Table of Contents

Advertisement

Revised 02-02

OPERATOR'S MANUAL

This Operator's Manual is an integral part of the safe operation

of this machine and must be maintained with the unit at all times.

READ, UNDERSTAND, and FOLLOW the Safety and Operation

Instructions contained in this manual before operating the

equipment. If the Operator's Manual is not with the equipment,

contact your local dealer or Servis-Rhino (800-446-5158) to

obtain a free copy before operating the

shipping and handling charges may apply)

RHINO

®

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@servis-rhino.com

Effective Serial No. LJ 60-10001 Through Current

Effective Serial No. LJ 72- 10330Through Current

© 2004 Alamo Group Inc.

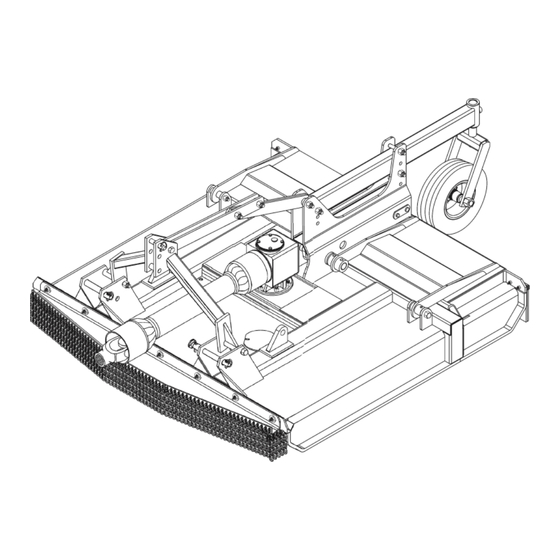

LUMBERJACK

60/72

TREE CUTTER

P/N 00772058C

equipment.(Some

®

$0.00

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for RHINO LUMBERJACK 60/72

- Page 1 READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment. If the Operator's Manual is not with the equipment, contact your local dealer or Servis-Rhino (800-446-5158) to obtain a free copy before operating the shipping and handling charges may apply) RHINO ®...

-

Page 2: Before You Start

TO THE OWNER/OPERATOR/DEALER All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents. - Page 3 In order to reduce accidents and enhance the safe operation of mowers, Alamo Group Ag Division, in cooperation with other industry manufacturers has developed the AEM/FEMA Industrial and Agricultural Mower Safety Practices video and guide book. The video will familiarize and instruct mower-tractor operators in safe practices when using industrial and agricultural mowing equipment.

- Page 4 Alamo Group Ag. Division is willing to provide one (1) AEM Mower Safety Practices Video Please Send Me: VHS Format – AEM/FEMA Mower Operator Safety Video DVD Format – AEM/FEMA Mower Operator Safety Video Mower Operator’s Manual AEM Mower Operator’s Safety Manual Requester Name: Requester Address: City...

-

Page 5: Table Of Contents

SAFETY SECTION ... 1-1 Safety Information ... 1-2 Safety Decal Location ... 1-11 Safety Decals ... 1-12 Federal Laws And Regulations ... 1-14 INTRODUCTION SECTION ..2-1 ASSEMBLY SECTION...3-1 A-Frame Assembly...3-2 Gearbox Shield...3-3 Driveline Attachment...3-3 Front Chainguard Assembly... OPERATION SECTION ..4-1 MAINTENANCE SECTION...5-1 Lubrication ... -

Page 7: Safety Section

SAFETY SECTION Safety Section 1-1... - Page 8 A safe and careful operator is the best operator. Safety is of primary importance to the manufac- turer and should be to the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and observing certain precautions. The first section of this manual includes a list of Safety Messages that, if followed, will help protect the operator and bystanders from injury or death.

