Table of Contents

Advertisement

Quick Links

See also:

Service Manual

Advertisement

Chapters

Table of Contents

Summary of Contents for Textron Motors MPE 850 OFF-ROAD

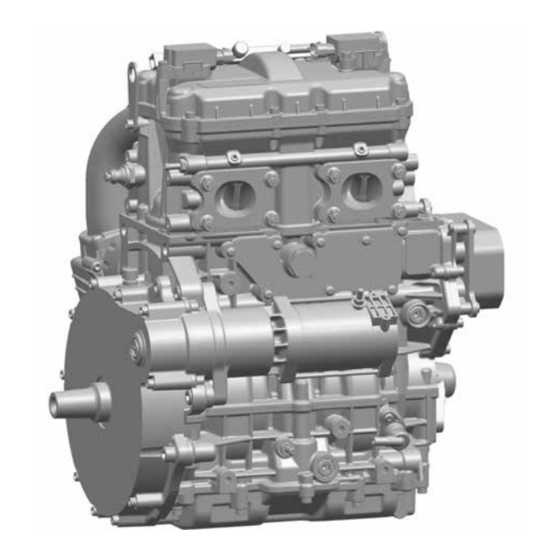

- Page 1 REPAIR MANUAL 4-Stroke Engine MPE 850 OFF-ROAD This repair manual is valid for the following engine models: – 409135 I2 846 UTV NA-80 TD409135_RLF Rev A Read the introductory chapter before performing the task on the engine. 04.09.2015 Pay particular attention to the safety messages.

- Page 3 Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development of its products. All documentation is therefore subject to technical modifications. Reprints and translations, in whole or in part, require written permission from Textron Motors GmbH.

-

Page 4: Table Of Contents

4.1.2 Textron Motors Diagnostic Tool........ - Page 5 Table of contents Replacing plugs ............23 Removing fitting .

- Page 6 Table of contents Installing spark plugs ............30 Removing switch oil pressure .

- Page 7 Table of contents Replacing throttle body ............35 Replacing rubber mount .

- Page 8 Table of contents Installing threaded sleeve ........... . . 40 110.05 Oil tank.

-

Page 9: About This Document

For the activity additionally required documents. 1.2 Change management Textron Motors GmbH strives to make continual improvements as part of the ongoing technical development of its products. You may find that descriptions in the repair manual are changed or amended. All changes are described in the chapter Overview of revisions. -

Page 10: Finding The Required Information

1 About this document 1.3 Finding the required information 1.3 Finding the required information When you planning a work on the engine, proceed as follows: For example, you want to replace the cylinder liners ► Identify the corresponding component in the spare parts catalog.. -

Page 11: Safety

This repair manual is solely intended for use in a workshop authorized by Textron Motors or the vehicle manufacturer. All work on the engine must be performed by appropriately trained personnel. -

Page 12: Important Safety Messages

All the components in your engine have been carefully tested and fulfill strict quality and safety requirements. ► Textron Motors offers spare parts to the highest quality. Ensure that equivalent spare parts corresponds with this quality requirements. Add-on parts and modifications Engine modifications may pose a safety risk to persons. - Page 13 2 Safety 2.2 Important safety messages Missing protective equipment poses a safety risk to personnel. Protective equipment ► Attach all protective equipment after completing the tasks. Hot engine components Engine components become extremely hot during operation. ► Do not touch any engine components during operation. ►...

- Page 14 2 Safety 2.2 Important safety messages Engine oil is flammable and can emit toxic gases. Engine oil ► Do not smoke in the vicinity of the engine and do not allow open flames or sparks near the engine. ► Engine oil on hot surfaces can cause fires. ►...

-

Page 15: Basic Instructions For Working On The Engine

3 Basic instructions for working on the engine 3.1 Before you begin working | 3.2 While working 3 Basic instructions for working on the engine 3.1 Before you begin working The following requirements must be met before performing any tasks: –... -

Page 16: Tightening Torque

Update the calibration of the engine control unit when engine installed again in the vehicle. ► Update the engine control unit calibration. (See the Textron Motors Diagnostic Tool manual.) ► Clear the trouble codes. (See the Textron Motors Diagnostic Tool manual.) 3.3.2 Checking the work carried out... -

Page 17: Tools And Accessories

4.1 Equipment workshop 4 Tools and accessories 4.1 Equipment workshop 4.1.1 Textron Motors special tools Textron Motors offers a tool case that contains the following Textron Motors special tools. Visit our web site www.weber-motor.com for more information. Figure Description Figure... -

Page 18: Textron Motors Diagnostic Tool

4.1.3 Commercially available workshop equipment and standard tools In addition to the Textron Motors special tools, you will require the following tools and accessories. The figures are only examples of suitable tools. All tools and accessories are available from specialist retailers. - Page 19 4 Tools and accessories 4.1 Equipment workshop Abbildung Bezeichnung Abbildung Bezeichnung Hexagon nut-driver Lockring pliers (bore holes) 6-point socket wrench 7, 10, 12, 14 Clamp pincer Open-end wrench 7, 12, 15, 19, 22, 24, Pin punch 5, 7, 8 Insert open-end wrench 7, 12, 15, 16, 19, 22, 24, 27...

-

Page 20: Commercially Available Special Tools

4 Tools and accessories 4.1 Equipment workshop 4.1.4 Commercially available special tools In addition you will require the following commercially available special tools. In the working instructions will be separately referred on these special tools. The figures are only examples of suitable tools. All tools and accessories are available from specialist retailers. -

Page 21: Supplies

4 Tools and accessories 4.1 Equipment workshop 4.1.5 Supplies You need the following supplies when working on the engine. Unless otherwise specified, use the products as directed by the manufacturer. Supplies Recommended products – Commercial petroleum jelly for industrial Petroleum jelly for fitting o-rings and gaskets applications –... -

Page 22: Overview Of Activities

5 Overview of activities 5 Overview of activities Valid for Activity For the activity required working instructions 010 Crankcase 010.01-1 Crankcase 409135 Replacing crankcase ► Remove the crank drive. See section 020.01 Crank drive in this chapter. ► 010.01-1.01 Replacing crankcase ►... -

Page 23: Replacing Oil Seal

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Replacing oil seal ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 010.03.01 Removing generator cover ► 090.02.01 Removing generator ►... -

Page 24: Oil Cooler Bracket

5 Overview of activities Valid for Activity For the activity required working instructions 010.02-1 Oil cooler bracket 409135 Removing oil cooler ► 000.01.01 Mount the engine on the drive side of the bracket engine stand ► 050.03.01 Removing oil cooler ►... -

Page 25: Replacing Oil Seal

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Replacing oil seal ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 010.03.01 Removing generator cover ► 010.03.04 Replacing oil seal ►... -

Page 26: Installing Crank Drive

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Installing crank drive ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 020.01.02 Installing crank drive ► 110.02.02 Installing oil pressure pump ►... -

Page 27: Installing Pistons And Con Rods

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Installing pistons and ► 000.01.02 Mount the engine across from the drive side of con rods the engine stand ► 020.01.06 Installing pistons and con rods ►... -

Page 28: Abdeckung Kurbelwelle

5 Overview of activities Valid for Activity For the activity required working instructions 020.03 Abdeckung Kurbelwelle 409135 Removing crankshaft ► 000.01.01 Mount the engine on the drive side of the cover engine stand ► 020.03.01 Removing crankshaft cover 409135 Installing crankshaft ►... -

Page 29: Cylinder Head

5 Overview of activities Valid for Activity For the activity required working instructions 030.02 Cylinder head 409135 Removing cylinder ► 000.01.02 Mount the engine across from the drive side of head the engine stand ► 070.01.01 Removing intake manifold ► 010.03.01 Removing generator cover ►... -

Page 30: Installing Spark Plugs

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Installing spark plugs ► 000.01 Mount the engine on the engine stand ► 030.02.05 Installing spark plugs ► 030.01.05 Installing ignition coils 409135 Removing switch oil ►... -

Page 31: Replacing Timing Chain

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Replacing timing chain ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 030.01.04 Removing ignition coils ► 030.01.01 Removing valve cover ►... -

Page 32: Valves

5 Overview of activities Valid for Activity For the activity required working instructions 040.03 Valves 409135 Removing valve ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 070.01.01 Removing intake manifold ► 010.03.01 Removing generator cover ►... -

Page 33: Replacing Thermostat

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Replacing thermostat ► 000.01 Mount the engine on the engine stand ► 070.01.01 Removing intake manifold ► 050.01.03 Removing fitting ► 050.01.05 Replacing thermostat ► 050.01.04 Installing fitting ►... -

Page 34: Removing Coolant Pump

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Removing coolant ► 000.01.02 Mount the engine across from the drive side of pump the engine stand ► 010.03.01 Removing generator cover ► 000.01.01 Mount the engine on the drive side of the engine stand ►... -

Page 35: Intake Area

5 Overview of activities Valid for Activity For the activity required working instructions 070 Intake area 070.01 Intake manifold 409135 Removing intake ► 000.01 Mount the engine on the engine stand manifold ► 070.01.01 Removing intake manifold 409135 Installing intake ►... - Page 36 5 Overview of activities Valid for Activity For the activity required working instructions 080 Engine management system See section 010.01-3 Crankcase in this chapter. Sensor crankshaft See section 030.01 Valve cover in this chapter. Sensor camshaft Sensor coolant See section 050.01 Thermostat housing in this chapter. temperature Sensor lambda You require the following documents:...

