Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for KUHN GA 300 GT

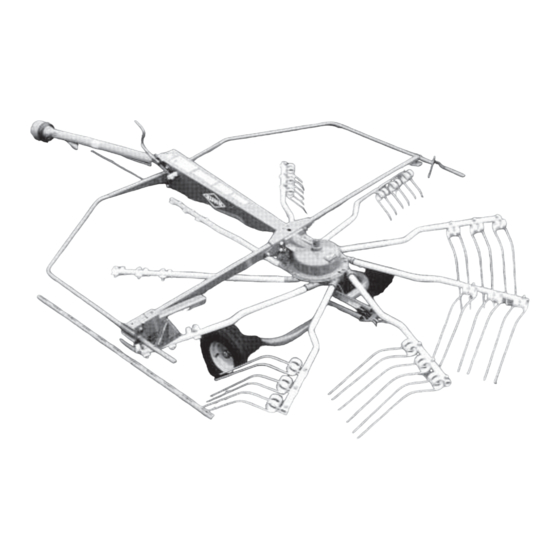

- Page 1 ASSEMBLY / OPERATOR'S MANUAL GA 300 GT GYRORAKE No 95312 A.GB - 01.97...

- Page 2 DEAR OWNER, In buying a KUHN machine you have chosen wisely. Into it have gone years of thought, research and improvements. You will find, as have thousands of owners all over the world, that you have the best that engineering skill and actual field testing can produce. You have purchased a dependable machine, but only by proper care and operation can you expect to receive the performance and long service built into it.

-

Page 3: Table Of Contents

CONTENTS PAGE Safety Safety decals Technical specifications Assembly Attachment - Fitting to tractor - PTO transmission shaft Working position and adjustments Operation Forward speed Swath screen Transport Parking Lubrication Important recommendations Optional equipment Conditions of limited warranty - 1 -... -

Page 4: Safety

These recommendations must be made known to all machine operators. DESIGNATED USE OF THE MACHINE The GA 300 GT Gyrorake must only be used for the work for which it has been designed : raking on the ground and forming windrows of pre-mowed fodder and straw. - Page 5 GENERAL SAFETY RECOMMENDATIONS Before operating the machine, always ensure that tractor and machine are in accordance with work safety and road traffic regulations. BASIC PRINCIPLES 1. In addition to the recommendations given in this manual, legislation on work safety and accident prevention must also be respected.

- Page 6 17. Before traveling on public roads, put the machine into its transport position as instructed in this operator’s manual. 18. Never leave the tractor seat while the machine is operating. 19. Drive speed must be adapted to ground conditions as well as to roads and paths. Always avoid abrupt changes of direction.

- Page 7 POWER TAKE-OFF 1. Use only the PTO shaft supplied with the machine or recommended by the manufacturer. 2. PTO guards must always be in place and in good condition. 3. Check for correct PTO overlap when at work and in transport. 4.

- Page 8 8. Spare parts used must be in accordance with specifications and standards as defined by the manufacturer. Use only genuine KUHN parts ! 9. Before any electric welding is carried out on tractor or attached machine, disconnect generator and battery terminals.

-

Page 9: Safety Decals

SAFETY DECALS THE FOLLOWING SAFETY PICTORIALS HAVE BEEN PLACED ON YOUR MACHINE IN THE AREAS INDICATED. THEY ARE INTENDED FOR YOUR PERSONAL SAFETY AND FOR THE SAFETY OF THE PEOPLE WORKING WITH YOU. THE TEXT SHOWN ON THEM GIVES THEIR PRECISE MEANING. ENSURE THAT THESE PICTORIALS ARE ALWAYS LEGIBLE. - Page 10 - 8 -...

-

Page 11: Technical Specifications

Number of tine arms Number of tines ASSEMBLY To facilitate transport, the GA 300 GT is delivered with tines, tine arms, guards, wheels, wheel column hinge and drawbar unassembled. To assemble these parts, proceed as follows : Mounting the wheels... - Page 12 Fitting the drawbar (photo 2) Attach the pre-assembled drawbar (V) - handle (N) to the chassis (O) using link pins (X) and (Y) and the 4 roll pins (Z) (8 x 40 mm). Do not forget to insert spacer (W) as shown in photo Fitting the tine arms (fig.3 &...

