position by inductive sensor ..............28 Check ATS locked ........................28 Locking unit for closed pressure frame ..................29 7.5.1 Stroke magnet NC (currentless; closed) ............... 29 7.5.2 Stroke magnet NO (currentless; open) ................. 30 ©INGUN: Subject to technical changes without notice. E&OE. - Page 3 10.1 Specification of components used ....................50 10.1.1 Stroke switch (Part number 20202) ................50 10.1.2 Inductive sensor (Part number 26466) ................. 50 10.1.3 Inductive sensor M8x1 (Part number 33831) ............... 50 ©INGUN: Subject to technical changes without notice. E&OE.

- Page 4 10.1.20 LED SMD strip red (Part number 45674) ..............53 10.1.21 Push button yellow (Part number 33466) ..............53 10.1.22 Push button red (Part number 33467) ................53 10.1.23 Push button green (Part number 33468) ..............53 Compatibility matrix ........................55 ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 5: Product Description

MA 2112/D/H/S-7/HG 33460 MA 2113/D/H/S-10 32500 MA 2113/D/H/S-10/HG 32700 32300 MA 2113T/D/H/2xS-5 MA 2113T/D/H/2xS-5/HG 36666 MA 2114/D/H/S-10 34350 MA 3211/D/H/S-5 43950 43630 MA 3212/D/H/S-7 43580 MA 3213/D/H/S-10 MA 3213T/D/H/2xS-5 43970 MA 3214/D/H/S-10 43960 ©INGUN: Subject to technical changes without notice. E&OE. -

Page 6: Ats Maxx

MA xx11 ATS MA11/S-5/HF 54111 ATS MA11/HF 54011 MA xx12 ATS MA12/S-7/HF 54112 ATS MA12/HF 54012 54113 54013 MA xx13 ATS MA13/S-10/HF ATS MA13/HF ATS is delivered mounted (see chapter 6.2, S. 18). ©INGUN: Subject to technical changes without notice. E&OE. -

Page 7: Safety

The demands on this part of the control unit are defined in the DIN EN ISO 13849-1 "Safety of machines; safety-related parts of the control unit – part 1: General design guideline". According to the risk evaluation carried out by INGUN, the test fixture with pneumatic or electro- magnetic functions presents the following risk evaluation:... -

Page 8: Dangers When Operating Electromagnets

The customising of the ATS requires care, as well as a lot of experience. High forces can occur when there is a large number of test points. These forces can lead to deformation of the probe ©INGUN: Subject to technical changes without notice. E&OE. -

Page 9: Customising For Stroke 22 Mm (Ma 3Xxx)

Furthermore, asymmetrical positioning of the test probes may require additional reinforcement of the unit. The ATS customised by INGUN is optimally equipped for the test application in question so that highly reliable testing is guaranteed. -

Page 10: Marking Units (Me)

The typical test sequence is displayed here using a flow-diagram. The steps carried out by the operator are displayed in green. The UUT (Unit Under Test) detection is part of the ATS custom- isation; it is not absolutely necessary, but highly recommended. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 11: Protection Conductor Wiring And Contact Protection For Dangerous Voltages

Technical manual MA xxxx with ATS MAxx The functional sequences displayed here are the basis of INGUN product design. These can differ depending on the test application. DDITIONAL UNCTIONS XXXX Different versions of the manual test fixtures are available with additional functions as bellow. -

Page 12: Esd Assembly

For ATS and test fixtures with ESD version of the first generation, new ESD discharge cable with ESD press-stud connector can be ordered at INGUN under Part no. 48215. The antistatic wrist strap must not be connected to the bush of the ESD discharge ca- ble. - Page 13 This dual-stage function is exclusively for contacting from the bottom side. (Dual-stage contacting from the top side is possible as a specialised solution in the exchangeable kit) Combination with self-opener, see chapter 5.5, pg. 15 ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 14: Locked Electrically

The electromagnetic in currentless locking unit used here must be actively switched to the “open” setting. CAUTION BURNING ON HOT SURFACES Hot coil housing on electromagnets Use INGUN magnet control when electromagnets are switched on for ex- tended periods of time. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 15: Pneumatic Locking

Specification of optional components (not included in delivery): Valve assembly 5/2-way (Part number 42702) (see chapter 10.1.10, p. 51) Compressed air combination (Part number 14241) (see 10.1.17, p. 53) Pneumatic plan ©INGUN: Subject to technical changes without notice. E&OE. -