- Page 37 5 Overview of activities Valid for Activity For the activity required working instructions 090.02 Generator 409135 Removing generator ► 000.01.02 Mount the engine across from the drive side of the engine stand ► 010.03.01 Removing generator cover ► 090.02.01 Removing generator 409135 Installing generator ►...

- Page 38 5 Overview of activities Valid for Activity For the activity required working instructions 409135 Replacing suction ► 000.01.02 Mount the engine across from the drive side of pump cover the engine stand ► 010.03.01 Removing generator cover ► 110.01.01 Removing suction pump cover ►...

- Page 39 5 Overview of activities Valid for Activity For the activity required working instructions 110.02 Oil pressure pump 409135 Removing oil pressure ► 000.01.02 Mount the engine across from the drive side of pump the engine stand ► 010.03.01 Removing generator cover ►...

-

Page 40: Installing Threaded Sleeve

5 Overview of activities Valid for Activity For the activity required working instructions 409135 Installing threaded ► 000.01.01 Mount the engine on the drive side of the sleeve engine stand ► 110.04.04 Installing threaded sleeve ► 110.04.02 Installing oil filter ►... -

Page 41: Working Instructions, Single

6 Working instructions, single 6.1 List of working instructions, single 6 Working instructions, single Observe that the single working instructions do not constitute a complete description of the activity. Always perform the activities, as described in chapter 5 Overview of activities. 6.1 List of working instructions, single 000.01 Mount the engine on the engine stand . - Page 42 6 Working instructions, single 6.1 List of working instructions, single 030.02.06 Removing switch oil pressure ..152 070.01.05 Removing sensor intake manifold pressure/temperature ........195 030.02.07 Installing switch oil pressure ..152 070.01.06 Installing sensor intake manifold 030.02.08 Removing fitting ......153 pressure/temperature ........

- Page 43 6 Working instructions, single 6.1 List of working instructions, single 120.01.02 Installing bracket on the drive side 228 120.01.03 Removing pipe clamp ....229 120.01.04 Installing pipe clamp ...... 229 120.01.05 Removing bracket across from the drive side ............230 120.01.06 Installing bracket across from the drive side ...............

-

Page 44: Mount The Engine On The Engine Stand

000.01 Mount the engine on the engine stand 000.01 Mount the engine on the engine stand WARNING! Crush injuries due to the engine overturning. Mount the engine to the engine stand before starting any work. If not otherwise specified in the chapter, mount the engine on the drive side or across from the drive side. -

Page 45: The Engine Stand

000.01 Mount the engine on the engine stand 000.01.01 Mount the engine on the drive side of the engine stand 000.01.01 Mount the engine on the drive side of the engine stand WARNING! Spinal column injury due to incorrect lifting of heavy loads. Always lift the engine using a workshop crane. -

Page 46: Mount The Engine Across From The Drive Side Of The Engine Stand

000.01 Mount the engine on the engine stand 000.01.02 Mount the engine across from the drive side of the engine stand 000.01.02 Mount the engine across from the drive side of the engine stand WARNING! Spinal column injury due to incorrect lifting of heavy loads. -

Page 47: 1.01 Replacing Crankcase

010.01-1 Crankcase 010.01-1.01 Replacing crankcase 010.01-1.01 Replacing crankcase – Pin punch axle intermediate gear – 7 plugs M18x1.5 – Universal strap wrench – 1 plug M10x1 – Crown wrench – 1 Oil filter – Cylinder liner puller – 1 Seal 8x12x1 Al –... - Page 48 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Unscrew the plug ► Punch the axle out using the pin punch axle intermediate gear and plastic hammer. ► Remove the intermediate gear suction pump ► Remove the sleeves RLF MPE850 Rev A | 409135 |...

- Page 49 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Unscrew the bolts ► Remove the chain rail ► Turn the upper case 180°. ► Unscrew the oil filter using a universal strap wrench. ► Unscrew the threaded sleeve using a crown wrench. ► Unscrew 10 bolts The thermostat housing is caulked with a silicone liquid seal.

- Page 50 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Remove the sleeve ► Unscrew the bolt ► Remove the chain rail ► Remove the cylinder liners using a cylinder liner puller. Prepare the new crankcase ► Replace the crankcase. ► Screw in a new plug Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] RLF MPE850 Rev A | 409135 |...

- Page 51 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Screw in new plugs Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] ► Screw in a new plug Tightening torque: 9 Nm +2 Nm [6.6 lbf ft +1.5 lbf ft] ►...

- Page 52 010.01-1 Crankcase 010.01-1.01 Replacing crankcase WARNING! Crush injuries due to a dropped crankcase. ► Lift the crankcase using a carrying strap. ► Mount the crankcase on the engine stand. Suitable mounting points M10 – Depth of thread 30 mm Suitable mounting points M6 ►...

- Page 53 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Screw in the oil filter by hand. Tightening torque: 10 Nm [7.4 lbf ft] ► Clean the sealing surface with sealing surface cleaner. ► Clean the sealing surface with sealing surface cleaner. RLF MPE850 Rev A | 409135 |...

- Page 54 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Apply the silicone liquid seal without gaps as illustrated. ► Hold the thermostat housing in position. ► Screw in 10 bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Replace the seal ►...

- Page 55 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Replace the o-ring on the sensor crankshaft ► Coat the o-ring lightly with petroleum jelly. ► Slide on the o-ring as illustrated. ► Insert the sensor crankshaft ► Screw in the bolt Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ►...

- Page 56 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Insert the sleeves ► Unscrew the bolt ► Remove the lower case ► Check if the welch plugs are installed. RLF MPE850 Rev A | 409135 |...

- Page 57 010.01-1 Crankcase 010.01-1.01 Replacing crankcase ► Insert the chain guide ► Screw in the bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Turn the upper case 180°. ► Insert the chain rail ► Screw in the bolt Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ►...

-

Page 58: 1.02 Replacing Welch Plugs

010.01-1 Crankcase 010.01-1.02 Replacing welch plugs 010.01-1.02 Replacing welch plugs The upper case is disconnected from the crankcase. – Welch plug 1 – Welch plug 2 ► Unscrew the banjo bolt ► Remove the welch plug ► Replace the welch plug ►... -

Page 59: 1.03 Replacing Tie Rod

010.01-1 Crankcase 010.01-1.03 Replacing tie rod 010.01-1.03 Replacing tie rod – Stud extractor – Anti-Seize assembly paste The lower case is disconnected from the crankcase. ► Unscrew the tie rod using a stud extractor. ► Replace tie rod. ► Apply Anti-Seize assembly paste to all threads ►... -

Page 60: 1.04 Replacing Plugs

010.01-1 Crankcase 010.01-1.04 Replacing plugs 010.01-1.04 Replacing plugs – Plug 1 – Plug 2 – Plug 3 Replacing plug 1 ► Unscrew the plug ► Replace the plug. ► Screw in the plug. Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] Replacing plug 2 The generator cover and rotor are removed. - Page 61 010.01-1 Crankcase 010.01-1.04 Replacing plugs Replacing plug 3 The generator cover and generator are removed. ► Unscrew the plug ► Replace the plug. ► Screw in the plug. Tightening torque: 9 Nm +2 Nm [6.6 lbf ft +1.5 lbf ft] RLF MPE850 Rev B...

-

Page 62: 2.01 Replacing Cylinder Liners

010.01-2 Crankcase 010.01-2.01 Replacing cylinder liners 010.01-2.01 Replacing cylinder liners – Cylinder liner puller ► Remove the cylinder liners using a cylinder liner puller. ► Replace the cylinder liners. ► Coat the o-rings lightly with petroleum jelly. ► Insert the cylinder liners. RLF MPE850 Rev A | 409135 |... -

Page 63: 2.02 Replacing Oil Seal

010.01-2 Crankcase 010.01-2.02 Replacing oil seal 010.01-2.02 Replacing oil seal – Oil seal slide hammer – Assembling kit oil seal crankshaft ► Pull the oil seal out using the oil seal slide hammer. ► Replace the oil seal ► Coat the inside of the oil seal lightly with petroleum jelly. - Page 64 010.01-2 Crankcase 010.01-2.02 Replacing oil seal ► Hold the sliding sleeve in position on the oil seal Use the M10x1x35 bolts you removed on the rotor. ► Screw in the bolt ► Screw in the bolt until the oil seal is flush with the crankcase.

