Summary of Contents for Rethink Robotics Sawyer

- Page 1 Intera 5 - User Guide/Getting Started Original Instructions Last updated June 18, 2018 Intera 5.3 User Guide/Getting Started Rev. A...

- Page 2 Please visit mfg.rethinkrobotics.com/intera for translated versions of the user guide. Additionally, you’ll find more details and links to more detailed tutorials. The Rethink Robotics support page is here: Rethink Support.

-

Page 3: Welcome

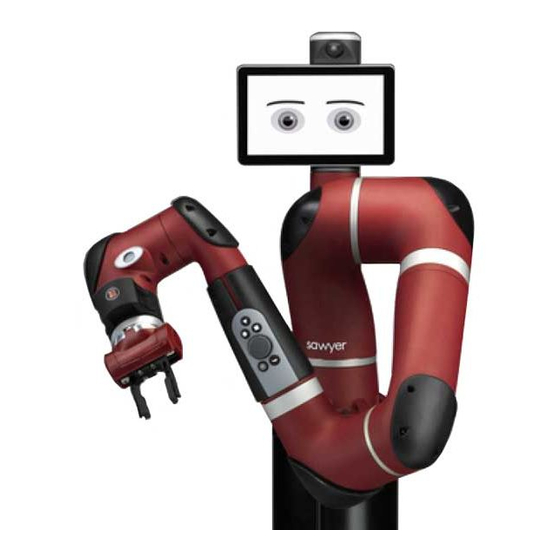

Thank you for purchasing Intera 5 software and Sawyer, our revolutionary new high performance collaborative robot. This user guide is designed to help you get started using Intera and Sawyer by providing you with an overview of the software and instructions on how to set up the Sawyer robot. -

Page 4: Warnings

The integrator and/or end user assumes all responsibility for damage and/or harm caused by use of the robot in a hazardous manner and agrees to indemnify Rethink Robotics from all liability relating to such damage or harm. - Page 5 Rethink Robotics’ collaborative robots are not intended for use in explosive atmospheres or any environment where intrinsic safety of equipment is required. Rethink Robotics’ collaborative robots ship with an E-Stop device that may be used in the event of emergency to remove power from the actuators and immobilize the arm. The E-Stop device is connected to the controller box by a cable which allows for flexibility in its positioning.

- Page 6 Rethink Robotics’ collaborative robots are not serviceable or repairable by end-users. In the event servicing or repairs are required for the robot, please contact your distributor or Rethink Robotics for technical assistance. When the robot is moving a heavy part (>2.5 kg) and a user removes the part from the gripper or the part unintentionally falls (and no logic has been trained to handle these issues), the arm will still try to compensate for a mass that is no longer there and the arm may move unexpectedly.

- Page 7 Rethink Robotics, Sawyer, and Intera are trademarks of Rethink Robotics, Inc. EtherNet/IP is a trademark of ODVA, Inc. PROFINET is a registered trademark of PROFINET International (PI) Welcome! Intera 5.3...

-

Page 8: Table Of Contents

Table of Contents Welcome! 3 Warnings 4 Table of Contents 1 Getting to Know Sawyer 7 Hardware Overview of Your Robot 8 Dimensions 9 Sawyer Reach 10 Sawyer Nomenclature 11 Workspace and Robot Joint Limits 11 Head 12 Controller 13... - Page 9 Getting Started with Intera 5 26 Some Intera Terms 30 Components of the Intera Studio Screen 32 Top Bar 32 Studio Menu 33 Node Palette 37 Behavior Editor 38 Node Colors - Meaning 38 3D View 49 How to Change the View of the Simulated Robot Arm 51 How to Move the Simulated Robot Arm 52 End of Arm Tooling 54 Attaching End of Arm Tooling 54...

- Page 10 Rethink’s Collaborative Robot Safety Features 136 Rethink’s Collaborative Robot Regulatory Certifications 138 IEC 6100-4-2 139 North America 139 Canada 139 Mexico 140 EU 140 China 140 Japan 141 Maintaining and Supporting Sawyer 142 Powering Down Sawyer Properly 142 Maintaining Sawyer 142 Contents Intera 5.3...

- Page 11 Cleaning Sawyer 142 Calibrating Sawyer 143 Appendix A: Glossary 144 Glossary 144 Appendix B: Support & Warranty 146 Appendix C: Certifications and Information for Integrators 147 Third Party Certifications 147 Declaration of Incorporation 150 EC Declaration of Incorporation (Original) 150...

- Page 12 Appendix F: Safety Subsystem 171 The Safety Subsystem 171 The Banner Safety Controller 172 Appendix G1: Intera PROFINET Reference 178 Overview 178 Default Connection - Standard Modules 178 Setup Resources 179 Summary of Modules 180 From-Robot Modules Summary 180 To-Robot Modules Summary 181 Modules Data Tables 182 Fixed Data 112 From Robot 183 Standard Booleans (113: To-Robot | 114: From-Robot 184...

- Page 13 Robot State Flags Meaning 204 Data Addressing and Format 205 Index 206 For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support.

-

Page 14: Getting To Know Sawyer

Getting to Know Sawyer For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Transportation and Handling: Use a Pallet Jack when transporting pallet. -

Page 15: Hardware Overview Of Your Robot

Hardware Overview of Your Robot Getting to Know Sawyer Intera 5.3... -

Page 16: Dimensions

Dimensions Getting to Know Sawyer Intera 5.3... -

Page 17: Sawyer Reach

Sawyer Reach Getting to Know Sawyer Intera 5.3... -

Page 18: Sawyer Nomenclature

20.73 Workspace and Robot Joint Limits The ability of Sawyer to perform actions at any given location is affected by the physical limits of the arm. When training an action, consider: • The robot’s joints J0 through J3 can rotate a maximum of 350 degrees. Joints J4... -

Page 19: Head

For example, you cannot incorrectly train the robot so the arm crashes into itself. In Intera Studio, you can click on the Joints Tab to see the extent of rotation of each of Sawyer's joints. A slider near either end of the slider range indicates proximity to a joint limit. You can also see the joint position indicators on the right side of the robot’s display screen. -

Page 20: Controller

Rethink Robotics Sawyer pedestal or nearby, for example, on a shelf. When installing Sawyer, make sure that the air inlet and exhaust fan ports on the controller are not blocked or obstructed. These ports must be clear to allow the controller to be properly ventilated. - Page 21 Bottom View Inputs Outputs - Power - (4x) Air - Air Input - Power and Data - Video Getting to Know Sawyer Intera 5.3...

-

Page 22: Navigator

Use the Navigator to scroll to and interact with options on the screen. When you press the OK button on the selector knob (or the action button on the cuff), the light indicators on the Navigator light up. Getting to Know Sawyer Intera 5.3... - Page 23 5. Rethink button: Press to display the Head Screen Menu. 6. Square button: Press and hold to toggle the Head Screen to follow the robot arm. Also used to select features when prompted on the display screen. Getting to Know Sawyer Intera 5.3...