-

Page 9: Safety Decals

Si no lee Ingles, pida ayuda a alguien que PELIGRO! si lo lea para que le traduzca las medidas de seguridad. (SG-3) Never operate the Tractor or Implement until you have read and DANGER! completely understand this Manual, the Tractor Operator’s Manual, and each of the Safety Messages found in the Manual or on the Tractor and Implement. - Page 10 Never allow children to operate or ride on the Tractor or Implement. DANGER! WARNING! Do not mount the Tractor while the tractor is moving. Mount the Tractor only when the Tractor and all moving parts are completely stopped. DANGER! Start tractor only when properly seated in the Tractor seat. Starting a tractor in gear can result in injury or death.

- Page 11 WARNING! Transport only at safe speeds. Serious accidents and injuries can re- sult from operating this equipment at unsafe speeds. Understand the Tractor and Implement and how it handles before transporting on streets and highways. Make sure the Tractor steering and brakes are in good condition and operate properly.

- Page 12 KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement DANGER! and possible serious injury or death. DANGER! Never allow children to play on or around Tractor or Implement. Children can slip or fall off the Equipment and be injured or killed. themselves or others.

- Page 13 DANGER! All Safety Shields, Guards and Safety devices including (but not limited to) - the Deflectors, Chain Guards, Steel Guards, Gearbox Shields, Hydraulic Tank Shields, and Retractable Door Shields should be used and main- tained in good working condition. All safety devices should be inspected carefully at least daily for missing or broken components.

- Page 14 DANGER! Replace bent or broken blade with new blades. NEVER ATTEMPT TO STRAIGHTEN BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM THROWN BLADES. (SGM-10) Do not mow with two machines in the same area except with Cab tractors with the windows closed. WARNING! (SGM-11) Rotary Mowers are capable under adverse conditions...

- Page 15 There are obvious and hidden potential hazards in the operation of this Implement as in all DANGER! power-driven or pulled equipment. REMEMBER! This machine is often operated in rough terrain conditions that include tall grass, weeds, gullies, holes, slopes, hidden obstructions and the like.

-

Page 16: Parts Information

Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. Servis-Rhino mowers use balanced and matched system components for blade carriers, blades, cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings. These parts are made and tested to Servis-Rhino specifications. - Page 17 NOTE: Rhino supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Rhino cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply).

- Page 18 2 - 00756004 4 - 00756005 1 - - 00749117 - Not Shown (See Inside Front Cover of Manual) 11 - - 03200347 SMV Reflector LJ60/72 02-02 © 2004 Alamo Group Inc. SAFETY 3 - 00725746 6 - 00756494 7 - 00760657 18 - 00776481 Safety Section 1-12...

- Page 19 SAFETY 14 - D303 5 - 02962764 10 - D103 10 - D114 8 - 00769736 13 - 00763977 12 - 00763613 9 - 00769737 7A - 00773723 LUMBERJACK 15 - 00771818 LJ60/72 02-02 Safety Section 1-13 © 2004 Alamo Group Inc.

-

Page 20: Federal Laws And Regulations

FEDERAL LAWS AND REGULATIONS This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning employer and employee equipment operators. This section is not intended as a legal interpretation of the law and should not be considered as such. -

Page 65: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 66 This Cutter is designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize, instruct, and train. The Assembly Section instructs the owner/operator in the correct assembly of the Mower using standard and optional equipment.

- Page 67 This cutter is available in lift-type models only. These rugged Cutters are designed for heavy-duty work. They can cut brush up to 6" in diameter. DANGER For Non-Agricultural use, OSHA, ASAE, SAE, and ANSI standards require the use of Chain Guards, Deflectors, or Solid Skirts at all times.

-

Page 69: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1... -

Page 70: Dealer Set-Up Instructions

540 or 1000 RPM PTO. DEALER SET-UP INSTRUCTIONS Assembly of this mower is the responsibility of the Servis-Rhino dealer. The mower should be delivered to the owner completely assembled, lubricated, and adjusted for normal cutting conditions. Set up mower as received from the factory with these instructions. Open parts box and lay parts out to make location easy. - Page 71 A-FRAME ASSEMBLY (FIGURE 2) 60" MODEL To assemble the Mower’s A-Frame, follow the procedures listed below: 1. One side at a time, position the mower’s left and right A-frame halves (21 and 22) to the inside of the respective front set of mower deck upright lugs. Align A-frame hole with with inside lug back hole. From inside the A-frame half, insert a 3/4”...

