Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Cellink BIO X 3D Bioprinter

- Page 1 BIO X 3D Bioprinter User Manual...

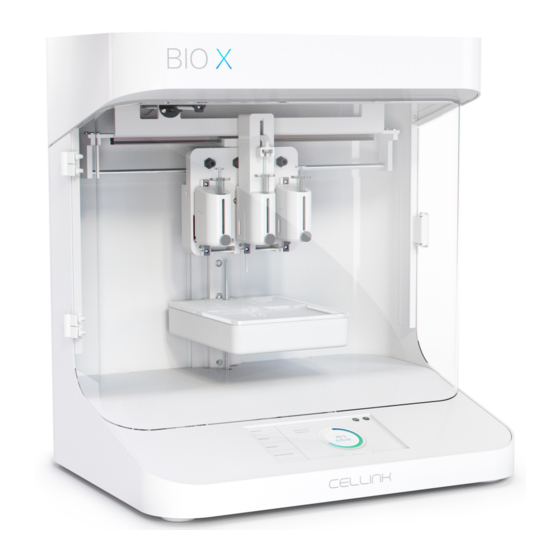

- Page 2 Welcome to the world of bioprinting! Not too long ago, the idea of creating living human tissue was no more than a dream. Not anymore. The technology in front of you is the next step on the path of regenerative medicine. BIO X is designed with your research in mind.

-

Page 3: Table Of Contents

4.3 Bioprinting droplets 4.4 Utilities 5. Maintenance 5.1 Changing the HEPA filter 5.2 Manual cleaning or sterilization 6. Terms and Conditions 6.1 General Terms and Conditions 6.2 End User Licence Agreement (EULA) 6.3 Warranty 7. Printhead manuals 7.1 CELLINK pneumatic-based printhead... - Page 4 ISO 9001...

-

Page 6: Safety Information

In order to respond to BIO X and its relevant security requirements, all personnel using BIO X must have read through the entire manual. Should anything appear out of order or a situation occur that is not described in the manual, contact CELLINK before using the instrument any further! Use the instrument only for its intended purpose as described in the documentation. -

Page 7: Unpacking, Lifting And Carrying

UV and temperature conditions. Should BIO X be damaged in any way, turn off and unplug BIO X, and contact CELLINK before further use of the equipment. 1.2 Unpacking, lifting and carrying Please read through the instructions on how to safely unpack and set up BIO X in Chapter 3: Getting started. -

Page 8: Hazardous Materials

“as is” and CELLINK makes no warranty as to its use or performance. Except for any warranty, condition, representation or term the extent... -

Page 10: Specifications

Specifications... -

Page 11: Product Map

2. Specifications 2.1 Product map Clean Chamber (tm) unit UV sterilization LED 1 UV sterilization LED 2 Printhead mount 1 Printhead mount 2 Printhead mount 3 Photo curing module mount 1 Photo curing module mount 2 Printbed 7’’ touch screen USB port Protective door... - Page 12 2.1 Product map 5 6 7 Heat vent from the printbed. Heat vent from the printbed. Power switch Fuse Power socket USB port Ethernet port Pneumatic port...

-

Page 13: Technical Specifications

2.2 Technical specifications Power input: 100-240 VAC, 50-60 Hz, 600 W Fuse: 250V T8A Air pressure input: 0-700 kPa Weight: 17 kg Height: 500 mm Width: 360 mm Depth: 450 mm Filter class: HEPA 14... - Page 15 Getting started!