-

Page 24: Training Cuff

The robot is equipped with brakes located in the J1, J2, and J3 joints that stop the arm from falling onto fixtures in the workspace. The brakes are activated when: • the arm motors are turned off • E-stop is engaged • the robot loses power or is turned off Getting to Know Sawyer Intera 5.3... -

Page 25: Active Collision Avoidance

Active Collision Avoidance Rethink robots are designed to “know” where their arm joints are at any given time and where the head and torso are so as to avoid collisions with any parts of itself. Getting to Know Sawyer Intera 5.3... -

Page 26: Included Accessories

• Landmarks #1-4 for use with Robot Positioning System. Tool Plate The tool plate on the Sawyer robot arm is designed per the ISO 9409-1-40-4-M6 specification. The robot tool plate has four M6 thread holes for attaching end-of-arm tooling to the robot. The holes need to be tightened with 9 N m. -

Page 27: Optional Accessories

Optional accessories: Rethink Robotics Family of ClickSmart Gripper Kits • • Sawyer pedestal • Landmarks #5-20 - for Robot Positioning System • Robot Mounting Plate - for positioning Sawyer precisely without the pedestal Getting to Know Sawyer Intera 5.3... -

Page 28: Safety Symbols

Notices” for specific safety information. HAZARDOUS VOLTAGES: Hazardous live voltages are present inside the controller box. The controller box has no end-user serviceable parts. Please contact your distributor or Rethink Robotics in the event servicing or repairs are required. Getting to Know Sawyer... -

Page 29: Getting Started With Sawyer

Getting Started with Sawyer Setting Up Sawyer For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Ensure that you have reviewed safety guidance provided in this document prior to installing and operating the robot. -

Page 30: Turning On Sawyer

Sawyer ships with an E-Stop device that may be used in the event of emergency to remove power from Sawyer’s actuators. The E-Stop device is connected to Sawyer’s controller box by a cable which allows for flexibility in its positioning. Ensure that the E-Stop device is not positioned in a manner that will make it difficult for an operator to access it during Sawyer’s operation. -

Page 31: Moving The Arm

Notice that the arm becomes fluid and easy to manipulate. This is what we call “Zero G” mode. It is the mode in which you train Sawyer to perform a task. While the arm is in Zero- G mode, the motors are enabled, essentially counteracting the effect of gravity on the robot. - Page 32 Release the training cuff and the arm becomes (semi-) rigid again. Note that the arm stays in the location and orientation it was in when you stopped squeezing the training cuff. The location and pose orientation of the arm (its shoulder, elbow, wrist, and so on) is called its Getting Started with Sawyer Intera 5.3...

-

Page 33: Getting Started With Intera 5

Getting Started with Intera 5 For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Before proceeding with this chapter, connect a Sawyer robot to your computer: 1. - Page 34 3. Press the Rethink Button on one of Sawyer's Navigators to display the Head Screen Menu. 4. Using the Navigator Scroll Knob, select the Info menu option. Note Sawyer's IP address in the About pane. Note: It may take 30-60 seconds for the IP address to appear in the About window. You may need to select the Info menu option several times before the IP address appears.

- Page 35 To achieve a working connection, you may need to change some settings. For example, if your PC or Sawyer is set to a static IP address, you will need to change them to DHCP. You may also need to make sure WiFi is disabled on your PC because it can cause addressing problems.

- Page 36 8. You also need to request control of Sawyer because someone else may be using that particular robot. 9. After clicking Grant, the connection is established and the icon turns green, as above. Note: If you try to use Intera Studio to move the robot arm before it’s connected, you will see the following: Click OK in Intera to request control, then Grant in the Head Screen on Sawyer.

-

Page 37: Some Intera Terms

Some Intera Terms To get started with Intera, it is necessary to be familiar with some of the terms it uses. The Head Screen refers to the head display User Interface on the Sawyer robot itself. Getting Started with Intera 5... - Page 38 Intera Studio refers to the Intera software accessed through a Google Chrome browser, which features a Behavior Editor of the task and a simulated Sawyer robot. Optionally Intera Studio may be connected to, and communicate with, an actual Sawyer robot.

-

Page 39: Components Of The Intera Studio Screen

Bottom Bar Top Bar The top bar contains main functions for creating tasks, changing how Studio displays, and running Sawyer. The Studio Menu Button displays a menu of Task, Template, and Intera options, described below. The Task name is displayed in the upper left. If a * is displayed, as in this example, there are changes to the task available to be saved. -

Page 40: Studio Menu

Studio Menu TASK • New... -- Create a new task. • Open -- open task from a list of existing tasks. You can also delete a highlighted task by clicking on the delete icon, then confirming your deletion. Search the list by entering the first letters of the task on the search line. - Page 41 TEMPLATE Note: A template is a basic or "skeleton" subtree behavior that can be inserted into a task as needed. Templates do not contain unique properties of the nodes, for example, references to poses, signals, or other variables. • Import Templates -- Open browser on your computer where templates are stored.

- Page 42 • Export Logs -- Downloads log data from the robot to your computer. • Lock Robot -- Toggle between locking and unlocking Sawyer. This feature helps prevent unauthorized personnel from tampering with the tasks stored on the robot.

- Page 43 3D view of the robot arm (default view), or only the robot arm 3D view. SAWYER CONNECTION These icons on the lower left corner of the screen display whether the Intera software on your computer is connected to a Sawyer robot. Getting Started with Intera 5 Intera 5.3...

-

Page 44: Node Palette

Node Palette The Node Palette contains all the nodes you'll use to create a behavior tree. Click on the arrow on the top, right of the panel to display/hide the full list of icons. Getting Started with Intera 5 Intera 5.3... -

Page 45: Behavior Editor

Behavior Editor Tool Selection Panel The Behavior Editor is used to create, view, and edit all nodes in the Task. A task is structured to activate nodes branching from left to right between parent and child nodes, and top to bottom between sibling nodes. The Tool Seletion Panel displays the current tool in use. - Page 46 Grey - Disabled: a disabled node and its children, if it has any, are ignored by its parent, and thus never run. Green - Running: the node is currently being executed in the running of the task. It is active until it either succeeds, fails or encounters an error.

- Page 47 • The Behavior Editor can be expanded to fill the entire Studio screen or split to display both the Behavior Editor and the 3D view. See “display options” on page 36. • CTRL + X - Cut • CTRL + C - Copy •...

- Page 48 Right clicking on a selected node, or nodes opens the Right Click Menu. • Add Child - Opens options to add a selected node as a child of a parent node. In the above example, "Child 3" has 2 children "Child A" and "Child B", and is a child of "Parent".

- Page 49 added in another location in this task or another task. The unique properties of the nodes are not transferred. • Save - saves the task • Export Graph to SVG - saves the entire Behavior Tree as an SVG file which can be opened in a browser and viewed as an image.

- Page 50 Toggle the node inspector button to turn its display on or off. You can also hide it by clicking on the x in its upper-right corner. JOINTS -- Control each Sawyer joint with sliding bars or by entering specific numbers in degrees. A slider near either end of the slider range indicates proximity to a joint limit.

- Page 51 Frames reference a parent frame until reaching the Base Frame. Each child is shown indented. Getting Started with Intera 5 Intera 5.3...

- Page 52 SIGNALS -- The Signals Tab is used to edit signals for input and outputs of devices connected to Sawyer. DEVICES -- The Devices Panel is used to set up Modbus, TCP/IP, and Fieldbus (PROFINET®, EtherNet/IP™) devices.

