Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Schuler Scientific A Series

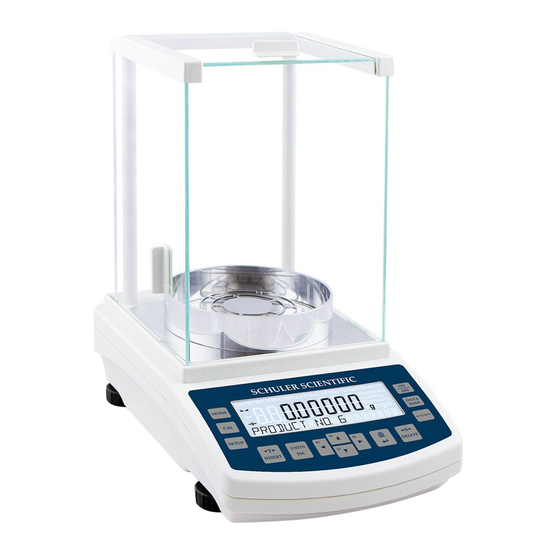

- Page 1 USER MANUAL SCHULER SCIENTIFIC A-SERIES BALANCES...

-

Page 2: Table Of Contents

GENERAL INFORMATION ..........................8 1.1 INTENDED USE ...............................8 1.2 PRECAUTIONS ..............................8 1.3 SUPERVISION OVER METROLOGICAL PARAMETERS ................8 1.4 WARRANTY CONDITIONS ..........................8 UNPACKING AND INSTALLATION ........................9 2.1 PLACE OF USE AND ASSEMBLING .......................9 2.2 STANDARD DELIVERY COMPONENTS LIST ..................... 10 2.3 UNPACKING .............................. - Page 3 5.2.10 NON-STANDARD INFORMATION ...................... 38 5.2.11 F SHORTCUT KEYS ..........................39 PARTS COUNTING (COUNTING PIECES) ....................40 6.1 PARTS COUNTING SETTINGS ........................40 6.1.1 FILTER LEVEL SETTING ........................40 6.1.2 VALUE RELEASE ..........................41 6.1.3 AUTOZERO FUNCTION ........................41 6.1.4 LAST DIGIT DISPLAY ..........................41 6.1.5 BALANCE AMBIENT CONDTIONS .......................

- Page 4 9.1.1 FILTER LEVEL SETTING ........................62 9.1.2 VALUE RELEASE ..........................62 9.1.3 AUTOZERO FUNCTION ........................63 9.1.4 LAST DIGIT DISPLAY ..........................63 9.1.5 BALANCE AMBIENT CONDTIONS ....................... 64 9.1.6 AUTOTARE ............................64 9.1.7 PRINT MODE ............................65 9.1.8 AUTOMATIC OPERATION ........................66 9.1.9 INFORMATION ............................

- Page 5 12.3 RUNNING THE PROCESS AUTOMATICALLY ..................85 13. STATISTICS ..............................87 13.1 STATISTICS SETTINGS ..........................87 13.1.1 FILTER LEVEL SETTING ........................87 13.1.2 VALUE RELEASE ..........................88 13.1.3 AUTOZERO FUNCTION ........................88 13.1.4 LAST DIGIT DISPLAY .......................... 89 13.1.5 BALANCE AMBIENT CONDTIONS ..................... 89 13.1.6 AUTOTARE ............................

- Page 6 16.1.9 AUTOMATIC TARING ........................106 16.2 PIPETTES CALIBRATION PROCEDURE ....................107 17. ADDING ................................109 17.1 PIPETTE CALIBRATION SETTINGS ......................109 17.1.1 AUTOZERO FUNCTION ........................109 17.1.2 LAST DIGIT DISPLAY ........................110 17.1.3 BALANCE AMBIENT CONDTIONS ....................110 17.1.4 INFORMATION ........................... 111 17.1.5 NON-STANDARD INFORMATION ....................

- Page 7 22.2.7 AUTO SWITCH-OFF .......................... 142 22.2.8 DATE ..............................142 22.2.9 TIME ..............................142 22.2.10 DATE FORMAT ..........................143 22.2.11 TIME FORMAT ..........................143 22.2.12 AUTOTEST GLP ..........................143 23. MAITENANCE ..............................145 24. ACCESSORIES .............................. 148 24.1 DENSITY DETERMINATION KIT ......................148 25.

-

Page 8: General Information

1.4 WARRANTY CONDITIONS A. Schuler Scientific will exchange, replace or repair the existing balance for any damage that appears to be faulty by production or by construction within the 5-year warranty period. B. Warranty is voided if: •... -

Page 9: Unpacking And Installation

2. UNPACKING AND INSTALLATION 2.1 PLACE OF USE AND ASSEMBLING • The balance should be stored and used in locations free of vibrations and shakes, free of air movement and dust. • Ambient air temperature should not exceed the range of: +10 °C ÷ +40 °C. Ambient relative humidity should not exceed 80%. -

Page 10: Standard Delivery Components List

2.2 STANDARD DELIVERY COMPONENTS LIST • Balance and components shown in Section 2.4 depending on balance model • Warranty Card • o User Manual o Balance USB Driver 2.3 UNPACKING To unpack the system, follow the diagram below- 2.4 BALANCE ASSEMBLY Model: SAS-225 Components: Installation:... - Page 11 2) Check grounding spring to insure it is in the appropriate location. Make sure that the grounding spring juts slightly out of the hole. 3) Install components following diagram below: i. Bottom insert ii. Centering ring [embossment side up] iii. Weighing pan iv.

- Page 12 Installation: 1) Remove the transport lock– gently press the transport lock and turn it accordingly to <OPEN>, keep the transport lock should your balance be transported in the future. 2) Check grounding spring to insure it is in the appropriate location. Make sure that the grounding spring juts slightly out of the hole.