-

Page 72: Gearbox Shield

GEARBOX SHIELD (FIGURE 2) Position the bell shield over the input shaft and align it with threaded holes in the gear- box. Make sure access windows are facing left and right ( Not up and down ). Install flatwashers, mounting bolts and tighten se- curely. - Page 73 FRONT CHAINGUARD ASSEMBLY 72 MODEL Install front chainguard as illustrated below. CAUTION! Do not operate Cutter without Front Chainguard in place. LJ60/72 02-02 © 2004 Alamo Group Inc. ASSEMBLY Assembly Section 3-5...

-

Page 75: Operation Section

OPERATION SECTION Operation Section 4-1... - Page 76 LUMBERJACK 60/72 HEAVY-DUTY TREE CUTTERS OPERATION INSTRUCTIONS Rhino Lumberjack 60 and Lumberjack 72 (LJ60/72) Heavy-Duty Tree Cutters are manufactured with quality material by skilled workers. Lumberjack cutters are engineered to cut vegetative material that a properly rated tractor can drive over (up to about 3” in diameter) and larger vegetation (up to 6” maximum diameter) by raising the retractable rear door and backing the cutter into the material.

- Page 77 (7) DRIVELINE ATTACHMENT...4-12 (7.1) Driveline Length Modification...4-13 (8) PRE-OPERATION INSPECTION AND SERVICE...4-14 (8.1) Tractor Pre-Operation Inspection/Service...4-15 (8.2) Cutter Pre-Operation Inspection/Service...4-15 (9) DRIVING THE TRACTOR AND CUTTER...4-18 (9.1) Starting the Tractor...4-19 (9.2) Brake and Differential Lock Setting...4-19 (9.3) Raising the Cutter...4-20 (9.4) Driving the Tractor and Cutter...4-20 (9.5) Crossing Ditches and Steep Inclines...4-21 (10) OPERATING THE TRACTOR AND CUTTER...4-22...

-

Page 78: Operator Requirements

1. OPERATOR REQUIREMENTS Safe operation of the Rhino Lumberjack 60 and Lumberjack 72 (LJ60/72) Heavy-Duty Tree Cutter is the responsibility of a qualified operator. A qualified operator has read and understands both the cutter and tractor Operator Manuals and is experienced in tractor and cutter operations and all associated safety practices. In addition to the safety messages contained in this manual, safety message decals are affixed to the cutter and tractor. -

Page 79: Tractor Requirements

2. TRACTOR REQUIREMENTS The tractor used to operate the cutter must have the power capacity to lift, pull, and operate the Power Take Off (PTO) at the required speed (540 or 1000 revolutions per minute, depending on cutter gearbox) while traveling at a ground speed between 1 and 3 mph. -

Page 80: (2.3) Tractor Horsepower

2.3 Tractor Horsepower The power required to operate a cutter is determined by the tractor PTO horsepower. For most cutting conditions, the LJ60 and LJ72 require a tractor with 50 and 90 HP, respectively. Operating the cutter with a tractor that does not have adequate power may damage the tractor engine. -

Page 81: (2.6) Power Take Off (Pto)

2.6 Power Take Off (PTO) Depending on the equipped gearbox, LJ60/72 cutters are designed to operate at either 540 or 1000 rpm. Most tractors operate at either 540, or a combination of 540 and 1000 rpm PTO speeds. The speed of the tractor PTO can be determined by the number of splines on the PTO output shaft. -

Page 82: (3.1) Boarding The Tractor

3.1 Boarding the Tractor Use both hands and equipped handrails and steps for support when getting on the tractor. Never use tractor control levers for support when mounting the tractor. Always seat yourself in the operator’s seat and fasten the seatbelt. -

