Table of Contents

Advertisement

Quick Links

intelligent motion systems, inc.

Excellence in Motion

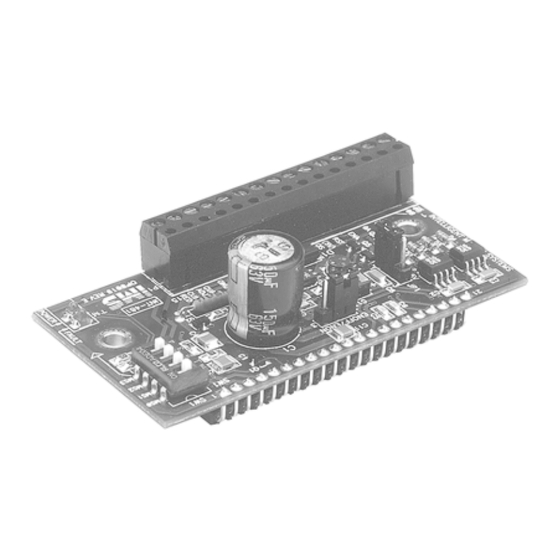

INT-481

INTERFACE BOARD FOR THE IM481H DRIVER

QUICK REFERENCE

370 N. MAIN ST., PO BOX 457, MARLBOROUGH, CT 06447

PH: (860) 295-6102, FAX: (860) 295-6107

Internet: www.imshome.com, E-Mail: info@imshome.com

I N T - 4 8 1 Q u i c k R e f e r e n c e G u i d e

The primary function of this Quick Reference Guide is to aquaint

the user with the specifications, basic wiring and configuration of

the INT-481 Interface Board for the IM481H Driver. More

information is available on both products in the full IM481H

product manual saved in Acrobat PDF format on the IMS Product

CD, shipped with the product. It also may be downloaded from

the IMS web site at http://www.imshome.com.

N o t e s A n d W a r n i n g s

Please observe the following when handling, connecting and using

your INT-481 Interface Board. Failure to observe these points may

result in damage to the Interface Board or the IM481H Driver. All

warranty and disclaimer information is located in the full product

manual on the CD and should be referenced for more information.

WARNING! The INT-481 Interface Board and IM481H Driver

components are sensitive to Electrostatic Discharge (ESD). All

handling should be done at an ESD protected workstation.

WARNING! Hazardous Voltage Levels may be present if you are

using an open frame power supply to power the INT-481 Interface

Board and IM481H Driver.

WARNING! Ensure that the Power Supply output voltage does not

exceed the maximum input voltage of the IM481H Driver.

WARNING! Do not operate the IM481H Driver without a

Current Adjustment Resistor! If you are installing the INT-481

Interface Board the resistors may be added to it.

A resistor MUST be placed between the Current Adjust Input (Pin

14) and ground (Pin 13) to keep the IM481H Driver, the INT-481

Interface Board and/or motor in a safe operating range.

WARNING! Do not connect or disconnect the motor leads or the

AC power supply with power applied.

Please see the motor and driver documentation for other warnings

and notes.

E l e c t r i c a l S p e c i f i c a t i o n s *

Opto Supply

Isolated Inputs .......................................... +5 ........................ +40 ........ V

Input Forward Current

Isolated Inputs ............................................ 5 ............................ 1 5 ....... m A

Opto Input Forward Voltage

Isolated Inputs .......................................................... 1 . 5 ...... 1 . 7 ......... V

Reverse Breakdown Voltage

Isolated Inputs ............................................ 5 ............................................... V

Signal Output Current

Full Step, Fault ............................................................................ 2 0 ....... m A

Drain Source Voltage

Full Step, Fault .......................................................................... 1 0 0 ........ V

Drain Source Resistance

= 25mA) .......................... 6 . 5 .......................... Ω

Full Step, Fault, I

DS

* All test data was taken at 25°C and +V = 45 VDC.

For More Information:

See the complete IM481H Product Manual

on the IMS Product CD or at www.imshome.com

Revision 061605

TM

TM

M I N

T Y P

M A X U N I T

I N T - 4 8 1 P 1 C o n n e c t o r P i n A s s i g n m e n t

Pin Name

Pin #

—

—

1

Phase B

Phase B Output

2

Phase B

Phase B Output

—

—

3

Phase A

Phase A Output

4

Phase A

Phase A Output

Enable

When this input is HIGH, motor phases are energized.