- Page 53 The internal Moxa I/O unit of Sawyer shows automatically as device "Robot IO.” A green status light indicates the device is communicating properly. Red indicates it is not communicating. Orange means an attempt at establishing communication. To delete a device, check its green square and select the delete icon. (You cannot delete the internal Moxa I/O.)

- Page 54 To create a device, return to the gallery of devices (if necessary) and click on the + icon. The following panel is displayed. Choose Modbus or TCP/IP. The above image is the device editor panel for a modbus device. The new device requires a user specified name and IP address.

- Page 55 VARIABLES -- Create user-defined variables that can be used in conditions. SHARED DATA -- Stores all the data for each item in the workspace. Displays the current status of variables and signals, whether created by the system or the user. You can view and set the value of some of these variables directly from Shared Data if you want to do so independent of the behavior editor.

-

Page 56: 3D View

The 3D view on the right side of the screen acts out the actions you have created via the nodes. The robot arm simulator can also run in parallel with an actual Sawyer under control of the Intera Studio Getting Started with Intera 5... - Page 57 software. The Live vs. Sim switch -- Toggles the mode between LIVE (on robot) and SIM (virtual simulation). Virtual simulation runs in the software only when a robot is connected. However the robot will not move. Getting Started with Intera 5 Intera 5.3...

-

Page 58: How To Change The View Of The Simulated Robot Arm

Click to display the jog hot keys for the simulator. The U, I, and O and J, K, L keys move an endpoint on an axis. Hold Shift while pressing those keys to move an endpoint around an axis. How to Change the View of the Simulated Robot Arm There are several ways to change the view of the image of the simulated robot arm. -

Page 59: How To Move The Simulated Robot Arm

To update the robot arm’s position, click on the Go To button. The simulated robot arm will then move to that location. If there is an active Sawyer robot connected to Intera Studio, its arm will move, slowly, along with the simulated robot arm. - Page 60 "Cartesian view" - Interface in 3D view that both displays the information associated with the selected item in 3D space, and allows you to edit it. This example shows the attributes of a waypoint: its position, rotation data, etc. You can change its data by entering new numeric values or by clicking on the up and down arrows.

-

Page 61: End Of Arm Tooling

End of Arm Tooling For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. “End of arm tooling” is the term for what is attached to the end of the robot’s arm that allows the robot to interact with parts in its environment. - Page 62 Ensure the Mass, Center of Mass (you can leave this as default) and Position Z are correct. The reason for inserting the Mass of the gripper is so that Sawyer knows how much mass to expect and where it is when the arm moves.

-

Page 63: Adding A Clicksmart Gripper

FYI, here is a reference on how to calculate center of mass. Note: Note the Tool Center Point position Z should be measured from the top of the adapter tool plate that meets with the cuff to the end of the fingertip. Once updated, click Save. - Page 64 • Select Gripper Type. • Test Grip, Open and Closed signals. Invert signals and adjust sensor positions if necessary. • Save your settings and exit. Detailed Steps 1. Follow the instructions in the latest User Guide to assemble this gripper and attach it to the robot.

- Page 65 6. Edit the Tool Center Point (TCP) to provide the best representation of the finger tips. For example, if the gripper is centered on the ClickSmart Plate, provide the distance in the z-direction from the Training Cuff to the tip of the gripper fingers. The TCP position z should be measured from the top of the ClickSmart Plate Robot Side that meets with the cuff to the end of the fingertip.

- Page 66 8. Working your way down the Tooling Editor, select the tool type. For a pneumatic gripper, select Gripper. For a vacuum gripper, select Vacuum. When a gripper type is selected, the signals are mapped automatically. 9. Actuation time is the time it takes for the gripper to close or the vacuum cup to firmly grasp the object.

- Page 67 nals. Select the pencil icons to verify the signals are configured correctly, but this is not necessary when using a ClickSmart gripper kit. 11. Any of the signals can be changed except for Power. The Grip, Open, and Closed signals can be defined based on the setup and task. For example, open and closed will be different for gripping an object from the outside versus from the inside.

-

Page 68: Using The Gripper In A Task

Note: For PLG and PSG, the Open and Closed Inputs are from the two magnetic sensors that slide in the tracks on either side of the pneumatic gripper. The sensor positions may need to be adjusted using the smallest hex key in the gripper kit. Please follow the instructions on the following pages in the Online User Guide to adjust the sensor position. - Page 69 To check if the gripper is opened or closed, use a DO IF node. Check for the condition Open == true or Closed == false. End of Arm Tooling Intera 5.3...

- Page 70 Default signal settings of ClickSmart grippers in Intera: For pneumatic grippers: Invert Default Signal Value Signal Outputs Power True Outputs Power True Inputs Open False Inputs Closed False • The Grip signal needs to be inverted so that when the pneumatic valve is powered off, the parallel actuator is in the closed state to keep the part in hand instead of dropping it accidentally.

- Page 71 For vacuum grippers: Invert Default Signal Value Signal Outputs Power True Vacuum Outputs True Sensor Vacuum Inputs Voltage = Sensor Vacuum Inputs Threshold • The Vacuum On signal needs to be inverted so that when the pneumatic valve is powered off, the vacuum generator is still on to keep the part in hand instead of dropping it accidentally.

-

Page 72: How To Calibrate The Rethink Electric Parallel Gripper

The Rethink electric parallel gripper must be calibrated before it can be used. Calibration opens and closes the gripper, so the gripper should not be holding an object when it is calibrated. 1. With the gripper plugged in to Sawyer, click on the Shared Data icon in the Top Tool Bar: 2. - Page 73 3. Click calibrate: false to highlight it. Note: Do not confuse “calibrate” with “is_calibrated.” 4. Click Set Value and type in True or the number 1 and press Enter. You can see some of the numbers quickly change on the shared data panel as the grippers are calibrated.

-

Page 74: To Add End Of Arm Tooling With Dual Tools

To Add End of Arm Tooling with Dual Tools 1. Click on the Tooling Gallery icon to display the Tooling Gallery. 2. Click the + TOOL icon. 3. Add a name for the end effector, its mass, and its center of mass. 4. - Page 75 5. To add the second tool, click on + SUBTOOL. 6. Give the second tool a name, position, and orientation, if needed. You can select a new orientation from dropdown menus, for example: End of Arm Tooling Intera 5.3...

- Page 76 7. Click Save. Here is the Tooling Gallery panel for end of arm tooling with two tools, "LEFT" and "RIGHT": The new tools show up as orange blocks on the robot in 3-D view. There are three cubes visible in this example. The black cube on the end of the arm represents the tool plate.

-

Page 77: How To Actuate The Tips Of Third Party End Effectors

How to Actuate the Tips of Third Party End Effectors To actuate third party end effectors without using a ClickSmart Plate, you have to create signals using the Moxa I/O device housed in the robot's controller. 1. Click on the Signals icon in the top tool bar to display the Signals panel. -

Page 78: Assigning A Signal

end effector, you may want to select DO_1. You will want to rename it and change its default state based on your application. 3. To do that, click the pencil icon to display the Edit Signal panel. 4. Enter a name for the signal. 5. -

Page 79: Train A Simple Pick And Place On The Head Screen

Train a Simple Pick and Place on the Head Screen For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. - Page 80 3. Use the Selector Knob to scroll to and then select tasks (by pressing the knob), then scroll to and select new. Train a Simple Pick and Place on the Head Intera 5.3...