- Page 13 Installation: 1) Remove transport lock, keep the transport lock should your balance be transported in the future. 2) Check that the grounding spring is in the correct location, the spring juts slightly out of the hole. 3) Install components following the diagram below: i.

- Page 14 Installation: 1) Remove transport lock, keep the transport lock should your balance be transported in the future. 2) Check that the grounding spring is in the correct location, the spring juts slightly out of the hole. 3) Install components following the diagram below: i.

- Page 15 Installation: 1) Remove transport lock, keep the transport lock should your balance be transported in the future. 2) Check that the grounding spring is in the correct location, the spring juts slightly out of the hole. 3) Install components following the diagram below: i.

-

Page 16: Balance Leveling

2.5 BALANCE LEVELING It is necessary to level the balance prior to plugging it in. To level the balance, turn its feet until the air bubble is in the center position. The balance should firmly rest on a surface, each of the feet must be supported. 2.6 POWERING THE DEVICE Before plugging in your balance, it is imperative to wait until the balance reaches thermal stabilization. -

Page 17: Balance Keyboard

• Press button located in the top right hand corner of the key pad. Remember to start the balance with no load on the weighing pan • Test of the display unit takes place right after connecting the balance to the power, all the elements and pictograms are backlit for a short time. -

Page 18: Balance Home Screen

Press to change measuring units. PRINT/ENTER button Press to send measurement to a printer or a computer (PRINT). Press to confirm selected parameter value or function (ENTER). Press to Zero the balance Press to Tare the balance Press to start adjustment / calibration process immediately. F6 button of the computer keyboard. -

Page 19: General Balance Operation

The blinking thermometer pictogram means that temperature inside the balance is not stable, this may result in inaccurate mass measurement. For such a case it is recommended to wait until the temperature stabilizes or to perform balance adjustment (blanking of the blinking thermometer pictogram). - Page 20 P3 COMMUNICATION COM1 [transmission parameters port COM 1] P3.1 P3.2 COM2 [transmission parameters port COM 2] P3.3 WIFI [transmission parameters port WIFI] P4 DEVICES COMPUTER P4.1 PC connection port P4.2 PRINTER [printer connection port] P4.3 BARCODE READER [barcode connection port] ADD.DISPLAY [additional display port] P4.4...

-

Page 21: Good Weighing Practice

P8.2 START UNIT [selection of a start unit, unit active on balance start- up] [parameter defining user’s unit 1] P8.3 USER UNIT U1 [parameter defining user’s unit 2] USER UNIT U2 P8.4 P9 IMPORT/EXPORT (parameter displayed upon inserting the USB flash drive to the balance) EXPORT [data export] IMPORT... -

Page 22: Balance Zeroing

When weighing any load, wait for the stability marker located in the top left of the screen to signify a stable reading of the load. 3.3 BALANCE ZEROING Zeroing is a function allowing to zero the mass on the indication. To perform this function, press button. -

Page 23: Balance Taring

3.4 BALANCE TARING Taring is a function allowing to determine net weight of a measured object. To determine the net weight of the object, place object’s container (packaging) on the weighing pan, and on stabilization of measurement result press key. The display indicates mass equaling zero and symbols: Net and . -

Page 24: Balance Calibartion

3.5 BALANCE CALIBARTION To ensure the highest weighing accuracy, it is recommended to periodically introduce a corrective factor of indications to balance memory, the said factor is referred to as a mass standard. Calibration should be carried out: • Before the beginning of weighing procedure •... -

Page 25: External Calibration

Procedure: • The balance detects the necessity of carrying out a calibration and signals it by displaying a thermometer or clock pictogram and <Cal> sign at the top of the display • Once the balance signals the need for a calibration, a 2-minute long time interval takes place allowing the weighing procedure to be completed •... -

Page 26: User Calibration

3.5.4 USER CALIBRATION An external calibration process can be carried out with an external mass standard of defined value by the user. The calibration mass must be at a value greater than 30% of the balances Max range Procedure: • Go to balance menu <P1.3 USER CALIBRATION>... -

Page 28: Working Modes- General Information

4. WORKING MODES- GENERAL INFORMATION The balance features the following working modes: Weighing Means of operation: weight of a load is determined through an indirect measurement. A balance measures gravitational force which attracts the load. An obtained result is processed to a digital format and displayed in a form of measurement result. -

Page 29: Running Working Mode

4.1 RUNNING WORKING MODE In order to run a particular mode press button, and select the mode from the list. Procedure: - press to select working mode - press to enter the selected working mode CAUTION Upon restart, the balance is launched with the most recently operated working mode. For settings of this function read later sections of this user manual. -

Page 30: Weighing Mode

5. WEIGHING MODE Load an object on the balance weighing pan. The stabilization of weighing result is indicated by a stability marker visible on the left side of balance display, read the measurement result. 5.1 WEIGHING UNITS To change the weighing unit, press the button. -

Page 31: Units Accessibility

5.1.1 UNITS ACCESSIBILITY The user may declare units to be available for use. Units with parameter value set to <YES> are available for selection in specified operating modes. Procedure: 5.1.2 START UNIT SELECTION Upon selection of start unit, the balance activates with the specified unit for these modes where change of the unit is possible. -

Page 32: Weigh Mode Settings

Procedure: 5.2 WEIGH MODE SETTINGS The balance allows setup of operating parameters (filters, value release and autozero function, deleting the last digit and other settings) separately for each working mode. It enables customizing the instrument and utilizing its properties depending on the user’s needs and expectations, or on specific requirements for selected working mode;... -

Page 33: Value Release

Procedure: CAUTION! The higher filter level, the longer the weighing time. 5.2.2 VALUE RELEASE Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST>... -

Page 34: Last Digit Display

Procedure: 5.2.4 LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 5.2.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. -