5

6

Reset

When LOW, this input will Reset the Driver.

7

Opto Supply

+5 to +24 VDC external Optocoupler power supply.

This input changes the direction of the motor. The physical

Direction

8

direction depends on the connection of the motor windings.

A positive going edge on this input advances the motor one

increment. The size of the increment is dependent on the

Step Clock

9

Microstep Select Inputs.

This Output indicates a short circuit has occurred or a low

Fault

10

was detected on the Fault Input. This Output is active HIGH.

This Output indicates when the driver positions the motor

one Full Step. This output can be used to count the number

11

Full Step

of Full Steps the motor has moved regardless of the

number of Microsteps. This output is active HIGH.

12

+V

+12 to +48 VDC Motor Power Supply.

13

Ground

Power Supply Ground.

Current

Phase Current Adjustment Input. A voltage applied to this

14

Adjust

Input sets the peak Phase Current of the motor.

Phase Current Reduction Input. A resistor connected

between this pin and Pin 14 (if used to set motor current)

Current

15

will proportionately reduce the current in both windings

Reduction

approximately 0.5 seconds after the last positive edge of

the Step Clock Input.

O u t p u t C u r r e n t A d j u s t / C u r r e n t R e d u c t i o n *

The INT-481 utilizes the IM481H's internal current source to

adjust the Output Current of the IM481H. To calculate both the

Run Current and the Reduced Current** (hold) refer to the

IM481H instruction manual. The figure below shows the resistor

connections for both run and hold currents.

21

ENOFF/ENON

1

JP2

Current Adjust Resistor

1/8 W 1% W

Pin 13

*

When connecting both the current reference and current reduction resistors,

connections should be made as short as possible to minimize the noise coupled

into the driver.

** WARNING! DO NOT install the Current Reduction resistor when the JP2 jumper is

in the "ENON" position. See JP2 under "Isolated Inputs".

I s o l a t e d I n p u t s

+5VDC Optocoupler Supply

Pin 7

Step Clock Pin 9

CW/CCW Direction Pin 8

Enable/Disable Pin 5

Reset Pin 6

Typical Opto Isolated Inputs

JP1: If the shunt is placed on the "OPTO" side of the jumper the

power for the Opto Isolators must be provided by the user at Pin

7 on the P1 connector. If the shunt is placed on the "+5V" side of

the jumper then the Opto Isolators will be powered by the

on-board supply and electrical isolation between the inputs and

the drive power will be eliminated.

JP2: If the shunt is placed on the "ENON" side of the jumper then

the drive outputs will be automatically disabled approximately 0.5

seconds after the last step clock input.

NOTE: In this mode the current reduction resister MUST NOT be

used or it will cause erratic operation of the driver. If the shunt is

placed on the "ENOFF" side of the jumper then a current reduc-

tion resister can be used to set the level of current in the motor

after the last step clock input.

21

JP1 And JP2 Jumpers

Description

1

SW1

MS0

MS1

3

MS2

MS3

GRN

RED

LED1

Reduction Adjust Resistor

1/8 W 1% W

Pin 15

Pin 14

+5V

OPTO/+5V

JP1

1

SW1

ENOFF/ENON

MS0

MS1

1

3

MS2

JP2

MS3

ENOFF/ENON

GRN

1

3

RED

LED1

JP2

Advertisement

Table of Contents

Summary of Contents for Intelligent Motion Systems INT-481

-

Page 1: Quick Reference

Interface Board the resistors may be added to it. A resistor MUST be placed between the Current Adjust Input (Pin OPTO/+5V 14) and ground (Pin 13) to keep the IM481H Driver, the INT-481 +5VDC Optocoupler Supply Pin 7 Interface Board and/or motor in a safe operating range. - Page 2 ** The hardware items A, B, C, E, F, H, are supplied with the H-481 Heat Sink Kit LED1 but not with the INT-481 Interface Board. NOTE: The torque specification for the #6-32 INT-481 and IM481H mounting screws is 5.0 - 7.0 lbs-in. MSEL Switch Shows 50 Microsteps/Step Selected...

Need help?

Do you have a question about the INT-481 and is the answer not in the manual?

Questions and answers