-

Page 65: 2.03 Replacing Plug

010.01-2 Crankcase 010.01-2.03 Replacing plug 010.01-2.03 Replacing plug ► Unscrew the plug ► Replace the plug. ► Screw in the plug. Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 66: 3.01 Removing Plug

010.01-3 Crankcase 010.01-3.01 Removing plug | 010.01-3.02 Installing plug 010.01-3.01 Removing plug ► Unscrew the plug 010.01-3.02 Installing plug – 1 Seal 18x22x1.5 Al ► Replace the seal ► Screw in the plug Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 67: 3.03 Replacing Plugs

010.01-3 Crankcase 010.01-3.03 Replacing plugs 010.01-3.03 Replacing plugs – Plugs 1 – Plug 2 – Plug 3 Replacing plugs 1 The oil cooler bracket is removed. Two threaded holes M18 remain open. ► Unscrew the plugs ► Replace the plugs. ►... - Page 68 010.01-3 Crankcase 010.01-3.03 Replacing plugs Replacing plug 2 ► Unscrew the plug ► Replace the plug. ► Screw in the plug. Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] Replacing plug 3 ► Unscrew the plug ►...

-

Page 69: 3.04 Removing Fitting

010.01-3 Crankcase 010.01-3.04 Removing fitting | 010.01-3.05 Installing fitting 010.01-3.04 Removing fitting ► Unscrew the fitting 010.01-3.05 Installing fitting – 1 Seal 8x12x1 Al ► Replace the seal ► Screw in the fitting Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 70: 3.06 Removing Sensor Crankshaft

010.01-3 Crankcase 010.01-3.06 Removing sensor crankshaft | … 010.01-3.06 Removing sensor crankshaft ► Unscrew the bolt ► Pull the sensor crankshaft out. 010.01-3.07 Installing sensor crankshaft – 1 O-ring sensor crankshaft ► Replace the o-ring on the sensor crankshaft ► Coat the o-ring lightly with petroleum jelly. -

Page 71: 3.08 Removing Sensor Knock

010.01-3 Crankcase 010.01-3.08 Removing sensor knock | … 010.01-3.08 Removing sensor knock ► Unscrew the bolt ► Remove the sensor knock 010.01-3.09 Installing sensor knock ► Hold the sensor knock in position. ► Screw in the bolt Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 72: 1.01 Removing Oil Cooler Bracket

010.02-1 Oil cooler bracket 010.02-1.01 Removing oil cooler bracket 010.02-1.01 Removing oil cooler bracket ► Unscrew 15 bolts ► Remove the oil cooler bracket RLF MPE850 Rev A | 409135 |... - Page 73 010.02-1 Oil cooler bracket 010.02-1.01 Removing oil cooler bracket ► Remove the sleeve RLF MPE850 Rev A | 409135 |...

-

Page 74: 1.02 Installing Oil Cooler Bracket

010.02-1 Oil cooler bracket 010.02-1.02 Installing oil cooler bracket 010.02-1.02 Installing oil cooler bracket – 1 Gasket oil cooler bracket ► Replace the gasket ► Insert the gasket into the groove and lightly coat with petroleum jelly. ► Insert the sleeve ►... - Page 75 010.02-1 Oil cooler bracket 010.02-1.02 Installing oil cooler bracket ► Screw in 1 bolt M6x30 Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Screw in 14 bolts M6x20 Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |...

-

Page 76: 2.01 Replacing Blanking Cover

010.02-2 Oil cooler bracket 010.02-2.01 Replacing blanking cover 010.02-2.01 Replacing blanking cover – 1 O-ring blanking cover WARNING! Serious eye injuries due to a flying circlip. Wear protective glasses. ► Remove the circlip using a lockring pliers. ► Remove the clamp ring ►... -

Page 77: 2.02 Replacing Plug

010.02-2 Oil cooler bracket 010.02-2.02 Replacing plug 010.02-2.02 Replacing plug – 1 Seal 14x18x1.5 Al ► Unscrew the plug ► Replace the plug. ► Replace the seal ► Screw in the plug. Tightening torque: 14 Nm +2 Nm [10.3 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 78: 2.03 Sealing Cover Oil Cooler Bracket

010.02-2.03 Sealing cover oil cooler bracket 010.02-2.03 Sealing cover oil cooler bracket – Silicone liquid seal Info rmatio n ! The cover oil cooler bracket should only be removed if it leaks. Textron Motors recommends replacing the entire oil cooler bracket. ► Unscrew 14 bolts The cover oil cooler bracket is caulked with a silicone liquid seal. - Page 79 010.02-2 Oil cooler bracket 010.02-2.03 Sealing cover oil cooler bracket ► Clean the sealing surfaces with sealing surface cleaner. ► Apply the silicone liquid seal without gaps as illustrated. RLF MPE850 Rev A | 409135 |...

- Page 80 010.02-2 Oil cooler bracket 010.02-2.03 Sealing cover oil cooler bracket ► Hold the cover oil cooler bracket position. ► Screw in the bolt Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Screw in 13 bolts Tightening torque: 5 Nm +1 Nm [3.7 lbf ft +0.7 lbf ft] RLF MPE850 Rev A | 409135 |...

-

Page 81: Removing Generator Cover

010.03 Generator cover 010.03.01 Removing generator cover 010.03.01 Removing generator cover ► Unscrew 10 bolts ► Unscrew 2 bolts The generator cover is caulked with a silicone liquid seal. ► Remove the generator cover RLF MPE850 Rev A | 409135 |... -

Page 82: Installing Generator Cover

010.03 Generator cover 010.03.02 Installing generator cover 010.03.02 Installing generator cover – 1 Oil seal generator cover – Silicone liquid seal – 1 Seal 10x16x1 Al ► Check if the sleeves are installed. ► Replace the oil seal ► Push the oil seal into the generator cover ►... - Page 83 010.03 Generator cover 010.03.02 Installing generator cover ► Clean the sealing surface with sealing surface cleaner. ► Clean the sealing surface with sealing surface cleaner. ► Apply the silicone liquid seal without gaps as illustrated. ► Hold the generator cover in position.

- Page 84 010.03 Generator cover 010.03.02 Installing generator cover ► Screw in 10 bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Screw in 2 bolts Tightening torque: 40 Nm +8 Nm [29.5 lbf ft +5.9 lbf ft] ►...

-

Page 85: Replacing Generator Cover

010.03 Generator cover 010.03.03 Replacing generator cover 010.03.03 Replacing generator cover – 1 Seal 10x16x1 Al ► Replace the generator cover ► Remove the plug from the old generator cover. ► Replace the seal ► Screw in the plug Tightening torque: 9 Nm +2 Nm [6.7 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 86: Replacing Oil Seal

010.03 Generator cover 010.03.04 Replacing oil seal 010.03.04 Replacing oil seal ► Pull the oil seal out. ► Replace the oil seal. ► Push the oil seal into the generator cover RLF MPE850 Rev A | 409135 |... -

Page 87: Replacing Vent Plug

010.03 Generator cover 010.03.05 Replacing plug 010.03.05 Replacing vent plug – 1 Seal 10x16x1 Al ► Unscrew the vent plug ► Replace the vent plug. ► Replace the seal ► Screw in the vent plug. Tightening torque: 9 Nm +2 Nm [6.7 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 88: Removing Crank Drive

020.01 Crankshaft 020.01.01 Removing crank drive. 020.01.01 Removing crank drive. – Chain tool – Anti-Seize assembly paste – Stud extractor – 12-point socket wrench 12 – Instruction manual chain tool Bearing damage, increased wear and leaks due to installing components swapped over. All components in the crank drive are inserted together. - Page 89 020.01 Crankshaft 020.01.01 Removing crank drive. ► Turn the engine 180°. ► Remove the timing chain ► Unscrew the nuts in the sequence as illustrated The rocker arm and cross bars are no longer firmly attached to the cylinder head. Do not turn the cylinder head.

- Page 90 020.01 Crankshaft 020.01.01 Removing crank drive. ► Remove the cylinder head ► Turn the engine 180°. Unscrew all bolts in the sequence as illustrated ► Unscrew 4 bolts M6 – ► Unscrew 5 bolts M8 – ► Pull the oil pressure valve out using a bar magnet.

- Page 91 020.01 Crankshaft 020.01.01 Removing crank drive. The crankcase is caulked with a silicone liquid seal. ► Remove the lower case ► If the screw connection of a tie rod loosened unscrew the tie rod using a stud extractor. ► Apply Anti-Seize assembly paste to all threads.

- Page 92 020.01 Crankshaft 020.01.01 Removing crank drive. ► Pull the pistons out. ► Remove the balance shaft ► Remove the crankshaft ► Remove the oil seal RLF MPE850 Rev A | 409135 |...

-

Page 93: Installing Crank Drive

020.01 Crankshaft 020.01.02 Installing crank drive. 020.01.02 Installing crank drive. – Piston ring compressor – 4 Con rod bolts – 12-point socket wrench 12 – 1 Cylinder head gasket – Assembling kit oil seal crankshaft – 1 Oil seal crankshaft –... - Page 94 020.01 Crankshaft 020.01.02 Installing crank drive. ► Check if the main bearing shells bearing shells balance shaft installed. ► When replacing a piston, continue with chapter 020.01.07 Replacing piston. ► When replacing a con rod, continue with chapter 020.01.08 Replacing con rod. ►...

- Page 95 020.01 Crankshaft 020.01.02 Installing crank drive. ► Displace the ring joints of the three piston rings 120°. ► Turn the engine 180°. ► Coat the pistons lightly with engine oil. ► Slide in the pistons using a piston ring compressor. ►...

- Page 96 020.01 Crankshaft 020.01.02 Installing crank drive. ► Insert con-rod covers ► Replace the con-rod bolts ► Tighten the con-rod bolts in three stages. Tightening torque: First stage 10 Nm [7.4 lbf ft] Second stage 20 Nm [14.8 lbf ft] Third stage +115° ►...

- Page 97 020.01 Crankshaft 020.01.02 Installing crank drive. Aligning the balance shaft to the crankshaft ► Observe the marking The marking ends flush with the crankcase. ► Turn the crankshaft 180°. ► Check if the centering pins are installed. RLF MPE850 Rev A | 409135 |...

- Page 98 020.01 Crankshaft 020.01.02 Installing crank drive. ► Apply the silicone liquid seal without gaps as illustrated. Checking the alignment of the balance shaft / crankshaft ► Check the markings Both markings appear as shown. ► Put the lower case RLF MPE850 Rev A | 409135 |...

- Page 99 020.01 Crankshaft 020.01.02 Installing crank drive. ► Assemble the oil pressure valve in the sequence as illustrated ► Insert the oil pressure valve Screw in all bolts in the sequence as illustrated ► Screw in 5 bolts M8 – Tightening torque: 9 Nm +1 Nm [6.6 lbf ft +0.7 lbf ft] ►...

- Page 100 020.01 Crankshaft 020.01.02 Installing crank drive. ► Turn the engine 180°. ► Check if the centering pins are installed. ► Replace the cylinder head gasket ► Put the cylinder head gasket on. Observe the installation position: – Exhaust side – Inscription –...

- Page 101 020.01 Crankshaft 020.01.02 Installing crank drive. ► Lubricate the nuts with engine oil. ► Screw on the nuts by hand. Do not tighten. ► Tighten the nuts in the sequence as illustrated in three stages. Tightening torque: First stage 20 Nm ±3 Nm [14.8 lbf ft ±2.2 lbf ft] Second stage 40 Nm ±3 Nm [29.5 lbf ft ±2.2 lbf ft] Third stage...

- Page 102 020.01 Crankshaft 020.01.02 Installing crank drive. ► Replace the oil seal ► Coat the inside of the oil seal lightly with petroleum jelly. ► Slide the oil seal onto guiding sleeve ► Slide the guiding sleeve onto crankshaft Use the M10x1x35 bolts you removed on the rotor. ►...

- Page 103 020.01 Crankshaft 020.01.02 Installing crank drive. ► Unscrew the bolt ► Remove the sliding sleeve ► Unscrew the bolts ► Remove the guiding sleeve ► Check if the oil seal is tilted. ► If the oil seal is tilted, it must be replaced. Setting valve timing ►...

- Page 104 020.01 Crankshaft 020.01.02 Installing crank drive. Use a hexagon screwdriver socket 8 and reversible ratchet. ► Turn the crankshaft on the TDC-adjusting tool in the direction shown until the marking ends flush with the crankcase halves ► Turn the engine 180°. If not installing a new timing chain, observe the running direction marked.

- Page 105 020.01 Crankshaft 020.01.02 Installing crank drive. ► Insert the chain link on the open ends of the timing chain. ► Turn the engine 180°. ► Close the timing chain. (See the instruction manual of the chain tool.) ► Replace the chain tensioner ►...

- Page 106 020.01 Crankshaft 020.01.02 Installing crank drive. Checking valve timing Use a hexagon screwdriver socket 8 and reversible ratchet. ► Turn the crankshaft on the TDC-adjusting tool in the direction shown until the marking ends flush with the crankcase halves ► Check whether the camshaft is at the crossing point.

-

Page 107: Replacing Crankshaft

020.01 Crankshaft 020.01.03 Replacing crankshaft 020.01.03 Replacing crankshaft – 020.01.10 Checking main bearing play – 020.01.09 Checking con rod bearing play ► Replace the crankshaft ► Check the main bearing play. (See chapter 020.01.10 Checking main bearing play.) ► Check the con rod bearing play. (See chapter 020.01.09 Checking con rod bearing play.) RLF MPE850 Rev A | 409135 |... -

Page 108: Replacing Balance Shaft

020.01 Crankshaft 020.01.04 Replacing balance shaft 020.01.04 Replacing balance shaft – 8 Bearing shell balance shaft ► Replace the bearing shells balance shaft ► Coat the bearing shells balance shaft lightly with engine oil. ► Insert the main bearing shells in crankcase. ►... -

Page 109: Removing Pistons And Con Rods

020.01 Crankshaft 020.01.05 Removing pistons and con rods 020.01.05 Removing pistons and con rods – 12-point socket wrench 12 Bearing damage, increased wear and leaks due to installing components swapped over. All components in the crank drive are inserted together. If the components are installed swapped over, they no longer fit together well. - Page 110 020.01 Crankshaft 020.01.05 Removing pistons and con rods ► Pull the pistons out. RLF MPE850 Rev A | 409135 |...

-

Page 111: Installing Pistons And Con Rods

020.01 Crankshaft 020.01.06 Installing pistons and con rods 020.01.06 Installing pistons and con rods – Piston ring compressor – 4 Con rod bolts – 12-point socket wrench 12 Bearing damage, increased wear and leaks due to installing components swapped over. All components in the crank drive are inserted together. - Page 112 020.01 Crankshaft 020.01.06 Installing pistons and con rods ► Displace the ring joints of the three piston rings 120°. ► Turn the engine 180°. ► Coat the pistons lightly with engine oil. ► Slide in the pistons using a piston ring compressor.

-

Page 113: Replacing Piston

020.01 Crankshaft 020.01.07 Replacing piston 020.01.07 Replacing piston Serious eye injuries due to a flying circlip. When installing or removing the circlip, it can be thrown at great speed and cause serious eye injuries. ► Wear protective glasses, along with any bystanders. Bearing damage, increased wear and leaks due to installing components swapped over. - Page 114 020.01 Crankshaft 020.01.07 Replacing piston ► Replace the piston ► Install the circlip using a litte screwdriver. ► Pull the piston pin out. ► Hold the con rod in position. Observe the piston's installation position. Installation position piston Arrow on top and inside arrow in the direction of the chain tensioner...

- Page 115 020.01 Crankshaft 020.01.07 Replacing piston ► Coat the piston pin lightly with engine oil. ► Slide in the piston pin. ► Install the circlip using a litte screwdriver. RLF MPE850 Rev A | 409135 |...

-

Page 116: Replacing Con Rod

020.01 Crankshaft 020.01.08 Replacing con rod 020.01.08 Replacing con rod – 020.01.09 Checking con rod bearing play Serious eye injuries due to a flying circlip. When installing or removing the circlip, it can be thrown at great speed and cause serious eye injuries. ►... - Page 117 020.01 Crankshaft 020.01.08 Replacing con rod ► Replace the con rod ► Hold the con rod in position. ► Coat the piston pin lightly with engine oil. ► Slide in the piston pin. ► Install the circlip using a litte screwdriver.

-

Page 118: Checking Con Rod Bearing Play

020.01 Crankshaft 020.01.09 Checking con rod bearing play 020.01.09 Checking con rod bearing play – Precision clearance gauges – Con rod bearing shells in different thicknesses Info rmatio n ! Con rod bolts are extension bolt and must be replaced after removal. However, when measuring the con rod bearing play, you can use the removed con rod bolts. - Page 119 020.01 Crankshaft 020.01.09 Checking con rod bearing play Installation instructions for the con rod bearings NOTICE! Serious damage to bearings due to con rod bearing shells being installed incorrectly. ► Insert the con rod bearing shells centered on the con rod. ►...

- Page 120 020.01 Crankshaft 020.01.09 Checking con rod bearing play ► Read con rod bearing play "A" on the precision clearance gauges according to the manufacturer's instructions. Required con rod bearing play: 0,025 – 0,040 mm The thicknesses of the upper and lower con rod bearing shell may differ.

