Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

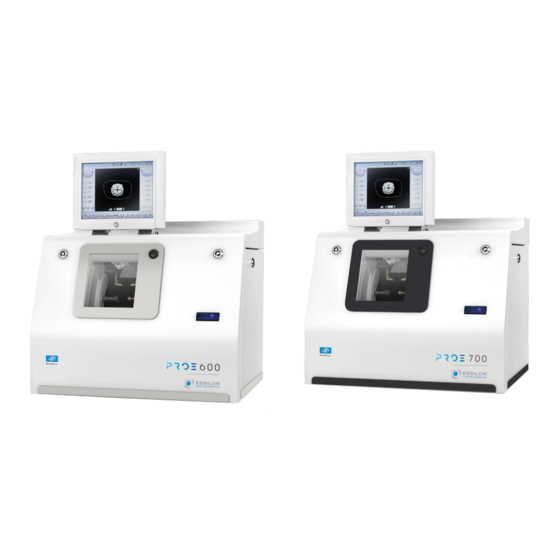

Summary of Contents for Essilor Pro-E 700 edger

- Page 1 User Manual...

-

Page 3: Table Of Contents

> C ANUAL ONTENTS ONTENTS NTRODUCTION I. F IRST STEPS WITH 1. Descriptive diagrams 2. Using the edger a. Turning on the edger b. Switching off the edger c. Using the touch screen and keypads d. Edging screen II. E DGING A LENS 1. - Page 4 > C ANUAL ONTENTS 12. Perform a “Super Chamfer” (Pro-E 700) 13. Perform a Chemistrie TM job (Pro-E 700) a. Prerequisites b. Preparing a Chemistrie TM job c. Prepare the Chemistrie TM lenses d. Cut a Chemistrie lens 14. Carry out a Half Jacket job (Pro-E 700) a.

- Page 5 > C ANUAL ONTENTS 5. Statistics and technical log a. Edger cycles b. Technical log and errors 6. Maintaining and cleaning the edger a. Precautions required b. Clean the door, the “small tools” module and the wheels c. Dress the wheels ECHNICAL DATA 1.

-

Page 7: Introduction

> I ANUAL NTRODUCTION NTRODUCTION To take full advantage of the features on your Pro-E 600 edger, we encourage you to read through the entire manual. You need to have at least memory version: • V 3 for Pro-E 600, •... -

Page 9: First Steps With Pro -E

I. F IRST STEPS WITH... - Page 10 > I. F ANUAL IRST STEPS WITH Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 11: Descriptive Diagrams

> I. F ANUAL IRST STEPS WITH This chapter contains all the information relating to the first use of the edger: • Description of the edger p.11) • Using the device p.13) 1. D ESCRIPTIVE DIAGRAMS This section consists of descriptions and lists of accessories. USB plug Trough Screen... - Page 12 > I. F ANUAL IRST STEPS WITH Power socket Solenoid valve socket Pump socket (tank + pump) / Solenoid valve socket (town) Accessories Stylus Posiblock removal pliers Triangular key White dressing stone for finishing wheel Square dressing stone for polishing wheel Transport wedges to be kept Accessory box Use :...

-

Page 13: Using The Edger

> I. F ANUAL IRST STEPS WITH • Wastewater evacuation pipe with attachment ring • 2 connectors to clip onto two internal water pipes and connect to the rinsing kit 2. U SING THE EDGER In this section, you will find all the information concerning the following: •... -

Page 14: Using The Touch Screen And Keypads

> I. F ANUAL IRST STEPS WITH > The edger will switch off. Extended period of non-use For a prolonged period of non-use (a few days), it is preferable to turn off the edger using the main switch. It must be turned off at least once a week. c. -

Page 15: Edging Screen

The alphanumeric keypad is displayed to save or search for jobs. • Job ID • Job reference (alphanumeric characters) • Collection list (when the edger is connected to a Essilor range tracer) • Job list & d. Edging screen Work screen indicator... - Page 16 > I. F ANUAL IRST STEPS WITH Information on the shape Size increase/reduction Work area Turning off the product/edging screen Job call: Tracer menu Actions available for the current screen Start the edging cycle Detailed functions For more information, consult the section Edging a lens > Work environment of the edger > Captioned screen.

-

Page 17: Edging A Lens

II. E DGING A LENS... - Page 18 > II. E ANUAL DGING A LENS Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 19: Edger Working Environment

> II. E ANUAL DGING A LENS This chapter describes the work environment of the edger and the procedures for edging any type of lens: • Edger working environment p.19) • Perform a Beveling p.24) • Beveling for a high-base frame p.32) •... -

Page 20: Menu Screen

> II. E ANUAL DGING A LENS • a. Menu screen Lens material ◦ Plastic lens -index 1.5 & ◦ Polycarbonate lens ◦ Medium or high index plastic lens - index > 1.5 ◦ Trivex lens ◦ Tribrid lens The configuration of the edging cycles depends on the type of material. An incorrect choice may result in material damage. - Page 21 > II. E ANUAL DGING A LENS ◦ Flat-edge finish ◦ Mixed job Drilling ◦ Drilling enabled ◦ Drilling disabled Edging mode ◦ Automatic mode The finish parameters are automatically calculated according to the information acquired when tracing the frame and feeling the lens. ◦...

-

Page 22: Calling Up A Shape

> II. E ANUAL DGING A LENS ◦ No chamfering Size reduction/increase (mm) Manual lens clamping Press and hold to close the lens clamp shafts manually. Start the edging cycle The door closing and lens clamping are automatic. Function also available via the “cycle start” button on the front surface. Always browse from left to right: depending on your selection, certain menus will be available while others will not. - Page 23 > II. E ANUAL DGING A LENS Check that the posiblock holder and the stop correspond to the posiblock used. Otherwise, you will need to remove them from the lens clamp shafts and replace them with the tools matching the diameter of the posiblock.

-

Page 24: Perform A Beveling

> II. E ANUAL DGING A LENS > As the lens is felt, its shape appears on screen. The double tracing represents the profile of the front surface of the shape (inner shape) and its rear surface (outer shape). > In the case of edging mode selection: •... -

Page 25: Automatic Beveling

> II. E ANUAL DGING A LENS ◦ a general modification of the bevel curve p.29) ◦ a modification at a point of the bevel curve p.30) ◦ a displacement of the bevel curve p.31) • You can consult the description of the customized bevel screen p.26) a. -

Page 26: Legend Screen For Customized Bevels

> II. E ANUAL DGING A LENS > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. -

Page 27: Customized Beveling

> II. E ANUAL DGING A LENS ◦ Frame rim tracking: the bevel tracks the groove precisely, according to the data obtained on frame tracing. Lens thickness ◦ Maximum lens thickness - represented by the white square along the shape. ◦... - Page 28 > II. E ANUAL DGING A LENS EVEL RAME DVANTAGES Classic Lens for which the front surface Makes it possible to do an aesthetically pleasing base is approximately equal to the job. The lens material does not protrude beyond frame base. the front of the frame.

