Table of Contents

Advertisement

THANK YOU FOR BUYING A RYOBI DETAIL BISCUIT JOINER.

Your new detail biscuit joiner has been engineered and manufactured to Ryobi's high standard for dependability, ease of

operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire owner's manual before using your new detail biscuit joiner.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your detail biscuit joiner properly and

only for what it is intended, you will enjoy years of safe, reliable service.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE

OWNER'S OPERATING MANUAL

DETAIL BISCUIT JOINER / DBJ50

DOUBLE INSULATED

SPECIFICATIONS:

No Load Speed

Rating

Fence Angles

Fence Height Adjustment

With Fence Angle Set on 90°

With Fence Angle Set on 45°

Depth Of Cut

With Micro Depth Of Cut Adjustment

Net Weight

5

16

45°

3

4

0

90°

120 volts, 60 Hz, AC

3.5 Amperes

5/16 in. - 13/16 in.

0 - 9/32 in. (0 - 7 mm)

3.625 lbs (1.65 kg.)

19,000 rpm

45° and 90°

0 - 3/4 in.

Advertisement

Table of Contents

Summary of Contents for Ryobi DBJ50

-

Page 1: Specifications

THANK YOU FOR BUYING A RYOBI DETAIL BISCUIT JOINER. Your new detail biscuit joiner has been engineered and manufactured to Ryobi's high standard for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance. -

Page 2: Double Insulation

For service we suggest you return the tool to your nearest RYOBI AUTHORIZED SERVICE CENTER for repair. When servicing use only identical Ryobi replacement parts. WARNING: Do not attempt to operate this tool until you have read thoroughly and understand completely all instructions, safety rules, etc. - Page 3 1. KNOW YOUR POWER TOOL. Read owner's manual carefully. Learn its applications and limitations as well as the specific potential hazards related to this tool. 2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT WITH GROUNDED SURFACES. For example: Pipes, radiators, ranges, refrigerator enclosures.

- Page 4 32. GUARD AGAINST KICKBACK. Kickback occurs when the blade stalls rapidly and the biscuit joiner is driven in the direction opposite blade rotation. Release switch immediately if blade binds or joiner stalls. 33. USE ONLY 1-1/2 in. (38 mm) DIAMETER SPECIFIED BLADES.

-

Page 5: Table Of Contents

WARNING: WEAR YOUR The operation of any biscuit joiner can result in foreign objects being thrown into your SAFETY GLASSES eyes, which can result in severe eye damage. Before beginning power tool operation, always wear safety goggles or safety glasses with side shields and a full face shield when needed. -

Page 6: Typical Applications

TYPICAL APPLICATIONS DETAIL BISCUIT JOINER / DBJ50 EDGE-TO-EDGE JOINTS BUTT JOINTS MITER JOINTS T- JOINT Page 6... -

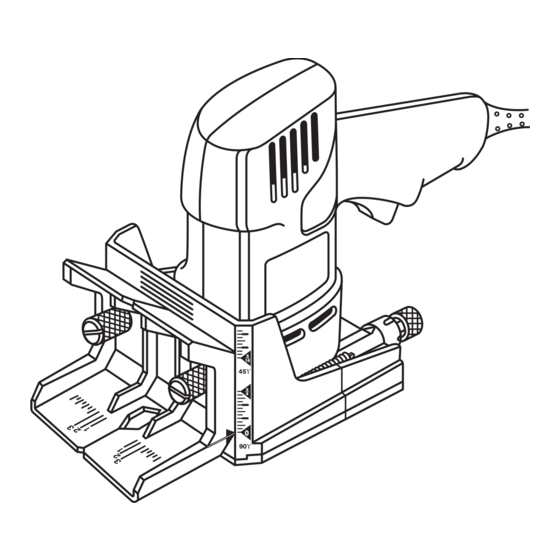

Page 7: Features

See Figure 2. WARNING: Your detail biscuit joiner should never be connected to power supply when you are assembling parts, making adjustments, assembling or removing blades, cleaning or when not in use. Disconnecting your detail biscuit joiner will prevent accidental starting that could cause serious personal injury. -