-

Page 121: Checking Main Bearing Play

020.01 Crankshaft 020.01.10 Checking main bearing play 020.01.10 Checking main bearing play – Precision clearance gauges – Main bearing shells in different thicknesses Bearing damage, increased wear and leaks due to installing components swapped over. All components in the crank drive are inserted together. If the components are installed swapped over, they no longer fit together well. - Page 122 020.01 Crankshaft 020.01.10 Checking main bearing play ► Insert the crankshaft ► Put the lower case ► Assemble the oil pressure valve in the sequence as illustrated ► Insert the oil pressure valve RLF MPE850 Rev A | 409135 |...

- Page 123 020.01 Crankshaft 020.01.10 Checking main bearing play Screw in all bolts in the sequence as illustrated ► Screw in 5 bolts M8 – Tightening torque: 9 Nm +1 Nm [6.6 lbf ft +0.7 lbf ft] ► Screw in 4 bolts M6 –...

- Page 124 020.01 Crankshaft 020.01.10 Checking main bearing play ► Put the cylinder head Observe the installation position: – Exhaust side – Starter side ► Lubricate the nuts with engine oil. ► Screw on the nuts by hand. Do not tighten. ► Tighten the nuts in the sequence as illustrated in three stages.

- Page 125 020.01 Crankshaft 020.01.10 Checking main bearing play ► Turn the engine 180°. ► Unscrew the nuts in the sequence as illustrated The rocker arm and cross bars are no longer firmly attached to the cylinder head. Do not turn the cylinder head.

- Page 126 020.01 Crankshaft 020.01.10 Checking main bearing play ► Pull the oil pressure valve out using a bar magnet. ► Remove the lower case ► Read main bearing play "B" on the precision clearance gauges according to the manufacturer's instructions. Required main bearing play: 0,04 –...

- Page 127 020.01 Crankshaft 020.01.10 Checking main bearing play The main bearing shells are marked on the side in color. Each color represent a specific thickness of the main bearing shells. x 26 Available thicknesses main bearing shells: – Red 1,990 mm –...

-

Page 128: Removing Stub Shaft

020.02 Stub shaft 020.02.01 Removing stub shaft 020.02.01 Removing stub shaft – Locking tool crankshaft ► Hold the locking tool crankshaft on rotor. ► Screw in the bolt and washer. ► Unscrew the bolts ► Remove the locking tool crankshaft ►... -

Page 129: Installing Stub Shaft

020.02 Stub shaft 020.02.02 Installing stub shaft 020.02.02 Installing stub shaft – Locking tool crankshaft – 6 Bolts M10x1x35 Leaks due to damage to the coating on the bolts. The threads of the 6 bolts on the rotor have a micro encapsulated coating. During fastening the bolt, the microcapsules will burst and the contained adhesive and curing agent are released and mixed. - Page 130 020.02 Stub shaft 020.02.02 Installing stub shaft ► Hold the locking tool crankshaft on rotor. ► Screw in the bolt and washer. ► Tighten the bolts Tightening torque: 60 Nm +10 Nm [44.3 lbf ft +7.4 lbf ft] ► Remove the locking tool crankshaft RLF MPE850 Rev A | 409135 |...

-

Page 131: Removing Crankshaft Cover

020.03 Crankshaft cover 020.03.01 Removing crankshaft cover 020.03.01 Removing crankshaft cover ► Unscrew the bolt ► Remove the cover 020.03.02 Installing crankshaft cover – 1 Gasket crankshaft cover ► Replace the gasket ► Coat the gasket lightly with petroleum jelly. ►... -

Page 132: Removing Valve Cover

030.01 Valve cover 030.01.01 Removing valve cover 030.01.01 Removing valve cover ► Unscrew the bolts ► Remove the valve cover RLF MPE850 Rev A | 409135 |... -

Page 133: Installing Valve Cover

030.01 Valve cover 030.01.02 Installing valve cover 030.01.02 Installing valve cover – 1 Sealing kit valve cover – Anti-Seize assembly paste ► Replace the valve cover seals ► Clean the sealing surface with sealing surface cleaner. ► Put the valve cover ►... -

Page 134: Replacing Valve Cover

030.01 Valve cover 030.01.03 Replacing valve cover 030.01.03 Replacing valve cover ► Replace the valve cover ► Affix the engine badge included with the valve cover. RLF MPE850 Rev A | 409135 |... -

Page 135: Removing Ignition Coils

030.01 Valve cover 030.01.04 Removing ignition coils | 030.01.05 Installing ignition coils 030.01.04 Removing ignition coils ► Unscrew the bolts ► Pull the ignition coils out. 030.01.05 Installing ignition coils – 2 Serrated lock washers ► Insert the ignition coils ►... -

Page 136: Removing Sensor Camshaft

030.01 Valve cover 030.01.06 Removing sensor camshaft | … 030.01.06 Removing sensor camshaft ► Unscrew the bolt ► Pull the sensor camshaft out. 030.01.07 Installing sensor camshaft ► Coat the o-ring lightly with petroleum jelly. ► Insert the sensor camshaft ►... -

Page 137: Removing Cylinder Head

030.02 Cylinder head 030.02.01 Removing cylinder head 030.02.01 Removing cylinder head – Chain tool – Instruction manual chain tool Engine damage from small components in the engine or cylinder head. Operating the engine when there are small components in the crankcase and cylinder head can result in serious damage and cause the crank drive to seize. - Page 138 030.02 Cylinder head 030.02.01 Removing cylinder head ► Mark the position of the rotor to the crankcase ► Unscrew the chain tensioner ► Open the timing chain. (See the instruction manual of the chain tool.) ► Secure the ends of the timing chain. ►...

-

Page 139: Installing Cylinder Head

030.02 Cylinder head 030.02.02 Installing cylinder head 030.02.02 Installing cylinder head – Chain tool – 1 Cylinder head gasket – 12-point socket wrench 12 – 1 Chain tensioner – 1 Chain link – Instruction manual chain tool – Service manual of the engine Engine damage from small components in the engine or cylinder head. - Page 140 030.02 Cylinder head 030.02.02 Installing cylinder head ► Put the cylinder head Observe the installation position: – Exhaust side – Starter ► Lubricate the nuts with engine oil. ► Screw on the nuts by hand. Do not tighten. ► Tighten the nuts in the sequence as illustrated in three stages.

- Page 141 030.02 Cylinder head 030.02.02 Installing cylinder head ► Check whether the crankshaft is at TDC (Top Dead Center). The markings fit together. ► If the markings do not line up, turn the rotor ► Close the timing chain. (See the instruction manual of the chain tool.) ►...

- Page 142 030.02 Cylinder head 030.02.02 Installing cylinder head ► Check whether the camshaft is at the crossing point. The position of the camshaft is as illustrated The marking ends flush with the cross bar. ► If the camshaft does not appear as shown, set the valve timing again.

-

Page 143: Replacing Cylinder Head

030.02 Cylinder head 030.02.03 Replacing cylinder head 030.02.03 Replacing cylinder head – Remover bearing cap – 1 Seal 8x12x1 Al – Stud extractor – 1 Plug M8x1 – 1 Plug M10x1 – Lubricant for injectors o-rings – Thread sealant ► Unscrew the bolts ►... - Page 144 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Unscrew the studs using a stud extractor. ► Unscrew the bolts ► Remove the fuel rail RLF MPE850 Rev A | 409135 |...

- Page 145 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Remove the sleeves ► Unscrew the bolt ► Remove the sensor knock ► Unscrew the bolts The hole in the remover bearing cap is provided for mounting a slide hammer. ► Remove the bearing cap using the remover bearing cap RLF MPE850 Rev A | 409135 |...

- Page 146 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Remove the camshaft ► Replace the cylinder head ► Unscrew the bolts ► Remove the bearing cap ► Check if the sleeves are installed. ► Coat the camshaft on the bearing surfaces lightly with engine oil.

- Page 147 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Insert the camshaft. The camshaft is marked at the 1st cylinder end only. Observe the installation position: – Inscription – Exhaust side NOTICE! Bearing damage due to the bearing cap being installed incorrectly. The bearing surfaces for supporting the camshaft in the cylinder head and in the bearing cap are processed together.

- Page 148 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Hold the sensor knock in position. ► Screw in the bolt Tightening torque: 20 Nm +4 Nm [14.8 lbf ft +3 lbf ft] ► Insert the sleeves ► Coat the o-rings lightly with lubricant. ►...

- Page 149 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Screw in the bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Apply Anti-Seize assembly paste to all studs ► Screw in the studs using a stud extractor. Tightening torque: 16 Nm +4 Nm [11.8 lbf ft +3 lbf ft] ►...

- Page 150 030.02 Cylinder head 030.02.03 Replacing cylinder head ► Coat the thread on the switch oil pressure with thread sealant. ► Screw in the switch oil pressure. Tightening torque: 9 Nm +2 Nm [6.6 lbf ft +1.5 lbf ft] ► Screw in a new plug Tightening torque: 6 Nm +2 Nm [4.4 lbf ft +1.5 lbf ft] ►...

-

Page 151: Removing Spark Plugs

030.02 Cylinder head 030.02.04 Removing spark plugs | 030.02.05 Installing spark plugs 030.02.04 Removing spark plugs ► Unscrew the spark plugs using a spark plug wrench. 030.02.05 Installing spark plugs – Spark plug wrench size 16 mm – Service manual of the engine ►... -

Page 152: Removing Switch Oil Pressure

030.02 Cylinder head 030.02.06 Removing switch oil pressure | … 030.02.06 Removing switch oil pressure ► Unscrew the switch oil pressure 030.02.07 Installing switch oil pressure – Thread sealant ► Coat the thread on the switch oil pressure with thread sealant. ►... -

Page 153: Removing Fitting

030.02 Cylinder head 030.02.08 Removing fitting | 030.02.09 Installing fitting 030.02.08 Removing fitting ► Unscrew the fitting 030.02.09 Installing fitting – 1 Seal 8x12x1 Al ► Replace the seal ► Screw in the fitting Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 154: Replacing Plugs

030.02 Cylinder head 030.02.10 Replacing plugs 030.02.10 Replacing plugs – Plugs 1 – Plug 2 – Plug 3 Replacing plugs 1 ► Unscrew the plugs ► Replace the plugs. ► Screw in the plugs. Tightening torque: 6 Nm +2 Nm [4.4 lbf ft +1.5 lbf ft] Replacing plug 2 ►... - Page 155 030.02 Cylinder head 030.02.10 Replacing plugs Replacing plug 3 ► Unscrew the plug ► Replace the plug. ► Screw in the plug. Tightening torque: 9 Nm +2 Nm [6.6 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |...

-

Page 156: Replacing Camshaft

040.01 Camshaft 040.01.01 Replacing camshaft 040.01.01 Replacing camshaft – Remover bearing cap Increased wear and leaks due to installing components swapped over. All components in the valve train are inserted together. If the components are installed swapped over, they no longer fit together well. ►... - Page 157 040.01 Camshaft 040.01.01 Replacing camshaft ► Remove the bearing cap using the remover bearing cap ► Remove the camshaft ► Replace the camshaft. ► Coat the camshaft on the bearing surfaces lightly with engine oil. ► Insert the camshaft. The camshaft is marked at the 1st cylinder end only.

- Page 158 040.01 Camshaft 040.01.01 Replacing camshaft NOTICE! Bearing damage due to the bearing cap being installed incorrectly. The bearing surfaces for supporting the camshaft in the cylinder head and in the bearing cap are processed together. Therefore, only use the bearing cap originally installed. Observe the markings during installation.

- Page 159 040.01 Camshaft 040.01.01 Replacing camshaft Installation instructions for rocker arms and cross bars Observe the installation position: – Counterbore – Fuel rail – Rocker arm short with cam spike – Rocker arm long RLF MPE850 Rev A | 409135 |...

-

Page 160: Replacing Timing Chain

040.01 Camshaft 040.01.02 Replacing timing chain 040.01.02 Replacing timing chain – Chain tool – 1 Chain tensioner – 1 Chain link – Instruction manual chain tool Setting valve timing ► Turn the crankshaft on a bolt in the direction shown until the camshaft stops as shown in the following figure. - Page 161 040.01 Camshaft 040.01.02 Replacing timing chain Replacing timing chain ► Unscrew the chain tensioner ► Open the timing chain. (See the instruction manual of the chain tool.) ► Turn the engine 180°. ► Remove the timing chain ► Replace the timing chain. ►...

- Page 162 040.01 Camshaft 040.01.02 Replacing timing chain ► Insert the chain link on the open ends of the timing chain. ► Turn the engine 180°. Setting valve timing ► Check whether the camshaft is at the crossing point. The position of the camshaft is as illustrated The marking ends flush with the cross bar.

- Page 163 040.01 Camshaft 040.01.02 Replacing timing chain Checking valve timing ► Turn the crankshaft on a bolt several times in the direction shown ► Turn the crankshaft on a bolt in the direction shown until the crankshaft is at TDC (Top Dead Center).

-

Page 164: Checking And Setting Valve Timing

040.01 Camshaft 040.01.03 Checking and setting valve timing 040.01.03 Checking and setting valve timing – TDC-Adjusting tool – 1 Chain tensioner – Chain tool – 1 Chain link – Instruction manual chain tool ► Hold the TDC-adjusting tool in position. Observe the positioning pin and positioning bore Use the M10x1x35 bolts you removed on the rotor. - Page 165 040.01 Camshaft 040.01.03 Checking and setting valve timing ► Unscrew the bolts ► Remove the TDC-adjusting tool Setting valve timing ► Unscrew the chain tensioner ► Open the timing chain. (See the instruction manual of the chain tool.) ► Secure the ends of the timing chain. ►...

-

Page 166: Replacing Chain Rail

040.01 Camshaft 040.01.04 Replacing chain rail 040.01.04 Replacing chain rail The cylinder head is removed. ► Unscrew the bolt ► Remove the chain rail ► Replace the chain rail. ► Insert the chain rail. ► Screw in the bolt. Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 167: Replacing Chain Guide

040.01 Camshaft 040.01.05 Replacing chain guide 040.01.05 Replacing chain guide The upper case is disconnected from the lower case. ► Unscrew the bolts ► Remove the chain guide ► Replace the chain guide. ► Insert the chain guide. ► Screw in the bolts. Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 168: Replacing Rocker Arms

040.02 Rocker arms 040.02.01 Replacing rocker arms 040.02.01 Replacing rocker arms – Service manual of the engine Increased wear and leaks due to installing components swapped over. All components in the valve train are inserted together. If the components are installed swapped over, they no longer fit together well. ►... - Page 169 040.02 Rocker arms 040.02.01 Replacing rocker arms The camshaft is marked at the 1st cylinder end only. ► Check whether the camshaft is at the crossing point. The position of the camshaft is as illustrated. The marking ends flush with the cross bar.

- Page 170 040.02 Rocker arms 040.02.01 Replacing rocker arms Replacing a rocker arm ► Remove the rocker axle using a universal pliers. ► Remove the rocker arm ► Replace the rocker arm ► Hold the rocker arm in position. ► Check if the circlip is installed.

-

Page 171: Removing Valve

040.03 Valves 040.03.01 Removing valve 040.03.01 Removing valve – Valve spring compressor Info rmatio n ! The following chapter describes how to remove one valve. If you want to remove several valves, apply the procedure for any number of valves. Increased wear and leaks due to installing components swapped over. - Page 172 040.03 Valves 040.03.01 Removing valve ► Remove the spring cup , valve spring and spring pad ► Pull the valve out. ► Remove the valve stem seal RLF MPE850 Rev A | 409135 |...

-

Page 173: Installing Valve

040.03 Valves 040.03.02 Installing valve 040.03.02 Installing valve – Piston ring compressor – 1 Valve stem for each removed valve – Valve spring compressor – Valve grinding compound Info rmatio n ! The following chapter describes how to install a valve. If you want to install several valves, apply the procedure for any number of valves. - Page 174 040.03 Valves 040.03.02 Installing valve Valve springs are sidewise color-coded. If you replace valve springs, all installed valve springs must have the same color-code. ► Insert the spring pad , valve spring and spring cup ► Install the valve spring compressor according to the manufacturer's instructions.

- Page 175 040.03 Valves 040.03.02 Installing valve Installation instructions for rocker arms and cross bars Observe the installation position: – Counterbore – Fuel rail – Rocker arm short with cam spike – Rocker arm long RLF MPE850 Rev A | 409135 |...

-

Page 176: Removing Thermostat Housing

050.01 Thermostat housing 050.01.01 Removing thermostat housing 050.01.01 Removing thermostat housing ► Unscrew 10 bolts The thermostat housing is caulked with a silicone liquid seal. ► Remove the thermostat housing RLF MPE850 Rev A | 409135 |... -

Page 177: Installing Thermostat Housing

050.01 Thermostat housing 050.01.02 Installing thermostat housing 050.01.02 Installing thermostat housing – Silicone liquid seal ► Clean the sealing surface with sealing surface cleaner. ► Clean the sealing surface with sealing surface cleaner. ► Apply the silicone liquid seal without gaps as illustrated. - Page 178 050.01 Thermostat housing 050.01.02 Installing thermostat housing ► Hold the thermostat housing in position. ► Screw in 10 bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |...