-

Page 29: Modifying The Bevel Curve

> II. E ANUAL DGING A LENS Select the type of customized bevel you want to do. To avoid reproducing defects when tracking a frame rim, check that the frame groove is in perfect condition and that the hinges are properly closed. All groove imperfections will be reproduced. Press to adjust the distribution value if required. -

Page 30: Modifying The Bevel Curve At A Particular Point

> II. E ANUAL DGING A LENS The curve cannot be moved more than the minimum distance between the front and rear surfaces observed on the bevel before the modification. > The position of the bevel as well as the distances between the crest of the bevel and the front and rear surfaces of the lens are displayed in the zoom window at the position of the cursor. -

Page 31: Displacing The Bevel Curve

> II. E ANUAL DGING A LENS • Press to move it towards the rear surface of the lens. The curve cannot be moved more than the minimum distance between the front and rear surfaces observed on the bevel before the modification. >... -

Page 32: Perform A High-Base Bevel

> II. E ANUAL DGING A LENS Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. > The edging screen for the second lens is displayed. -

Page 33: Captioned Screens

> II. E ANUAL DGING A LENS a. Captioned screens High-base bevel screen “front surface monitoring” Work area Image of the shape to be edged: Frame shape at bottom of groove Bevel trajectory on rear surface Bevel trajectory on rear surface if the lens used is too thin to achieve the desired finish. Cursor movement The cursor is represented by the square located along the shape. -

Page 34: High-Base Beveling

> II. E ANUAL DGING A LENS Frame base Lens base Bevel Base_Range of values of the lens base necessary for the frame If the lens base used is out of range: the range values are shown in red. Reminder of size reduction/increase applied to lens diameter Window showing the bevel trajectory on the lens section Centre of the flat side of the bevel Front surface/rear surface of lens... - Page 35 > II. E ANUAL DGING A LENS Choose to create or not create a small or large chamfer on the rear surface of the lens. “Super Chamfer” is not available for the high-base bevel finish. For more information, consult the section Edging a lens > Perform a polishing and Edging a p.67) lens >...

- Page 36 > II. E ANUAL DGING A LENS High-base bevel in “automatic trajectory” mode Press to select the bevel in “automatic trajectory ” mode. > The following screen will appear: Press the buttons on the right of your screen to modify the width of the flat side of the bevel. >...

- Page 37 > II. E ANUAL DGING A LENS Move the cursor along the shape to see the bevel profile in the zoom window. > The edger calculates the shelf bevel value to be applied between each of the four points in each area. >...

- Page 38 > II. E ANUAL DGING A LENS > The following screen will appear: Press the buttons on the right of your screen to modify the width of the flat side of the bevel. > The result can be viewed in the zoom window. Press the buttons to modify the shelf bevel value at each point of the shape in each area:...

- Page 39 > II. E ANUAL DGING A LENS Move the cursor along the shape to see the bevel profile in the zoom window. > The edger calculates the shelf bevel value to be applied between each of the four points in each area. >...

-

Page 40: Perform A Step Bevel

> II. E ANUAL DGING A LENS 4. P ERFORM A TEP BEVEL A step bevel is strongly recommended for a high-base sports frame or a safety frame. The step bevel finishing is active and available only if the tool is installed on the “small tools” module p.168) For more information, refer to the section Maintenance servicing>... -

Page 41: Captioned Screens

> II. E ANUAL DGING A LENS a. Captioned screens Automatic trajectory step bevel screen. In this screen, the trajectory on the lens section cannot be configured: it is calculated automatically. This calculation harmonises as best as possible, the lens base, the base of the frame and the shape. Work area Image of the shape to be edged: Frame shape at bottom of groove... -

Page 42: Perform A Step Bevel

> II. E ANUAL DGING A LENS Bevel tilt Front surface tracking step bevel screen Front surface tracking value The value of front surface tracking must be between 0 mm and 1.3 mm. This value is definable only in the “front surface tracking” screen. Frame base Lens base Bevel Base_Range of values of the lens base necessary for the frame... - Page 43 > II. E ANUAL DGING A LENS Press to select the Step bevel. The button appears grayed if the step bevel wheel was not mounted beforehand: Select lens material. Select the type of cycle. Choose or not to chamfer your lens. If you have a pro-E 700, it is to recommend to carry out a “Super Chamfer”...

- Page 44 > II. E ANUAL DGING A LENS Step bevel in “automatic trajectory” mode Press to select the bevel in “automatic trajectory ” mode. > The following screen will appear: Press the buttons on the right of your screen to modify the width of the flat side of the bevel. >...

- Page 45 > II. E ANUAL DGING A LENS • Lower • Mid-lower Move the cursor along the shape to see the bevel profile in the zoom window. > The edger calculates the shelf bevel value to be applied between each of the four or eight points of each area.

- Page 46 > II. E ANUAL DGING A LENS Press the “cycle start” button (front face) or > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens.

- Page 47 > II. E ANUAL DGING A LENS • Mid-nasal • Lower • Mid-lower Move the cursor along the shape to see the bevel profile in the zoom window. > The edger calculates the shelf bevel value to be applied between each of the four or eight points of each area.

- Page 48 > II. E ANUAL DGING A LENS Press the buttons on the right of your screen to modify the value of front surface tracking. > The result can be viewed in the zoom window and the display window of the bevel trajectory on the lens section.

-

Page 49: Grooving

> II. E ANUAL DGING A LENS Press the “cycle start” button (front face) or > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. -

Page 50: Automatic Grooving

> II. E ANUAL DGING A LENS a. Automatic grooving Call up the desired shape located on the tracer or on the job management program. > The shape is displayed on the edger work screen. > After tracing a pattern, demo lens or re-cut lens, without any drilling settings: •... -

Page 51: Customized Groove Legend Screen

> II. E ANUAL DGING A LENS Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. > The edging screen for the second lens is displayed. -

Page 52: Customised Grooving

> II. E ANUAL DGING A LENS ◦ Minimum lens thickness - represented by the red square along the shape Cursor movement The cursor is represented by the green square along the shape. To move it, select it directly or use the buttons. - Page 53 > II. E ANUAL DGING A LENS ROOVE RAME DVANTAGES Standard Lens for which the rear surface Minimises the risks of the nylon thread coming out. groove base is not as high as the front surface base. Standard Thin lens Makes it possible to balance out the groove when thin groove lenses are used.

