Summary of Contents for Triad 600 Series

- Page 1 OPERATIONS MAINTENANCE MANUAL STEAM Boilers SERIES 300 SERIES 600 SERIES 900 SERIES 1600 TRIAD Boiler Systems, Inc. West Chicago, IL 60185 Ph: 630-562-2700 Fax: 630-562-2800 Email sales@triadboiler.com 05/01/05...

-

Page 2: Table Of Contents

TRIAD BOILER SYSTEMS, INC. Operations and Maintenance Manual For Steam Boiler Models TABLE OF CONTENTS: Section I BASIC BOILER WARNINGS Section II STEAM BOILER MODEL INFORMATION Packing Slip Wiring Diagrams Section III STEAM BOILER SYSTEM COMPONENTS Section IV GENERAL OPERATIONS Section V INSTALLATION &... -

Page 3: Section I

Bulletin, Fall, 1997) system is properly maintained. 1) Keep the boiler room clean and clear of all TRIAD Boilers can provide years of dependable unnecessary items. The boiler room should not be service with proper maintenance and by carefully considered a storage area. The burner requires... - Page 4 9) Observe equipment extensively before allowing automatic operating systems to be used without supervision. TRIAD reminds end-users that boilers and boiler rooms may fall under many code and regulatory requirements with local...

-

Page 5: Steam Boiler Model Information

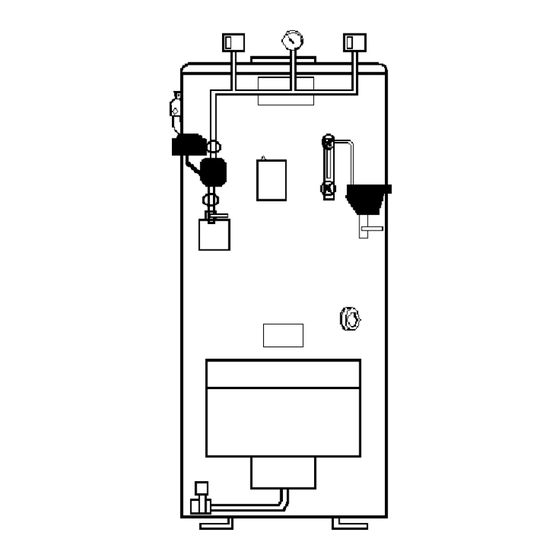

Failure to follow the directions and warnings can result in property damage or serious injury. Each TRIAD Boiler is certified to meet or exceed the requirements of the American Society of Mechanical Engineers (ASME) Code for pressure vessels. Each... - Page 6 Fuel Train -- connects gas or oil supply to burner, controls pressure, contains shut-off valves. Gauge Glass special glass tube displaying internal boiler water level. HEP -- Power draft burner; Note: Category I venting in a TRIAD boiler. L.W.C.O. -- Low Water Cut Off -- controls boiler by monitoring water level. Latent Heat heat associated with phase conversion from liquid to steam.

- Page 7 TRIAD MODULAR STEAM BOILERS Series 300 fires at 399MBH. Series 600 fires at 700MBH Series 900 fires at 1000MBH Series 1600 fires at 1100 1700MBH STANDARD COMPONENTS: Series Number 1600 X4-400 Powerflame Gas Burner X4-700 Powerflame Gas Burner JR30A Powerflame Gas Burner...

-

Page 8: Steam Boiler System Components

TRIAD uses only UL listed controls and UL or AGA the boiler. Scale is a very effective insulator that will listed burners and gas trains. Every boiler is a... - Page 9 The R845A control is wired in series with the Low If the manual reset is tripped OPEN then a serious Water Cut-off controls (LWCO) problem exists with your boiler. The boiler should not Pressuretrols and will activate the boiler control be put back into service until the problem has been circuit only if a low water condition does not exist and identified and corrected...

- Page 10 Indicates boiler vessel operating pressure. Air Separation System -- Removes dissolved gases LIFTING LUGS (optional on some boilers) from recirculating system water, which TRIAD highly recommends for open systems. Lifting point of boiler for ease of installation. Water Treatment System -- Helps ensure water...

-

Page 11: General Operations

With this switch in the ON position, all of the controls on the boiler are live and great caution TRIAD steam boilers may be used in many different must be taken before touching any wiring. Turning applications. The boiler is designed to convert water the ON/OFF switch to OFF means only that the to steam under controlled pressure. - Page 12 SETTINGS NOTE 1 - At times the boiler pressure may rise above the setting of the Operating Pressure On/Off Nominal system design pressure is established by Control - L404A or P7810C, which will open the the pipe size chosen by the design engineer. Typical contacts in the control stopping the burner from systems are 2 to 4 psi.