Page 8: Features

Inspect your new biscuit joiner carefully to make sure no breakage or damage has occurred during shipping. If any parts are damaged or missing, contact your local Ryobi factory or authorized service center to obtain replacement parts before attempting to operate your biscuit joiner. -

Page 9: Depth Of Cut Adjustments

Failure to do so could result in possible serious personal injury. DEPTH OF CUT ADJUSTMENTS Your biscuit joiner can be adjusted to three standard cutting depths to accommodate three standard size biscuits — #R1, #R2, and #R3. Adjustments are made by engaging slots on depth adjustment knob with tabs on rear base. -

Page 10: Adjustments

FENCE HEIGHT ADJUSTMENT See Figure 5. The fence on your biscuit joiner can be moved up and down to adjust the position of the blade in relation to the top of the workpiece. A scale on both sides of the front base indicates height settings for both 45°... -

Page 11: Edge-To-Edge Joints

Clamp workpiece securely so that it will not move during the cut. Plug your biscuit joiner into power supply and prepare to make your first cut. Grasp and hold your biscuit joiner securely with both hands. OPERATION... -

Page 12: Butt Joints

Clamp workpiece securely so that it will not move during the cut. Plug your biscuit joiner into power supply and prepare to make your first cut. Grasp and hold your biscuit joiner securely with both hands. Place the fence against the board and align the indicator marks on the fence with the centerline mark(s) on the board. - Page 13 Plug your biscuit joiner into power supply and cut slots in all boards that require end slots. See Figure 13. Follow procedures explained in "Edge-To-Edge Joints". Rotate fence angle to 90°, set fence height at desired dimension...

- Page 14 T-JOINTS (Continued) Plug your biscuit joiner into power supply and prepare to cut slot. Depress the switch trigger and let the motor build to its maximum speed, then gradually push biscuit joiner forward to extend the blade into the wood.

- Page 15 Align indicator mark on fence with the centerline on the workpiece. Make sure the front base is pressed flat against the mitered edge of the workpiece. Plug your biscuit joiner into power supply and prepare to cut slot. Depress the switch trigger and let the motor build to its maximum speed, then gradually push biscuit joiner forward to extend the blade into the wood.

-

Page 16: Operation

HINGE JOINTS See Figure 19. Hinge joints are used when joining two boards using hinges supplied in one of Ryobi's optional hinge kits. Jewelry boxes, doors on clocks, recipe boxes, etc. are typical applications. HOW TO MAKE HINGE JOINTS Unplug your detail biscuit joiner. -

Page 17: Blade Replacement

BLADE REPLACEMENT See Figures 20– 22. After extended use, the blade on your biscuit joiner may become dull. If you accidentally hit a nail or other blunt object, it will dull or break the blade. These situations require replacing the blade. - Page 18 WARNING: When servicing, use only identical Ryobi replacement parts. Use of any other part may create a hazard or cause product damage. CLEANING BASE ASSEMBLY See Figures 23-25. After extended use, wood particles and resin may build up inside the base assembly of your biscuit joiner and clog the path for wood particles going through dust exhaust opening.

-

Page 19: Optional Accessories

Test difficult set-ups on scrap—Don’t waste lumber. Plan each operation before you begin. Provide for smoother operation by cleaning your bis- cuit joiner frequently. Shake biscuit joiner or blow with an air jet to remove wood particle build-up. DO NOT ABUSE POWER TOOLS. Abusive practices can damage tool as well as workpiece. -

Page 20: Troubleshooting

PROBLEM 1. Biscuits do not fit slots. Biscuits not fitting slots may also cause misalignment of boards being joined. 2. Wood particles begin to backup on front of unit. 3. Blade becomes difficult to push in when cutting slots. Blade does not retract properly when cutting slots. - Page 21 NOTES Page 21...

-

Page 22: Service Information

Now that you have purchased your tool, should a need ever exist for repair parts or service, simply contact your nearest Ryobi Authorized Service Center. Be sure to provide all pertinent facts when you call or visit. Please refer to the Service Center insert or call 1-800-525-2579 in the United States or 1-800-265-6778 in Canada for your nearest Authorized Service Center.

Need help?

Do you have a question about the DBJ50 and is the answer not in the manual?

Questions and answers