Page 35: Autotare

5.2.6 AUTOTARE Autotare is used for quick determination of net weight for loads with different tare values, wherein they are measured one after another. the function is active when <AUTOTARE> is set to <YES> option. Procedure: • Make sure that the weighing pan is empty and press button responsible for zeroing. •... -

Page 36: Print Mode

5.2.7 PRINT MODE Function designed to enable print mode setting, it activates key. Print mode options: • <WHEN STAB>, for this option stable measurement result, along with the settings for parameter <GLP PRINTOUT>, is sent to the printer port. On pressing key, when the result is not stable (no marker on a display), the balance software sends the... -

Page 37: Automatic Operation

Procedure: 5.2.8 AUTOMATIC OPERATION For automatic operation adjust the threshold value. It is also necessary to specify interval value in [min]. The picture presents interval setting, value set to 2 min. Procedure: • Press button to zero the balance (marker of stable measurement and zero marker are shown on a display). -

Page 38: Information

5.2.9 INFORMATION Function enables displaying additional information in the bottom line. Depending on the needs, you can choose the following options, which are shown while working in <WEIGHING> mode: <BARGRAPH> option presents amount of used weighing capacity in a graphic form, it covers 0 –... -

Page 39: F Shortcut Keys

If you want the declared non-standard information is to be visible, set parameter P2.2.4 to < NSTD. INF. > option. 5.2.11 F SHORTCUT KEYS Function enables assigning quick access for weighing functions which are to be accessible by pressing F1, F2, F3 or F4 keys. You can choose between the following options for <WEIGHING>... -

Page 40: Parts Counting (Counting Pieces)

6. PARTS COUNTING (COUNTING PIECES) Parts counting is a working mode which enables determination of quantity of small parts with equal weight. Determined mass of a single part is used for the counting procedure. 6.1 PARTS COUNTING SETTINGS The balance allows setup of operating parameters (filters, value release and autozero function, deleting the last digit and other settings) separately for each working mode. -

Page 41: Value Release

6.1.2 VALUE RELEASE Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST> or <RELIABLE>. Depending on the selected option, weighing time is either shorter or longer. -

Page 42: Balance Ambient Condtions

Procedure: 6.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 43: Print Mode

• The balance cancels tare value (packaging weight recorded in balance storage during the first step of the operating process) after the gross weight value (set in <AUTO THRES> parameter) has been exceeded. • Put packaging of the next product on a weighing pan, automatic taring of the packaging weight proceeds after measurement stabilization (Net marker appears in the top section of the display);... -

Page 44: Automatic Operation

interval. The interval is set in minutes, in parameter P2.3.3.3 <AUTO INT.>. Interval range is 1-9999 min. CAUTION Each result is printed and recorded (stable and unstable for a non-verified balance, stable for a verified balance). Automatic operation with interval starts at the moment of switching the function on and it lasts until it is switched off. -

Page 45: Non-Standard Information

• Gross • User • Product • None Standard Information For procedure refer to Section 5.5 6.1.10 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.3.4 to <... -

Page 46: Setting Reference Mass: Mass Determination For The Sample Of Known Quantity

6.2 SETTING REFERENCE MASS: MASS DETERMINATION FOR THE SAMPLE OF KNOWN QUANTITY While determining the mass of a single piece, ACAI function (Automatic Accuracy Correction) is in use. Means of operation of ACAI function: Number of pieces (on adding) on balance’s weighing pan has to be greater than before •... -

Page 47: Setting Reference Mass: Entering Mass Value

CAUTION! Remember that: • The total mass of all the pieces put on the weighing pan must not be greater than the balance maximum weighing range. • The mass of a single piece cannot be lower than 0.1 reading unit of the balance. If this condition is not met, the balance displays message: <Single part mass too low>. -

Page 48: Checkweighing

7. CHECKWEIGHING Checkweighing is a working mode using two thresholds (LOW and HIGH) in order to check mass of the samples. It is generally assumed that the mass is correct if it is contained within the threshold values. 7.1 CHECKWEIGHING SETTINGS The balance allows setup of operating parameters (filters, value release and autozero function, deleting the last digit and other settings) separately for each working mode. -

Page 49: Autozero Function

Procedure: 7.1.3 AUTOZERO FUNCTION The balance features an autozero function (Auto). This function automatically controls and corrects the zero reading. When Autozero is enabled, it compares balance readings at declared time interval e.g. 1s, if weighing pan is unloaded and display indication is close to zero. If results vary less than declared AUTOZERO range e.g. -

Page 50: Balance Ambient Condtions

Procedure: 7.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 51: Print Mode

• The balance cancels tare value (packaging weight recorded in balance storage during the first step of the operating process) after the gross weight value (set in <AUTO THRES> parameter) has been exceeded. • Put packaging of the next product on a weighing pan, automatic taring of the packaging weight proceeds after measurement stabilization (Net marker appears in the top section of the display);... -

Page 52: Automatic Operation

interval. The interval is set in minutes, in parameter P2.3.4.3 <AUTO INT.>. Interval range is 1-9999 min. CAUTION Each result is printed and recorded (stable and unstable for a non-verified balance, stable for a verified balance). Automatic operation with interval starts at the moment of switching the function on and it lasts until it is switched off. -

Page 53: Non-Standard Information

• • Gross • User • Product • None Standard Information (NSTD INF) For procedure refer to Section 5.2.9 7.1.10 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.4.4 to <... -

Page 54: Declaring Threshold Values

7.2 DECLARING THRESHOLD VALUES Procedure: • Press F button to which the function <ASSIGN THRESHOLDS> is assigned, the editing window is displayed and the value of MIN low threshold can be ascribed. The ascribed value must be given in a current unit. •... -