-

Page 13: Installation & Startup Instructions

Damage claims should be filed immediately the design engineer. with the carrier. Claims of shortages should be filed in writing with TRIAD Boiler Systems, Inc. within five The rise in the connector from the boiler to the (5) days of receipt. - Page 14 FIRST, THE BOILERS avoid ignition sources. Fuel lines should be checked with an appropriate leak detection fluid or procedure. 1. TRIAD recommends that all water connections be Many fuel supply companies can provide assistance completed prior to the connection of fuel and with appliance connections electrical power.

- Page 15 F. NEXT - THE BURNER - All stack and breeching dampers are set The burner should not be connected to the fuel supply line until all testing and leak detection of the - All flue and breeching passages are clear of fuel delivery system is completed any fuel accumulations STOP The burner connections warrant special...

- Page 16 New steam boilers need to be thoroughly cleaned before being placed into normal operations. This process is called Surface Skimming and involves removing any residual oil and contaminates that are floating on the surface of the boiler water. Failure to completely clean a new boiler will result in wet steam production and erratic boiler performance.

-

Page 17: Oem Component Product Data

TRIAD BOILER SYSTEMS, INC. Section VI OEM COMPONENT PRODUCT DATA It is imperative that the documentation in this section be thoroughly reviewed before placing the boiler in operation. These materials include specific operating warnings that must be followed for proper boiler operations. -

Page 18: General Maintenance

All TRIAD boilers are built to meet or exceed the Section IV ASME standard and are registered with WARNING: NEVER operate the boiler without an... - Page 19 and plumbing. If the valve has buildup, fails to Regularly verify that all ventilation, combustion air operate or leaks, replace the valve only with an openings and louvers are clean and free of debris. ASME approved steam relief valve of both the same pressure and BTU/hr rating.

- Page 20 The waterside and fireside of the boiler should be If the boiler is not to be returned to service soon, dry inspected to determine their condition. Boilers out of the inside with forced warm air and minimize t service for extended periods (more than seasonal) exposure to humidity and moisture..

- Page 21 carefully open the safety relief valve) before Check all venting and breeching for leaks. performing maintenance Have the water retested and the water treatment 4. Disconnect the fuel supply from the burner and system serviced. the power to the boiler and all its accessories. If required, have the boiler inspected by an 5.

- Page 22 TRIAD BOILER SYSTEMS, INC. Section VIII TROUBLESHOOTING CAUTION: Start with a review of the power to the boiler is present. Check the fuse(s)! OEM equipment information found in Turn ON the power. Section VI of this manual and the burner manufacturer's manual -- note all Check to see if the power switch on the burner s WARNINGS.

- Page 23 C. IF - NO CALL FOR HEAT control. Refer to the heading checkout for trouble shooting assistance. WITH AN R7810C PRESSURETROL D. THERE IS A CALL FOR HEAT -- BUT THE The R7810C control requires line voltage power to BURNER WON T FIRE operate.

- Page 24 Pressure limit is set lower than the Safety Pressure circulation system that is unable to carry away the High Limit. If so, the L404A control may be defective BTU/hr output of the boilers. The causes can range and should be replaced from misadjusted controls to sensor location.

- Page 25 TRIAD boilers and burners are matched for optimum performance. Difficulty in setting the burner or in C. Open the skim tap shut-off valve carefully to...

- Page 26 BOILER LEAKS It is possible to re-expand the tubes in place, but this WARNING: If the pressure vessel should only be attempted by a NBBI registered "R" should develop a leak, repairs should (repair) stamp technician. The repaired shell must by made only by an ASME certified be pressure checked and reinspected before the shop.

- Page 27 TRIAD Boiler Systems, Inc. Steam Systems Check Sheet (Daily check of gauge glass and blow-down recommended) Site/System: Boiler Model: Date: - to - Week 1: Week 3: Monthly: Boiler operation. Boiler operation. Boiler operation. Normal burner light-off. Normal burner light-off.

- Page 28 WAYS TO PREVENT WET STEAM: Follow the near boiler piping suggestions. The steam header MUST be at least 24 above the boiler. Connection to the supply header should be through the top of the header. Do not alter the steam tap at the rear of the boiler. Skim the surface multiple times before placing boiler into normal service.

Need help?

Do you have a question about the 600 Series and is the answer not in the manual?

Questions and answers