-

Page 54: Modifying The Groove Curve

> II. E ANUAL DGING A LENS Press > The edging cycle starts. > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. -

Page 55: Modifying A Point In The Groove Curve

> II. E ANUAL DGING A LENS > When the edging cycle is finished, the retouch screen is displayed. Press to release the lens. If necessary, retouch the lens. Otherwise, start edging the second lens. Select the lens directly on the screen, on the left or right of the work area. -

Page 56: Displacement Of The Groove Curve

> II. E ANUAL DGING A LENS f. Displacement of the groove curve The displacement of the groove curve enables you to move the groove without modifying its curve or perimeter. Press from the customized groove finish screen. > You will access the trajectory modification screen. Press to select the displacement of the curve. -

Page 57: Do A Mixed Job

> II. E ANUAL DGING A LENS Press to select the flat-edge finish. Select the type of cycle. Choose whether or not to polish and/or chamfer your lens. For more information, consult the section Edging a lens > Perform a polishing and Edging a p.67) lens >... -

Page 58: Legend Screens

> II. E ANUAL DGING A LENS To do a mixed finish, you need to define the points between which the two types of finish will be done. Only the customized mode is thus accessible. a. Legend screens Main screen for mixed jobs Modes available for a mixed finish ◦... - Page 59 > II. E ANUAL DGING A LENS ◦ Groove finish ◦ Flat-edge finish Zoom window Display of the distance from the edges of the lens to the position of the cursor. Position of the center of the groove or bevel Value expressed in mm ('Front surface tracking' mode) or in % ('Distributed mixed finish' mode).

-

Page 60: Configuring The Mixed Finish

> II. E ANUAL DGING A LENS Enable area delimitation on the touch screen Modify the selected value Legend of colours delimiting the shape areas: (pink) Bevel finish (yellow) / (orange) Groove finish (in the case of a Groove - Groove mixed job, the colours make it possible to differentiate grooves with different parameters) (black) Flat-edge finish b. - Page 61 > II. E ANUAL DGING A LENS > The area definition screen is displayed on a 1:1 scale. You can thus refer to a sample lens placed on the screen. Select the finish you want in area 1, then area 2. Press the button to unlock an area delimitation point.

-

Page 62: Perform A Drilled Job

> II. E ANUAL DGING A LENS 8. P ERFORM A RILLED JOB You have the option of adding or modifying drillings on a job. The function can be accessed on the edging screen: Carry out: • a short click on (when the job does not show drilling), •... -

Page 63: Automatic Drilling

> II. E ANUAL DGING A LENS • Drilled groove • Drilled mixed finish You have the option of adding or modifying drillings on a job. The function can be accessed on the edging screen: Carry out: • a short click on (when the job does not show drilling), •... -

Page 64: Legend Screen For Customized Drilling

> II. E ANUAL DGING A LENS For more information, consult the section Edging a lens > Perform a polishing and Edging a p.67) lens > Perform a chamfering p.67) Press the “cycle start” button (front face) or > The door closes, the lens is clamped and then felt. >... -

Page 65: Customized Drilling

> II. E ANUAL DGING A LENS Select the drilling points ◦ Nasal side ◦ Temporal side ◦ All drilling points Modify the selected value Modify the diameter ◦ Diameter value (mm) ◦ Difference between the initial value and the modified value Modify the drilling angle ◦... - Page 66 > II. E ANUAL DGING A LENS For more information, consult the section Edging a lens > Perform a polishing and Edging a lens > Perform a chamfering p.67) Press the “cycle start” button (front face) or > The feeling cycle starts. >...

-

Page 67: Perform A Polishing

> II. E ANUAL DGING A LENS 9. P ERFORM A OLISHING Press the button to activate/deactivate polishing. ENS MATERIAL VAILABLE OPTIONS The polishing option is pre-selected and is strongly recommended by the manufacturer to prevent small cracks. Make sure you select the correct type of material for MHI (> 1.5) or Tribrid lenses and never polish a lens of this type without water. -

Page 68: Perform A Retouching

> II. E ANUAL DGING A LENS • Thickness at the edge of the lens ENS THICKNESS VAILABLE OPTIONS > 1.2 mm between 1 and 1. 2 mm < 1 mm • Distance between the edge of the groove and the edge of the lens ISTANCE VAILABLE OPTIONS >... - Page 69 > II. E ANUAL DGING A LENS Diameter modification Manual lens clamping Retouch launch Differences with the edging screen The edging screen is different to the retouch screen through: • the presence of the posiblock • no frame thickness • the “departure cycle”...

-

Page 70: Perform A "Super Chamfer" (Pro-E 700)

> II. E ANUAL DGING A LENS > The edging screen for the second lens is displayed. > All finishes chosen and the modifications made are kept. The retouch done on the first lens is automatically saved for the edging of the second lens. 12. - Page 71 > II. E ANUAL DGING A LENS Without the “Super Chamfer” With the “Super Chamfer” The “Super Chamfer” allows you to break the ridge of the lens on the rear surface at a defined distance and configure it in relation to: •...

-

Page 72: Perform A Chemistrie Tm Job (Pro-E 700)

> II. E ANUAL DGING A LENS Availability of the “Super Chamfer” by finish INISHING WHEEL Not available 13. P -E 700) ERFORM A HEMISTRIE is a technical solution that, through a magnet system, allows you to superimpose a pair of additional “CLIP” lenses on the “ophthalmic” lenses initially mounted on the customers’ frames. Near vision Blue light Solar... -

Page 73: Preparing A Chemistrie Tm Job

> II. E ANUAL DGING A LENS b. Preparing a Chemistrie TM job The Chemistrie screens are accessible via the “drilling” menu in the preparation screen for a drilled job. For more information, consult the section Preparing a drilled job. p.128) Carry out: •... - Page 74 > II. E ANUAL DGING A LENS The button changes 2/ At the second mount, the shape of the magnet becomes round: The button changes Press for a few seconds on the setting value to be modified according to the selected shape: Square Circle Height...

- Page 75 > II. E ANUAL DGING A LENS > The numeric keypad is displayed. You can also use the buttons to decrease or increase the selected value. Press to access the binocular view. > The following screen will appear: Press to confirm the job. Chemistrie TM (clip) lenses Press to configure the Chemistrie lens...