Page 55: Dosing

8. DOSING Dosing is a working mode comprised of the process of sample weighing, where the samples weighing is performed until target mass is reached. The target mass is defined along with dosing tolerance value. The tolerance value is set as a percentage of the target mass. An example: Target weight = 100.000g Tolerance = 2.5% (2.5% of 100g, which amounts to 2. -

Page 56: Value Release

8.1.2 VALUE RELEASE Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST> or <RELIABLE>. Depending on the selected option, weighing time is either shorter or longer. -

Page 57: Balance Ambient Condtions

Procedure: 8.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 58: Print Mode

• The balance cancels tare value (packaging weight recorded in balance storage during the first step of the operating process) after the gross weight value (set in <AUTO THRES> parameter) has been exceeded. • Put packaging of the next product on a weighing pan, automatic taring of the packaging weight proceeds after measurement stabilization (Net marker appears in the top section of the display);... -

Page 59: Automatic Operation

• <AUTO+INT.> select this option to start automatic printout and record of indications in Weighings database and Alibi database, carried out in a cyclic manner in a specified time interval. The interval is set in minutes, in parameter P2.3.4.3 <AUTO INT.>. Interval range is 1-9999 min. -

Page 60: Non-Standard Information

• Bargraph • Tare • • Gross • User • Product • None Standard Information (NSTD INF) For procedure refer to Section 5.2.9 8.1.10 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. -

Page 61: Setting Target Mass: Entering Mass Value

8.2 SETTING TARGET MASS: ENTERING MASS VALUE Procedure: • Press F button to which function <ENTER SAMPLE> is assigned, the editing window is displayed. The target weight value must be given in a current unit. • Use arrow buttons to enter the target weight, press button to confirm. -

Page 62: Percent Weighing (Deviations)

9. PERCENT WEIGHING (DEVIATIONS) The balance software has an option of control of deviation (in percentage) between weighed loads mass and specified reference mass. The reference mass can be determined by means of a weighing process or it can be entered into memory by the user. 9.1 PERCENT WEIGHING (DEVIATIONS) SETTINGS The balance allows setup of operating parameters (filters, value release and autozero function, deleting the last digit and other settings) separately for each working mode. -

Page 63: Autozero Function

Procedure: 9.1.3 AUTOZERO FUNCTION The balance features an autozero function (Auto). This function automatically controls and corrects the zero reading. When Autozero is enabled, it compares balance readings at declared time interval e.g. 1s, if weighing pan is unloaded and display indication is close to zero. If results vary less than declared AUTOZERO range e.g. -

Page 64: Balance Ambient Condtions

9.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 65: Print Mode

For correct operation of the balance with <AUTOTARE> function, it is necessary to adjust the threshold value <AUTO THRES>. <AUTO THRES> parameter is connected with the following functions: • automatic tare • automatic operation No automatic taring takes place as long as the gross weight value stays within the range set in <AUTO THRES>... -

Page 66: Automatic Operation

On switching the function of auto print with interval, PRINT button becomes inoperative (no indication is printed when pressed). For procedure refer to Section 5.2.7 9.1.8 AUTOMATIC OPERATION For automatic operation adjust the threshold value. It is also necessary to specify interval value in [min]. The picture presents interval setting, value set to 2 min. -

Page 67: Non-Standard Information

For procedure refer to Section 5.2.9 9.1.10 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.4.4 to <... -

Page 68: Setting The Reference Mass: Weighing Reference Sample

9.2 SETTING THE REFERENCE MASS: WEIGHING REFERENCE SAMPLE Procedure: • Press F button to which function <DETERMINE SAMPLE> is assigned, <PUT 100%> editing window is displayed. • Place the reference sample (to represent 100%) on the pan, and when the result is stable symbol is displayed) press button to confirm. -

Page 69: Density Of Solids

DENSITY OF SOLIDS Solids density is a working mode enabling determination of density of a representative sample material. In order to operate this mode, an optional Density Determination Kit (additional information located in Section 24.1) is available for purchase. For the measurement, an appropriate model of the kit is used for the balance depending on pan configuration. -

Page 70: Value Release

Depending on the filter, the weighing time is shorter (V.FAST and FAST) or longer (SLOW and V. SLOW). Refer to Section 5.2.1 for procedure. 10.1.2 VALUE RELEASE Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST>... -

Page 71: Last Digit Display

10.1.4 LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 10.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. -

Page 72: Non-Standard Information

For procedure refer to Section 5.2.9 10.1.7 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.7.2 to <... - Page 73 5. Set the process following the displayed messages. 6. Select liquid in which the determination is to be carried out. 7. After selecting and entering a liquid type by pressing <ENTER> button, the software proceeds to setting the liquid temperature. 8.

-

Page 74: Density Of Liquids

12. On the second confirmation of the indication, the program automatically calculates and displays the tested solid object density. At the same time, a report on the measurement is sent to a selected port of a printer. An example report: The report may be reprinted upon pressing button. -

Page 75: Density Of Liquids Settings

A − B ρ = ρ - density of liquid A - sinker weight measured in the air B - sinker weight measured in water V - volume of the sinker d - air density (max 0.001 g/cm The basic element for measuring liquids density is the sinker (9). Its volume is precisely determined and given on a sinker’s hanger. -

Page 76: Value Release

11.1.2 VALUE RELEASE Since ambient conditions at a workplace vary, it is necessary to determine the value release parameter that are best for your working environment, parameter options are: <FAST.+REL.>, <FAST> or <RELIABLE>. Depending on the selected option, weighing time is either shorter or longer. -

Page 77: Balance Ambient Condtions

Procedure: 11.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 78: Non-Standard Information

For procedure refer to Section 5.2.9 11.1.7 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.8.2 to <... - Page 79 6. Set volume of the sinker used for measuring. On entering the data, the software proceeds to weighing. 8. First, place the sinker on the hook (a sample mass determination in the air), and confirm the indication when stable. Next, take the sinker out of the hook, put the beaker with liquid on the beaker’s basis (the beaker cannot touch the hook), gently hang the sinker on the hook providing that it is totally immersed in the tested liquid (sample mass determination in liquid) –...