Page 83: Starting The Tractor

4. STARTING THE TRACTOR The operator must have a complete understanding of the placement, function, and operational use of all tractor controls before starting the tractor. Review the tractor operator’s manual and consult an authorized dealer for tractor operation instructions if needed. Essential Tractor Controls: "... -

Page 84: Connecting The Cutter To The Tractor

5. CONNECTING THE CUTTER TO THE TRACTOR Use extreme caution when connecting the cutter to the tractor. The cutter should be securely resting at ground level or setting securely on blocks. Keep hands and feet from under cutter deck and clear of pinch points between tractor hitch arms and cutter pins. -

Page 85: Setting The Cutter

6. SETTING THE CUTTER Properly setting the cutter height is essential for efficient and safe operation. A properly set cutter will make a more uniform cut, distribute clippings more evenly, require minimal tractor work, and follow the contour of uneven terrain. -

Page 86: (6.2) Setting Deck Level

6.2 Setting Deck Level The cutter deck should be level from front to rear and side to side. It is especially important that the cutter be level with the ground when cutting large diameter trees. If the cutter is not level, the blades are making contact with the tree on an elevated angle, and its ability to cut is greatly reduced. -

Page 87: (7.1) Driveline Length Modification

7.1 Driveline Length Modification WARNING! Before operating the Mower, check to make sure the driveline will not bottom out or become disengaged. Bottoming out occurs when the inner shaft penetrates the outer housing until the assembly becomes solid-it can shorten no more. Bottoming out can cause serious damage to the Tractor PTO by pushing the PTO into the Tractor and through the support bearings or downward onto the PTO shaft, breaking it off. -

Page 88: Pre-Operation Inspection And Service

With the driveline attached, raise and lower the cutter within its operating range. Position the mower at the point where the telescoping driveline is at its maximum extension. Turn off the tractor and apply the parking brake. Securely block the cutter at this height. Mark the inner shield 1/8”... -

Page 89: (8.1) Tractor Pre-Operation Inspection/Service

8.1 Tractor Pre-Operation Inspection/Service Refer to the tractor operator’s manual to ensure a complete pre-operation inspection and scheduled service is performed according to manufacturer recommendations. The following is a partial list of items requiring inspection: " Tire condition/air pressure " Wheel lug bolts "... - Page 90 " Ensure chain guards and rubber deflectors are in position and not damaged. Replace worn, broken, and missing pieces. " Check the condition of the retractable rear guard and ensure it raises and lowers properly. " Ensure the cylinder operating the retractable door is correctly installed and attached.

- Page 91 " Ensure the driveline slip clutch shield is in place and in good condition. " Ensure the driveline integral shield is in good condition and rotates freely " Make sure the tractor PTO master shield is in place, lowered, and in good condition. "...

-

Page 92: Driving The Tractor And Cutter

9. DRIVING THE TRACTOR AND CUTTER Safe tractor transport requires the operator possess a thorough knowledge of the model being operated and precautions to take while driving with an attached implement. Ensure the tractor has the capacity to handle the weight of the cutter and the tractor operating controls are set for safe transport. -

Page 93: (9.1) Starting The Tractor

9.1 Starting the Tractor The procedure to start the tractor is model specific. Refer to the tractor operator’s manual for starting procedures for your particular tractor. Consult an authorized dealer if the starting procedure is unclear. Ensure the 3-point control lever is in the lowered position and the PTO lever is off before starting the tractor. -

Page 94: (9.3) Raising The Cutter

9.3 Raising the Cutter Using the tractor 3-point hitch control lever, raise the cutter off the ground about 6”, or just high enough to clear any ground obstacles. When raising the cutter, make sure all connection points are securely attached and at least 1” clearance is maintained between the driveline and the deck. -

Page 95: (9.5) Crossing Ditches And Steep Inclines

To avoid overturns, drive the tractor with care and at safe speeds, especially when operating over rough ground, crossing ditches or slopes, and turning corners. Tractor wheel tread spacing should be increased when working on inclines or rough ground to reduce the possibility of tipping. Use extreme caution when operating on steep slopes. -

Page 96: Operating The Tractor And Cutter

10. OPERATING THE TRACTOR AND CUTTER Before starting any cutting operation, the operator must become familiar with the area to be cut and any obstacles and hazards contained within to ensure safety to the operator, bystanders, and equipment. Special attention should be paid to foreign debris, rough terrain, steep slopes, and passersby and animals in the area. - Page 97 If you hit a solid object or foreign debris, stop the cutter and tractor at once. Immediately idle the engine speed and disengage the PTO. Wait for all cutter rotating motion to stop, then raise the cutter and move the tractor and implement off the object.