Page 16: Mechanical Stroke Limitation

ATS MA09 ATS MA11 ATS MA12 ATS MA13 ATS MA11 ATS MA14 48266 dual-stage mechanism Dual-stage contacting with self-opener The dual-stage contacting process with self-opener is shown in the following function diagram: ©INGUN: Subject to technical changes without notice. E&OE. -

Page 17: Electrical Dual-Stage Contacting With Self-Opener

MA 2x09 MA 2x11 MA 2x12 MA 2x13 MA 2x13T MA 2x14 42701 42700 42700 42700 (2x) 42700 59555 59507 59507 59507/100700 59507 51434 59558 59559 59558 (2x) 59559 59507 59558 42700 ©INGUN: Subject to technical changes without notice. E&OE. -

Page 18: Mechanical Dual-Stage Contacting With Pneumatic Self-Opener

Compressed air combination (Part number 14241) (see 10.1.17, p. 53) Pneumatic plan 5.5.3 Mechanical dual-stage contacting with pneumatic self-opener MA 2x09 MA 2x11 MA 2x12 MA 2x13 MA 2x13T MA 2x14 42701 103550 51434 ©INGUN: Subject to technical changes without notice. E&OE. -

Page 19: Esd Version

The ESD layer around the GKS has to be removed. For ATS and test fixtures with ESD version of the first generation, new ESD discharge cable with ESD press-stud connector can be ordered at INGUN under Part no. 48588. (For more information see product information “Premium ESD-customising”) - Page 20 See chapter.1.2.3, p. 5 for part numbers Figure 7: ATS MA12/HF backside Figure 8: ATS MA12/S-7/HF backside without internal interface with internal interface Spare parts and parts subject to wear can be found under chapter 9.3.3, page 48. ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 21: Safety Switch For Closed Pressure Frame

“Safety-related parts of the control unit”. Note for the use The safety switch with locking cannot be used as protection for the testing function. The magnetic safety switch cannot be used with the dual-stage functions. ©INGUN: Subject to technical changes without notice. E&OE. - Page 22 Technical manual MA xxxx with ATS MAxx INGUN recommends the integration of the safety switch in accordance with the following func- tional sequence: ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 23: Safety Switch With Locking No (Currentless; Open)

Thermal continuous current I : 10 A Usage category: AC-15: 230 V /4 A DC-13: 24 V / 4 A Displayed in green = forced opening Shorts protection: 6 A gG D safety opener contact ©INGUN: Subject to technical changes without notice. E&OE. -

Page 24: Safety Switch With Locking Nc (Currentless; Closed)

Thermal continuous current I : 10 A Usage category: AC-15: 230 V /4 A DC-13: 24 V / 4 A Displayed in green = forced opening Shorts protection: 6 A gG D Safety opener contact ©INGUN: Subject to technical changes without notice. E&OE. -

Page 25: Magnetic Safety Switch

(this brake cylinder is not included in delivery MA 2x09). An MA-control unit, devel- oped and designed by INGUN is offered to control the self-opener function (see chapter 7.16, p. 36). - Page 26 The self-opener cannot be used in the dual-stage basic units. When the locking unit is set to “NDH-closed” do not attempt to activate the self-opener. The self-opener can only be used with the “open NDH” setting. ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 27: Pneumatic

Specification of optional components (not included in delivery): Valve assembly 5/2-way (Part number 42702) (see 10.1.10, p. 51) Compressed air combination (Part number 14241) (see 10.1.17, p. 49) Pneumatic plan ©INGUN: Subject to technical changes without notice. E&OE. -

Page 28: Electric

MA xx13 MA xx13T MA xx14 33840 33840 (2x) 33840 Specification of the components used: Stroke switch (Part number 20202) (see 10.1.1, p. 50) Note for use: Not suitable for dual-stage function ©INGUN: Subject to technical changes without notice. E&OE. -

Page 29: Check Stroke Position By Inductive Sensor

Check ATS locked MA 2x09 MA xx11 MA xx12 MA xx13 MA xx13T MA xx14 43246 43246 (2x) 43246 Specification of the components used: Switching probe: SKS-415 002 300 A 1402 E ©INGUN: Subject to technical changes without notice. E&OE. -

Page 30: Locking Unit For Closed Pressure Frame

When using the currentless locking unit, the electromagnet has to be switched in active mode (NC). When used for a long duty cycle with high current they get very hot. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 31: Stroke Magnet No (Currentless; Open)

Specification of optional components (not included in delivery): Valve assembly 5/2-way (Part number 42702) (see 10.1.10, p. 51) Compressed air combination (Part number 14241) (see 10.1.17, p. 53) Pneumatic plan ©INGUN: Subject to technical changes without notice. E&OE. -

Page 32: Locking Unit For Pressure Frame Open

Inductive sensor (Part number 38413) (see 10.1.5, p. 50) Stroke magnet NO (currentless; open) (Part number 33491) (see 10.1.8, p. 51) Such a test is displayed in the following functional sequence: ©INGUN: Subject to technical changes without notice. E&OE. -

Page 33: Pressure Frame Unit Opening Limited

Force Part number 150 N 41150 200 N 39200 300 N 39300 39400 400 N 500 N 39500 ©INGUN: Subject to technical changes without notice. E&OE. -

Page 34: Gas Pressure Springs For The Drive Unit (Kit)

MA 2x09 MA xx11 MA xx12 MA xx13 MA xx13T MA xx14 47715 We recommend the hinged metal handle when test fixtures are very heavy or when high ESD requirements are given. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 35: Pass / Fail Led Indicator

(see chapter 10.1.21, p. 53) Push button red (Part number 33467) (see chapter 10.1.22, p. 53) Push button green (Part number 33468) (see chapter 10.1.23, p. 53) Blanking plug (Art-Nr. 48687) ©INGUN: Subject to technical changes without notice. E&OE. -

Page 36: Oil Break

Closing force is reduced by 30% when the extended handle is used. Compressive force in complete assembly with 2.000 N: Standard handle: approx. 120 N Extended handle: approx. 80 N: ©INGUN: Subject to technical changes without notice. E&OE. -

Page 37: Ma Control Unit

Locking unit for pressure frame open (see 7.6, p. 31) Lifting unit (see Operating/Assembly Instructions Manual ATS MA xx) Marking unit LED signal pass/fail (pass -> green permanent / fail -> red impulse) ©INGUN: Subject to technical changes without notice. E&OE. - Page 38 Technical manual MA xxxx with ATS MAxx Connection to 15-pole sub connector (external signals) Connection to 37-pole sub connector (signals for test fixtures internal) Configuration jumper for permanent jumper for signal (instead of im- marking unit pulse) ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 39: Magnet Control Unit

Here the op- clocked operation erating voltage for the magnet is clocked with approx. 4 kHz frequency. This operat- ing mode is selected by setting the respec- tive jumper. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 40: Dual-Stage Upgrade Kit

ATS in a dual-stage test fixture. With this upgrade kit the height of the UUT/PC board is increased so that the longer FCT test probes do not protrude and cannot be damaged when the PC board is inserted. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 41: Reinforcement For Customisations With Large Number Of Test Points

8.2.2 Stiffener kit for KTE Normal ESD Compatible with ATS version ATS MA09 ATS MA11 ATS MA12 ATS MA13 ATS MA14 45719 46861 46863 Included in delivery: mounting material for each bar ©INGUN: Subject to technical changes without notice. E&OE. -

Page 42: Insertion Blocker For Stroke 22Mm

(yellow/green cable) to all relevant parts and the check via insulation resistor check at pre-defined positons. cover plate NSRL- stacking screw Note for use The hole for the stacking screw is not permitted. Subsequently the stacking screw can- not be inserted. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 43: Ats Ma09

Included in delivery: six bending pins, six limiting pins and one SKS-check. Note for usage The lifting unit cannot be used in case of contacting from above. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 44: Ats Ma12

Check for pressure frame closed via stroke switch Compatible with ATS version Normal ESD ATS MA09 ATS MA11 ATS MA12 ATS MA13 ATS MA14 33510 Note for use Not suitable for dual-stage function ©INGUN: Subject to technical changes without notice. E&OE. -

Page 45: Ma Xx13

46020 = with locking NC (currentless; closed) 42066 = without locking Note for use When testing at a dangerous voltage, the protection type IP3x according to DIN EN 60529 must be fulfilled. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 46: Actuator For Magnetic Safety Switch

Note for usage All test probes (GKS) in the ground plate must be drilled with larger diameter than the GKS diameter. ©INGUN: Subject to technical changes without notice. E&OE. -

Page 47: Contacting From Above (Mounting Kit)

Furthermore, the alignment can also be affected by manipulation of the functional parts such as e.g. hinges or other connecting parts. Therefore, INGUN recommend periodically checking the centring accuracy. The INGUN exchangeable kits both have two 4 entering holes (the so-called “Lenz holes”);... -

Page 48: Replacement And Wear Parts Ma Xxxx

Wear can occur depending on the load on and use of some components. The following compo- nents can be exchanged by the operator themselves, but with other possible wear, INGUN has to be contacted and the test fixture has to be checked by INGUN. -

Page 49: Replacement And Wear Parts Ats Maxx

41766 41765 42410 9.3.5 Probe plate (KTP) ATS MA09 ATS MA11 ATS MA12 ATS MA13 ATS MA14 45987 45897 45901 45907 45981 ESD 46234 ESD 45706 ESD 46049 ESD 46237 ESD 46241 ©INGUN: Subject to technical changes without notice. E&OE. -

Page 50: Moving Plate (Adp)

ATS MA12 ATS MA13 ATS MA14 45991 45885 45711 45876 45868 9.3.9 Knurled-head screw ATS ATS MA09 ATS MA11 ATS MA12 ATS MA13 ATS MA14 46869 for standard version 46871 for dual-stage version ©INGUN: Subject to technical changes without notice. E&OE. -

Page 51: Specification Of Components Used

Switching frequency: 5 kHz Nominal voltage: 10 - 30 VDC Current consumption max.: 12 mA Output current: <200 mA Protection category: IP 67 Working temperature: -25 - +75 °C Nominal switching distance: 2 mm ©INGUN: Subject to technical changes without notice. E&OE. -

Page 52: Inductive Sensor (Part Number 44833)

Operating air pressure: 0.9 – 10 bar Pneumatic connection: M5 Return type: Mixed, pneumatic/ mechanical Ambient and medium temperature: -5 - 50 °C Nominal voltage: 24 VDC Power: 1 W Display: LED ©INGUN: Subject to technical changes without notice. E&OE. -

Page 53: Pneumatic Cylinder 12-10 (Part Number 49273)

Plunger diameter: 32 mm Theoretical force with 6 bar: Advance 483 N, Return 415 N Operating air-pressure: 0.6 – 10 bar Pneumatic connection: G1/8 Cylinder switch: Part no.: 25638 (not initially supplied) ©INGUN: Subject to technical changes without notice. E&OE. -

Page 54: Compressed Air Combination (Part Number 14241)

Operating voltage: -25°C to 70°C 10.1.23 Push button green (Part number 33468) LED colour: green Contact rated current: 200 mA @ 42 VDC Switching run: momentary IO protection type: IP 67 Operating voltage: -25°C to 70°C ©INGUN: Subject to technical changes without notice. E&OE. - Page 55 Technical manual MA xxxx with ATS MAxx ©INGUN: Subject to technical changes without notice. E&OE.

-

Page 56: Version

ATS Contacting from above, normal assembly FB-ZSK 22652 ok NO NO NO NO ok NO ok 8.9.2 ATS Contacting from above, ESD assembly FB-ZSK-ESD 45704 NO NO NO ok NO ok ess. ess. Stand: 10/18, Index 1.30 INGUN, Irrtümer und technische Änderungen vorbehalten... - Page 57 Technical manual MA xxxx with ATS MAxx ©INGUN: Subject to technical changes without notice. E&OE.

- Page 58 Technical manual MA xxxx with ATS MAxx ©INGUN: Subject to technical changes without notice. E&OE.

- Page 59 Germany Vietnam INGUN Türkiye Hungary Africa INGUN UK Italy INGUN USA Norway South Afirca Poland Tunesia Portugal Australia Romania Serbia Australia Slovenia New Zealand Slovak Republic INGUN Prüfmittelbau GmbH America Spain Sweden Argentinia Switzerland Brazil Turkey Canada United Kingdom Mexico...

Need help?

Do you have a question about the MA 2x09 Series and is the answer not in the manual?

Questions and answers