-

Page 16: Getting Started! 3.1 Unpacking Bio

3. Getting started! 3.1 Unpacking BIO X To unpack BIO X, follow the simple steps below. Caution! To avoid injury to personnel and to avoid damaging BIO X during the unpacking process, follow the instructions provided bellow. DO NOT attempt to unpack BIO X in any other way than the one instructed. Caution! BIO X is a heavy instrument. -

Page 17: Contents Of The Box

[5x] Female to female luer lock adapters............ [20x] 3mL empty cartridge with piston and end caps......[2x] STARTINK-kit (sterile), each containing:............[1x] Cell syringe....................[1x] Syringe with 3 mL of CELLINK Bioink..........[1x] Dispensing unit..................[1x] Mixing unit....................[1x] Filling cartridge.................. - Page 18 3.2 Contents of the box Nozzles and consumables box containing: [1x] Empty 12mL syringe................... [1x] Sterile nozzle kit....................[1x] Sterile high precision conical nozzles, 50 pcs (Blue, GA 22)...... [1x] Sterile high precision conical nozzles, 50 pcs (Red, GA 25)....... [1x] Sterile high precision conical nozzles, 50 pcs (Clear, GA 27).....

-

Page 19: Setting Up Bio

3.3 Setting up BIO X When BIO X is unpacked, it is time to set up. Before connecting BIO X to a wall socket, ensure that the socket is grounded. Next, connect BIO X to the power outlet (see 2.1 Product map) and the grounded wall socket with the included power cable. BIO X has an internal air supply capable of supplying 200 kPa to the printheads. -

Page 20: Starting Bio X For The First Time

Droplet Print - Tap to use the droplet menu. It allows the user to print droplets only by selecting the wellplate -used. Clean chamber - Tap to toggle settings related to CELLINK’s clean chamber technology or to initialize an UV sterilization procedure. - Page 22 Bioprinting...

-

Page 23: Bioprinting With Bio

To ensure a sterile environment, BIO X is equipped with a UV sterilization system which will create a sterile printchamber which is then maintained sterile by the Clean Chamber Technology. CELLINK recommends running the UV sterilization procedure before each bioprinting session. -

Page 24: Bioprinting From A 3D Model

4.2 Bioprinting from a 3D model Choose this option to start a new bioprinting process using a 3D model. BIO X will guide you through the process and help you to set up for a perfect bioprint. Open file Insert an USB-drive containing your 3D model and any custom profiles you would like to use into the USB-port on the front of BIO X. - Page 25 4.2 Bioprinting from a 3D model Print surface Next select the surface on which to bioprint. BIO X can bioprint on a range of different surfaces, from petri dishes to well plates to glass slides. Select the surface that you want to print on and the size of the surface.

- Page 26 Printhead type – Select the type of printhead you want to use. Different settings will appear below depending on what type of printhead you select. BIO X comes preloaded with profiles for all CELLINK’s intelligent printheads. Photo curing – Toggle whether to use UV to crosslink the model. If...

- Page 27 4.2 Bioprinting from a 3D model Printheads and printbed When you have selected to use a printhead further settings regarding the printhead will appear. You can choose either to use or tweak a predefined profile or to create an entirely new one. The bioink and photo curing parameters remain the same for all different bioinks and printheads, however, the printhead parameters change depending on what type of printhead you decide to use.

- Page 28 4.2 Bioprinting from a 3D model Printheads and printbed In the printbed settings you can adjust the temperature of the printbed. You can choose between having the printbed at a certain temperature or to turn the temperature control off and bioprint at the ambient temperature. Clean chamber fan –...

- Page 29 Layer profile – Select one of the saved layer profiles or choose to create a new one. Infill density – Tap to select how dense the model should be (%). Layer height – Tap to select layer height. CELLINK advises to use the same layer height as the nozzle diameter.

- Page 30 4.2 Bioprinting from a 3D model Layer settings - Infill pattern Honeycomb pattern – The honeycomb pattern is suitable as an infill for tissue constructs that must be mechanically rigid such as bone. The pattern is most relevant for constructs to withstand compression. Linear pattern –...

- Page 31 4.2 Bioprinting from a 3D model Layer settings - Printhead use In the ‘Printhead use’ settings, you can decide which printhead should bioprint which part of your 3D structure. This enables you to use support structures when bioprinting, allowing for the creation of complex structures using multiple infill materials. Three different modes are available: Infill –...