- Page 76 > II. E ANUAL DGING A LENS Press to select the Chemistrie clip “SUN”. > The clip is selected: > The tool bar appears: Press to configure the size increase (or size decrease=> less frequent) applied to the shape of the ophthalmic lens to configure the shape of the Chemistrie lens Press a few seconds on the setting to be modified: =>...

-

Page 77: Prepare The Chemistrie Tm Lenses

> II. E ANUAL DGING A LENS > Your job has been configured. You can prepare other Chemistrie jobs if necessary Press to validate the Chemistrie job c. Prepare the Chemistrie TM lenses This procedure is valid for the clips, =>... -

Page 78: Cut A Chemistrie Lens

> II. E ANUAL DGING A LENS For more precision, you can verify it using the tracer, by using the centering function. Position the posiblock in the center of the lens. > The lenses are ready to be edged d. Cut a Chemistrie lens Press to call up the desired shape located on the tracer. - Page 79 > II. E ANUAL DGING A LENS Place the lens in the posiblock holder. Place the metal peg of the posiblock upwards and the positioner downwards: a magnet is used to hold the lens in position on the axis. You can clamp the lens manually by pressing Make sure you move your hand well away before you start the edging cycle.

- Page 80 > II. E ANUAL DGING A LENS Place the two lenses (prepared beforehand) in the posiblock holder. Place the metal peg of the posiblock upwards and the positioner downwards: a magnet is used to hold the lens in position on the axis. You can clamp the lens manually by pressing Make sure you move your hand well away before you start the edging cycle.

-

Page 81: Carry Out A Half Jacket Job (Pro-E 700)

> II. E ANUAL DGING A LENS For the clips , by default, edging is configured as follows: Material Finishing wheel Edging mode Type of cycle Polishing Press to start the cycle. Re-start the procedure for as many times as you have Chemistrie clips to perform. - Page 82 > II. E ANUAL DGING A LENS Press to select the Half Jacket finish. Select lens material. The cycle is automatically configured in “Customized”. Choose to perform a “super chamfer” on the rear surface of the lens. It is strongly recommended to perform a “Super Chamfer” as part of a “Half Jacket”...

- Page 83 > II. E ANUAL DGING A LENS Front surface tracking step bevel screen Work area Image of the shape to be edged Access to step bevel definition screen Zoom window Represents the bevel profile at the position of the cursor. Width of the flat side of the bevel The value of the flat side of the bevel must be between 0.4 mm and 2 mm.

- Page 84 > II. E ANUAL DGING A LENS Transition from 4 to 8 shelf bevel values. Transition from 8 to 4 shelf bevel values. Transition into free shelf-bevel creation mode (Half Jacket specific) Navigation ◦ Stop the cycle ◦ Back to the main edging screen ◦...

- Page 85 > II. E ANUAL DGING A LENS : Addition of points to outline the shelf bevel trajectory. > When the button is selected, it changes: : Deletion of points to outline the shelf bevel trajectory. > When the button is selected, it changes: To add or remove points, the shape must be selected beforehand.

- Page 86 > II. E ANUAL DGING A LENS Create the step bevel trajectory From the customized screen for the step outline, press to select the shape, then to add points. > The following screen will appear: Press and hold the stylus to set the first point of the step bevel trajectory. >...

- Page 87 > II. E ANUAL DGING A LENS > An audible signal informs you that the second point is registered. > The segment is displayed in blue within the work space and in the display window on scale 1. If you raise the stylus, the bevel curve is displayed in green, it is calculated automatically. You can redo this trajectory by setting the third point using the stylus.

- Page 88 > II. E ANUAL DGING A LENS Press and hold with the stylus to set the other points of the step bevel trajectory, one after the other. With each audible signal, raise the stylus a few seconds before setting a new point by pressing and holding It is preferable to create a greater number of points at the angles to gain precision, if you wish to adjust more precisely the bevel trajectory using the zoom.

- Page 89 > II. E ANUAL DGING A LENS Increase a particular point Press to switch into Zoom mode. Press and hold the stylus on the point of the shape that you want to see more precisely. Press on the Frame shape at bottom of groove in white ( >...

- Page 90 > II. E ANUAL DGING A LENS When the enlargement is at a maximum, the icon is grayed Press again to shrink the area. Enlarge a defined area Press to switch into Zoom mode. Using the stylus press on a point of the shape. Move the stylus over the shape.

- Page 91 > II. E ANUAL DGING A LENS > The area is displayed: Adjust the step bevel trajectory Press to select the shape: > The points of reference appear, the shape can be modified. Using the stylus press on a point of the shape. Move the stylus over the shape.

- Page 92 > II. E ANUAL DGING A LENS > The defined segment appears in yellow. Press and hold the stylus to set the end of the segment. > An audible signal sounds 3 times. The segment appears in green. Move the segment using the stylus. When the trajectory passes by the closed area: •...

- Page 93 > II. E ANUAL DGING A LENS Raise the stylus to validate the modification. > An audible signal sounds 3 times. > The segment becomes blue (only the points of reference set by you will appear), the machine recalculates the trajectory of the curve => the trajectory becomes green. The modification is validated.

-

Page 94: Finalize The Step Bevel Settings In "Front Surface Follow-Up" Mode

> II. E ANUAL DGING A LENS Press to confirm the shelf bevel. b. Finalize the step bevel settings in “front surface follow-up” mode Configure the flat side of the bevel and the front shelf bevel of the bevel step. Press the buttons on the right of your screen to modify the width of the flat side of the bevel. - Page 95 > II. E ANUAL DGING A LENS > The result can be viewed in the zoom window and the display window of the bevel trajectory on the lens section. Press systematically to tilt of the bevel (mounting aid). > The bevel tilt is selected >...

-

Page 96: Modify The Shape On Essibox

> II. E ANUAL DGING A LENS > The edging screen for the second lens is displayed. All finishes chosen and the modifications made are kept. If the test is not mounted correctly in the frame, go to Essibox to modify the shape. c. - Page 97 > II. E ANUAL DGING A LENS You can visualize the job by pressing Adjust the display to a scale of 1 to superimpose the demo lens on the shape. Press to return to the “M’Eye Touch” creative modification screen. >...

- Page 98 > II. E ANUAL DGING A LENS Press to select the point from which you wish to modify the shape Press to select the “angle” tool : Reference point: point from which the shape modification will be started. : Check-points: points allowing you to modify the curve. Modify the shape to ensure optimal mounting in the Half Jacket frame.