- Page 13 Fitting the tines (fig. 4) The tines (A) must be attached underneath the tine arms (E) so that their fingers are slanting away from the direction of rotation (see arrow). The tines are secured to the arms by using the screw (B) (M12 x 75), the self-locking nut (G) (M12), the washer (C) (13 x 35 x 7), the spring washer (F) and the tine bracket (D).

-

Page 14: Attachment

I) Fitting to tractor (photo 7) The ideal hitch point for the GA 300 GT is on a multi-holed drawbar attached to the tractor lower link arms which should be set at a height of 40 cm (16") from the ground and locked in place. -

Page 15: Pto Transmission Shaft

(3-point attachment yoke) and the other by the hole located in the top plate of the chassis. Replace worn or damaged guards immediately using only genuine KUHN parts. - 13 -... -

Page 16: Working Position And Adjustments

When working, the tractor linkage must always be stabilized from both sideways and vertical movement. The height of the GA 300 GT is correct when the tines brush the ground at the front and all tine arms are approximately horizontal. -

Page 17: Operation

OPERATION The GA must never be operated at PTO speeds above 540 rpm. In general, reduce tractor engine speed until the PTO drive shaft rotates at less then 540 rpm to give gentle crop handling. If the raking is poor, it may be for either of the following reasons : 1. -

Page 18: Swath Screen

SWATH SCREEN Lateral adjustment : There are 4 positions (C). According to crop density, extend or retract the swath screen. Vertical adjustment : There are five positions (H). Generally, the swath screen is secured in the middle position. The other four positions should be used as needed. -

Page 19: Parking

PARKING The stand (X) fixed to drawbar (Z) allows the GA 300 GT to be parked without its tines resting on the ground. PTO shaft (Y) should be rested on its support (V) to avoid damage and deterioration to the yoke due to contact with the ground (photo 15). -

Page 20: Important Recommendations

IMPORTANT RECOMMENDATIONS - Before adjusting or servicing the machine, make sure that the tractor engine is switched off. - After the first few hours of operation, check all nuts and bolts for tightness, especially the tine bolts. - Check tire pressure regularly (approximately 2 bar - 29 psi). - Check regularly that the machine is well lubricated. -

Page 21: Conditions Of Limited Warranty

SOUND LEVELS Sound levels given out by : GA 300 GT Gyrorake Sound levels have been measured in accordance with the measuring methods as defined in : HM Agricultural Inspectorate AGRICULTURAL MACHINERY NOISE Legislation and guidance on methods of testing... - Page 22 1. Normal maintenance such as greasing, maintenance of oil levels, minor adjustments, etc. 2. Transportation of any kind of any KUHN product to and from the place the warranty work is performed. 3. Dealer travel time to and from the machine or to deliver and return the machine from the workshop for repair.

- Page 23 Company and have no right or authority to assume any obligation on their behalf, express implied, or to bind them in any way. KUHN S.A. reserves the right to incorporate any change in design in its products without obligation to make such changes on units previously manufactured.

- Page 24 - N O T E S -...

- Page 27 This machine complies with the safety requirements of the European machinery directive. The Operator should respect all Health and Safety regulations as well as the Highway Code. For your own safety, use only genuine KUHN spare parts. The manufacturer disclaims all responsibilities due to incorrect use or non-compliance with the...

- Page 28 KUHN parts KUHN S.A. 4 Impasse des Fabriques F - 67706 SAVERNE CEDEX (FRANCE) Tél. : + 33 (0) 3 88 01 81 00 - Fax : + 33 (0) 3 88 01 81 03 www.kuhnsa.com - E-mail : info@kuhnsa.com...

Need help?

Do you have a question about the GA 300 GT and is the answer not in the manual?

Questions and answers