- Page 32 4.2 Bioprinting from a 3D model Overview and mounting of bioprinting equipment In this step, all the settings can be reviewed. Should a setting or value be incorrect you can easily go back to that step and correct it by pressing the navigation bar at the bottom of the screen.

- Page 33 4.2 Bioprinting from a 3D model Overview and mounting of bioprinting equipment It is now time to load and mount the printheads and print surface in BIO X. By following your settings on the screen, it is easy to set up BIO X correctly for your bioprinting process.

- Page 34 4.2 Bioprinting from a 3D model Overview and mounting of bioprinting equipment When inserting your print surface, use the spring-loaded arms to securely fasten it according to the figure below. If you are using a well plate, simply turn the arms to the sides.

- Page 35 4.2 Bioprinting from a 3D model Calibration and ABL In the calibration settings, you can proceed to the calibration of your printheads and the surface probe. The surface probe is used to proceed to the ABL (Auto Bed Leveling). The ABL probes the bed at 3 points and enables bed leveling compensation in software by using a matrix to compensate for bed and/or print surface tilt.

- Page 36 4.2 Bioprinting from a 3D model Print model This screen gives an overview of the bioprinting process. It will allow you to monitor the activity of each printhead and curing module during the whole process. Caution! Do not open the door without pausing the bioprinting process and do not remove the printheads before the bioprinting process has completed.

- Page 37 4.2 Bioprinting from a 3D model Print model While you are printing, you can choose to pause the printing at any moment. Then you can choose to cancel the printing or resume. Pause – Tap to pause the bioprinting process. Resume - Tap to resume the bioprinting process.

-

Page 38: Bioprinting Droplets

4.2 Bioprinting droplets Choose this option to start bioprinting droplet without having to create a gcode for it. BIO X will guide you through the process and help you to set up for a perfect bioprint. Choose Print surface Select the wellplate on which you wish to bioprint. BIO X can bioprint on a range of different wellplates, from 6 to 96 wells. - Page 39 If you select to use the printhead further settings will appear. Bioink profile – Select the bioink profile you want to use or create a new one. BIO X comes preloaded with profiles for all CELLINK’s bioinks. Printhead type – Select the type of printhead you want to use.

- Page 40 4.2 Bioprinting droplets Overview and mounting of bioprinting equipment In this step, all the settings can be reviewed. Should a setting or value be incorrect you can easily go back to that step and correct it by pressing the navigation bar at the bottom of the screen.

- Page 41 4.2 Bioprinting droplets Calibration and ABL As in the bioprinting menu, in the calibration tab you can proceed to the calibration of your printheads and the surface probe. The surface probe is used to proceed to the ABL (Auto Bed Leveling). The surface probe only needs to be calibrated once, the printer will then remember this calibration and apply it for each prints.

- Page 42 4.2 Bioprinting droplets Print model This screen gives an overview of the bioprinting process and will allow you to monitor the activity of each printhead during the whole process. Caution! Do not open the door without pausing the bioprinting process and do not remove the printheads before the bioprinting process has completed.

-

Page 43: Utilities

4.4 Utilities Update your Software version The first tab in the “utilities” menu allows you to update your Software version. Once the update is dowloaded on the USB drive, insert it in the Bio X. You can then access it via this tab and procede to the updating of your Bio X. USB content list –... - Page 44 4.4 Utilities Printhead & printbed temperature control The second tab allows you to control the temperature of your printheads and the printbed. That way you can choose to pre heat your printhead and/or printbed so that they would have the proper temperature as soon as you want to start Bioprinting. You can also choose to pre cool the printbed.

- Page 45 4.4 Utilities Printheads pressure control This allows you to test the pressure needed for the printhead to extrude correctly the material being used. This pressure mainly depends on the viscosity of the material. Set pressure for each printhead (0-200kPa, when using the internal air compressor).