- Page 99 > II. E ANUAL DGING A LENS • Large wheels • Drill bit Press to confirm the new shape. Recall the shape on the edger to make a new test lens. Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 100: M'eye Sign Feature (Pro-E 700)

> II. E ANUAL DGING A LENS 15. M’EYE S -E 700) IGN FEATURE This section describes the procedures relating to performing an engraving: • the choice of engraving and preparation of engraving on Essibox (or on a networked computer), p.100) •... - Page 101 > II. E ANUAL DGING A LENS Current job number If you return to the engraving menu without selecting a job, no number is shown. Choice of a category ◦ Animals ◦ Stars ◦ Celebration ◦ Cultures and communities ◦ Flowers and plants ◦...

- Page 102 > II. E ANUAL DGING A LENS Configuration of engravings on shapes Function only available if a job containing a shape was selected before accessing the engraving menu (see the paragraph “Screen for configuration of engravings on shapes”). Motif view bar If a category is selected, its name is displayed at the top of the bar.

- Page 103 > II. E ANUAL DGING A LENS Select the motif from the display bar, then drag-and-drop it onto the side of the lens. To delete a motif, drag-and-drop the motif out of the frame. You can setup your favorites, refer to the section setting up favorites p.116) You can engrave different motifs on the right and left lens.

- Page 104 > II. E ANUAL DGING A LENS Name First name: Right side motif Left side motif Confirm Cancel Enter the first and last name of the customer for whom the job or the selection of motifs is intended, then press to confirm.

- Page 105 > II. E ANUAL DGING A LENS Sorting It is possible to sort each column. Search Enter your search criteria. To erase Select the motifs to be removed by ticking the boxes then press Delete More To display a more significant number of engravings in the queue. Double click on the chosen motif selection.

- Page 106 > II. E ANUAL DGING A LENS Job number Accessible settings screen Press to set up the engraving 2nd work option: Choosing a motif after having selected a Job beforehand Press to start “Job Management”. > The screen below is displayed: Pro-E 600_Pro-E 700 >...

- Page 107 > II. E ANUAL DGING A LENS Select the job you wish to carry out an engraving on, then press to access the engraving menu. You can access the engraving menu without selecting a job in the list. >You can save a simple selection of motifs, under the name of the customer, while waiting for the job preparation.

- Page 108 > II. E ANUAL DGING A LENS Press to set up the engraving Setting up the engraving Prerequisite: You can access this screen if a job containing a shape was selected before entering the M'Eye Sign menu and if at least one engraving has been selected. The screen allows you to position the motif on the lens shape and adjust its size if necessary.

- Page 109 > II. E ANUAL DGING A LENS The motif is displayed in red when it is incorrectly positioned and therefore not possible. It becomes blue when its position is correct: Frame representing the recommended engraving area Boxing center Optical center Circle representing the “prohibited”...

- Page 110 > II. E ANUAL DGING A LENS Procedure Press to access the engraving settings screen. > The engraving settings screen appears: Press to input the 1/2 pupillary distances and press for the heights. The values are automatically transmitted to the centering device. Press: to move the motif towards the right or the left hand side, to move the motif upwards or downwards.

- Page 111 > II. E ANUAL DGING A LENS • to carry out a symmetrical copy of the selected motif onto the other lens. Press to increase or decrease the motif. You can also resize the motif using the mouse: position the mouse on the mark and keep the button pressed down to vary the size.

-

Page 112: Performing Engraving

> II. E ANUAL DGING A LENS b. Performing engraving You must have performed lens centering and blocking on the tracer before performing edging Call up the job on the edger. For more information, consult the section Edging a lens > Edger work environment > Calling up a shape p.22) >... - Page 113 > II. E ANUAL DGING A LENS Change the tool. For more information, consult the Maintenance section and servicing>Maintenance and servicing> to install and change the engraving tip p.171) The engraving tip should only be in the edger when engraving cycles are being performed. The chuck must always contain a tool to avoid any risk of oxidation.

- Page 114 > II. E ANUAL DGING A LENS Press to start the cycle directly. Press to use the mode “engravings in series.” Engraving in series Perform the lens edging of engraved jobs without carrying out the engravings and keeping the blocked lenses. At the end of the edging job including engraving, all the necessary information for the engraving is saved (feeling data, jobs, engravings).

- Page 115 > II. E ANUAL DGING A LENS You can redo an engraving run by pressing It is impossible to start the engraving cycle on the second lens if it has not been cut. button is not available. Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 116: Setting Up The Favorites

> II. E ANUAL DGING A LENS c. Setting up the favorites Captioned screen Activation or deactivation of the Add/Delete favourites bar Add favourites Becomes when the view bar displays favourites to allow you to delete them. Name of the category viewed. Selected motif (gray circle) ◦... -

Page 117: M'eye Touch Feature (Pro-E 700)

This section describes the procedures relating to the creation of a creative shape (M’Eye Touch). To create your own shapes, with an Essilor Instruments tracer centerer blocker you can use the pre-cut patterns and carry out an optical tracing, cut out your own patterns according to your imagination and carry out an optical tracing, use the software available on Essibox. -

Page 118: On Essibox

> II. E ANUAL DGING A LENS The user must ensure that the reproduced shapes are not copyrighted. The optician must inform the patient that wearing lenses with creative shapes must be compatible with the activity of the patient/final customer. The optician must ensure that wearing the glasses is not harmful to the user. - Page 119 > II. E ANUAL DGING A LENS Selection of curve and check-points Display mode To display or mask XY markers. To display or mask the markings of progressive lenses. To display or mask the rough lens. To display or mask the posiblock (after edging simulation). (nonfunctional) To display the initial form (before shape modification).

- Page 120 > II. E ANUAL DGING A LENS ◦ A: A-dimension ◦ B: B-dimension ◦ D: D-dimension (bridge) ◦ E: Larger radius from the Boxing center ◦ Pd: Half pupillary deviation ◦ H: Pupillary height ◦ X: Coordinate of the mouse in X in the boxing repository of the lens being worked on ◦...

- Page 121 > II. E ANUAL DGING A LENS To use the creative shape modification tool Press to start “Job Management”. Select the job you wish to modify. Press to access “the creative shape modification” menu. > The following screen will appear: Press to select the point from which you wish to modify the shape Press...

- Page 122 > II. E ANUAL DGING A LENS Press to symmetrically modify the segments on both sides of the reference point. Press to select a segment. > The following screen is displayed: menu becomes active. Select the segment to be modified using the mouse. >...

- Page 123 > II. E ANUAL DGING A LENS Press to create a straight line. > The following screen will appear: if you selected , the initial form remains displayed in gray ( Press to check workability. Pro-E 600_Pro-E 700 > v1 -10.18...