- Page 81 The left side of the screen shows the list view of the task with the currently selected tool displayed in the lower left corner (Electric Parallel Gripper Tip). The right side shows the tree view. Note that the task node is already selected. 4.

- Page 82 FYI, if you were to scroll to the Smarts node on the tree to display it in more detail, you would see the following branch, where the actions of the Success and Fail nodes are already defined. (Success means the grippers feel the force of an object when gripping; Fail means a failure to feel the force of an object.) Train a Simple Pick and Place on the Head Intera 5.3...

- Page 83 6. Scroll back to the Task in the list view. 7. Move the robot arm in zero-G to the location of the Place. 8. Press the Grasp button to display the Place options. Train a Simple Pick and Place on the Head Intera 5.3...

- Page 84 9. Press the Grasp button to select the Basic Place option. A Place branch is cre- ated. Train a Simple Pick and Place on the Head Intera 5.3...

- Page 85 10. Press the Rethink button to display the Head Screen Menu. 11. Select run and then restart to run the task. Train a Simple Pick and Place on the Head Intera 5.3...

- Page 86 The basic pick and place task should run as trained. Sawyer will recognize mispicks and display an error message should two mispicks occur. Train a Simple Pick and Place on the Head Intera 5.3...

-

Page 87: Train Pick And Place Patterns On The Head Screen

Train Pick and Place Patterns on the Head Screen For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. -

Page 88: Train The Pick Pattern

We will use the following 2x3 grid pattern to represent the pick locations and boundaries: Train the Pick Pattern 1. Start a new task. 2. Move the robot arm in zero-G mode to the first point in the picking location, in this example, #1. - Page 89 4. Scroll to Pattern and press the Grasp button to select it. The gripper will close on the part you are picking. The left side of the Head Screen now displays the steps you need to perform to create a pattern. The first step is to define the type of pat- tern.

- Page 90 Note: The currently active step is indented on the list of pattern-creating steps. 6. Select the Grid option, as shown. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 91 Note: In the list of steps, Grid now has a green check mark, meaning its selection has been confirmed. Since you chose to create a grid, the next step is to define its corners. 7. Press OK to start defining corners. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 92 You will now set the outside corner -- the outer pick location of the first part -- for the first corner in the grid. 8. If the robot arm is not already there, move it in zero-G to the first corner, which would be #1 in our 2x3 grid example.

- Page 93 11. Press OK to go to the next step. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 94 Remember that, in our example, there are 2 rows across the top of the grid, from corner #1 to corner #2, and 3 rows down, from corner #2 to corner #3. 12. Scroll to display 2 in the box on top of the screen and select it with the OK but- ton.

- Page 95 13. There are three rows from corner #2 to corner #3, so scroll to the small box on the right side of the screen and change the number to 3 and press OK, as show below. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 96 14. Scroll to the 5x5x1 checkbox and press OK. The setup of rows will look like this: Train Pick and Place Patterns on the Head Intera 5.3...

- Page 97 15. Press OK to go to the next step, defining the direction. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 98 16. Press OK to allow modifications to the direction, Train Pick and Place Patterns on the Head Intera 5.3...

- Page 99 17. Scroll to choose the direction of the arm movement, that is, in which direction the first two picks are going to be. This example shows the arm will move from 1 to 2. 18. Press OK to confirm your choice. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 100 19. Select the type of arm movement desired for the picks, either Snake or Zigzag. Train Pick and Place Patterns on the Head Intera 5.3...

- Page 101 20. The last step is to confirm the settings you have trained for your pattern. Press OK to confirm your pattern and to create the behavior tree. Train Pick and Place Patterns on the Head Intera 5.3...

-

Page 102: Train The Place Pattern

Notice how the parent node for the pick is a pattern node. Train the Place Pattern Now you can do the same for a Place pattern! 21. Press the Grasp button and select Pattern. Train Pick and Place Patterns on the Head Intera 5.3... - Page 103 Follow the same steps you performed for creating the pick pattern. When you’re done, your Head Screen should look much like this one: Train Pick and Place Patterns on the Head Intera 5.3...

- Page 104 You may now run the task. Train Pick and Place Patterns on the Head Intera 5.3...

-

Page 105: Intera Insights

Intera Insights For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Intera Insights Overview Intera Insights is a set of tools designed to allow easy real-time monitoring of task data. This includes all arm data (including position, rotation, and forces), EOAT sensor data, cycle time, and more. -

Page 106: Intera Insights Panel

Intera Insights Panel Robot Runtime Visuals Select a Robot Runtime Visual to control what is displayed on the head screen as Sawyer runs a task. If ‘Eyes’ is selected, Intera will display Sawyer’s eyes. If ‘Logo’ is selected, the Rethink Robotics logo will be displayed on the screen during the task. - Page 107 Item to Watch Use the ‘Item to Watch’ drop-down menu to select a specific variable to add to the chart. This can include any variable in the Shared Data panel. Chart Name Use ‘Chart Name’ to name the chart. This will default to the same as the name of the variable being charted;...

- Page 108 Values List The ‘Values List’ can be used to track the value of specific variables throughout a task. To add a variable, follow the same process by which a chart was added; instead of selecting ‘chart’ under watch mode, select ‘value.’ Values cannot be given names. Runtime Data The Runtime Data section of the Intera Insights panel is used to control which variables and charts are monitored on the Head Screen if ‘Data’...

- Page 109 3 charts can be added to the head screen. Once a chart has been created, add it to the head screen by selecting it in the ‘Chart 1,’ ‘Chart 2,’ or ‘Chart 3’ dropdown menus. The chart will then be displayed on Sawyer’s head during the task, along with the current value, maximum value, minimum value, and average value.

-

Page 110: Tracking Cycle Time

Tracking Cycle Time The cycle time of any given task can be monitored using the Intera Insights. Defining a Cycle Before a cycle can be tracked, the user must tell Intera what is considered a cycle. The cycle time of any Loop, Sequence, Priority, Parallel, Do If, Loop If, Vision Inspector, Vision Locator, Contact Mode, or Pattern can be tracked. -

Page 111: Viewing Data On Robot When Task Is Paused

Viewing Data on Robot when Task is Paused When the robot is paused, you may view the stored Intera Insights data by pressing the Rethink button > Selecting INFO > Selecting STATS Intera Insights Intera 5.3... -

Page 112: Setting Head Angle

Setting Head Angle When the task is started, continued, or restarted, the head will make a best effort to remain in that same angle relative to the base and regardless of arm movement. In order to change the angle, pause the task and move the head to desired angle. Then continue or restart a task. Intera Insights Intera 5.3... -

Page 113: Force Sensing And Selective Arm Stiffness

Rethink Support. As of Intera 5, Sawyer can sense and measure force on the robot end point. It can therefore react to outside conditions, as well as make use of its own measured force when performing tasks. In addition, it is now possible to select how stiff the arm should be per axis, and the maximum amount of force the robot may use when trying to reach a point in space. - Page 114 If the wheel turns properly when that force is applied, it passes inspection. If not, it fails. And, because Sawyer is a non-rigid robot, it does not have to be positioned perfectly concentric with the center of the wheel as a rigid robot would.