- Page 46 4.4 Utilities Miscellaneous tab With this tab you can enable special features of the printerm either for experimental or customer support purposes. Enable dark mode - turn off all the chamber lights. This allows you to work with photo sensitive material. Clean chamber fan –...

- Page 47 4.4 Utilities Printhead movement test Thanks to this tab you can test the movement of the printheads along the 3 axis (x,y,z) before printing. Printhead 1 - test movement for printhead 1. Printhead 2 - test movement for printhead 2. Printhead 3 - test movement for printhead 3.

- Page 48 4.4 Utilities Customer support tabs The output data tab is exclusively used when performing customer support. It allows us to check and test the different sensors. Output data - Allows customer support to check and test the different censors. License - Gives you access to all the licenses of the printer and the software.

-

Page 49: Maintenance

Maintenance... -

Page 50: Changing The Hepa Filter

5. Maintenance 5.1 Changing the HEPA filter The HEPA filter is part of CELLINK’s patented Clean Chamber (tm) technology, ensuring a sterile printchamber for your research. To ensure this, the HEPA filter must be changed after 160 hours of runtime. Simply follow the instructions below to do this: Turn off BIO X and disconnect the power cable. -

Page 51: Manual Cleaning Or Sterilization

5.2 Manually cleaning or sterilizing BIO X BIO X is covered with chemically resistant coating. It can be cleaned or sterilized with ethanol. Turn off and uplug BIO X before cleaning it with ethanol. Then simply spray the surface you wish to sterilize and wipe the surface with a soft cloth. Caution! If ethanol has been used to clean the printchamber of BIO X, wait a minimum of 60 seconds before starting BIO X. -

Page 53: Terms And Conditions

Terms and Conditions... -

Page 54: General Terms And Conditions

In the event that the Buyer at any time should fail to make payment in full on the due date Cellink shall be entitled to claim interest on the sum overdue until payment is made at the rate equivalent to the reference rate of interest (as determined by the Central Bank of Sweden) plus eight percentage points per annum. -

Page 55: General Terms And Conditions

Buyer shall perform a full inspection of the Product where such was not possible on receipt of the Product in question. The obligation to report any defects to Cellink as set out in section below shall apply in such context. - Page 56 If Cellink fails to fulfil its obligations under this section within a reasonable time, the Buyer may by written notice require Cellink to do so within a final time. If Cellink fails to fulfill its obligations within that time limit, the Buyer may terminate the purchase of the defective Products in question by written notice.

- Page 57 Cellink (the “Product Software”), is licensed, not sold, to the Buyer for use in accordance with these General Terms. Cellink [and its licensors] retain ownership of the Product Software itself and reserve all rights not expressly granted to you.

- Page 58 Products with respect to which the loss, damage or breach occurred. In no event shall Cellink be liable towards the Buyer for any loss of production or profit, loss of use, loss of data, loss of contracts or for any other consequential, economic or indirect loss whatsoever in respect of the sale, purchase, use or disposition of the Product.

- Page 59 6.1 General Terms and Conditions 13. FORCE MAJEURE The Parties shall be relieved from liability for a failure to perform any obligation under the Agreement during such period, and to the extent that the due performance thereof by either of the Parties is prevented by reason of any circumstance beyond the control of the Parties (“Discharging Circumstance”).

- Page 60 6.1 General Terms and Conditions 15. MISCELLANEOUS The Agreement, including all appendices hereto including the General Terms, contains the final, complete and exclusive agreement of the Parties relative to the subject matter hereof and supersedes all prior and contemporaneous understandings and agreements relating to its subject matter.