- Page 124 > II. E ANUAL DGING A LENS > The following screen will appear: • Large wheels • Drill bit • if Mr Blue 2.0=> high-base wheel/If Pro-E 700 Drill bit Possible form but in an approximate way in the red sector Displaying the markers Pro-E 600_Pro-E 700 >...

-

Page 125: On The Edger

> II. E ANUAL DGING A LENS b. On the edger • If M'Eye Touch is not activated and a negative shape arrives on the edger from the tracer-centerer- blocker, Essibox or a connected software application (PMS, Opsys, VisionWeb, etc.), a warning is displayed: Press to confirm. - Page 126 > II. E ANUAL DGING A LENS > The colours symbolise the various tools that will be used to machine the shape: ◦ 2 drilling mill but ◦ Large wheels Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 127: Preparing A Drilled Job

III. P REPARING A DRILLED JOB... - Page 128 > III. P ANUAL REPARING A DRILLED JOB Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 129: Menu Screen

> III. P ANUAL REPARING A DRILLED JOB This chapter describes the procedure for the positioning of drilling points (drill-holes, oblong holes, notches) on a lens. • Description of the drilling screen p.129) • Configuring drilling settings p.130) 1. M ENU SCREEN From the edging screen: •... -

Page 130: Configuring A Drilling Point

> III. P ANUAL REPARING A DRILLED JOB The selected eye has an orange frame around it. Type of drilling ◦ Drill-hole ◦ Slot ◦ Notch Drilling coordinates ◦ X and Y coordinates in relation to the boxing center of the shape. &... -

Page 131: Creating A Drilling Point

> III. P ANUAL REPARING A DRILLED JOB • Adjusting the position of a drilling point p.132) The positions of the various drilling points must be set before the centering of the lens. a. Creating a drilling point Press to create a new drilling point. Select the type of drilling (drill-hole, slot or notch). -

Page 132: Adjusting The Position Of A Drilling Point

> III. P ANUAL REPARING A DRILLED JOB > The numeric keypad is displayed. You can also use the buttons to decrease or increase the selected value. Enter the new value of the parameter and press to confirm. > The drilling point has been modified. Grouping the drilling points If you need to modify several drilling points simultaneously, you can group them together provided they are on the same side of the shape (nasal side / temporal side). - Page 133 > III. P ANUAL REPARING A DRILLED JOB For greater precision, when you use the virtual mouse or the buttons, press zoom in on the selected drilling point: the displacement step is 0.01mm (0.1mm for normal display). Press on the drill-hole, slot or notch to select it. >...

- Page 134 > III. P ANUAL REPARING A DRILLED JOB Grouping the drilling points If you need to modify several drilling points simultaneously, you can group them together provided they are on the same side of the shape (nasal side / temporal side). By default, the symbol is displayed: each drilling point can be modified individually.

- Page 135 > III. P ANUAL REPARING A DRILLED JOB You can position each drilling point in relation to the reference drilling point by modifying the values in the columns: • X coordinates in relation to the reference drilling point • Y coordinates in relation to the reference drilling point To select another drilling point as the reference drilling point: Select the drilling point you want to use as the reference drilling point Press...

-

Page 137: Configuring The Edger

IV. C ONFIGURING THE EDGER... - Page 138 > IV. C ANUAL ONFIGURING THE EDGER Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 139: Configure The Edger

> IV. C ANUAL ONFIGURING THE EDGER This chapter allows you to set up the edger according to your use. You can: • Configure the edger (hour, date, language, logins, screen-saver) p.139) • Adjusting the precision of the edger p.141) •... -

Page 140: Connections

> IV. C ANUAL ONFIGURING THE EDGER Other languages Press to display the other languages. Confirm Press to save the time. Once the settings has been adjusted, press to go back to the work screen. b. Connections The connections are configured from the tracer. The screen which you access from the edger is only available for consultation purposes. -

Page 141: Screensaver

> IV. C ANUAL ONFIGURING THE EDGER c. Screensaver This menu enables you to configure a screensaver. To access this menu from your work screen, select > > The following screen is displayed: Screensaver display Enable or disable the screensaver. Triggering Set the waiting time before the display of the screensaver (in seconds). -

Page 142: Adjusting The Position Of The Bevel And Groove

> IV. C ANUAL ONFIGURING THE EDGER To access that menu from your edger work screen, select > > The following screen is displayed: Types of frame ◦ Metal ◦ Plastic ◦ Optyl ◦ Drilled / Grooved / Flat Lens materials ◦... -

Page 143: Adjusting The Diameter Of Drill-Holes

> IV. C ANUAL ONFIGURING THE EDGER After edging a lens, if the position of the bevel or groove always seems too close to the front or rear surface, you can adjust it. To access that menu from your edger work screen, select >... -

Page 144: Adjusting The Chamfer

> IV. C ANUAL ONFIGURING THE EDGER Drill bit diameters 0.8 mm or 1.0 mm. Lens materials ◦ Plastic ◦ Polycarbonate ◦ ◦ Trivex ◦ Tribrid Increasing or reducing the default drill-hole diameter a. Press the value to be modified. >... -

Page 145: Adjusting The Groove

> IV. C ANUAL ONFIGURING THE EDGER Chamfer ◦ Small, front surface ◦ Large, front surface ◦ Small, rear surface ◦ Large, rear surface Lens materials ◦ Plastic ◦ Polycarbonate ◦ ◦ Trivex ◦ Tribrid ◦ Glass (not available) Increasing or reducing the default chamfer a. -

Page 146: To Adjust The Engraving

> IV. C ANUAL ONFIGURING THE EDGER Adjusting the default groove width ◦ Press to reduce the width of the groove. ◦ Press to increase the width of the groove. Adjusting the default groove depth ◦ Press to reduce the depth of the groove. ◦... -

Page 147: Adjust The Position Of High-Base Bevel

> IV. C ANUAL ONFIGURING THE EDGER Lens materials ◦ Plastic ◦ Polycarbonate: it is recommended to set the value to 2 minimum. ◦ ◦ Trivex ◦ Tribrid ◦ Glass: you cannot engrave glass. To adjust the number of tool strokes depending on the material : ◦... - Page 148 > IV. C ANUAL ONFIGURING THE EDGER To access this menu from your edger work screen, select > > The following screen is displayed: High-base bevel Increase or reduce the front surface tracking value a. Press the value to be modified. >...

