Advertisement

Table of Contents

- 1 Dear Reader

- 2 Safety Rules

- 3 Environmental Conditions

- 4 Obligations of the Operator

- 5 Obligations of Personnel

- 6 Protecting Yourself and Others

- 7 General Remarks

- 8 Controls and Connections

- 9 Before Commissioning

- 10 Preparing for Cutting

- 11 Troubleshooting

- 12 Service Codes Displayed

- 13 Care, Maintenance and Disposal

- 14 Every Start-Up

- 15 Technical Data

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Fronius TransCut 300

- Page 1 / Battery Charging Systems / Welding Technology / Solar Electronics Operating Instructions TransCut 300 Spare Parts List Plasma cutting unit 42,0426,0039,EN 002-11042012...

-

Page 3: Dear Reader

Read the manual carefully and you will soon be familiar with all the many great features of your new Fronius product. This really is the best way to get the most out of all the advantages that your machine has to offer. -

Page 5: Safety Rules

Safety rules DANGER! „DANGER!“ indicates immediate and real danger. If it is not avoided, death or serious injury will result. WARNING! „WARNING!“ indicates a possibly dangerous situation. Death or serious injury may result if appropriate precautions are not taken. CAUTION! „CAUTION!“... -

Page 6: Environmental Conditions

General remarks Before switching on the device, remove any faults that could compromise (continued) safety. Your personal safety is at stake! Utilisation in The device is to be used exclusively for its intended purpose. accordance with „intended purpo- The device is designed exclusively for plasma cutting. se“... -

Page 7: Obligations Of Personnel

Obligations of Before using the device, all persons instructed to do so undertake to: personnel follow the basic instructions regarding safety at work and accident prevention read the „Safety rules“ section and warning notices in these operating instructions, and sign them to confirm that they have understood them and will follow them. - Page 8 Danger from The smoke produced during cutting contains harmful gases and vapours. toxic gases and vapours This smoke contains substances which may, under certain circumstances, cause birth defects or cancer. Hold your head away from any developing smoke or gases. Developing smoke and harmful gases should not be breathed in be sucked out of the working area using appropriate methods.

- Page 9 Danger from All cables and leads must be complete, undamaged, insulated and adequate- mains current ly dimensioned. Loose connections, scorched, damaged or inadequately and cutting dimensioned cables and leads must be repaired/replaced immediately . current (continued) Do not sling cables or leads either around the body or parts of the body. Never immerse the plasma cutting torch in liquids (e.g.

- Page 10 EMC and EMF Supporting measures for avoidance of EMC problems: measures (continued) a) Requirements for the mains connection if electromagnetic interference arises despite correct mains connection, additional measures are necessary (e.g. use a suitable line filter). High-performance devices can affect the quality of mains voltage through their current input.

- Page 11 Specific hazar- Never touch the workpiece or tip of the cutting torch during or after cutting - dous areas risk of burns. (continued) Slag can sometimes fly off workpieces as they cool down. The specified protective equipment must therefore also be worn when reworking workpi- eces, and steps must be taken to ensure that other people are also adequa- tely protected.

- Page 12 Safety measures A device that topples over can easily kill someone. Place the device on a at the installation solid, level surface. The maximum permissible slope is 10°. location and during transport Special regulations apply in rooms at risk of fire or explosion. Observe relevant national and international regulations.

- Page 13 Disposal Do not dispose of this device with normal domestic waste! To comply with the European Directive 2002/96/EC on Waste Electrical and Electronic Equipment and its implementation as national law, electrical equipment that has reached the end of its life must be collected separately and returned to an approved recycling facility Any device that you no longer require must be returned to our agent, or find out about the approved collec- tion and recycling facilities in your area.

-

Page 15: General Remarks

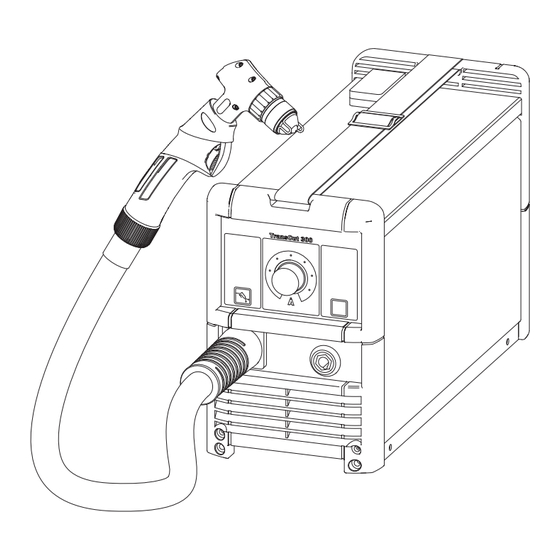

The carrying strap facilitates easy transportation, both in-house or on-site. The TransCut 300 plasma cutting system is particularly well suited for mobile deploy- Application areas ment on construction sites and in installation projects due to its integrated supply of liquid cutting medium and its compact size. -

Page 16: Controls And Connections

Controls and connections General remarks WARNING! Operating the equipment incorrectly can cause serious injury and damage. You should not use the functions described until you have thoroughly read and understood the following documents: These operating instructions all operating instructions for the system components, especially the “Safety rules”... - Page 17 Controls (7) Overtemperature indicator (continued) comes on when the device is too hot (8) Error indicator comes on if a malfunction occurs Connections (10) (11) (13) (12) Fig.3 Connections on the front and rear of the plasma cutting device n° Function (8) Spacer (9) Plasma cutting torch (10) Fill valve with protective cap...