-

Page 80: Animal Weighing

The report may be reprinted upon pressing button. In order to finish, press button. The software returns to the main window of the mode and a next measurement can be performed. The balance operates with previously set parameter values (liquid, temperature) thus shortening time needed for the exact measurement. -

Page 81: Autozero Function

Procedure: 12.1.3 AUTOZERO FUNCTION The balance features an autozero function (Auto). This function automatically controls and corrects the zero reading. When Autozero is enabled, it compares balance readings at declared time interval e.g. 1s, if weighing pan is unloaded and display indication is close to zero. If results vary less than declared AUTOZERO range e.g. -

Page 82: Balance Ambient Condtions

Procedure: 12.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 83: Non-Standard Information

For procedure refer to Section 5.2.9 12.1.7 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.9.2 to <... -

Page 84: Threshold

12.1.10 THRESHOLD It is a value expressed in mass measuring units. To start measurement, the indication value has to exceed the set threshold value. 12.1.11 AUTOSTART Determines start criterion for measurements: whether they are to be initiated manually, on pressing a button or selecting <START>, or automatically. When the parameter is set to <YES> option, the measurement starts automatically if an indication on a balance display exceeds the set threshold value. -

Page 85: Running The Process Automatically

The <THRESHOLD> parameter is not required for this measurement mode. Select <ANIMAL WEIGHING> mode. Place the container in which the measurement is to be carried out on the weighing pan and when the indication is stable carry out taring. Next, enter the mode options and start the measurement procedure following the instruction below. After weighing process completion, the measurement result is locked and automatically printed. - Page 86 Info field provides the following information: • N (number of samples), • Sum (total weight of samples within a series) • AVG (average value of the series) • Min (minimum value in a series) • Max (maximum values in a series) •...

-

Page 87: Statistics

• The information on number of saved measurements is displayed in a bottom line. On pressing , the type of displayed information changes. • Selecting an option <PRINT> and pressing button initiates printing out the statistics data in a form of a report. An example report: -------------- Statistics ------------- 455.600 g... -

Page 88: Value Release

The effectiveness of the filter is different throughout the weighing range. The filter works slower when “approaching” the weighed mass, it works more quickly for weighed mass within the set range of the filter (parameter for setting filter range is accessible only from the service menu – the user does not have any access to it). -

Page 89: Last Digit Display

13.1.4 LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 13.1.5 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. -

Page 90: Autotare

13.1.6 AUTOTARE Autotare is used for quick determination of net weight for loads with different tare values, wherein they are measured one after another. The function is active when <AUTOTARE> is set to <YES> option. Procedure: • Make sure that the weighing pan is empty and press button responsible for zeroing. •... -

Page 91: Automatic Operation

Print mode options: • <WHEN STAB>, for this option stable measurement result, along with the settings for parameter <GLP PRINTOUT>, is sent to the printer port. On pressing key, when the result is not stable (no marker on a display), the balance software sends the measurement result to the port after reaching stability for the measurement. -

Page 92: Information

Function enables displaying additional information in the bottom line. Depending on the needs, you can choose the following options, which are shown while working in <STATISTICS> mode: • (number of samples), • (total weight of samples within a series) • (average value of the series) • (minimum value in a series) •... -

Page 93: F Shortcut Keys

13.1.11 F SHORTCUT KEYS Function enables assigning quick access for weighing functions which are to be accessible by pressing F1, F2, F3 or F4 keys. You can choose between the following options for < STATISTICS> mode: <NONE / RESULT/ END / SELECT PRODUCT / LOG IN / ENTER TARE / SELECT TARE / PRINT HEADER / PRINT FOOTER / VARIABLE 1 / VARIABLE 2>. -

Page 94: Deleting Statistics

---------------------------------------- 13.3 DELETING STATISTICS To delete statistics data carried out for a series of measurements, follow this procedure: Activating <FINISH> option results in printing out the statistics data and moving to a <RESULT> window, using this window it is possible to check the data and print it out again, if necessary. -

Page 95: Totalising

TOTALISING The Totalising function allows you to weigh individual ingredients of a mixture and totalize its total mass. The software enables adding up approximately 30 ingredients for one mixture. 14.1 TOTALISING SETTINGS 14.1.1 FILTER LEVEL SETTING To set the filter level for Animal Weighing, set parameter P2.11.1.1 <FILTER> Filter settings adjustment depends on the working environment. -

Page 96: Autozero Function

14.1.3 AUTOZERO FUNCTION The balance features an autozero function (Auto). This function automatically controls and corrects the zero reading. When Autozero is enabled, it compares balance readings at declared time interval e.g. 1s, if weighing pan is unloaded and display indication is close to zero. If results vary less than declared AUTOZERO range e.g. -

Page 97: Information

• If the ambient conditions are unstable it is recommended to use UNSTABLE mode. By default, the parameter is set to <STABLE> option. Procedure: 14.1.6 INFORMATION Function enables displaying additional information in the bottom line. Depending on the needs, you can choose the following options, which are shown while working in <TOTALISING> mode: •... -

Page 98: F Shortcut Keys

14.1.8 F SHORTCUT KEYS Function enables assigning quick access for weighing functions which are to be accessible by pressing F1, F2, F3 or F4 keys. You can choose between the following options for < TOTALISING> mode: <NONE / END / DELETE LAST / SELECT PRODUCT / LOG IN / ENTER TARE / SELECT TARE / PRINT HEADER / PRINT FOOTER / VARIABLE 1 / VARIABLE 2>. - Page 99 • When all the ingredients have been weighed finish the procedure of totalising. Procedure: • The message <RESULT> is displayed in a bottom line, this means that the total result of all the ingredients that have been weighed is shown on the main display. Additionally, the final report, containing information on mass of individual ingredients, total sum and mass of the applied tare, is printed out.