-

Page 149: Adjust The Position Of The Step Bevel

> IV. C ANUAL ONFIGURING THE EDGER h. Adjust the position of the step bevel After the edging of a lens, if the position of high-base bevel or step bevel seems consistently too far ahead or too far behind, you can adjust it. To access that menu from your edger work screen, select >... -

Page 150: Restore The Factory Settings

> IV. C ANUAL ONFIGURING THE EDGER ◦ Positive value: the flat side of the bevel will be larger. c. Press to confirm. 3. R ESTORE THE FACTORY SETTINGS At the bottom right of certain settings screens, the button enables you to restore the page's factory settings. -

Page 151: Maintenance & Servicing

V. M & AINTENANCE SERVICING... - Page 152 > V. M & ANUAL AINTENANCE SERVICING Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 153: Carrying Out The Autotests

> V. M & ANUAL AINTENANCE SERVICING This chapter describes the maintenance procedures you can carry out on the edger without the aid of a technician. • Carrying out edger autotests p.153) • Calibrating the touch screen p.154) • Consulting the preventive maintenance screen of the “small tools” module p.174) p.155) •... -

Page 154: Calibrating The Touch Screen

> V. M & ANUAL AINTENANCE SERVICING Movement of Grooving/Milling/Drilling (GMD) module Transfer initialization Door Water test ◦ trough spraying ◦ door spraying 1. Select the autotest to be carried out. 2. Press to start the test cycle. You can press to stop the cycle at any moment. -

Page 155: Consulting The Preventive Maintenance Screen Of The "Small Tools" Module

> V. M & ANUAL AINTENANCE SERVICING 3. C “ ” ONSULTING THE PREVENTIVE MAINTENANCE SCREEN OF THE SMALL TOOLS MODULE This menu enables you to know the level of wear of your “small tools” module. To access this menu from your work screen, select >... - Page 156 > V. M & ANUAL AINTENANCE SERVICING Second wear-out threshold A warning message appears upon start-up “Maintenance is needed. Have you contacted your service technician?” The icon appears beside the small maintenance access button and flashes: press above to directly access the preventive maintenance menu of the “small tools”...

- Page 157 > V. M & ANUAL AINTENANCE SERVICING The icon appears on the worn spindle. Third wear threshold A warning message appears: • At start-up: "Module maintenance needed urgently. Please contact your support technician.” • With each cycle launch: " Proper functioning of a component is no longer assured. This could impact the edging of your lenses.

-

Page 158: Changing Or Cleaning The Edger Tools

• Always use tools recommended by Essilor. • Never use the edger if one of the tools is missing from the module. Never remove a used or broken tool if you cannot replace it. -

Page 159: Changing Or Cleaning The Drill Bit

> V. M & ANUAL AINTENANCE SERVICING The lifespan of the tools mentioned below do not account for possible incidents that can occur within the trough (shocks, collision with part of a milled lens, etc.) a. Changing or cleaning the drill bit The wear indicator informs you of the need to change the 0.8 mm drill bit after 250 holes and the 1.0 mm bit after 10,000 holes. - Page 160 > V. M & ANUAL AINTENANCE SERVICING Press to cancel the action. Block the axle with the blocking key. Put the adjustable wrench onto the chuck. The adjustable wrench must never touch the drill bit. Loosen the chuck with the adjustable wrench (two notches towards yourself). Remove the adjustable wrench then the drill bit.

- Page 161 > V. M & ANUAL AINTENANCE SERVICING Insert the new drill bit all the way in. Tighten the chuck with the adjustable wrench (two notches towards the back of the trough). Remove the blocking key and the adjustable key. > The new drill bit is in place.

-

Page 162: Changing Or Cleaning The Mill Bit

> V. M & ANUAL AINTENANCE SERVICING During the installation of a new drill bit, the statistics are automatically reset to zero by default. >The icon appears by default at the bottom of the screen. When replace a drill bit with a different diameter drill bit or when cleaning the machine, the statistics are saved by default. - Page 163 > V. M & ANUAL AINTENANCE SERVICING Press > The GMD module moves to facilitate the operation. Press to receive more image information about the tool assembly/dismantling procedure. Press to cancel the action. Block the axle with the blocking key. Put the adjustable wrench on the chuck The adjustable wrench must never be in contact with the mill bit.

- Page 164 > V. M & ANUAL AINTENANCE SERVICING Remove the adjustable wrench then the mill bit. Inset the new mill bit all the way at the back. Put the adjustable wrench onto the chuck, then tighten (two notches towards the bottom of the trough). >...

-

Page 165: Changing The Chamfering Wheel

> V. M & ANUAL AINTENANCE SERVICING Remove the adjustable key and the blocking key. > The mill bit is in place. During the installation of a new tool, the statistics are automatically reset to zero by default. >The icon appears by default at the bottom of the screen. Press at the bottom of the screen to confirm the tool change-over. - Page 166 > V. M & ANUAL AINTENANCE SERVICING Press to receive more image information about the tool assembly/dismantling procedure. Press to cancel the action. Position the blocking key on the back axle of the chamfering wheel. Insert the Allen key into the screw at the center of the wheel and unscrew (towards yourself) the wheel, using the Allen key.

- Page 167 > V. M & ANUAL AINTENANCE SERVICING The blue part of the wheel must be oriented towards the outside of the module, and the gray part must be placed against the spindle. Put the screw back on, insert the key and tighten the wheel (towards the back of the trough) with the Allen key.

-

Page 168: Install And Change The Step Bevel ++ Tool

> V. M & ANUAL AINTENANCE SERVICING During the installation of a new tool, the statistics are automatically reset to zero by default. >The icon appears by default at the bottom of the screen. When replacing a chamfering wheel with a step bevel wheel, or cleaning the machine, the statistics will be saved. - Page 169 > V. M & ANUAL AINTENANCE SERVICING From your edger work screen, you can also select > > > The following screen will appear: Press to select the step bevel wheel: CX3834. Press to confirm the tool. > The GMD module moves to facilitate the operation. Press to receive more image information about the tool assembly/dismantling procedure.

- Page 170 > V. M & ANUAL AINTENANCE SERVICING Remove the chamfering wheel and the spacer. Position the “step ++” wheel on the axis. Tighten (towards yourself) the “step ++” wheel using the torque wrench. Ensure that the tool is correctly fixed onto the axle using the keys. Remove the mounting tool and the Allen key Pro-E 600_Pro-E 700 >...

-

Page 171: Installing And Changing The Engraving Tip

> V. M & ANUAL AINTENANCE SERVICING > The wheel is installed. When replacing a chamfering wheel with a step bevel wheel, or cleaning the machine, the statistics will be saved by default. >The icon appears by default at the bottom of the screen. In case of replacement: •... - Page 172 > V. M & ANUAL AINTENANCE SERVICING • an engraving tip • an Allen key • an adjustable wrench The engraving tip should only be in the edger when engraving cycles are being performed. The chuck must always contain a tool to avoid any risk of oxidation. You must replace the engraving tip with the drill bit as soon as you go back to the edging menu.

- Page 173 > V. M & ANUAL AINTENANCE SERVICING Loosen the chuck with the adjustable wrench (two notches towards yourself). Remove the adjustable wrench then the drill bit. Insert the engraving tip all the way, then tighten the chuck firmly by hand. Pro-E 600_Pro-E 700 >...

-

Page 174: Statistics And Technical Log

> V. M & ANUAL AINTENANCE SERVICING Remove the Allen key, in order to not lock up the mechanism. 5. S TATISTICS AND TECHNICAL LOG This menu enables you to visualize the number of cycles performed by the edger. It also gives you access to the technical history. -

Page 175: Technical Log And Errors

> V. M & ANUAL AINTENANCE SERVICING ◦ Milling ◦ Bevel ◦ Flat-edge finish ◦ Groove ◦ Drill-holes/oblong hole ◦ Notch ◦ Polishing ◦ Chamfer ◦ High-base bevel ◦ Step bevel Drilling Number of drilling operations performed for each lens material, according to the drill bit used. Calibration of the touch screen Number of lenses cut Dressing cycle... -

Page 176: Maintaining And Cleaning The Edger

> V. M & ANUAL AINTENANCE SERVICING To sort the partial counters press , press again to define the sort direction (ascending, descending). Total counter You can sort the error codes generated by the machine by frequency of appearance. To sort the total counters press , press again to define the sort direction (ascending, descending). - Page 177 > V. M & ANUAL AINTENANCE SERVICING The following screen is displayed: Cleaning the door and the “small tools” module Cleaning the door a. Press to start the door cleaning cycle. The module moves to facilitate the cleaning. > The door opens. b.

-

Page 178: Dress The Wheels

> V. M & ANUAL AINTENANCE SERVICING c. Dress the wheels Pro-E 600 wheel train Finishing wheel Polishing wheel Plastic roughing wheel This wheel cannot be dressed Pro-E 700 wheel train Finishing wheel Polishing wheel Plastic roughing wheel This wheel cannot be dressed Pro-E 600_Pro-E 700 >... - Page 179 > V. M & ANUAL AINTENANCE SERVICING From the work screen of the edger, select > > to access the wheel dressing menu. You can access the dressing menu by pressing on the work screen. > The following screen is displayed. Pro-E 600 no.

- Page 180 > V. M & ANUAL AINTENANCE SERVICING Roughing wheel Number of lenses edged since the last wheel change and/or since the machine was last serviced. Make sure that the 22 mm accessories (posiblock holder and stop) are installed on the lens clamp shafts. Select the dressing cycle of the finishing wheel Insert the white dressing stone that corresponds to the selected cycle between the lens clamp...

-

Page 181: Technical Data

ECHNICAL DATA... - Page 182 > T ANUAL ECHNICAL DATA Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 183: Edger

• Engraving: All materials except glass. Engraving was initially confirmed on the following lens panel: ◦ Essilor Crizal Forte Orma ◦ Essilor Crizal Forte PC Plano ◦ Essilor Crizal Forte 1.67 ◦ Essilor Crizal Alize Orma ◦ Essilor Crizal Alize 1.67 ◦... - Page 184 > T ANUAL ECHNICAL DATA ◦ Zeiss Photochromic “Photofusions” ◦ Zeiss clear Polycarbonate with Teflon coating ◦ Zeiss light varnished Polycarbonate ◦ Hoya 1.5 light with Long Life coating ◦ Hoya 1.5 light with Blue Control coating ◦ Hoya 1.67 light with Long Life coating ◦...

-

Page 185: Environment

> T ANUAL ECHNICAL DATA 2. E NVIRONMENT Your machine should preferably be installed on a perfectly flat and stable work surface of suitable height (about 70 cm), free from shocks and vibrations, to benefit from the high accuracy of your edger. Your edger can be placed to the right or left of the tracer. However, leave enough space between the two devices for the opening of the side covers. -

Page 187: Eneral Information

ENERAL INFORMATION... - Page 188 > G ANUAL ENERAL INFORMATION Pro-E 600_Pro-E 700 > v1 -10.18...

-

Page 189: Symbols

Essilor cannot be held responsible for any malfunction or loss of data resulting from such errors or omissions. -

Page 190: Declaration Of Conformity

All edgers obtain a final shape on a lens, by removing material. This process generates dust, which depends on the lens and the materials used. The materials used for coating the Essilor wheel and consumed during its use are not toxic or allergenic. Nevertheless, users must check that the ground materials are not toxic. -

Page 191: Electromagnetic Waves

General information Essilor International (hereafter called “Essilor”) grants you a license for use of its M’Eye Sign™ software exclusively for the use set out in these terms and conditions. Essilor reserves all rights which are not expressly granted to you. Rights granted by the terms of this license and its updated version (available at the following address: http://www.mleiyceesnicgen.com/fr), apply to possible software updates used... -

Page 192: Accepted Use Of The Software And Restrictions

Termination This license is granted for an unlimited time. It may be terminated by you or Essilor with 3 months notice. Your rights rising from this license will be immediately terminated without further notice from Essilor if you do not comply with the conditions of the license. As soon as... -

Page 193: Applicable Law

> G ANUAL ENERAL INFORMATION the license is terminated, you must stop using the Software and Essilor will be authorized to remotely erase the Software from any equipment in your possession, to which Essilor has access (via Essibox®). g. Applicable law This license is subject to French law. -

Page 195: Glossary

LOSSARY... - Page 196 > G ANUAL LOSSARY OXING DIMENSIONS The boxing system is a standard method to indicate the dimensions of frame contours (or gauges). This operation consists in fitting the frame into a rectangle whose dimensions are indicated. • Boxing center: geometric center of the rectangle •...

- Page 197 > G ANUAL LOSSARY EFRACTIVE INDEX Characterizes the refractive power of a transparent optical material. The indices vary according to the materials used for the lenses: • Plastic lens: 1.5 • Polycarbonate lens: 1.59 • Medium or High Index lens: > 1.5 •...

- Page 198 Essilor Instruments USA 8600 W. Catalpa Avenue, Suite 703 Chicago, IL 60656 Phone: 855.393.4647 Email: info@essilorinstrumentsusa.com www.essilorinstrumentsusa.com...

Need help?

Do you have a question about the Pro-E 700 edger and is the answer not in the manual?

Questions and answers