Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Alunar M508 Prusa i3

- Page 1 3D Printer Quick Start Guide...

-

Page 2: Table Of Contents

Catalogue Foreword ....................................3 1. Machine parameters ..............................3 2. Flow Diagram for Quick Use Manual ..........................4 3.Important Notice and Attentions ............................4 4. Preparatory Work ................................5 4.1 Tool and kit preparing ............................5 4.2. Prompt ..................................5 5. - Page 3 10. Frequently Asked Questions and Solutions......................42 10.1 “Err: MINTEMP ” Alarm processing method ....................42 10.2 Trouble :LCD screen is not bright ........................ 43 10.4 Trouble :Rotation button can not be up and down the selection menu ..........44 10.5 No extruded filament when printing .........................

-

Page 4: Foreword

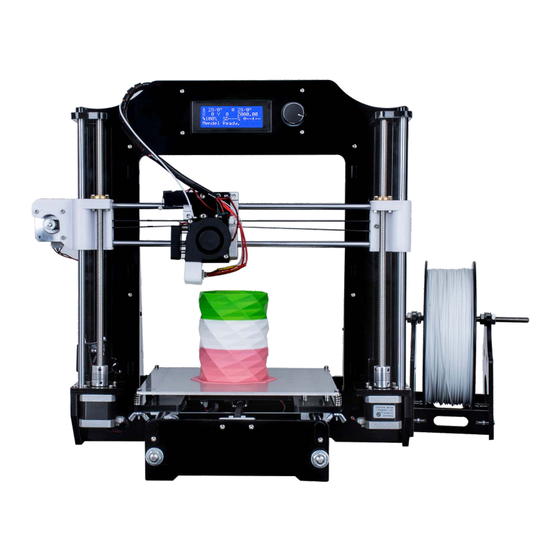

3D Printer M508 Quick Start Guide Foreword Thanks in advance for choosing our M508 3D Printer! With the Quick Use Manual (hereinafter as “Manual”) guide, you could enjoy accomplishing the assembly, Test and Printing step by step. Meanwhile, you will also learn the structure principle and its special FDM printing technology deeply, and then you will get great progress on not only the theoretical knowledge but also the manipulative ability. -

Page 5: Flow Diagram For Quick Use Manual

2. Flow Diagram for Quick Use Manual Matters and Attentions Preparatory Work Preinstallation Checklist Assembly and Calibration Printing Test Senior Instruction Frequently Asked Questions and Settle 3.Important Notice and Attentions 3.1 Keep the assembling operation platform level 3.2 Please ensure that you move to the right tap position for input voltage (110V or 220V) of the power supply (as shown in the picture) Input Voltage 100~160V... -

Page 6: Preparatory Work

3.9 Before installation, please remove the protective paper. 3.10 Please before printing label on crepe paper. 4. Preparatory Work 4.1 Tool and kit preparing One level desk at more than 2 sq. m. size, one computer, one scissor, SD card reader, power supply and so on. -

Page 7: Take An Account Of Kits

5.2 Take an account of kits Please check out all the parts and make sure if any part is lost or damaged as per the “Packing List” and video “Check out the kits”. Please feel free to contact our customer service once you find out that you lost or got any defective parts (except leading by the unartificial reason). -

Page 8: Step1 Frame Assembly

6.2 step1 Frame assembly ) \Video\1-Frame assembly.mp4 Video( SD-Card:... -

Page 9: Step2 Y Axis Assembly And Hotbed Assembly

6.3 step2 Y axis assembly and hotbed assembly ) \Video\ 2-Y-AxisAnd HotbedAssembly.mp4 Video(SD-Card:... - Page 12 6.4 Step3 Z axis assembly and X axis assembly ) \Video\3-Z-X-AxisAssembly.mp4 Video(SD-Card:...