-

Page 98: (10.3) Engaging The Power Take Off (Pto)

10.3 Engaging the Power Take Off (PTO) Before engaging the PTO, make certain that the area is clear of bystanders and passersby. Set the tractor engine speed at approximately 1,000 rpm before engaging the PTO. Shift the PTO control to the on position, and slowly increase the engine speed until the PTO is operating at 540 or 1000 rpm. -

Page 99: (10.5) Operating The Cutter

WARNING! Mow at the speed that you can safely operate and control the Tractor and Mower. Safe mowing speed depends on terrain condition and grass type, density, and height of cut. Normal ground speed range is from 1 to 3 mph. Use slow mowing speeds when operating on or near steep slopes, ditches, drop-offs, overhead obstructions, power lines, or when debris and foreign objects are to be avoided. - Page 100 When you get to the end of a pass, slightly raise the cutter (2-4”) before turning. Never raise the cutter entirely while the blades are turning. If the cutter must be raised higher than 12” from ground level, disengage the tractor PTO and wait for all cutter rotation to come to a complete stop before proceeding to raise the cutter.

-

Page 101: (10.6) Shutting Down The Cutter

OPERATION Stay alert and watch for trees, low hanging limbs, power lines, and other overhead obstacles and solid ground objects while you are operating. Use care to avoid hitting these items. Do not cut, or drive the tractor into, material that is burning, or areas that recently burnt and may contain hot spots. -

Page 102: Disconnecting The Cutter From The Tractor

11. DISCONNECTING THE CUTTER FROM THE TRACTOR DANGER! Never stand or allow another person to stand between a running Tractor and the Mower when disconnecting the Implement from the Tractor 3-point hitch. Always shut the Tractor off completely and set the parking brake before attempting to disconnect the Mower pins from the Tractor hitch. -

Page 103: Cutter Storage

12. CUTTER STORAGE Properly preparing and storing the cutter at the end of the season is critical to maintaining its appearance and to help ensure years of dependable service. The following are suggested storage procedures: 1. Thoroughly clean all debris off the cutter to prevent damage from rotting grass and standing water. -

Page 104: Transporting The Tractor And Cutter

13. TRANSPORTING THE TRACTOR AND CUTTER Inherent dangers of operating the tractor and cutter and the possibility of accidents are not left behind when you finish cutting an area. Therefore, the operator must employ good judgement and safe operation practices when transporting the tractor and cutter between locations. -

Page 105: (13.1) Transporting On Public Roadways

Before transporting the tractor on a public roadway or boarding a trailer for transport, the tractor brake pedals should be locked together. Locking the pedals ensures that both wheels brake simultaneously while stopping, especially when making an emergency stop. Use extreme caution and avoid hard applications of the tractor brakes when towing heavy loads at road speeds. - Page 106 Make sure that all tractor flashing warning lights, headlights, and brake/taillights are functioning properly before proceeding onto public roads. While newer model tractors have plenty of lighting to provide warning signals as well as artificial operating lighting, most older models where only equipped with operating lights.