-

Page 179: Removing Fitting

050.01 Thermostat housing 050.01.03 Removing fitting | 050.01.04 Installing fitting 050.01.03 Removing fitting ► Unscrew 2 bolts ► Remove the fitting 050.01.04 Installing fitting – 1 O-ring fitting thermostat housing ► Replace the o-ring ► Coat the o-ring lightly with petroleum jelly. ►... -

Page 180: Replacing Thermostat

050.01 Thermostat housing 050.01.05 Replacing thermostat 050.01.05 Replacing thermostat – 1 Distance washer ► Remove the thermostat and distance washer ► Replace the thermostat ► Replace the distance washer ► Put the distance washer on thermostat. Observe the installation position: –... -

Page 181: Replacing Sensor Coolant Temperature

050.01 Thermostat housing 050.01.06 Replacing sensor coolant temperature 050.01.06 Replacing sensor coolant temperature – Thread sealant ► Unscrew the sensor coolant temperature ► Replace the sensor coolant temperature. ► Coat the thread on the sensor coolant temperature with thread sealant. ►... -

Page 182: Replacing Plug Thermostat Housing

050.01 Thermostat housing 050.01.07 Replacing plug thermostat housing 050.01.07 Replacing plug thermostat housing – Thread sealant ► Unscrew the plug ► Replace the plug. ► Coat the thread on the plug with thread sealant. ► Screw in the plug. Tightening torque: 14 Nm +2 Nm [10.3 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 183: Removing Closing Cap Thermostat Housing

050.01 Thermostat housing 050.01.08 Removing closing cap thermostat housing | … 050.01.08 Removing closing cap thermostat housing ► Open the hose clamp ► Remove the closing cap 050.01.09 Installing closing cap thermostat housing ► Insert the closing cap ► Close the hose clamp Tightening torque: 3 Nm +0,5 Nm [2.2 lbf ft +0.4 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 184: Removing Impeller

050.02 Coolant pump 050.02.01 Removing impeller 050.02.01 Removing impeller – Locking tool crankshaft ► Hold the locking tool crankshaft on rotor. ► Screw in the bolt and washer. ► Unscrew the nut ► Remove the impeller RLF MPE850 Rev A | 409135 |... -

Page 185: Installing Impeller

050.02 Coolant pump 050.02.02 Installing impeller 050.02.02 Installing impeller – Locking tool crankshaft – Thread locker, medium strength The locking tool crankshaft is still installed. ► Insert the impeller ► Coat the thread on the water pump axle with medium strength thread locker. ►... -

Page 186: Removing Coolant Pump

050.02 Coolant pump 050.02.03 Removing coolant pump 050.02.03 Removing coolant pump – Locking tool crankshaft The locking tool crankshaft is still installed. ► Unscrew the water pump axle using a open-end wrench. RLF MPE850 Rev A | 409135 |... -

Page 187: Installing Coolant Pump

050.02 Coolant pump 050.02.04 Installing coolant pump 050.02.04 Installing coolant pump – Locking tool crankshaft – 1 Repair kit slide ring seal – Assembling kit slide ring seal The locking tool crankshaft is still installed. ► Replace the water pump axle ►... - Page 188 050.02 Coolant pump 050.02 Coolant pump 050.02.04 Installing coolant pump 050.02.04 Installing coolant pump ► Screw in the guide using a open-end wrench. ► Replace the slide ring seal ► Slide the slide ring seal onto guide. ► Hold the sliding sleeve in position.

- Page 189 050.02 Coolant pump 050.02 Coolant pump 050.02.04 Installing coolant pump 050.02.04 Installing coolant pump ► Screw in the nut using a open-end wrench until the slide ring seal is inserted completely. Tightening torque: 10 Nm +1 Nm [7.4 lbf ft +0.7 lbf ft] ►...

-

Page 190: Removing Oil Cooler

050.03 Oil cooler 050.03.01 Removing oil cooler 050.03.01 Removing oil cooler ► Unscrew the bolts ► Remove the oil cooler RLF MPE850 Rev A | 409135 |... -

Page 191: Installing Oil Cooler

050.03 Oil cooler 050.03.02 Installing oil cooler 050.03.02 Installing oil cooler – 4 Gaskets oil cooler ► Replace the gaskets ► Insert the gaskets into the grooves and lightly coat with petroleum jelly. ► Hold the oil cooler in position. ►... -

Page 192: Instructions For Mounting Nuts And Exhaust Gasket

060.01 Mounting exhaust manifold 060.01.01 Instructions for mounting nuts and exhaust gasket | … 060.01.01 Instructions for mounting nuts and exhaust gasket – 8 Nuts – Anti-Seize assembly paste – 2 Exhaust gaskets ► Replace the nuts ► Apply Anti-Seize assembly paste thoroughly to all studs ►... -

Page 193: Removing Intake Manifold

070.01 Intake manifold 070.01.01 Removing intake manifold 070.01.01 Removing intake manifold ► Unscrew 4 bolts ► Unscrew the bolts ► Remove the intake manifold RLF MPE850 Rev A | 409135 |... -

Page 194: Installing Intake Manifold

070.01 Intake manifold 070.01.02 Installing intake manifold 070.01.02 Installing intake manifold – 2 O-rings intake manifold ► Replace the o-rings ► Insert the o-rings into the grooves lightly coat with petroleum jelly. ► Hold the intake manifold in position. ► Screw in the bolts lightly. -

Page 195: Removing Sensor Intake Manifold Pressure/Temperature

070.01 Intake manifold 070.01.05 Removing sensor intake manifold pressure/temperature 070.01.05 Removing sensor intake manifold pressure/temperature ► Unscrew the bolt ► Pull the sensor intake manifold pressure/ temperature out. 070.01.06 Installing sensor intake manifold pressure/temperature ► Coat the o-ring lightly with petroleum jelly. -

Page 196: Replacing Cap

070.01 Intake manifold 070.01.07 Replacing cap 070.01.07 Replacing cap – Clamp pincer – 1 Hose clamp 8.8-10.5/5 The hose clamp will be destroyed during removal. ► Remove the hose clamp ► Remove the cap ► Replace the cap. ► Insert the cap. ►... -

Page 197: Removing Throttle Body

070.02 Mounting throttle body 070.02.01 Removing throttle body 070.02.01 Removing throttle body ► Open the hose clamp ► Remove the throttle body RLF MPE850 Rev A | 409135 |... -

Page 198: Installing Throttle Body

070.02 Mounting throttle body 070.02.02 Installing throttle body 070.02.02 Installing throttle body ► Insert the hose clamp and throttle body ► Close the hose clamp Tightening torque: 3 Nm +0,5 Nm [2.2 lbf ft +0.4 lbf ft]w RLF MPE850 Rev A | 409135 |... -

Page 199: Replacing Throttle Body

070.02 Mounting throttle body 070.02.03 Replacing throttle body 070.02.03 Replacing throttle body Info rmatio n ! When replacing the throttle body, it must be recalibrated. Before putting the engine into operation again, turn the ignition on for about a minute, until the throttle body opens and closes again. ►... -

Page 200: Replacing Rubber Mount

070.02 Mounting throttle body 070.02.04 Replacing rubber mount 070.02.04 Replacing rubber mount ► Unscrew the bolts ► Remove the rubber mount ► Replace the rubber mount ► Hold the rubber mount in position. Observe the orientation of the throttle body the rubber mount. -

Page 201: Removing Starter

090.01 Starter 090.01.01 Removing starter 090.01.01 Removing starter ► Unscrew 2 bolts ► Unscrew the bolt ► Remove the starter RLF MPE850 Rev A | 409135 |... -

Page 202: Installing Starter

090.01 Starter 090.01.02 Installing starter 090.01.02 Installing starter – 1 O-ring starter ► Replace the o-ring ► Coat the o-ring lightly with petroleum jelly. ► Hold the starter in position. ► Screw in the bolt lightly. Do not tighten. ► Screw in 2 bolts Tightening torque: 40 Nm +8 Nm [29.5 lbf ft +5.9 lbf ft]... -

Page 203: Replacing Starter

090.01 Starter 090.01.03 Replacing starter 090.01.03 Replacing starter ► Unscrew the bolt ► Remove the bracket ► Replace the starter. ► Hold the bracket in position. ► Screw in the bolt Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 204: Removing Generator

090.02 Generator 090.02.01 Removing generator 090.02.01 Removing generator – Locking tool crankshaft ► Hold the locking tool crankshaft on rotor. ► Screw in the bolt and washer. ► Unscrew the bolts ► Remove the locking tool crankshaft RLF MPE850 Rev A | 409135 |... - Page 205 090.02 Generator 090.02.01 Removing generator ► Remove the rotor ► Remove the stub shaft ► Unscrew the bolts The connector plug of the stator is not shown. ► Disconnect the connector plug of the stator. ► Remove the stator ► Remove the distance washer RLF MPE850 Rev A | 409135 |...

-

Page 206: Installing Generator

090.02 Generator 090.02.02 Installing generator 090.02.02 Installing generator – Locking tool crankshaft – 6 Bolts M10x1x35 – Thread locker, medium strength Leaks due to damage to the coating on the bolts. The threads of the six bolts on the rotor have a micro encapsulated coating. - Page 207 090.02 Generator 090.02.02 Installing generator ► Insert the distance washer ► Hold the stator in position. ► Coat the thread on the bolts with medium strength thread locker. ► Screw in the bolts. Tightening torque: 7 Nm +1 Nm [5.2 lbf ft +0.7 lbf ft] The connector plug of the stator is not shown.

- Page 208 090.02 Generator 090.02.02 Installing generator ► Replace the bolts ► Screw in the bolts by hand. Do not tighten. ► Hold the locking tool crankshaft on rotor. ► Screw in the bolt and washer. ► Tighten the bolts Tightening torque: 60 Nm +10 Nm [44.3 lbf ft +7.4 lbf ft] ►...

-

Page 209: Removing Fuel Rail

100.01 Fuel rail 100.01.01 Removing fuel rail 100.01.01 Removing fuel rail Burn injuries due to ignited fuel. Fuel is highly flammable. Leaks in the fuel system can lead to burns and vapors may ignite and cause an explosion. ► When working on the fuel system, observe the safety messages in chapter 2.2 Important safety messages. -

Page 210: Installing Fuel Rail

100.01 Fuel rail 100.01.02 Installing fuel rail 100.01.02 Installing fuel rail – Lubricant for injectors o-rings Burn injuries due to ignited fuel. Fuel is highly flammable. Leaks in the fuel system can lead to burns and vapors may ignite and cause an explosion. ►... -

Page 211: Replacing Injector

100.01 Fuel rail 100.01.03 Replacing injector 100.01.03 Replacing injector – Lubricant for injectors o-rings Burn injuries due to ignited fuel. Fuel is highly flammable. Leaks in the fuel system can lead to burns and vapors may ignite and cause an explosion. ►... - Page 212 100.01 Fuel rail 100.01 Fuel rail 100.01.03 Replacing injector 100.01.03 Replacing injector ► Replace the injector ► Coat the o-ring lightly with lubricant for injectors o-rings. ► Insert the injector until it engages in the bracket. ► Check that the injector is engaged in the bracket RLF MPE850 Rev A | 409135 |...

-

Page 213: Removing Suction Pump Cover

110.01 Dry sump 110.01.01 Removing suction pump cover 110.01.01 Removing suction pump cover ► Turn the engine 180°. ► Unscrew 14 bolts The suction pump cover is caulked with a silicone liquid seal. ► Prize off the suction pump cover using the grooves ►... -

Page 214: Installing Suction Pump Cover

110.01 Dry sump 110.01.02 Installing suction pump cover 110.01.02 Installing suction pump cover – Silicone liquid seal ► Clean the sealing surface with sealing surface cleaner. ► Clean the sealing surface with sealing surface cleaner. ► Check if the sleeves are installed. - Page 215 110.01 Dry sump 110.01.02 Installing suction pump cover ► Apply the silicone liquid seal without gaps as illustrated. ► Put the suction pump cover ► Screw in 7 bolts M6x20 Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ►...

-

Page 216: Replacing Suction Pump Cover

110.01 Dry sump 110.01.03 Replacing suction pump cover 110.01.03 Replacing suction pump cover – 1 Seal 18x22x1.5 Al – Thread sealant ► Replace the suction pump cover ► Replace the seals ► Coat the thread on the fittings with thread sealant. ►... -

Page 217: Removing Oil Suction Pump

110.01 Dry sump 110.01.04 Removing oil suction pump 110.01.04 Removing oil suction pump ► Unscrew the bolts ► Remove the oil screen ► Unscrew the bolts ► Remove the oil suction pump RLF MPE850 Rev A | 409135 |... -

Page 218: Installing Oil Suction Pump

110.01 Dry sump 110.01.05 Installing oil suction pump 110.01.05 Installing oil suction pump ► Insert the oil suction pump ► Screw in the bolts Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] ► Insert the oil screen ►... -

Page 219: Replacing Fitting

110.01 Dry sump 110.01.06 Replacing fitting 110.01.06 Replacing fitting – 1 Seal 18x22x1.5 Al – Thread sealant ► Turn the engine 180°. ► Unscrew the fitting ► Replace the fitting. ► Replace the seal ► Coat the thread on the fitting with thread sealant. -

Page 220: Removing Intermediate Gear Suction Pump

110.01 Dry sump 110.01.07 Removing intermediate gear suction pump 110.01.07 Removing intermediate gear suction pump – Pin punch axle intermediate gear ► Unscrew the plug ► Punch the axle out using the pin punch axle intermediate gear and plastic hammer. ►... -

Page 221: Installing Intermediate Gear Suction Pump

110.01 Dry sump 110.01.08 Installing intermediate gear suction pump 110.01.08 Installing intermediate gear suction pump – 1 Seal 18x22x1.5 Al ► Hold the intermediate gear suction pump in position. ► Slide in the axle . Observe the position of the bevel ►... -

Page 222: Removing Oil Pressure Pump

110.02 Oil pressure pump 110.02.01 Removing oil pressure pump 110.02.01 Removing oil pressure pump WARNING! Serious eye injuries due to a flying circlip. Wear protective glasses. ► Remove the circlip using a lockring pliers. ► Remove the oil pump cover using a universal pliers. -

Page 223: Installing Oil Pressure Pump

110.02 Oil pressure pump 110.02.02 Installing oil pressure pump 110.02.02 Installing oil pressure pump – 4 O-rings oil pump cover NOTICE! Engine damage due to the lack of lubrication. If the timing insert is installed in reverse, the engine cannot build up any oil pressure. -

Page 224: Removing Oil Pressure Valve

110.03 Oil pressure valve 110.03.01 Removing oil pressure valve 110.03.01 Removing oil pressure valve ► Unscrew the bolt ► Pull the oil pressure valve out using a bar magnet. RLF MPE850 Rev A | 409135 |... -

Page 225: Installing Oil Pressure Valve

110.03 Oil pressure valve 110.03.02 Installing oil pressure valve 110.03.02 Installing oil pressure valve ► Assemble the oil pressure valve in the sequence as illustrated ► Insert the oil pressure valve ► Screw in the bolt Tightening torque: 23 Nm +2 Nm [17 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 226: Removing Oil Filter

110.04 Oil filter 110.04.01 Removing oil filter | 110.04.02 Installing oil filter 110.04.01 Removing oil filter – Universal strap wrench ► Unscrew the oil filter using a universal strap wrench. 110.04.02 Installing oil filter – 1 Oil filter ► Replace the oil filter ►... -

Page 227: Removing Threaded Sleeve

110.04 Oil filter 110.04.03 Removing threaded sleeve | 110.04.04 Installing threaded sleeve 110.04.03 Removing threaded sleeve – Crown wrench ► Unscrew the threaded sleeve using a crown wrench. 110.04.04 Installing threaded sleeve – Crown wrench ► Screw in the threaded sleeve using a crown wrench. -

Page 228: Removing Bracket On The Drive Side

120.01 Lifting eye 120.01.01 Removing bracket on the drive side | … 120.01.01 Removing bracket on the drive side ► Unscrew the bolt ► Remove the bracket 120.01.02 Installing bracket on the drive side – Thread locker, high strength ► Hold the bracket in position as illustrated. -

Page 229: Removing Pipe Clamp

120.01 Lifting eye 120.01.03 Removing pipe clamp | … 120.01.03 Removing pipe clamp ► Unscrew the bolt ► Remove the pipe clamp 120.01.04 Installing pipe clamp ► Hold the pipe clamp in position. ► Screw in the bolt Tightening torque: 8 Nm +2 Nm [5.9 lbf ft +1.5 lbf ft] RLF MPE850 Rev A | 409135 |... -

Page 230: Removing Bracket Across From The Drive Side

120.01 Lifting eye 120.01.05 Removing bracket across from the drive side | … 120.01.05 Removing bracket across from the drive side ► Unscrew the bolts ► Remove the bracket 120.01.06 Installing bracket across from the drive side ► Hold the bracket in position. - Page 231 Appendix Overview of revisions Appendix Overview of revisions Revision Date Chapter Description Note Rev 1.0 04.09.2015 – 1st edition repair manual – RLF MPE850 Rev A | 409135 |...

- Page 232 Appendix Index Index Generator cover, replace 85 Generator, install 206 Balance shaft, replace 108 Generator, remove 204 Blanking cover, replace 76 Bracket 120.01, install 228, 230 Bracket 120.01, remove 228, 230 Ignition coils, remove 135 Impeller, install 185 Impeller, remove 184 Camshaft, replace 156 Injector, replace 211 Cap, replace 196...

- Page 233 Appendix Index Plug 030.02, replace 154 Valve, remove 171 Plug 050.01, replace 182 Valve timing, check 164 Vent plug, replace 87 Rocker arm, replace 168 Rubber mount, replace 200 Welch plug, replace 58 Sensor camshaft, remove 136 Sensor coolant temperature, replace 181 Sensor crankshaft, install 70 Sensor crankshaft, remove 70 Sensor intake manifold pressure/temperature,...

Need help?

Do you have a question about the MPE 850 OFF-ROAD and is the answer not in the manual?

Questions and answers