-

Page 18: Before Commissioning

Before commissioning General remarks WARNING! Operating the equipment incorrectly can cause serious injury and damage. You should not use the functions described until you have thoroughly read and understood the following documents: These operating instructions All the operating instructions for the system components, especially the safety regulations The device is designed exclusively for plasma cutting. - Page 19 Commissioning General remarks WARNING! An electric shock can be fatal. If the machine is plugged into the mains electricity supply during installation, there is a high risk of very serious injury and damage. Only carry out work on the machine when the mains switch is in the „O“...

-

Page 20: Preparing For Cutting

Cutting General remarks WARNING! Operating the equipment incorrectly can cause serious injury and damage. You should not use the functions described until you have thoroughly read and understood the following documents: These operating instructions All the operating instructions for the system components, especially the safety regulations CAUTION! Danger of injury or damage from escaping steam and hot pieces of metal being thrown around When you press the torch trigger:... - Page 21 Igniting the CAUTION! Risk of injury and damage from electric shock and escaping plasma jet steam. When you press the torch trigger: hold the cutting torch so that it points away from your face and body do not point the cutting torch at people Cut in straight If possible, move the cutting torch towards you (pulling) over the workpiece.

- Page 22 Hole punching Hole punching is necessary when a piece is to be cut out of a workpiece but the cut is not started across the edge of the workpiece. Important! Hole punching considerably reduces the service life of wearing parts. The tip of the cutting torch should never touch the workpiece.

- Page 23 Replace wearing CAUTION! Danger of burns from hot cutting torch. The cutting torch must be parts allowed to cool down before it can be cleaned or wearing parts are replaced. Switch the device off and allow the cutting torch to cool down. After operating for only a short time the wearing parts and the cutting torch can attain extremely high temperatures.

-

Page 24: Troubleshooting

Troubleshooting General remarks WARNING! An electric shock can be fatal. Before opening up the machine Move the mains switch to the “O” position Unplug machine from the mains Put up an easy-to-understand warning sign to stop anybody inadvertently switching it back on again Using a suitable measuring instrument, check to make sure that electri- cally charged components (e.g. -

Page 25: Service Codes Displayed

Fault diagnosis Excessive formation of „dross“ during the cutting operation (continued) Cause: Cutting speed too fast Remedy: Reduce cutting speed Cause: Cutting speed too slow Remedy: Increase cutting speed Cause: Cutting current too low Remedy: Increase cutting current Cause: Wrong operating mode selected Remedy: Select a different mode Cause:... -

Page 26: Care, Maintenance And Disposal

Care, maintenance and disposal General remarks Under normal operating conditions the charger requires only a minimum of care and maintenance. However, it is vital to observe some important points to ensure the plasma cutting system remains in a usable condition for many years. WARNING! An electric shock can be fatal. -

Page 27: Technical Data

Technical data Special voltage For machines designed for special voltages, the technical data on the rating plate ap- plies. TransCut 300 Mains voltage 230 V Mains voltage tolerance + 10 % / -15 % Mains frequency 50/60 Hz Mains fuse protection... - Page 29 TransCut 300 4,065,023 42,0401,0500 (4x) 42,0300,2767 40,0009,0092 AM2,0201,2144 42,0406,0320 44,0350,2738 45,0200,1233 42,0401,0841 (6x) 40,0006,1042 43,0004,1750 44,0350,2496 44,0350,2501 43,0002,0295 42,0300,2711 42,0402,0101 43,0004,0519 43,0001,1183 42,0201,2367 4,070,856,Z - WDPSNTH 42,0409,3134 42,0300,2721 42,0300,0648 43,0006,0221 42,0300,2720 42,0401,0841 (2x) 42,0300,2724 43,0013,0025 43,0001,1241 42,0300,2722 41,0009,0057 42,0401,0748 (8x)

- Page 30 CTW 300 4,035,838,635 42,0405,0501 42,0401,0936 44,0350,2499 42,0001,3638 32,0405,0360 42,0001,3637 44,0350,2558 42,0407,0273 42,0201,2167 42,0435,0021 44,0350,2494 40,0001,0486* 42,0407,0273 44,0350,2498 43,0009,0046 * gewünschte Länge angeben 42,0407,0245 * Specify the length required * Indiquer la longueur désirée * Indicar la longitud deseada * Indicare la lunghezza desiderat * indicar o comprimento desejado 43,0004,2834 44,0350,2535...

- Page 31 TransCut 300 - plasma cutting device...

- Page 32 TransCut 300 - cutting torch...

- Page 33 TransCut 300 - functional principle...

- Page 34 FRONIUS INTERNATIONAL GMBH Froniusplatz 1, A-4600 Wels, Austria Tel: +43 (0)7242 241-0, Fax: +43 (0)7242 241-3940 E-Mail: sales@fronius.com www.fronius.com www.fronius.com/addresses Under http://www.fronius.com/addresses you will find all addresses of our Sales & service partners and Locations. ud_fr_st_so_00082 012011...

Need help?

Do you have a question about the TransCut 300 and is the answer not in the manual?

Questions and answers