Summary of Contents for Ampco Pumps Company ZP3 6

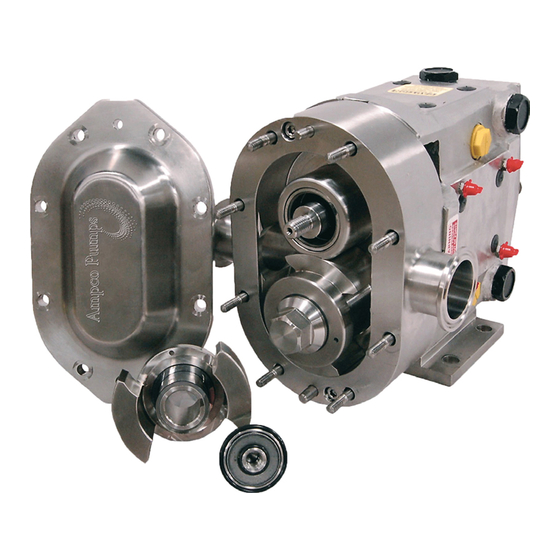

- Page 1 Ampco ZP3 Series Positive Displacement Pumps Installation and Maintenance Manual Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15...

-

Page 2: Table Of Contents

Assembly ......................27 Ampco Pumps Available Options ................... 32 Troubleshooting ........................33 Remanufacturing Program ..................... 36 ATEX Certification Information .................... 37 Terms and Conditions ......................38 Return Policy ..........................41 Page 2 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 3: Introduction

To ensure the best results and service, please read and fully understand this manual prior to putting this pump into service. For any questions regarding operation, maintenance, or installation, please contact your local distributor or Ampco Pumps Company: Ampco Pumps Company 2045 W. Mill Road... -

Page 4: Receiving/Safety

CAUTION: Hazards or unsafe practices that COULD result in minor personal injury or damage to product or property. Page 4 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 5: Pump Information

ZP3 130 150 34.1 25.0 0.946 3" 4" ZP3 180 230 52.2 38.0 1.450 3" ZP 210 68.1 50.0 1.900 4” ZP3 220 310 70.4 52.0 1.980 4" 6” Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 5... -

Page 6: Label Information

3.87 x 11.00 4" 102 For operating parameters that fall outside the standard values defined in Table 1 and Table 2, please contact the Engineering Department at Ampco Pumps Company (414-643-1852). Standard rotors operate within a temperature range of –40 F to 200 F. -

Page 7: Installation

WARNING: To ensure safety, protective guards must be properly installed over all external rotating parts and components. Failure to do so may result in injury. Ampco Pumps provides protective guards for complete base packages (pump and drive unit). Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 7... -

Page 8: Piping And Connections

Sloping the piping on the inlet side away from the pump will prevent air pockets if the pump is installed above the supply (Figure 7). Figure 6: Correct Piping (Supply Above) Figure 7: Correct Piping (Supply Below) Page 8 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 9: Check/ Isolation/ Relief Valves

In order to prevent damage to the pump, it is recommended a relief valve be installed on the pump’s discharge side. The relief valve can either divert flow into a drain or back to the inlet side (Figure 10). Figure 10: Relief Valve Examples Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 9... -

Page 10: Strainers And Gauges

Place the straight edge along the coupling to ensure that both sides are concentric (Figure 12, Parallel Alignment). Straight Edge Angular Alignment Parallel Alignment Figure 12: Check Alignment Page 10 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 11: Pump Rotation

15). Flush flow rate should be 1/4 GPM (30 psi Flush In pressure). high temperature applications flush flow may be increased to Figure 15: Proper Flushing for remove excess heat. ZP3 Double Seal Page 11 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 12: Maintenance

6.0 oz 9.5 oz GRADE, NLGI Grade No. 2 180, 220, 224 11 oz 20 oz *Replacement oil and grease is available from 210, 320 17 oz 44 oz Ampco Page 12 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 13: Preventive Maintenance/Inspection

Inspect the rotor hub and rotor keyway (Figure 19) for wear and replace, if necessary. Rotor and shaft wear at these locations is caused by extended operation with loose rotor nuts. Rotor Keyway Rotor Hub Figure 19: Rotor Inspection Points Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 13... -

Page 14: Gear And Bearing Inspection

If any movement is felt the bearing may need replacing. If disassembly of the entire gear case is required, please refer to page 16 for instructions. Figure 21: Check for Bearing Movement Page 14 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 15: Annual Maintenance

The fluid velocity (typically 5 ft/sec) and differential pressure (30 psi recommended) are critical components of a correct CIP setup. For additional support, please contact the Engineering Department at Ampco Pumps Company (414-643- 1852). -

Page 16: Pump Disassembly

3 ZP3 Rotor 4 Rotating Seal O-ring 5 Rotating Seal 6 Stationary Seal 7 Stationary Seal O-ring 8 Wave Spring 9 Seal Sleeve Figure 25: Exploded View Single Mechanical Page 16 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 17: Single Seal Maintenance

Align the slot Stationary Seal and pin O-ring Figure 28: Stationary Seal Assembly Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 17... - Page 18 Rotating Seal Align Figure 30: Inserting Rotating O-ring 5) Slide the rotors onto the shafts until they seat against the shaft shoulder (Figure 31). Shoulder Figure 31: Rotor Assembly Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 18...

- Page 19 Tighten the rotor nuts in an opposing manner, as seen on Figure 34, so that the cover is evenly tightened to the body. Figure 34: Cover Assembly Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 19...

-

Page 20: Double Seal Maintenance

(Figure 37). Check that the seal stop pins are aligned with the notches on the outer Double Mechanical Seal stationary seal. Figure 37: Installing Stationary Seals Page 20 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 21: Seal Cutaways

(Figure 38). Flush flow rate should be 1/4 GPM (30 psi max pressure). For high temperature applications Flush In flush flow may be increased to remove excess heat. Figure 38: Proper Flushing for ZP3 Double Seal Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 21... -

Page 22: Pump Clearances

6, 15, 18 30, 34 .002 .002 .005 45, 60, 64, .004 .005 .008 130, 134 .004 .005 .008 180, 220, 224 .005 .006 .008 210, 320 .005 .010 .011 Page 22 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 23: Pump Assembly

Tighten the rotor nuts in an opposing manner as seen on Figure 42, so that the cover is evenly tightened to the body. Figure 42: Cover Assembly Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 23... -

Page 24: Exploded View

Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... -

Page 25: Gear Case Maintenance

Slowly remove the gears from the shafts. Remove the gear keys and gear spacers from the shafts. Wedge Figure 45: Bending Tabs on Lock Figure 46: Removing Lock Washers Washers Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 25... - Page 26 (Figure 49, B). Clean the bearing retainers as they will be reused. Clean excess grease and sludge inside of the gear case before reassembling. Page 26 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15...

-

Page 27: Assembly

(Figure 51, Drawing 3). Bearing Spacer Drawing 1 Drawing 2 Drawing 3 Front Bearing Check Seat With Shim Figure 51: Pressing Front Bearing onto Shaft Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 27... - Page 28 Gear Case Maintenance 2) Single ball bearings are used for the rear bearings in models ZP3 6, ZP3 15, ZP3 18, ZP3 30, and ZP3 34 and will require a light press to install. Tapered roller bearings are used for all other models and will be pressed on similar to the front bearings.

- Page 29 If the clearances are correct, remove the rotors and body. .010”-.050” Bearing Retainer Bearing Figure 55: Bearing Figure 56: Important Retainer Clearance Clearances Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 29...

- Page 30 To time the gears, align them so that the single punch mark falls between the two punch marks on the opposite gear (Figure 59, B). Figure 59: Installing Gears with Correct Timing Page 30 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15...

- Page 31 Install the oil plugs and fill the gear case with the recommended amount of oil using Table 3 on page 12. Silicone Seal Placement Oil Seal (Spring faces towards gears) Figure 62: Installing Gear Casing Back Cover Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 31...

-

Page 32: Ampco Pumps Available Options

Pumps for replacement information. The pressure limit for the jacketed cover is 60 psi. ZP3 Pump Model Thread Size 6,15, 18, 30 3/4” NPT 45, 60, 130, 180, 220 1” NPT Figure 64: Jacketed Cover Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 32... -

Page 33: Troubleshooting

Pump may be worn out out rotors. Check pressure required. Change, if Inlet pressures too low necessary Differential pressure differences Install check valves on discharge to prevent not developing large back pressures Page 33 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... - Page 34 Heat product, or change system parameters breakers are tripping) Viscous product sits in line Install a soft start on motor drive, clean lines during shutdown or change system to avoid problem Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 34...

- Page 35 Water build up in Gear case Check that all gear case plugs are in place Misalignment in system (piping or Check and modify system to eliminate pump drive) alignment issues Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 35...

-

Page 36: Remanufacturing Program

These upgrades are standard to Ampco positive displacement new and remanufactured pumps. Contact your local distributor or the factory (414) 643-1852 for more information. Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 36... -

Page 37: Atex Certification Information

3) ATEX approval becomes void if non-Ampco replacement parts are used in the pump. For additional support regarding ATEX certification, please contact the Engineering Department at Ampco Pumps Company, (414) 643-1852. Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 37... -

Page 38: Terms And Conditions

CIRCUMSTANCES FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY LOST PROFITS OR LABOR COSTS) ARISING FROM THE BREACH OF THIS WARRANTY OR OTHERWISE ARISING FROM OR RELATING TO THE PRODUCTS OR THEIR SALE, USE OR INSTALLATION. Page 38 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15... - Page 39 16. PERIOD FOR ACCEPTING QUOTATIONS. Unless accepted without modification within thirty (30) days of issuance, or prior to withdrawal by Seller if earlier, all quotations automatically expire at the end of such thirty (30) day period Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 39...

- Page 40 The agreement is governed by and shall be construed in accordance with the laws of the State of Wisconsin, including the Uniform Commercial Code as enacted by such state, without giving effect to its conflict of laws principles. Page 40 Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15...

-

Page 41: Return Policy

Credit will be issued only after parts are returned and inspected. Customer is responsible for packaging parts so they are returned in “as new” condition. Any labor required by Ampco to return the parts to “as new” condition will be deducted from the credit. Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15 Page 41... - Page 42 Glendale, WI 53209 Phone: (800) 737-8671 or (414) 643-1852 Fax: (414) 643-4452 Email: ampcocs@ampcopumps.com For additional information on the ZP3 series and other Ampco Pumps products, please visit our website: www.ampcopumps.com Ampco Pumps Company ZP3 Manual M-004 Rev A 10.15...

Need help?

Do you have a question about the ZP3 6 and is the answer not in the manual?

Questions and answers