-

Page 107: (13.2) Hauling The Tractor And Cutter

OPERATION 13.2 Hauling the Tractor and Cutter Before transporting a loaded tractor and cutter, measure the height and width dimensions and gross weight of the complete loaded unit. Ensure that the load will be in compliance with the legal limits set for the areas that will be traveled through. -

Page 108: Troubleshooting

PROBLEM POSSIBLE CAUSE NOT CUTTING CLEAN Blades dull. Blade rotation incorrect. Carrier RPM too low. Mower not leveled. Ground speed too fast. Blades locked back. Blades riding up due to blade bolt wear. Blades bent up. BREAKING BLADE Operating with loose BOLTS Blade Bolts. - Page 109 PROBLEM POSSIBLE CAUSE BROKEN CROSS OR Load too high for joint. CUPS END GALLING OF Speed too high. CROSS AND CUPS Ears have deformed. NEEDLE ROLLERS Load too high for joint. HAVE BRINELLED INTO CUP AND CROSS SHAFT OR TUBE Over-loaded.

- Page 110 PROBLEM POSSIBLE CAUSE GEARBOX Damaged Oil Seal. LEAKING No Oil Seal. Oil too light. Bent Shaft. Oil Seal race rough. Oil Seal installed wrong. Oil Seal not sealing in the housing. Bearings loose. Vent Plug stopped up. Oil level too high. Gasket damaged.

-

Page 111: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1... -

Page 112: Lubrication

Before operating your Rotary Cutter, make sure it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricate and maintain this machine to provide long life and trouble free operation. WARNING! Always disengage the PTO before raising the Rotary Cutter for transporting or making adjustments. -

Page 113: Gearbox

MAINTENANCE GEARBOX The Gearbox has been filled with lubricant to the Test Plug Level prior to shipment. However, you should check the oil level at Test Plug before operating, and frequently thereafter. The gearbox should not require additional lubricant unless the box is cracked or a seal is leaking. It is recommended that the oil level plug be removed after every 8 to 10 hours of operation and oil added until it runs out Test Plug hole. -

Page 114: Driveline

DRIVELINE LUBRICATION Grease Fittings are located on the Cross Assembly of each U-Joint and on the telescoping tubes. Grease the U- Joint after each 8 hours of use. Figure 5. Grease the telescoping tubes after every 8 hours use. Some PTO-to- Hitch connections may necessitate cutting a hole in the shields to be able to align the Grease Fitting holes for lubrication. -

Page 115: Main Driveline & Cat 4 Safety Shield

MAIN DRIVELINE & CAT 4 SAFETY SHIELD To remove the main inner driveline shield, Remove the locking screws. Align the bearing tabs with the cone pockets. FIGURE 7. Remove the half-guard and remove the bearing ring. FIGURE 8. Inspect the driveline shield for worn areas or cracks. If the shield has any dents or cracks, replace the Shield. While the Shields are off, examine the Driveline for signs of abnormal wear, bent or twisted shafts, or cracks in the shafts or tubes. -

Page 116: Blade Sharpening

BLADE SERVICING Inspect blades before each use to determine that they are properly installed and in good condition. Replace any blade that is bent, excessively nicked, worn, or has any other damage. Small nicks can be ground out when sharpening. IMPORTANT! When sharpening blades, grind each blade the same amount to maintain balance. -

Page 117: Slip Clutch

BLADE REMOVAL/INSTALLATION To remove blades for sharpening or replacement, remove the cover plate on deck of cutter near gear box. Remove lock nut from blade bolt. NOTE: Inspect lock nut after removal and replace if threads are damaged. Always replace nut when replacing blade bolt. -

Page 118: Seasonal Clutch Maintenance

SEASONAL CLUTCH MAINTENANCE It is important that the clutches slip when an obstacle or load heavier than the clutch setting is encountered. Therefore, if the machine sits outside longer than 30 days and is exposed to rain and/or humid air it is important to make sure that the clutch lining plates are not rusted/coroded together. -

Page 119: Gearbox Maintenance

LJ60/72 02-02 © 2004 Alamo Group Inc. MAINTENANCE GEARBOX MAINTENANCE 20,21,22 FIGURE 14 Maintenance Section 5-9 29,30,31 ITEM DESCRIPTION Casing Bearing, Lower Output Seal, Lower Output Nut, Slotted Cotter Pin Shaft, Output Gear, Output Nut, Slotted Cotter Pin Bearing, Upper Output, Inner &... - Page 120 RIGHT ANGLE GEARBOX (OUTBOARD) ASSEMBLY & DISASSEMBLY PROCEDURES INPUT SHAFT REMOVAL Step 1. Place Gearbox on appropriate work surface. Step 2. Remove Vent Plug (item #16) or Complete Top Cover (item #18) Step 3. Turn Gearbox upside doan allowing Oil to drai from gearbox into catch pan for proper disposal. Step 4.