-

Page 15: Step4 Extruder Assembly

6.5 Step4 Extruder assembly ) \Video\4-ExtruderAssembly.mp4 Video(SD-Card:... -

Page 18: Step5 Lcd Assembly

6.6 Step5 LCD assembly ) \Video\5-LCD-Assembly.mp4 Video(SD-Card: 6.7 Step6 power and mainboard assembly ) \Video\ 6-PowerAndMainboardAssembly.mp4 Video(SD-Card:... -

Page 20: Step7 Filament Rack Assembly

6.8 Step7 Filament rack assembly ) Video(SD-Card: \Video\7-FilamentRackAssembly.mp4 7. Testing and Commissioning 7.1 Power on test When connecting the power supply to your printer, please make sure whether the power indicator light is on, LCD screen show correctly or not, hotbed and the extruder can be heated rightly or not, the thermistor, turbine fan and radiator fan works normally or not;... -

Page 21: Fan Check

7.1.2 Fan check Switch on the power, this fan works 7.1.3 Nozzle and hot bed heating inspection “Prepare” →“Preheat PLA” 7.1.4. Back to the origin inspection “Prepare” →“Auto Home” X axis will move towards left ,Y axis will move towards back, Z axis will move down, each axis will stop moving till their limit switch... -

Page 22: Hotbed Leveling Test

X axis move Z axis move Y axis move 7.2 Hotbed leveling test: Please make calibration to level the hotbed according to the video ( \Video\HotBedLeveling.mp4) SD-Card: After assembling, you need to level the bed when firstly print 7.2.1 Rough Debugging to level hotbed 7.2.1.1 Adjust the screws at the 4 angle of the hotbed to make the screws 4mm out of the nut (Picture 7.1);... -

Page 23: Accurate Debugging

Picture 7.3 Picture 7.1 Picture 7.2 Picture 7.4 Picture 7.5 7.2.2 Accurate Debugging 7.2.2.1 Auto home and make the XYZ axis back to origin(Picture 7.6) ; 7.2.2.2 Screw the screws at 4 angle of hotbed to make the nozzle above 1mm to the hotbed (Picture 7.7) (PS: After Auto home, please click “Disable Steppers”... -

Page 24: Fine Debugging When Printing

7.2.3 Fine Debugging When printing Please check the printing status of first layer when you first printing by your printer. If you need, you can screw the screws at 4 angle of hotbed to the best position(as shown on picture 7.10) The different printing effect depends on the different distance between nozzle and hotbed:... -

Page 25: Change The Filament When Printing

down to extrude part of filament (Picture7.12) , then let the aluminum piece go, finally clear up the filament extruded . Filament he Upper Aluminum Piece Picture 7.12 Picture 7.11 Picture 7.13 7.3.2. Change the Filament When Printing 7.3.2.1 Click“tune” →“change filament”;The printer stop working and the XY axis would be back to the origin, then the extruder would send back the filament from the printer automatically (Picture 7.14)... -

Page 26: Instruction Of Operation Part For Off-Line Printing

7.4.1 Instruction of Operation part for Off-line Printing SD Card Power Switch Outlet LCD Screen Knob Picture7.16 Off-line printing operation for 3D printer constitute 5 parts as below( as shown above Picture 7.16): the Power Switch, Outlet, LCD Screen, Spin Button, and SD Card And you can control the knob easily and quickly by rotating and pressing. -

Page 27: The Secondary Memo Interface

current is 31° 2. 2 line It will show the exact position of XYZ axis move onto in the printing. 3. 3 line It will show the speed and rate of progress of printing, and used time for printing. And it shows the multiple speed of printing which is set up in the slicing.“100%”... -

Page 28: Prepare For Printing(Prepare)

7.4.3.2 The 2 memo interface when printing(as shown on picture 7.19) Information Current Parameter Adjustment Parameter Adjustment Pause print Stop print Picture 7.19 Click the (Info screen) and back the 1 page of memo interface Click the(Tune) and adjust the temperature of nozzle& hotbed, speed of fan when printing Click the (Control) and set up for the temperature of nozzle&... - Page 29 (4) Click the (Preheat ABS) and then the nozzle would be heating up to the same as the setting temperature for ABS, meanwhile, the LCD will also go back to the first memo interface (5)Click the (Cooldown), the temperature for nozzle and hotbed would be cool down to 0°automatically. (6)Click the(switch power off) to turn off the power ( it is not put into use at present) (7) Click the (Move Axis) to control the move of XYZ, input&...