-

Page 100: Peak Hold

PEAK HOLD Peak Hold is a function that enables snapping peak hold applied to the weighing pan during a single checkweighing process. Apart from standard settings for this mode (described in the weighing mode), additional setting for threshold values activating function has been introduced. 15.1 PEAK HOLD SETTINGS 15.1.1 AUTOZERO FUNCTION The balance features an autozero function (Auto). -

Page 101: Balance Ambient Condtions

15.1.3 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. There are two options: <STABLE> and <UNSTABLE>. • Selecting <STABLE> mode makes the balance work much faster, i.e. weighing takes much less time than for <UNSTABLE> mode. •... -

Page 102: F Shortcut Keys

15.1.6 F SHORTCUT KEYS Function enables assigning quick access for weighing functions which are to be accessible by pressing F1, F2, F3 or F4 keys. You can choose between the following options for <PEAK HOLD> mode: <NONE / ON/OFF LAST DIGIT / PROFILE / SELECT PRODUCT / LOG IN / ENTER TARE / SELECT TARE / PRINT HEADER / PRINT FOOTER / VARIABLE 1 / VARIABLE 2>. -

Page 103: Pipettes Calibration

The start of the next process of peak hold measurement is possible only after removing the load from the weighing pan and pressing button. This causes returning to the main window of <PEAK HOLD> mode, pictogram <Max> is automatically deleted. CAUTION! Current unit may be selected only if the weighing result is not snapped. -

Page 104: Pipette Calibration Settings

Prior to pipettes calibration pour 2/3 of the evaporation ring with distilled water. The set is ready to be used after about 1 hour – it takes this long for humidity to stabilize. Excess water can be removed using automatic pump or an external pipette. To minimize any humidity changes inside the chamber and to avoid air draft influence while opening the door, dose the liquid from a pipette to an evaporation ring via an opening of a weighing chamber lid. -

Page 105: Last Digit Display

16.1.2 LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 16.1.3 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. -

Page 106: Non-Standard Information

• Product For procedure refer to Section 5.2.9 16.1.5 NON-STANDARD INFORMATION Function enables declaring non-standard information, which is to be displayed in the bottom line of the display. You can insert any text consisting of 19 characters maximum. For procedure refer to Section 5.2.10 If you want the declared non-standard information is to be visible, set parameter P2.13.2 to <... -

Page 107: Pipettes Calibration Procedure

Remember to select correct values of the above options before pipettes calibration procedure is performed. The settings should reflect expectations and needs being a result of working environment. 16.2 PIPETTES CALIBRATION PROCEDURE • Enter <PIPETTES CALIBRATION.> mode. • Start the process. •... - Page 108 • Enter (V3) control volume. • Upon entering the data the computer software proceeds to pipettes calibration. • Follow the displayed description and complete the procedure. • By means of a pipette, dose the first portion of water, wait until the measurement is stable and press ENTER to confirm.

-

Page 109: Adding

An example report: adjustable volume pipette, 3 volumes tested: ADDING Caution! Function valid for SAS with d=0.01/0.1 mg and d=0.1mg series balances exclusively. Adding function allows you to add net masses of weighed samples. This function enables adding maximum 9999 ingredients in one cycle or such quantity of samples which value of totalized masses is possible to be displayed on 8-section display. -

Page 110: Last Digit Display

Procedure: 17.1.2 LAST DIGIT DISPLAY Function enables displaying the last digit of decimal place for a weighing result. There are three available options: • <ALWAYS> all digits visible • <NEVER> last digit is not displayed • <WHEN STB> last digit is displayed only for a stable weighing result Procedure: 17.1.3 BALANCE AMBIENT CONDTIONS Parameter relating to ambient and environmental conditions in which the balance operates. -

Page 111: Information

17.1.4 INFORMATION Function enables displaying additional information in the bottom line. Depending on the needs, you can choose the following options, which are shown while working in <ADDING> mode: • None • Profile • None Standard Information (NSTD INF) • Tare •... -

Page 112: Adding Procedure

17.2 ADDING PROCEDURE • Enter <ADDING> mode. • The bottom line shows total sum and data relating to the number of ingredients which are added to the total sum and the total mass (if such information is selected in the settings for totalising mode). - Page 113 • In the bottom line message <RESULT> is displayed. It means that the total result of all measured samples masses is displayed and the sum is automatically printed. An example printout: CAUTION: On adding process completion, only a summary is printed. Masses of particular samples are printed on confirmation You can print the sum once again.

-

Page 114: Databases

In order to continue adding process, press button on printing out the sum. Home screen of the main mode is displayed. If samples are measured with packagings, load the weighing pan with the packaging, wait for stabilization and press button . DATABASES The balance software has 3 databases that can be edited (USERS, PRODUCTS, TARES) as well as 2 databases (WEIGHINGS AND ALIBI), to which all the measurements, carried out by means of the... - Page 115 Access levels The balance software has three access levels: USER, ADVANCED, ADMINISTRATOR. Access levels Permissions Access to parameters of the submenu <Reading>, permission to change settings for parameter group <Other> except for <Date and Time>. USER Permission to start and carry out all the weighing processes. You can preview information in <Databases>...

-

Page 116: Products

• Press button • The software shows <DELETE?> message in the bottom line • Confirm by pressing button • When confirmed, the software removes the selected user from the list 18.2 PRODUCTS The balance can store 1000 different products that can be weighed, counted, and controlled. The following data can be inserted for each product: •... - Page 117 Additional data is saved along with the measurement. • Date of the measurement • Time of the measurement • Measurement result (mass) • Tare value • Name of the product that has been weighed • Person carrying out the measurement (logged-in user) •...