-

Page 121: Output Shaft Installation

OUTPUT SHAFT INSTALLATION Step 1. Install Upper Output Shaft Bearing Cup (item # 12) into Main Housing from the top, Install Output Shaft Lower Bearing Cup (item # 2) into Main Housing (item # 1) from the bottom, Make sure both Bearing Cup are seated firmly against housing. -

Page 122: Storage

MAINTENANCE STORAGE Your rotary cutter represents an investment from which you should get the greatest possible benefit. Therefore, when the season is over, the cutter should be thoroughly checked and prepared for storage so that a minimum amount of work will be required to put it back into operation for the next season. The following are suggested storage procedures: 1. - Page 123 1. LIMITED WARRANTIES 1.01. Servis-Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser (“Purchaser”) that the goods purchased are free from defects in material or workmanship.

- Page 125 To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT (1928.51 Subpart C) makes these minimum safety requirements of tractor operators: REQUIRED OF THE OWNER:...

- Page 126 LUMBERJACK 60/72 TREE CUTTER LJ60/72-SOM - 02/02 P/N 00772058C Printed U.S.A.

- Page 127 00763505 FILE. SIGNED COMPLETED, SERVIS-RHINO ® SIGN. MUST MACHINE. THIS WITHIN MAILED MUST REGISTRATION EFFECT, MAILBOX. INFORMATION REGISTRATION mailbox. CARD REGISTRATION UNTIL REFUSED SUBMITTED CLAIM PURCHASER DATE DELIVERY SIGNED, WARRANTY WARRANTY THIS IMPORTANT! COPY LAST DROP WARRANTY drop tape, tear),...

- Page 128 BEFORE MAILING WARRANTY CARD, MAKE SURE ALL INFORMATION IS LEGIBLE SERVIS-RHINO Servis-Rhino Model Purchaser Last Name Street & No., RFD, Box, &/or Apt. No. City Dealer City • I have informed the Purchaser of this product of Warranty terms, provisions, and procedures that are applicable, reviewed the contents of the Operator’s Manual including safety equipment, safe operation, and maintenance, reviewed the Safety Signs on implement (and tractor if possible), shown the AEM Mower Safety Practices Video, and reviewed Purchaser’s responsibility to train his operators in safe operation.

- Page 130 1. PRINT FIRMLY. 2. REMOVE WHITE COPY FOR CUSTOMER RECORDS. SERVIS-RHINO Servis-Rhino Model Purchaser Last Name Street & No., RFD, Box, &/or Apt. No. City Dealer City • I have informed the Purchaser of this product of Warranty terms, provisions, and procedures that are applicable, reviewed the contents of the Operator’s Manual including safety equipment, safe operation, and maintenance, reviewed the Safety Signs on implement (and tractor if possible), shown the AEM Mower Safety Practices Video, and reviewed Purchaser’s responsibility to train his operators in safe operation.

- Page 132 1. PRINT FIRMLY. 2. REMOVE WHITE COPY FOR CUSTOMER RECORDS. SERVIS-RHINO Servis-Rhino Model Purchaser Last Name Street & No., RFD, Box, &/or Apt. No. City Dealer City • I have informed the Purchaser of this product of Warranty terms, provisions, and procedures that are applicable, reviewed the contents of the Operator’s Manual including safety equipment, safe operation, and maintenance, reviewed the Safety Signs on implement (and tractor if possible), shown the AEM Mower Safety Practices Video, and reviewed Purchaser’s responsibility to train his operators in safe operation.

Need help?

Do you have a question about the LUMBERJACK 60/72 and is the answer not in the manual?

Questions and answers