Summary of Contents for Flowserve Argus Series

- Page 1 ARGUS Installation, Operation Instructions and Maintenance Safety Advice ARGUS Metal Seat Ball Valve – FK 75C and FK 76C Original Installation and Operating Instruction EN English...

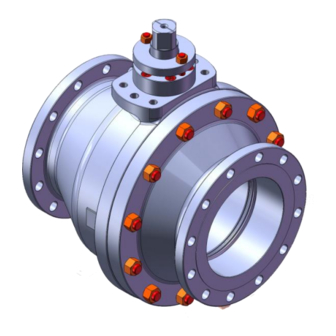

- Page 2 Installation & Operating Instructions Ball Valve FK 75C and FK 76C ARGUS ARGUS Metal Seat Ball Valve Series FK 75C and FK 76C • Valve Wrench Typical cut view of ARGUS FK 75C: • Connection Plate Stem Sealing • Stem • Body 1 •...

- Page 3 Graphite seals Seats ASTM A182 F51 Crabide HVOF Body Spiral-wound-gasket A316L/Graphite seals A193 B7; A193 Bolts B8M CL2 Nuts A194 Gr. 4; A194 Gr. 8M For detail information, please contact your Flowserve representative or find the Technical Bulletins on www.flowserve.com.

-

Page 4: Table Of Contents

These Instructions ........................5 Safety Relevant Marking on the Ball Valve ................5 ARGUS Series FK 75C and FK 76C – Metal Seat Ball Valves ..........5 Customer Specification / Requisition – Inquiry and Order ............5 Automated Ball Valve ....................... 5 Safety Information .......................... -

Page 5: General

Such marking must remain identifiable and legible. ARGUS Series FK 75C and FK 76C – Metal Seat Ball Valves The ARGUS series FK 75C and FK 76C, are highly performant Metal Seat Ball Valves. The series are designed, manufactured and qualified to cope with severe applications. -

Page 6: Safety Information

Comprehensive Quality Assurance, certified in accordance with ISO 9001 e.g., has always been a determining factor within the overall process of design, procurement, manufacturing and marketing at all Flowserve sites. All relevant laws, directives, standards and specifications are adopted for specific applications of the valves. -

Page 7: Safety Relevant Symbols

Installation & Operating Instructions Ball Valve FK 75C and FK 76C Safety Information ARGUS Safety Relevant Symbols Main Symbols used in these instructions: Symbol Signal word Meaning Failure to observe this “Danger” may result in loss of life or serious injury. DANGER Failure to observe this “Warning”... -

Page 8: Ball Valve As Pressure Equipment

Installation & Operating Instructions FK 75C and FK 76C Safety Information ARGUS Ball Valve as Pressure Equipment A valve is pressure bearing equipment usually integrated into a piping system. Any hazard for persons or for the environment which might arise from the pressurized substances (“fluids”) being transported within the pipeline system must be eliminated. -

Page 9: Delivery / Goods Receipt

Immediately after receipt of the product/system it must be checked against the delivery/shipping documents for its completeness and that there has been no damage in transportation. Any shortage and/or damage must be reported immediately to Flowserve. Later claims cannot be accepted. Goods Acceptance / Verification of the Delivery and Accompanying Documents A delivery note is enclosed with each delivery. -

Page 10: Nameplate: Identification Of The Ball Valve

Installation & Operating Instructions FK 75C and FK 76C Nameplate: Identification of the Ball Valve ARGUS Nameplate: Identification of the Ball Valve The manufacturer nameplate permanently affixed to the ball valve body provides the most important information regarding the design and use of the ball valve. If the type plate is missing or illegible, the ball valve must not be put into operation. -

Page 11: Installation

The ball valve is designed for use under normal load in the pipework. Particular operating conditions must be clearly specified in the customer requisition/inquiry. In the case of deviations from these conditions, Flowserve must be consulted. Preparation for Installation The following points must be observed before installation: Pipework must be strong enough to safely bear the ball valve and its accessories. - Page 12 Installation & Operating Instructions FK 75C and FK 76C Installation ARGUS 052-03 Assembling the first flange: – Fix the ball valve to the connection with some bolts and position the seal. – Ensure the correct position of the ball valve and seal (052-04). 052-04 Tighten the bolts crosswise (052-05).