-

Page 118: Alibi Memory

To swap between data relating to the measurement, press . The data relating to the measurement can be printed out by selecting the option <PRINT> and pressing button. An example printout: Date 21.06.2013 Time 13:05:02 User Product Tare 0.000 g Gross 0.000 g 0.000 g... -

Page 119: Import/Export Of Databases

The measurements saved in the balance’s memory cannot be deleted. It is possible for a user to view and print out the data saved in the “ALIBI” memory. Procedure: Each measurement is saved with its individual number. The format is: b4.5.n, where <n> is the consecutive number of the saved measurement. -

Page 120: Database Export

export or import of the database is displayed. The following options are available when entering this parameter: • Database EXPORT • Database IMPORT 18.6.1 DATABASE EXPORT To export the database, select an option EXPORT. The following functions are available: • Export of all the databases •... -

Page 121: Communication

COMMUNICATION Communication menu enables configuration of port settings. The settings are accessed upon pressing button. Communication with peripheral devices is established via the following ports: • COM 1 (RS232) • COM 2 (RS232) • USB type A • USB type B 19.1 RS 232 PORTS SETTING Procedure: •... - Page 122 Please remember that for PCL printer, the drivers print completely filled page, i.e. the page will be printed only upon pressing button, located on a balance, for several times (it depends on a printout size how many times the PRINT button shall be pressed prior printout). USB port of type B is intended for: •...

- Page 123 “Ready to Install” window: In order to run installation process, press “Install” key and clicking respective keys, follow the install wizard.

-

Page 124: Wi-Fi Port Settings

Having completed driver installation, connect balance to a computer, use 1,8-meter long USB A/B cable maximally (in case of already connected balance, it is necessary to disconnect it and using USB cable connect the balance again). The system detects the new USB device and automatically starts searching a respective driver Go to Device Manager and check number assigned to virtual COM port. - Page 125 • P3.3.3.2 – NAME (the name of the network that has been selected) • P3.3.3.3 – PASSWORD (password – ‘stars’ are displayed) • P3.3.3.4 – IP (balance ID number, make sure that the number is not engaged by a different device using this network) •...

-

Page 126: Peripheral Devices

PERIPHERAL DEVICES PERIPHERAL DEVICES menu is comprised within Parameters menu. It is accessed by pressing key. The menu features list of devices that can cooperate with the balance. 20.1 COMPUTER Balance Menu: P4.1 COMPUTER Computer submenu allows the user to select a port for connection of a computer running software which enables: •... - Page 127 transferred decimal values are separated by coma (,) o value ‘NO’ – cooperation with other programs (mass value transferred in a form of text), • <DELAY> – if the transferred information is incomplete, i.e. part of it gets lost (due to auto- entering or auto-formatting of data by computer program) during cooperation with Excel type program, set the parameter value to 2.

-

Page 128: Printer

P4.1.7 Printout- Type of the printout sent to the port chosen for the computer. Procedure: • Press button • Enter P4 DEVICES menu • Enter menu group P4.1 COMPUTER • Enter P4.1.7 PRINTOUT parameter • Select printout: • <NONE> – no printout selected •... - Page 129 entered to computer programs, e.g. Excel, Word, Notepad etc. P4.2.2 PORT SET • <SPREADSHEET> o value ‘YES --.—‘ – cooperation with Excel type program, transferred decimal values are separated by dot (.) o value ‘YES --,--‘ – cooperation with Excel type program, transferred decimal values are separated by coma (,) o value ‘NO’...

-

Page 130: Barcode Reader

CAUTION! CODES MUST BE ENTERED IN A HEXADECIMAL FORM! 20.3 BARCODE READER Balance Menu: P4.3 BARCODE READER Comprises settings for cooperation with a barcode reader. Procedure: • Press button • Enter P4 DEVICES menu • Enter menu group P4.3 BAR CODE READER •... -

Page 131: Measurement Data Printout (Usb Drive)

CAUTION: The balance program enables cooperation with one or both buttons. If you need to connect both external buttons, first connect a several electrical outlet to COM 2 port, next connect buttons TARE and PRINT to the electrical outlet. Connect the printer or terminal to COM 1 or to the electrical outlet (determine the PRINTER- BALANCE transfer parameters). -

Page 132: Print Mode

• Press button to switch the balance off, next remove the pendrive from the port and read the data on a computer. Keeping to this sequence of actions you are guaranteed that the data is saved. More data can be recorded in the same file. The balance software will add the data to the file that has already been created on a flash drive. -

Page 133: Adjustment Report

Procedure: • Press button to zero the balance (marker of stable measurement and zero marker are shown on a display). • Deposit load, the balance sends the first stable measurement to the printer port. • Remove the load from the pan. •... -

Page 134: Header, Footer, Glp Printouts

PROJECT Option enables printing out the name of the project (see parameter Project). DATE Option enables printing out the date of the carried out adjustment. TIME Option enables printing out the time of the carried out adjustment. BALANCE ID Option enables printing out the balance ID number. CAL. - Page 135 Option enables printing out the name of a logged-in user. Header USER GLP printout Footer PRODUCT Option enables printing out the name of a currently Header selected product. GLP printout Footer Header DATE Option enables printing out the date of the carried out GLP printout adjustment.

-

Page 136: Non-Standard Printouts

Header GLP printout Footer 21.3 NON-STANDARD PRINTOUTS The balance software enables entering 4 non-standard printouts. Non-standard printout may include: • Variables dependent on the working mode and other needs (mass, date etc.) • Permanent text from the user menu, remember to use capital letters exclusively •... - Page 137 Variable Description Mode for which the variable is active Standard mass 1 pcs PARTS COUNTING High threshold CHECKWEIGHING Low threshold Target mass DOSING Reference mass PERCENT WEIGHING Non-standard characters used in designing non-standard printouts a single “\” character CRLF Tabulator Form feed (for PCL printers) Crop the paper for EPSON printers Every single printout can contain max 160 characters (letters, numerals, non-standard characters,...