-

Page 115: How To Access And Modify Force Data In Intera Studio

When it rotates the wheel, Sawyer will absorb some of the impact in the environment and perform the task. How to Access and Modify Force Data in Intera Studio To display current force information, select the Shared Data button from the Task Bar. The live force data is located under Robot Data. - Page 116 3. Set a pose by clicking on + Arm pose in the node inspector. 4. Specify Sawyer's stiffness in relation to either the Base Frame or the Active End- point Frame by entering a value in the x,y, and/or z boxes set to Stiffness mode.

- Page 117 (compliant in z) relative to the end effector, and rigid along the x and y axes. To limit the amount of force with which Sawyer pushes, check the Force or Torque Limit box for the appropriate axis or rotation, and enter a value. Sawyer's arm will then push no more than the defined amount of force.

-

Page 118: I/O Devices

I/O Devices For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. This section describes the electrical interfaces available to the Sawyer robot. The different inter- faces are: •... - Page 119 Moxa ioLogik E1212 Hardware SPECIFICATIONS Digital Inputs (8 channels) Sensor type: Wet Contact (NPN or PNP), Dry Contact I/O Mode: DI or Event Counter Dry Contact: • On: short to GND • Off: open Wet Contact (DI to COM): • On: 10 to 30 VDC •...

- Page 120 • Over-Voltage Protection: 45 VDC • Over-Current Protection: 2.6 A (4 channels @ 650 mA) • Over-Temperature Shutdown: 175°C (typical), 150°C (min.) • Current Rating: 200 mA per channel Physical Characteristics • Wiring: I/O cable max. 14 AWG Environmental Limits •...

-

Page 121: I/O Wiring Diagram

LED INDICATORS I/O Wiring Diagram ATTENTION Determine the maximum possible current for each power wire and common wire. Observe all electrical codes dictating the maximum current allowable for each wire size. If the cur- rent exceeds the maximum rating, the wiring could overheat, causing serious damage to your equipment. - Page 122 INPUTS The inputs belong on channels DI0-DI7. Please follow the diagram below in order to understand how to connect an input device into the Moxa ioLogik E1212 device: A Dry Contact is a contact that does not provide voltage. A Wet Contact is a contact that will provide voltage when closed. OUTPUTS The outputs belong on channels DIO0-DIO7.

-

Page 123: External I/O

IMPORTANT: Remove power (unplug) robot before wiring to I/O device. External I/O The Sawyer controller comes with 8 Digital Inputs and 8 Digital Outputs. If more I/O is required, Sawyer may communicate to external machines by adding an external Ethernet-connected Mod- bus TCP/IP Remote Terminal Unit (RTU). - Page 124 This section will help explain: the Modbus TCP protocol; how to correctly configure or network an external device to communicate with Sawyer; and what information is sent or received via Modbus TCP. Sawyer is configured as the Modbus TCP Client (Master) and any external device must be I/O Devices...

- Page 125 Modbus addresses. The Lines are 0 based, meaning that 8 configured lines on Sawyer correspond to lines 0-7. The corresponding Modbus addresses are 1 based, meaning that 8 configured lines on Sawyer correspond to modbus addresses 1-8.

-

Page 126: Safety Rated Controller

NOTE: The link-local IP address range is 169.254.#.#, where "#" is any number between and includ- ing 1 to 254. The subnet mask for link-local address is 255.255.0.0 If Sawyer is connected to a DHCP network, the IP address and subnet mask will be assigned to reflect the connected network. - Page 127 • Non-expandable SC26-2evm with analog voltage monitoring. • Bus Monitor input monitors redundant analog DC voltage inputs to determine if the voltage is greater than or less than a preset level. • Upper and lower thresholds are independently selectable from 7 V dc to 14 V dc, in 0.25 V dc increments.

- Page 128 PERFORMING A RISK ASSESSMENT RIA TR R15.306:2014 provides a detailed methodology for performing risk assessments. For Power and Force Limited collaborative robots, ISO TS 15066 and ANSI R15.06/ISO 10218-2 provide guidance on the right aspects to be evaluating. It is important to evaluate the entire robotic application including not just the robot itself, but all tools, fixtures, parts, end effectors, machinery, etc.

- Page 129 SPECIFICATIONS Safety Category 4, PL e (EN ISO 13849) SIL CL 3 (IEC 62061, IEC 61508) Product Performance Standards See Standards and Regulations section in the Instruction Manual for a list of industry applicable U.S. and international standards. Meets or exceeds all EMC requirements in IEC 61131-2, IEC 62061 Annex E, Table E.1 (increased immunity levels), IEC 61326-1:2006, and IEC61326-3-1:2008 Convertible I/O ·...

- Page 130 · Safety Output SO..a to SO..b turn On differential (used as a pair, not split): · 6 to 14 ms typical, ±25 ms maximum · Output SOx to Output SOy turn on Differential (same input, same delay): · 3 scan times +25 ms max. ·...

-

Page 131: Tcp/Ip

Internet, over Ethernet or wifi. Built into the UNIX operating system, it is used in Intera 5 to enable Sawyer to communicate with work cell devices such as PLCs, barcode readers, and cameras. -

Page 132: Intera Tcp/Ip Communications

Intera TCP/IP Communications There are two ways to connect using TCP/IP: Either Sawyer is the server and the other device is the client, or vice versa. Note: The server is not required to give an IP address, but it must give a port number for devices to connect to. -

Page 133: To Create A Device For Tcp/Ip

• Boolean -- True/False or 1/0. (Intera recognizes both.) • Max. Bytes -- Defines maximum number of bytes that constitute a received message, i.e., when 7 bytes are received, that’s considered a complete message. • Timeout -- If a full message is not received in x seconds, it’s dropped; wait for another message. - Page 134 The Set To node in the Behavior Editor is used to output information: TCP/IP Intera 5.3...

- Page 135 NOTE: You cannot send any “unit-ed” data from Sawyer, that is, any data defined in units. So, force newtons, newton meters, millimeters, position over time, etc. -- none of that data can be sent over TCP. Input information is through the Variables panel: TCP/IP Intera 5.3...

-

Page 136: Fieldbus Devices

Fieldbus Devices For the latest and most detailed information on Sawyer and Intera 5, please refer to the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Sup- port. The Industrial Fieldbus Protocols available on the Sawyer robot include: •... -

Page 137: Enabling The Fieldbus Protocol

1. With the robot powered off, attach a USB keyboard to a USB port located inside or outside the Controller and power on the robot. 2. When Sawyer’s eyes first appear, continually press and release “F” on the key- board until the FSM menu appears (this process may take up to 4 minutes). The robot's GUI has started when Sawyer's eyes appear on the screen. - Page 138 3. Using a keyboard, navigate to CONFIGURATION and press ENTER. Fieldbus Devices Intera 5.3...

- Page 139 4. In the CONFIGURATION menu, enable the inside port and select which industrial Fieldbus protocol to use. 5. Then press the “config” button for the Inside Port to configure the network parameters. Fieldbus Devices Intera 5.3...

- Page 140 7. In the task bar in Intera Studio, the Industrial Network Device is in the Device Edi- tor panel. 8. Configure the Master Device (e.g. PLC) to look for the Sawyer Device. 9. Install the relevant files (EDS/GSDML) on the Master Device.

- Page 141 10. Verify Sawyer is visible from the Industrial Device Master. 11. In Intera, configure signals by selecting the appropriate Modules/Assemblies on the Device Editor. 12. The Fieldbus is set up and the device configuration is complete. The robot should be able to communicate with the devices.

-

Page 142: Sawyer And Safety

Sawyer and Safety For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Safety Statement Complying with ISO 10218-2 requires performing a risk assessment of each application to determine the needed safety performance and safeguarding. -

Page 143: How These Unique Collaborative Robots Safely Manage Operational Risks

Unlike typical industrial robots that operate behind safeguarding, Sawyer(TM), the collaborative robot from Rethink Robotics, is designed to work effectively directly alongside people in a factory setting, making it possible to deploy in environments which have historically been off-limits to robotic automation. - Page 144 (Category 0 protective stop per IEC 60204-1). • Brake Applied at Joints on Power Loss: When experiencing a power loss, Sawyer will brake using residual power to slow to a stop. Sawyer’s small joints will slowly return to a gravity-neutral position. Sawyer also has physical brakes that hold the position of the shoulder and elbow joints, yet can be released simply by pressing a button to allow manual re-positioning of the robot arm.

-

Page 145: Rethink's Collaborative Robot Regulatory Certifications

If either presents a hazard, safeguarding can be required. For example, a risk assessment for an application where Sawyer would be handling “knives” or sharp- edged objects would result in excluding collaborative operation and using Sawyer as a typical machine that is safeguarded. -

Page 146: Iec 6100-4-2

IEC 6100-4-2 Sawyer has been tested to IEC 61000-4-2, electrostatic discharge immunity, with the following limits: air discharges +/-8kV, contact discharges +/-4kV. See the results below: • CISPR 11 Radiated Emissions - PASSED - Class A • CISPR 11 Conducted Emissions - PASSED - Class A •... -

Page 147: Mexico

[RFSHT]. OVERVIEW Sawyer conforms to the applicable requirements in relevant EU Directives including those under Machinery, EMC, Low Voltage and RoHS, and is placed on the market in the EU as partly completed machinery under a Declaration of Incorporation. The robot must not be put into service until the final installation has been declared in conformity with the Machinery Directive. -

Page 148: Japan

• Industrial robots are not listed under DENAN regulations (electrical safety), however, IEC 61010-1 CB certificate covers general electrical & fire safety requirements Learn More To learn more about Sawyer’s safety and regulatory compliance, contact your authorized Rethink Robotics Distributor Partner or visit www.rethinkrobotics.com. Sawyer and Safety Intera 5.3... -

Page 149: Maintaining And Supporting Sawyer

Cleaning Sawyer To clean Sawyer, you may periodically wipe it down with a clean, damp cloth. Do not use abrasives or solvents. Check the fan filter in the controller box periodically and clean if necessary. -

Page 150: Calibrating Sawyer

Calibrating Sawyer In order to Calibrate Sawyer, you must access the CALIBRATE routine on Sawyer’s Head Screen: On the main screen, press the Rethink Button, then go to SYSTEM, and then click on CALIBRATE. Use this feature to calibrate each of Saywer's 7 joints. The calibration routine takes about 5 minutes. -

Page 151: Appendix A: Glossary

Appendix A: Glossary For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Glossary • Approach Point - The pose that immediately precedes an action. - Page 152 • Intera Studio - The Intera 5 software on the Chrome browser, used to create the programming logic for Sawyer tasks. It features a behavior editor of the task and a simulated Sawyer robot. The second screen may be connected to an actual Sawyer robot.

-

Page 153: Appendix B: Support & Warranty

Appendix B: Support & Warranty For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. The Sawyer robot comes with a one (1) year limited warranty. -

Page 154: Appendix C: Certifications And Information For Integrators

Appendix C: Certifications and Information for Integrators For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Third Party Certifications... - Page 155 Intera 5.3...

- Page 156 Intera 5.3...

-

Page 157: Declaration Of Incorporation

Declaration of Incorporation EC Declaration of Incorporation (Original) We, Rethink Robotics, Inc. of 27-43 Wormwood St, Boston, MA, U.S.A, declare under our sole responsibility that the product described below Type: Collaborative Robot Model: Sawyer Robot Arm Serial Number________________________________________________ Controller Serial Number ________________________________________________... -

Page 158: Information For Integrators

Information for Integrators Risk assessment Sawyer is supplied for assembly with other equipment to form a complete machine and is not itself a complete machine. Integrators must therefore perform an application risk assessment based on general shop safety rules and safety standards that considers the installation, surroundings, work- force training and competence, and the general safety culture. -

Page 159: Use Considerations

Safe use of Sawyer requires that integrators and users follow Rethink’s installation and mounting instructions for Sawyer. Sawyer is not intended for use in explosive atmospheres or any environment designated as a haz- ardous location under relevant electrical codes. Use of Sawyer without perimeter safeguarding requires risk assessment to determine whether or not associated hazards pose unacceptable risks, for example, hazards could be present with the use of sharp end-effectors/parts or with the handling of toxic or other hazardous substances. -

Page 160: End-Effectors

Sawyer must be positioned to ensure separation from other workstations and traffic aisles (to limit opportunities for passersby to enter the workspace). If personnel are working close to Sawyer they must have an unobstructed view of Sawyer at all times. -

Page 161: Awareness

Awareness Integrators may provide a status lamp to indicate to personnel that Sawyer is operating at normal speed. Users must be made aware that a potential pinch hazard is present when either of the lower corners... - Page 162 ISO 10218-1: 2011, Robotics and robotic devices - Safety requirements - Part 1: Industrial robots. ISO 10218-2: 2011, Robots and robotic devices - Safety requirements - Part 2: Industrial robot systems and integration. ISO 12100: 2010, Safety of machinery - General principles for design - Risk assessment and risk reduction.

-

Page 163: Appendix D: Ratings And Performance Specs

Appendix D: Ratings and Performance Specs For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Supply Ratings... -

Page 164: Environmental Ratings

Environmental Ratings: Parameter Rating Environment Indoor use Noise Sawyer's weighted emission sound pressure level at workstation does not exceed 70 dB(A) Altitude Up to 2000 meters Operating Temperature 5°C to 40°C Relative Humidity 80% for temperatures up to 31°C, decreasing linearly to 50% relative humidity at 40°C Mains Supply Voltage Fluctuations Up to ±10% nominal voltage Transient Overvoltage Overvoltage Category II Pollution Degree Intera 5.3... -

Page 165: Tool Tip Speed

Tool Tip Speed The tool tip speed is a measured at Sawyer’s tool plate when it is moving through space. There is an unlimited number of variables that contribute to the measured tip speed, including pose of the arm, end of arm tooling specs (weight, moment load, part presence, etc.), and speed settings in the software. - Page 166 Task 2: Pick and Place task with joint acceleration set to Express A typical Pick and Place task where the robot is picking an object from a table, moving approxi- mately 120 degrees around J0, placing the object, and stating again. The joint acceleration setting in the software is set to express and the move is defined as a...

-

Page 167: E-Stop Performance

J0 and J2 are set to rotate around the base for a 180 degree move- express ment. The joint acceleration setting is set to in the Intera software. Sawyer Safety For more information regarding speed as it relates to safety standards, please see Overview: Safety by Design E-Stop Performance When an emergency stop is performed, the power is cut to the arm at the motor level, and the robot stops wherever it is in the task. -

Page 168: Payload Vs. Reach

Low Power Mode Payload vs. Reach Depending on where Sawyer is in the workspace and how the end-effector is designed, the combi- nation of speed, acceleration, reach and payload can have an impact on overall performance of the robot. We can use Figure D-4 to represent the workspace in terms of speed ratio, acceleration, reach and payload, unless one of the following conditions is met: •... - Page 169 The reach is defined as the straight-line distance between Sawyer’s center point mounting location and the center of mass of the payload. The payload includes the end-effector and object weights. The speed ratio and acceleration can be set in the software.

- Page 170 Please be aware operating the robot out of the recommended ranges may negatively impact the robot performance and increase the risk of hardware damage, which may not be cov- ered by warranty. Please consult Rethink Robotics’ Support Team or Channel Partners if you need assistance.

-

Page 171: Performance With Advanced End-Effectors

1 m, the payload is under 2 kg and the offset from the J6 axis is less than 10 cm. First, let’s define the on-axis and off-axis distances with respect to Sawyer’s cuff according to Fig- ure D-5. - Page 172 Any end-effector should operate within both the on-axis and off-axis boundaries. If the maximum reach of the robot is greater than 1 m or for regions where express is not recommended, the speed ratio should not be set to greater than 0.6. You are free to set the speed ratio up to 1 in any other regions.

- Page 173 Figure D-6: Recommended acceleration setting as a function of on-axis payload position (defined in Figure D-5) and payload. Figure D-7: Recommended acceleration setting as a function of off-axis payload position (defined in Figure D-5) and payload. To interpret the data, find the appropriate on-axis and/or off-axis distance and payload you are looking for.

- Page 174 Please be aware operating the robot out of the recommended range may negatively impact the robot performance and increase the risk of hardware damage, which may not be cov- ered by warranty. Please consult Rethink Robotics’ Support Team or Channel Partners if you need assistance.

- Page 175 Figure D-8: Flow chart for determining when to use (1) Figure D-4 or (2) Figures D-6 and D-7. Intera 5.3...

-

Page 176: Appendix E: Warnings & Notices

Rethink Support. Warnings & Notices If Sawyer is used in a manner not specified by Rethink Robotics, the protection provided by the equipment may be impaired. FCC Part 15 Notice: This equipment complies with part 15 of the FCC Rules. Operation is subject to the... - Page 177 Sawyer is considered ‘Electrical and Electronic Equipment’ (EEE) under EU Council Directive 2012/19/EU on waste electrical and electronic equipment (recast) [WEEE] and contains an internal non-rechargeable coin cell battery. Do not dispose of the equipment with general waste at the end of its life. Users are encouraged to discard WEEE separately from other waste and may obtain guidance on disposal from their local electronic equipment waste management authority.

-

Page 178: Appendix F: Safety Subsystem

Appendix F: Safety Subsystem For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. The Safety Subsystem The main function of the safety subsystem is to control the motor bus power relays and to report the status of the safety subsystem. -

Page 179: The Banner Safety Controller

The Banner Safety Controller Sawyer uses a Banner Safety Controller (SC26-2evm), which is housed in Sawyer's controller box, as the controller of its safety subsystem. Here is a block diagram illustrating how the subsystem is wired: Intera 5.3... - Page 180 Intera 5.3...

- Page 181 The Banner Safety Controller is customer-accessible for customers who may want to attach other safety devices. It is also configurable, so customers can configure the desired behavior, if not already supported via the standard configuration provided by Rethink Robotics and documented here.

- Page 182 EMERGENCY STOP SWITCH Sawyer ships with an E-stop device (Emergency Stop button), which can be used in the event of an emergency to remove power from Sawyer's arm. The E-Stop button is a safety-rated safety device that meets functional safety performance level PLd CAT3.

- Page 183 When the operator leaves the safety space and presses the Re-Enable button, for example, the Banner Safety Controller receives that signal and closes the motor bus relays, making bus power available to Sawyer's arm again. (This is the same effect as pressing OK on the Sawyer navigator to Intera 5.3...

- Page 184 Access Switch - If Sawyer is housed in a cage or behind a door whose lock is wired to the Banner Safety Controller, the owner of the key has access and will be able to override the other safety devices.

-

Page 185: Appendix G1: Intera Profinet Reference

Appendix G1: Intera PROFINET Reference For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. This document describes the data structures and connections of Intera's PROFINET implementation and GSDML. -

Page 186: Setup Resources

Setup Resources The Rethink Intera GSDML will be necessary to setup the Intera PROFINET IO Device on the PLC. • The GSDML and corresponding image icon can be downloaded directly from the robot via a link in the 'Device Editor' window, found in Intera Studio. •... -

Page 187: Summary Of Modules

Summary of Modules From-Robot Modules Summary Module Name Contents Size** (bytes) * Fixed Data 112 From-Robot Robot data Version Status Flags {Robot, Arm, Task, and Safety} Times * Standard Bools 114 From-Robot 114 64 Booleans * Standard Ints 116 From-Robot 24 Integers (32-bit) * Standard Floats 118 From- 24 Floats (32-bit) -

Page 188: To-Robot Modules Summary

bytes), followed by a 2 byte spacer (88 bytes total). **** Reserved for future use. To-Robot Modules Summary Module Name Contents Size** (bytes) * Standard Bools 113 To-Robot 64 Booleans * Standard Ints 115 To-Robot 24 Integers (32-bit) * Standard Floats 117 To-Robot 24 Floats (32-bit) Small Bools 119 To-Robot 32 Booleans... -

Page 189: Modules Data Tables

Modules Data Tables • Robot Output data modules (from Robot to PLC) are formatted with the byte off- sets shown in the following tables (per module). • Robot Input data modules (from PLC to Robot) do not include a 'Fixed Data' module, but are otherwise formatted the same, with each To-Robot module mir- roring a corresponding From-Robot module in the opposite direction. -

Page 190: Fixed Data 112 From Robot

Fixed Data 112 From Robot Intera 5.3... -

Page 191: Standard Booleans

Standard Booleans (113: To-Robot | 114: From-Robot Standard Integers (115: To-Robot | 116: From-Robot) Intera 5.3... -

Page 192: Standard Floats (117: To-Robot | 118: From-Robot)

Standard Floats (117: To-Robot | 118: From-Robot) Small Booleans (119: To-Robot | 120: From-Robot) Intera 5.3... -

Page 193: Small Integers (121: To-Robot | 122: From-Robot)

Small Integers (121: To-Robot | 122: From-Robot) Small Floats (123: To-Robot | 124: From-Robot) Intera 5.3... -

Page 194: Small Strings

Small Strings (125: To-Robot | 126: From-Robot Large Bools (127: To-Robot | 128: From-Robot) Large Integers (129: To-Robot | 130: From-Robot) Intera 5.3... -

Page 195: Large Floats (131: To-Robot | 132: From-Robot)

Large Floats (131: To-Robot | 132: From-Robot) Large Strings (133: To-Robot | 134: From-Robot) Intera 5.3... -

Page 196: State Flags Definitions

State Flags Definitions Bit Definitions for State Flags Below are the bit positions for the various State Flag fields within the predefined data from the robot. Robot State Flags 0 Ready 1 Enabled 2 Error Arm State Flags 0 Arm Moving 1 Zero-G Active Task State Flags 0 Task Running... -

Page 197: Robot State Flags Meaning

Safety Mat Released Protected Stop Released Continue Task Released Restart Task Released Re-Enable Button Released Robot State Flags Meaning Ready Enabled Error State Action OK - Ready None Not Ready - Most likely not Home Robot Homed (e.g. after initial boot) Error/Stopped - Hardware Error Clear Safeguard &... -

Page 198: Data Addressing And Format

Data Addressing and Format Notes: • Numeric data is by default sent/received in Big-Endian byte-order. • Boolean and String Variables are arrays of bytes, and may be treated as Little- Endian byte-order. • However, the order of bits inside each byte is still largest bit first. EXAMPLE: BOOLEAN VARIABLES ADDRESSING Using example offset addresses Byte 40 - Byte 47 (Adjust for the memory offsets of the Intera Modules in your PLC program). - Page 199 Address by Byte (8-bit): Addressing by Double Word (32-bit): %IB40.0= Boolean Variable 0 %ID40.0= Boolean Variable 24 %IB40.1= Boolean Variable 1 %ID40.1= Boolean Variable 25 %ID40.2= Boolean Variable 26 %IB41.0= Boolean Variable 8 %IB41.1= Boolean Variable 9 %ID40.7= Boolean Variable 31 %ID40.8= Boolean Variable 16 %IB42.0= Boolean Variable 16 %ID40.9= Boolean Variable 17...

-

Page 200: Appendix G2: Intera Ethernet/Ip Reference

Appendix G2: Intera EtherNet/IP Reference For the latest and most detailed information on Sawyer and Intera 5, we always recommend you see the Online User Guide at: mfg.rethinkrobotics.com/intera. The Rethink Robotics support page is here: Rethink Support. Overview The data tables in this document describe the format and byte addressing of the EtherNet/IP Assemblies defined in the EDS (Electronic Data Sheet) for Intera. - Page 201 • The EDS can be downloaded directly from the robot via a link in the 'Device Edi- tor' window, found in Intera Studio. • The 'Device Editor' also provides helpful address lookups when creating signals. EtherNet/IP will also need to be enabled on the controller and the network properly configured from the Field-Service-Menu (FSM) on the robot.

-

Page 202: Summary Of Assemblies

Summary of Assemblies From-Robot Assemblies Summary Assembly Name Size** Contents Section Offset (bytes) Sizes** * Standard From-Robot Robot data Assembly Version Status Flags {Robot, Arm, Task, and Safety} Times 64 Booleans 24 Integers (32-bit) 24 Floats (32-bit) +144 1 String*** +240 Small Assembly 32 Booleans... -

Page 203: To-Robot Assemblies Summary

To-Robot Assemblies Summary Assembly Name Size** Contents Section Offset (bytes) Sizes** * Standard To-Robot 64 Booleans Assembly 24 Integers (32-bit) 24 Floats (32-bit) +104 1 String*** +200 Small Assembly 32 Booleans 3 Integers 6 Floats Large Assembly 512 Booleans 42 Integers 42 Floats +232 1 String***... -

Page 204: Assembly Data Tables

Assembly Data Tables From-Robot Standard Assembly (112) Robot Output data (from Intera to PLC) is formatted with the following byte offsets Intera 5.3... -

Page 205: To-Robot Standard Assembly (113)

To-Robot Standard Assembly (113) Robot Input data (from PLC to Intera) is formatted with the following byte offsets Intera 5.3... -

Page 206: Small Assembly (114: From-Robot | 115: To-Robot)

Small Assembly (114: From-Robot | 115: To-Robot) Intera 5.3... -

Page 207: Large Assembly (116: From-Robot | 117: To-Robot)

Large Assembly (116: From-Robot | 117: To-Robot) Intera 5.3... -

Page 208: Floats+ (118: From-Robot | 119: To-Robot)

Floats+ (118: From-Robot | 119: To-Robot) Intera 5.3... -

Page 209: Strings+ (120: From-Robot | 121: To-Robot)

Strings+ (120: From-Robot | 121: To-Robot) Intera 5.3... -

Page 210: State Flags Definitions

State Flags Definitions Bit Definitions for State Flags Below are the bit positions for the various State Flag fields within the predefined data from the robot. Robot State Flags 0 Ready 1 Enabled 2 Error Arm State Flags 0 Arm Moving 1 Zero-G Active Task State Flags 0 Task Running... -

Page 211: Robot State Flags Meaning

E-Stop Released Safety Mat Released Protected Stop Released Continue Task Released Restart Task Released Re-Enable Button Released Robot State Flags Meaning Ready Enabled Error State Action OK - Ready None Not Ready - Most likely not Home Robot Homed (e.g. after initial boot) Error/Stopped - Hardware Error Clear Safeguard &... -

Page 212: Data Addressing And Format

Data Addressing and Format Notes: • Data is sent/received in Little-Endian byte-order between Intera and the PLC. • Boolean and String Variables are considered arrays of bytes. EXAMPLE: BOOLEAN VARIABLES ADDRESSING Using example offset addresses Byte 40 - Byte 47 (Adjust for the memory offsets of the Intera Assemblies in your PLC program). -

Page 213: Index

28 Google Chrome 27, 31 button Go To 52 cable networking 26 Calibrate 65 Calibrating Sawyer 143 Cartesian view 53 Charts List 99 cleaning Sawyer 142 ClickSmart Gripper 56 ClickSmart Robot Side Adapter 19 collision avoidance 12 Compliance 108... - Page 214 Force Sensing 106, 124 Frame 144 Frames 43 Getting Started 22 getting started 26 Getting Started with Intera 5 26 Getting Started with Sawyer 22 Glossary 144 Go To button 52 Google Chrome 27 Google Chrome browser 31 Graphical User Interface (GUI) 12...

- Page 215 hot keys 42, 51 IEC 6100-4-2 139 Impedance Mode 108 Import Task 33 Installation risk guidelines 153 Integer 125 Integrators information for 147 Risk assessment 151 Intended use 4 Intera 5 Getting Started 26 Intera Insights 98 Intera Insights Panel 99 Intera Studio 31, 145 3D View 49 components 32...

- Page 216 Safety Statement 3, 135 Safety Subsystem 171 Safety Symbols 21 Sawyer simulated 31 turning on 23 selective arm stiffness 106, 124 selector knob 15, 16 Sequence Node 145 service how to acquire 21 Setting Up Sawyer 22 Settings 34 Shared Data 48...

- Page 217 Signal Variable 145 Signals 45 Signals tab 45 Simulated Robot change view of 51 how to move 52 simulated Sawyer robot 31 Snapshot Editor 45 SOPs & training 153 Square button 16 start, how to 26 State Flags 189, 203...

- Page 218 Zero G button 16, 17 Zero G mode 24 Zero Gravity mode 17 zoom reset 42...

- Page 220 Last updated June 18, 2018 Intera 5.3 User Guide/Getting Started Rev. A...

Need help?

Do you have a question about the Sawyer and is the answer not in the manual?

Questions and answers