-

Page 61: End User Licence Agreement (Eula)

BE DEEMED LICENSEE’S CONCLUSIVE ACCEPTANCE OF THE MODIFIED TERMS. CELLINK holds all right, title, and interest in and to the CELLINK 3D Bioprinter Software (“Licensed Software”) and all associated websites, platforms, and applications, and is the sole and exclusive owner of https://cellink.com (the “Website”). - Page 62 4. UPDATES OR REVISIONS. CELLINK is not obligated to provide any services, updates or revisions to the Licensed Software, however, such updates may be introduced by CELLINK from time to time. The Licensed Software may communicate with CELLINK or its third- party provider servers to check for available updates (e.g., enhanced functionality and new...

- Page 63 INTERRUPTION OR CORRUPTION OF DATA OR OTHER INFORMATION TRANSMITTED IN CONNECTION WITH USE OF THE LICENSED SOFTWARE. Licensee agrees that CELLINK is not responsible or liable in any way for any of Licensee’s information or content. CELLINK and its service providers may use, access and retain Licensee’s information or content in order to provide services to Licensee, the information or...

- Page 64 Licensed Software to develop another product or service. Licensee agrees not to interfere with or disrupt servers, networks or the hosting of data by CELLINK or its service providers, including by transmitting computer viruses or other malicious computer code, programs or files.

- Page 65 6.2 BIO X EULA 10. LIMITATION OF LIABILITY. TO THE FULLEST EXTENT ALLOWED BY LAW, IN NO EVENT SHALL CELLINK OR ITS SUBSIDIARIES, SUPPLIERS, OFFICERS, DIRECTORS, EMPLOYEES, AGENTS, PARTNERS, SUCCESSORS OR ASSIGNS BE LIABLE FOR ANY CONTRACT, TORT, INCLUDING WITHOUT LIMITATION...

- Page 66 Licensee’s use of the Licensed Software or CELLINK 3D Bioprinter. Licensee agrees not to settle any such matter without the prior written consent of CELLINK. For any matter which Licensee is required to indemnify CELLINK, CELLINK at its sole option may assume and control the defense at Licensee’s expense.

- Page 67 User License. Ambiguities in this User License will not be construed against the drafter. Licensee agrees that any terms of service may by modified by CELLINK upon written notice of such changes or additions to Licensee. If there is a conflict between this User License and other CELLINK terms of service, the other terms will apply.

-

Page 68: Warranty

DOA (dead on arrival) part (detailed description and documentation required), CELLINK will most likely send a replacement part to you. In the case that a customer has already been through all these previous options stated and is still not satisfied with the results, the customer must have the bioprinter sent back at their own expense. - Page 69 Concerning Refunds: A refund is possible only with the BIO X 3D Bioprinter itself and will not be offered for any filaments, or spare parts. If within two weeks (14 days) after receiving your BIO X 3D Bioprinter you are not completely satisfied, we offer you a refund option.

- Page 70 You ship it back at your own expense and after we receive it, we will deduct a 10% restocking fee from the total refund of the price of the BIO X 3D Bioprinter (excluding the tax and other fees). There will also be a thorough inspection of the bioprinter, and upon finding any damages deemed on the part of the buyer, other deductions from the refund would be made accordingly.

-

Page 72: Printhead Manuals

Printhead manuals... -

Page 73: Cellink Pneumatic-Based Printhead

The CELLINK pneumatic-based printhead is an extrusion based printhead. It is equipped with heating function up to 60°C and thanks to the possibility of connecting an external air supply, the CELLINK pneumatic-based printhead can be used when bioprinting most bioinks. - Page 74 Secure the cartridge in the printhead by turning the cartridge fastening screw. The CELLINK pneumatic-based printhead needs to be connected to an air supply in order to function. Do not forget to connect the pressure hose to the pressure connector...

- Page 75 Imagination is the beginning of creation. You imagine what you desire, you will what you imagine, and at last, you create what you will. -George Bernard Shaw Happy 3D bioprinting!

Need help?

Do you have a question about the BIO X 3D Bioprinter and is the answer not in the manual?

Questions and answers