-

Page 138: Variables

Paper must be cropped underneath the FOOTER. Example settings: P5.4.14 STANDARD PRINTOUT | NSD. PRN. 1 P5.5 NSD. PRN. 1 | %E The way of inserting texts: • By means of balance keyboard Selecting a character to be replaced. Moving a cursor or an active (blinking) character to the right. -

Page 139: Advanced Features

ADVANCED FEATURES 22.1 BAR GRAPHS The bar graph function is accessible for all weighing modes. The bar graph presents in a graphic form how much of balance capacity is in use. Additionally, it shows Min and Max thresholds positions for the Check weighing mode, and for Dosing mode it shows target weight value along with permissible tolerance. -

Page 140: Autotare

• The balance returns to the weighing mode, and the display indicates entered tare value with a minus “–" sign. 22.2.2 AUTOTARE Autotare is used for quick determination of net weight for loads with different tare values, wherein they are measured one after another. When the function is active (<AUTOTARE>... -

Page 141: Menu Language

22.2.3 MENU LANGUAGE Balance Menu: P6.1 LANGUAGE Language parameter enables selecting the language of the balance menu descriptions. Available languages: POLISH, ENGLISH, GERMAN, SPANISH, FRENCH, TURKISH, CZECH, ITALIAN, HUNGARIAN. 22.2.4 PERMISSIONS Balance Menu: P6.2 ACCESS LEV Permissions parameter enables choosing access level for a particular user, one that is not logged in. -

Page 142: Auto Switch-Off

STAND- BY MODE, than the display goes out immediately. The backlight activates upon change of indication (no stability pictogram on the display) or pressing any key on the balance keypad. Blanking works also when balance menu is entered. 22.2.7 AUTO SWITCH-OFF Balance Menu: P6.6 AUTO SWITCH-OFF Parameter <P6.6 AUTO OFF>... -

Page 143: Date Format

22.2.10 DATE FORMAT Balance Menu: P6.9 DATE FORM Date form. parameter enables altering the date format on the printout [YYYY.MM.DD / YYYY.DD.MM / DD.MM.YYYY / MM.DD.YYYY], where: YYYY – year; MM – month; DD – day. 22.2.11 TIME FORMAT Balance Menu: P6.10 TIME FORM Time form. - Page 144 An example report: ............. --------- Autotest GLP: Report --------- Balance type 3000.R2 Balance ID 400010 User Admin Software ver. v.0.4.9 Date 2013.07.16 Time 09:17:16 -------------------------------------------------------- Number of measurements Reading unit 0.001/0.01g Internal weight mass 1402.094 g Filter Average Value release Fast &...

-

Page 145: Maitenance

MAITENANCE Disassemble the balance weighing pan and other detachable components (the components differ depending on a balance type – see Unpacking and Installation, Section 2). Be careful while detaching the components so as not to cause any damages to the balance mechanism. •... - Page 146 While cleaning aluminum components use products that are acidic by nature, e.g. spirit vinegar, lemon. Do not use abrasive substances. Avoid using hard brush as this may cause scratches. It is recommended to use microfiber cloth. Polishing the surface using circular movements. Use a clean, dry cloth. Cleaning draft shield panes: Select dissolvent depending on a dirt.

- Page 147 Remove back pane. Remove side panes. Side panes shall not be swapped therefore it is necessary to remember which one is right, and which one is left to install them back properly. CAUTION! Do not remove the front pane! Remove the weighing pan and the draft shield bottom insert prior to cleaning.

-

Page 148: Accessories

ACCESSORIES Available Accessories for Schuler Scientific balances 24.1 DENSITY DETERMINATION KIT Kit intended for Analytical balances. Balance Models: d=0.01/0.1mg Beaker base Stand Sinker Beaker Thermometer holder Thermometer Flexible connector for sinker Hanger Top weighing pan for solids density determination Flexible connector for weighing pans... - Page 149 Top weighing pan for solids density determination Beaker Hanger Thermometer Thermometer holder Sinker 10 Beaker basis 11 Additional stand for a set of pans or a sinker Additional set of weighing pans for density determination of solids with density lower that density of water Kit intended for Precision balances featuring 195x195 mm weighing pan Balance Models: d= 0.01/0.1g Weighing pan with stand...

- Page 150 Installation Procedure: Analytical Balance Models Precision Balance Models (128x128 mm weighing pan):...

- Page 151 Precision Balances Models (featuring 195x195 mm weighing pan): CAUTION! • Components of density determination kit shall be stored in a respective box. • Weighing pans and sinker shall not be put directly on a table, this might cause their damage. •...

-

Page 152: Appendix

APPENDIX 25.1 SAS/SPS Series Balances MODEL CAPACITY READABILITY LINEARITY REPEATABILITY PAN SIZE SAS-225 82g/220g 0.01mg/0.1mg ±0.2mg 0.1mg 90 mm SAS-164 160g 0.1mg ± 0.2mg 0.1mg 100 mm SAS-224 220g 0.1mg ± 0.2mg 0.1mg 100 mm SAS-314 310g 0.1mg ± 0.3mg 0.2mg 100 mm SPS-363... -

Page 153: Connectors

SPS series (SPS-363, SPS-603) SPS series (SPS-1202, SPS-2102, SPS-4502, SPS-6002) 25.3 CONNECTORS Power supply socket COM 2 connector (additional display or external buttons) COM 1 connector (printer) USB 2, type B (computer) USB 1, type A (keyboard) 25.4 ERROR MESSAGES -Err2- Value beyond zero range -Err3-...

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers