Summary of Contents for Chromalox MaxPac series

- Page 1 PK480-2 User's Manual www.chromalox.com 800-443-2640 © 2014 Chromalox, Inc. P/N 0037-75428...

- Page 2 ® price and performance. For more than 80 years, customers have relied on Chromalox for the utmost in quality and innovative solu- tions for industrial heating applications. Chromalox manufactures the world’s largest and broadest line of electric heat and control products.

-

Page 3: Table Of Contents

4.2.7 ..... Calibration ....................23 5 ..........Specifications ....................24 6 ..........Maintenance ....................25 7 ..........Troubleshooting .................... 26 8 ..........Parts and Accessories .................. 27 9 ..........Warranty and Return Information ..............28 10 ..........EC Declaration of Conformity ............... 37 - 2 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... -

Page 4: Important Safeguards

Throughout the MaxPac User Manual, the safety alert and the international electric shock/electrocution sym- bols will alert you to potential hazards. Safety precautions should always be followed to reduce the risk of personal injury to persons from fire and electrical shock hazards. Safety Alert Symbol International Shock/Electrocution Symbol Each safety message is preceded by a safety alert symbol and one of three words: DANGER, WARN- ING, or CAUTION. These mean: DANGER You WILL be killed or seriously hurt if you do not follow instructions. WARNING You CAN be killed or seriously hurt if you do not follow instructions. CAUTION You CAN be hurt if you do not follow instructions. Damage Prevention Messages: CAUTION You will see other IMPORTANT messages that are proceeded by the word that are intended to help prevent damage to the MaxPac™ or other equipment. Note that Damage Prevention Messages are NOT accompanied by the Safety Alert Symbol. 1-888-996-9258 © 2014 Chromalox , Inc. - 3 - ®... -

Page 5: Description

MaxPac IP The Chromalox MaxPac IP utilizes Single Phase, Phase Angle firing to modulate power to an inductive or resistive load. Phase Angle control has the advantage of proportioning every cycle thereby providing very fine resolution of power. Fast responding loads in which the resistance changes as a function of temperature require Phase Angle control. The MaxPac IP offers a Soft Start feature that assures that the load power is gradually increased from zero to the value set by the command signal in the event of a power interruption. In addition, optional Current Limit is used to protect the load, SCR controller and the total system from large surge currents that could occur at start-up. † This can be set to three cycles ‘On’ / three cycles ‘Off’ (see section on installation options). - 4 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... -

Page 6: Before You Install

High humidity or hosing down a unit should be avoided. Clearance Choose a location that will provide adequate spacing around the unit when mounted. This will en- sure proper air flow necessary to cool the device. WARNING Hazardous Voltage: Disconnect and lockout power before install- ing or servicing. Failure to comply could result in personal injury or equipment damage. 1-888-996-9258 © 2014 Chromalox , Inc. - 5 - ®... -

Page 7: Installation

Configuration One Warm Air Out Cool Air In Phase 3 Phase 1 or In or In Configuration Two Warm Air Out Cool Air In Phase 1 Phase 3 or In or In Configuration Three Warm Air Out Phase 3 or In Phase 1 or In Cool Air In - 6 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... - Page 8 Pagoda Top MaxPac Enclosure Louvers Forced Air Out Since hot air rises naturally, it is not recommended that cooling air enter from the top and exhaust at the bottom of the enclosure. 1-888-996-9258 © 2014 Chromalox , Inc. - 7 - ®...

-

Page 9: Mounting

4....100A, 150A, 200A, 300A & 400A 1-Leg Touch-Safe 4....400A 1-Leg Open Type 5....100A, 150A, 200A, 300A & 400A 2-Leg Touch-Safe 5....400A 2-Leg Open Type 6....100A, 150A, 200A, 300A & 400A 3-Leg Touch-Safe 6....300A & 400A 3-Leg Open Type 7....550A & 650A 1-Leg Touch-Safe 7....550A & 650A 1-Leg Open Type 8....550A & 650A 2-Leg Touch-Safe 8....550A & 650A 2-Leg Open Type 9....550A & 650A 3-Leg Touch-Safe 9....550A & 650A 3-Leg Open Type ....800-1200 Amp units, consult factory IMPORTANT: Please note that the figures on the following pages are not drawn to the same scale. - 8 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... - Page 10 Figure 4 8.4" [214mm] 0.0" [0mm] 1.3" [33mm] Ø.3125" [Ø7.94mm] (8 HOLES) 5.3" [135mm] FIRING PACKAGE 9.3" [237mm] 13.3" [338mm] 14.6" [371mm] FAN END 14.7" [375mm] 15.75" [400mm] Figure 5 1-888-996-9258 © 2014 Chromalox , Inc. - 9 - ®...

- Page 11 FIRING PACKAGE 11.3" [287mm] 11.3" [287mm] 16.3" [414mm] 16.3" [414mm] 17.6" [448mm] 17.6" [448mm] FAN END FAN END 25.5" [648mm] 17.5" [444mm] 26.5" [673mm] 18.5" [470mm] Figure 8 Figure 9 - 10 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

-

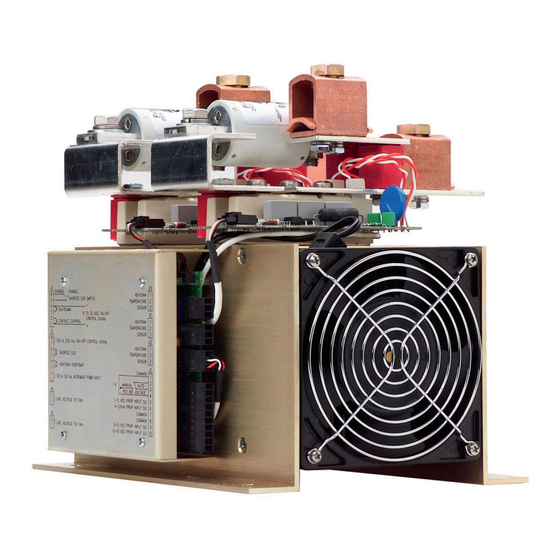

Page 12: Wiring

FOR WIRING FROM EITHER DIRECTION AND MULTIPLE DIRECTION AND MULTIPLE LOAD CIRCUITS LOAD CIRCUITS FUSE COOLING AIR HEATSINK FINS COOLING AIR LONG LIFE, HIGH OUTPUT BALL BEARING FANS PROVIDE RELIABLE COOLING 1-888-996-9258 © 2014 Chromalox , Inc. - 11 - ®... -

Page 13: Cover Removal And Installation

Tighten all thumb screws. 4.2.3 - Power/Load Wiring The following illustrations depict how to connect the MaxPac to a resistive or inductive load. Make sure you refer to the correct illustration for the MaxPac series you have purchased. For the power/load drawings: On open design units up to 300 Amps, X1, X2, X3, L1, L2, and L3 refer to copper lugs. - Page 14 NOT on MaxPac CAUTION IMPORTANT: The I t fuses installed on the SCR are designed to protect the SCR from faults on the load connection side. They are NOT intended to provide wire protection. 1-888-996-9258 © 2014 Chromalox , Inc. - 13 - ®...

- Page 15 CAUTION IMPORTANT: The I t fuses installed on the SCR are designed to protect the SCR from faults on the load connection side. They are NOT intended to provide wire protection. - 14 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

- Page 16 View From Top The bus bars are designed to accept NEMA standard two-hole crimp lugs in accordance with the charts below. Touch-Safe Units 100 - 400 Amps Input Bus Output Bus Up to (3) 1/0 - 300 mcm (70 mm — 150 mm Up to (10) #8 - #1 (10 mm — 50 mm Up to (3) 1/0 - 300 mcm (70 mm — 150 mm Up to (2) 350 - 500 mcm (185 mm — 240 mm Up to (2) 350 - 500 mcm (185 mm — 240 mm 550 - 650 Amps Input Bus Output Bus Up to (4) 1/0 - 300 mcm (70 mm — 150 mm Up to (12) #8 - #1 (10 mm — 50 mm Up to (4) 1/0 - 300 mcm (70 mm — 150 mm Up to (3) 350 - 500 mcm (185 mm — 240 mm Up to (3) 350 - 500 mcm (185 mm — 240 mm 800 - 1200 Amps Open Design Input and output bus drilled to accomodate qty (4) 1/0 - 500 mcm NEMA standard two-hole crimp lugs per phase. 1-888-996-9258 © 2014 Chromalox , Inc. - 15 - ®...

-

Page 17: Instrument Power

Fig. 1 on page 21). This supply is fused on the main circuit board. 4.2.5 - Grounding Chasis is provided with hole pattern for standard NEMA two-hole crimp lugs. WARNING Hazardous Voltage: This Electrical Equipment must be installed by a qualified person and effectively grounded in accordance to the National Electric Code and local codes. - 16 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... -

Page 18: Command Signal Wiring

POTENTIOMETER control input (see Fig. 4 on page (SW) NC NO 21). The unit is shipped with a AUTO HAND jumper from terminals 2 and 3 of terminal block J2 (see illustra- tion 3). Remove jumper to install auto/manual input. Illustration 3 CAUTION IMPORTANT: When enabling the Auto/Manual Input, the jumper from terminals 2 and 3 of terminal block J2 must be removed. Demand Indicator The LED demand indicator is located on the main PC board and is viewable through the cover. With the On/Off control option, the indicator will display steady “on” and steady “off”. With the DOT Firing option, the indicator will display the rapid firing sequence. 1-888-996-9258 © 2014 Chromalox , Inc. - 17 - ®... - Page 19 The Shorted SCR Alarm: The plug-in receptacle for the shorted SCR board is located on this board. Signals from the SCR are routed to the option board. When a short is detected the externally connected device output is activated. 2AMP (2AG) CHROMALOX P/N 0024-01097 LITTLEFUSE P/N 225 002 - 18 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

- Page 20 CAUTION IMPORTANT: This shutdown overrides the control input only. It will NOT protect against faulted or damaged SCRs. Shorted SCR Detection (optional) This option provides a means of alerting an operator to a problem with the system. An external indicating lamp or relay can be connected to J1 - 5 & 6 (see Fig. 2 on page 21). This indicator must be rated for the instrument power applied to J1 - 1 & 2. Three diagnostic LEDs show which SCR pair is faulted. These lights are synchronized with the demand indicator and can only indicate while the demand is active. Shorting J3 - 5 & 6 can disable the output at J1 - 5 & 6. The alarm can be selected as latching or non-latching. A latching alarm means that if the alarm activates and the system subsequently returns to normal, the alarm will remain latched until a reset button (external switch – customer provided) is pressed. A non-latching alarm resets automatically. DEMAND SHORTED SCR DETECTION 1-888-996-9258 © 2014 Chromalox , Inc. - 19 - ®...

- Page 21 UNIT SHIPPED IN NON-LATCHING MODE. Heat Sink Over-Temperature An external lamp or relay may be connected to J1 - 3 & 4 (see Fig. 2 on page 21) (this must be rated for the instrument power applied to J1 - 1 & 2). This will provide an indication to the operator that the heat sink is approaching an unsafe temperature level. The unit will enter a shutdown mode if the temperature continues to rise. - 20 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

- Page 22 0 TO +5 VDC PROPORTIONAL INPUT 0 +10 VDC PROPORTIONAL INPUT 0 TO +5 VDC PROPORTIONAL INPUT SIG 0 +10 VDC PROPORTIONAL INPUT SIG 120~240 ON/OFF CONTROL FIG 10. FIG 11. FIG 12. COMMON COMMON EXTERNAL +5~32 VDC ON/OFF DRY CONTACT ON/OFF REMOTE SHUTDOWN 1-888-996-9258 © 2014 Chromalox , Inc. - 21 - ®...

- Page 23 JUMPER JB1 FOR 0-5mA OPEN JB1 FOR 0-10V 10-50mA FUSE CLOSE FOR REMOTE SHUTDOWN INSTRUMENT JUMPER 4 TO 5 WIRE WHEN NOT USING REMOTE POT UNIT SHIPPED WITH JUMPER INSTALLED Customer Connection - 22 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

-

Page 24: Calibration

18. With Manual pot (CW) at 100% and I LIM (Current Limit) at for operation. 0%, adjust I LIM towards 100% noting that voltage output de creases with the adjustment of the 5. Check for polarity of input signal. Current Limit pot. Adjust Current Limit pot for your application, if needed. 6. Adjust input signal to low end of scale. Zero Adjust control sets the power output starting point 19. Turn POWER OFF and remove meters. TEST COMPLETE. or reference. Thus, it effectively cancels positive inputs to the MaxPac Power Pak. EXAMPLE: 0 - 5 mA input à set to 0 mA input 4 - 20 mA input à set to 4 mA input 1-888-996-9258 © 2014 Chromalox , Inc. - 23 - ®... -

Page 25: Specifications

Thermostat .....4 Amps @ 120V resistive Resolution (proportional) Better than 0.1% 2 Amps @ 240V resistive N.C. Contact Standard Line Voltage ....120, 208, 240, 277, 380, ........480 and 575 Vac Current Limit ....10 - 100% of rated ± 10% 50/60 Hz output current Load Current Rating .. 100, 150, 200, 300, 400, Soft Start ......25% demand per second 550, 650, 800, 1000, 1200A typical reset speed 8.3 milliseconds - 24 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... -

Page 26: Maintenance

The filters used with these devices should be changed on a periodic basis to insure adequate enclo- sure cooling is maintained. Dust – Periodically check for dust or other particulate buildup on heatsinks and bus bars. 1-888-996-9258 © 2014 Chromalox , Inc. - 25 - ®... -

Page 27: Troubleshooting

If Demand Light is “Off” 1. Check incoming line power. 2. Check the instrument power. 3. Check the fuse on the main board. 4. Verify the input signal. 5. Check that remote shutdown J3 - 3 to 4 is open. 6. Check that the J2 - 2 to 3 is Jumpered. 7. Verify that heat sink is not in over temperature mode by removing temperature sensor plugs from J10, J11, and J12. If Demand Light is “On” 1. Check the connections to SCR trigger board. 2. Check the power fuses (I 3. Look for damage on the trigger board. - 26 - © 2014 Chromalox , Inc. 1-888-996-9258 ®... -

Page 28: Parts And Accessories

Parts and Accessories Instrument Power Fuse Chromalox Part Number Description 0024-01097 Littlefuse # 225 002 2 AG 2AMP T Fuses for 500 Vac Applications 0024-07634 200 Amp I t Fuse 0024-07630 250 Amp I t Fuse 0024-07632 400 Amp I t Fuse 0024-03116 500 Amp I t Fuse 0024-07633 700 Amp I t Fuse 0024-03118 800 Amp I... -

Page 29: Warranty And Return Information

This warranty extends for three years from date of shipment from the factory or authorized distributor. Limitations Products must be installed and maintained in accordance with Chromalox instructions. Users are responsi- ble for the suitability of the products to their application. There is no warranty against damage resulting from corrosion, misapplication, improper specification or other operating conditions beyond our control. Claims against the carrier company for damage in transit must be filed by the buyer. - Page 30 Open Design Code Line Voltage 120 Vac - 480Vac 575 Vac Code Instrument Power 120 Vac 50/60 Hz 230 Vac 50/60 Hz Code Compression Lug Kits (Open Design up to 300 Amps) For Other Ranges See Crimp Lug Chart None 100 - 150 Amp PAK 1(#2 - 4/0)/connection 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection MXPC I - (Continued on next page) 1-888-996-9258 © 2014 Chromalox , Inc. - 29 - ®...

- Page 31 0135-10004 LCD4-14A-L #4 AWG or #4 Weld Note: 0135-10005 LCD2-56B-Q #2 AWG Storage Temperature 14ºF to 158ºF 0135-10006 LCD1-56C-E #1 AWG or #2 Weld (-10ºC to 70ºC). CE application requires filters. 0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld Chromalox Part Numbers 0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 0005-60055: Line filter, single phase, 0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 230VAC 0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 0005-60057: Line filter, 120-230VAC 0135-10012 LCD300-12-X 300 MCM 0135-10013 LCD350-12-6 350 MCM...

- Page 32 240 Vac 277 Vac 480 Vac 575 Vac Code Fan Power 120 Vac 50/60 Hz 230 Vac 50/60 Hz Code Compression Lug Kits (Open Design up to 300 Amps) For Other Ranges See Crimp Lug Chart None 100 - 150 Amp PAK 1(#2 - 4/0)/connection 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection MXPC IP - 2 (Continued on next page) 1-888-996-9258 © 2014 Chromalox , Inc. - 31 - ®...

- Page 33 0135-10004 LCD4-14A-L #4 AWG or #4 Weld Note: 0135-10005 LCD2-56B-Q #2 AWG Storage Temperature 14ºF to 158ºF 0135-10006 LCD1-56C-E #1 AWG or #2 Weld (-10ºC to 70ºC). CE application requires filters. 0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld Chromalox Part Numbers 0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 0005-60055: Line filter, single phase, 0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 230VAC 0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 0005-60057: Line filter, 120-230VAC 0135-10012 LCD300-12-X 300 MCM 0135-10013 LCD350-12-6 350 MCM...

- Page 34 Code Line Voltage 120 Vac - 480Vac 575 Vac Code Instrument Power 120 Vac 50/60 Hz 230 Vac 50/60 Hz Code Compression Lug Kits (Open Design up to 300 Amps) For Other Ranges See Crimp Lug Chart None 100 - 150 Amp PAK 1(#2 - 4/0)/connection 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection MXPC II - 2 (Continued on next page) 1-888-996-9258 © 2014 Chromalox , Inc. - 33 - ®...

- Page 35 0135-10004 LCD4-14A-L #4 AWG or #4 Weld Note: 0135-10005 LCD2-56B-Q #2 AWG Storage Temperature 14ºF to 158ºF 0135-10006 LCD1-56C-E #1 AWG or #2 Weld (-10ºC to 70ºC). CE application requires filters. 0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld Chromalox Part Numbers 0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 0005-60055: Line filter, three phase, 0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 440VAC 0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 0005-60057: Line filter, 120-230VAC 0135-10012 LCD300-12-X 300 MCM 0135-10013 LCD350-12-6 350 MCM...

- Page 36 Line Voltage 120 Vac - 480Vac 575 Vac Code Instrument Power 120 Vac 50/60 Hz 230 Vac 50/60 Hz Code Compression Lug Kits (Open Design up to 300 Amps) For Other Ranges See Crimp Lug Chart None 100 - 150 Amp PAK 1(#2 - 4/0)/connection 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection Note: 550-1200 Amp and all Touch-Safe Designs: Buss MXPC III - 1 (Continued on next page) 1-888-996-9258 © 2014 Chromalox , Inc. - 35 - ®...

- Page 37 0135-10004 LCD4-14A-L #4 AWG or #4 Weld Note: 0135-10005 LCD2-56B-Q #2 AWG Storage Temperature 14ºF to 158ºF 0135-10006 LCD1-56C-E #1 AWG or #2 Weld (-10ºC to 70ºC). CE application requires filters. 0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld Chromalox Part Numbers 0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 0005-60055: Line filter, three phase, 0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 440VAC 0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 0005-60057: Line filter, 120-230VAC 0135-10012 LCD300-12-X 300 MCM 0135-10013 LCD350-12-6 350 MCM...

-

Page 38: Ec Declaration Of Conformity

6. Voltage Dips and Interrupts Immunity EN 61000-6-2:2005 / EN 61000-4-11:1994 Voltage Rating: 400 Vac 50 Hz Line 230 Vac 50 Hz Instrument max 7. Electrostatic Discharge Immunity 75 watts EN 61000-6-2:2005 / EN 61000-4-2:1995 Impulse Rating: 2.5 KV for 5 seconds 8. Voltage Fluctuations/Flicker EN 61000-3-3 / A2:2005 Overload 140% for 1 second Current Profile: 9. Harmonic Current Emissions EN 61000-3-2:2006 Fuses: 500 Volt, 200KA RMS symmetrical interrupting rating, t fusing provided with all CE units. 1-888-996-9258 © 2014 Chromalox , Inc. - 37 - ®... - Page 39 Filters Required: Instrument power filter: 10. Surge Immunity Chromalox P/N 0005-60057 EN 61000-6-2:2005 / EN 61000-4-5:1995 Line Filter, single phase: Chromalox P/N 0005-60055 Line Filter, three phase: Chromalox P/N 0005-60056 The Technical documentation required by Annex IV (3) of the Low Voltage Directive is maintained by (Name) of (company and location in the European Union) Year in which CE Marking was affixed: 2002 Authorized Signature/Date: ________________________________________ __________________________ Jim Birnie Date Engineering Manager Title of Signatory: ________________________________ Chromalox, International Unit 1.22, Lombard House 2 Purley Way Croydon CRO 3JP Surrey U.K. - 38 - © 2014 Chromalox , Inc. 1-888-996-9258 ®...

Need help?

Do you have a question about the MaxPac series and is the answer not in the manual?

Questions and answers