-

Page 13: Actuator Mounting / Orientation Of The Valve-Actuator Unit

Actuators are usually installed above the ball valve. The shaft connection is in a vertical position. Other installation orientations are possible according to the evaluation of the specific conditions. If in doubt, please consult Flowserve. In case of heavy and/or asymmetrical actuators or with units which are not installed vertically, bending and/or torsional forces can occur –... -

Page 14: Commissioning - Recommended Practice

Installation & Operating Instructions FK 75C and FK 76C Commissioning – Recommended Practice ARGUS Commissioning – Recommended Practice Before commissioning and putting into service, the valve tightness must be verified. Flushing and Pressure Testing the Pipework Flushing, "hydro testing" and drying are necessary steps before commissioning or placing the unit in service: Thorough flushing cleans pipework, valves and fittings from dirt and foreign particles. - Page 15 Installation & Operating Instructions Ball Valve FK 75C and FK 76C Commissioning – Recommended Practice ARGUS When using a valve wrench, the position of the ball valve must be recognizable by the position of the wrench – for safety reasons: –...

-

Page 16: Maintenance

Only original spare parts may be used. Spare Part Information Flowserve provides spare parts for all ARGUS ball valve types. For inquiry or order, it is important that the ball valve in use is clearly specified. Technical identification is made either with reference to the item in the order documents of the valve i.e. the order acknowledgment, delivery note or invoice, or the data taken from the nameplate: order number, article number or serial number. -

Page 17: Returning The Ball Valve: "Valve Information Sheet

According to the Flowserve Returned Goods Safety Procedure ball valves, which are returned to Flowserve, must be free of dangerous fluid residues. The sender will receive from Flowserve a form, which must be filled-in and signed by the responsible organization and which must clearly attest the fact that the valve does not pose any risk to persons or to the environment when it is delivered and/or during and after disassembly. -

Page 18: Decommissioning, De-Installation And Disposal

Installation & Operating Instructions FK 75C and FK 76C Decommissioning, De-Installation and Disposal ARGUS Decommissioning, De-Installation and Disposal Decommissioning and De-Installation After decommissioning, it is advisable to disconnect the actuation unit and the control components from the valve before dismounting it from the pipework. DANGER Ball valve must be depressurized! Operate the ball valve so that trapped pressure can escape. -

Page 19: Fk 75C Disassembly / Assembly

Additionally, belleville washer (17) and ring (43) are needed. Inspect all parts for wear and tear or for any sign of improper functioning. Partial disassembly may be sufficient. For reassembly, proceed in reverse order of disassembly. Replace the worn items by original Flowserve spare parts. -

Page 20: Fk 76C Disassembly / Assembly

Remove and replace sealing rings (63). Inspect all parts for wear and tear or for any sign of improper functioning. Partial disassembly may be sufficient For reassembly, proceed in reverse order of disassembly. Replace the worn items by original Flowserve spare parts. -

Page 21: Disclaimer

Disclaimer Information in this user manual is believed to be complete and reliable. In spite of all Flowserve’s efforts to provide comprehensive information and instructions, sound engineering and safety practices must always be used. Qualified personnel must be consulted. For any further query, Flowserve should be contacted. - Page 22 Suite 100 Houston, TX 77043 Tel: +1 281 469 4166 Flowserve ARGUS Lead Product Operation contact: Flowserve Flow Control GmbH Rudolf-Plank-Str.2 76275 Ettlingen Germany Tel: +49 7243 103 0 These instructions and detailed product bulletins are also available for download under:...

Need help?

Do you have a question about the Argus Series and is the answer not in the manual?

Questions and answers