-

Page 30: The Parameter Adjustment When Not Printing(Control

7.4.5 The Parameter Adjustment when not printing(Control) When not printing, you can rotate the knob and click the “Control” at the secondary memo interface (Picture 7.26), then you will access to the (Picture 7.27) ,4 (Picture 7.28) and 5 memo interface and make setting accordingly. -

Page 31: Realtime Parameter Adjustment (Tune

VTrav min: The Maximal speed of quicken enablement Amax X: The maximal acceleration speed of X axis Amax Y: The maximal acceleration speed of Y axis Amax Z: The maximal acceleration speed of Z axis Amax E: The maximal acceleration speed of Extruder A-retract: The acceleration at * mm/s Xsteps/mm: The distance of each step for X axis motor Ysteps/mm: The distance of each step for Y axis motor... -

Page 32: Parameter Adjustment When Printing(Control)

7.4.6 Parameter adjustment when printing(Control) When 3D printer printing, the secondary memo interface would be shown as(Picture 18), click the “Control” to access (Picture 7.27), 4 (Picture 7.28,7.29), ,5 (Picture to the 3 7.30) memo interface Picture 7.35 Picture 7.34 Picture 7.33 Pict2ure 7.37 You needn’t to adjust it since all the setting on Picture 7.35,... -

Page 33: Printing Test

8. Printing Test After all the above-mentioned test and you make sure the printer works well. Now you can get start a printing test. Please insert the SD Card into the card slot on the left back of the screen and then choose the “test-*.gcode”... - Page 34 Step1: Step2:...

- Page 35 Step3: Step4: Step5:...

- Page 36 Step6: Step7:...

- Page 37 Step8: Step9:...

- Page 38 Step10: Step11: Open file (STL)

- Page 39 Step12: Step13: Scale...

-

Page 40: Online Printing

Step14: Rotate Save as G-code Step15: 9.1.2 Online Printing Connect the printer to your computer and then you can get start printing by computer control. Connecting to your computer with USB cable: Please open the “SD-Card: \ Software \RepetierHost_1_0_6” and click the software“RepetierHost_1_0_6”, then you can start printing with slicing the printing file by Repetier according to “How to use Repetier”. - Page 41 Note: How to set up 3D printers and computer connections Step1: Choose the correct baud rate and COM port USB serial port Step2: Set print range...

- Page 42 Step3: Start connect Step4: Connect successfully...

-

Page 43: Frequently Asked Questions And Solutions

10. Frequently Asked Questions and Solutions Please get the “Common problem” from the SD card for your reference(SD-Card:\ Common problem) 10.1 “Err: MINTEMP ” Alarm processing method ① ② Hot bed Normal temperature display interface Nozzle Motherboard ①:Nozzle real time temperature ②:Hot bed real time temperature Reason: the hot bed thermistor is not connected to the main board "TB";... -

Page 44: Trouble :Lcd Screen Is Not Bright

(Normal temperature display interface) ① ② (Temperature display) Press the reset button on the motherboard or after (Reset button) power-off restart,Appear “Ready Mendel”,“Err: MINTEMP ” Alarm release. 10.2 Trouble :LCD screen is not bright Solution method: (1).Confirm whether the power supply is normal ; (2).Confirm the LCD screen on the EXP1, EXP2 port is connected with the EXP1, EXP2 port on the motherboard, and no loose or poor contact (... -

Page 45: Trouble :Rotation Button Can Not Be Up And Down The Selection Menu

10.4 Trouble :Rotation button can not be up and down the selection menu (By rotating the button on the left side of the pointer can be up and down the selection menu) figure) (Normal (No response to the left pointer by the rotation button) figure)... -

Page 46: Problems On The Distance Between Nozzle And Hotbed

Extrusion Wheel (Figure 3) Picture 10.3 10.6 Problems on the distance between nozzle and hotbed The distance between nozzle The distance between nozzle The nozzle is too close to and hotbed is too high and hotbed is proper hotbed Settle way: adjust the nozzle to the thickness of 1 A4 paper above the hotbed. 10.7 Model Dislocation when printing Y Direction Dislocation for X direction... - Page 47 Y axis Belt Motor drum in-phase of X axis X axis Belt Motor drum in-phase of Y axis...

-

Page 48: Wire Diagram Of Mainboard

11. Wire Diagram of Mainboard...

Need help?

Do you have a question about the M508 Prusa i3 and is the answer not in the manual?

Questions and answers