Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for STIEBEL ELTRON SOM 8 PLUS

- Page 1 InstallatIon solar Controller » som 8 plus...

- Page 2 Safety advice Target group Note notes are indicated with an information please pay attention to the following safety advice these instructions are exclusively addressed to au- symbol. in order to avoid danger and damage to people and thorised skilled personnel. property.

-

Page 3: Table Of Contents

Contents Overview ............4 Arrangement ..........47 1.1 optional functions ............5 9.1 optional functions ...........47 Installation .............5 10 Heating ............59 2.1 mounting ...............5 10.1 Demands ..............60 2.2 electrical connection ..........6 10.2 Heating circuits ............60 2.3 Data communication / Bus ........7 10.3 optional functions ...........64 2.4 sD card slot ..............8 11 HQM ............. -

Page 4: Overview

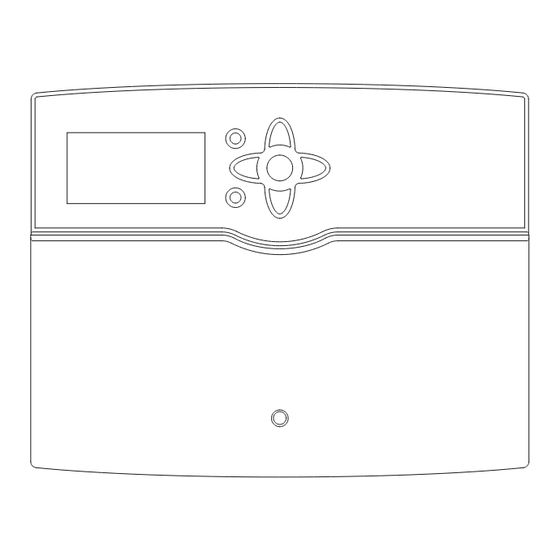

Overview Technical data SOM 8 plus • Extra large graphic display 230933 • 14 relay outputs Height • 12 temperature sensors Width (system-dependent) Depth • 4 inputs for Grundfos Direct Sensors™ Ip-rating Ip20 (2 × analog, 2 × digital) rated voltage 100...240... -

Page 5: Optional Functions

Installation Optional functions Mounting the unit must only be located in dry interior rooms. Solar the controller must additionally be supplied from a Bypass double pole switch with contact gap of at least 3 mm [0.12"]. Cs Bypass please pay attention to separate routing of sensor external heat exchanger cables and mains cables. -

Page 6: Electrical Connection

Electrical connection Note WARNING! Electric shock! Connecting the device to the power supply upon opening the housing, live must always be the last step of the instal- parts are exposed. lation! Î Always disconnect the the controller is equipped with 14 relays in total to controller from power supply which loads such as pumps, valves, etc. -

Page 7: Data Communication / Bus

Data communication / Bus the controller is equipped with the VBus ® for data the terminals s13 to s15 can be used as impulse in- transfer with and energy supply to external modu- puts for V40 flowmeters or as inputs for Fs08 flow les. -

Page 8: Sd Card Slot

For further information about the registration of mo- the som 8 plus is a controller that offers a broad For further information about heating circuits and dules and sensors see page 72. variety of functions to the user. at the same time, optional heating functions see page 59. -

Page 9: Operation And Function

Operation and function Buttons Selecting menu points and adjusting values the controller is energised via the 7 buttons next to the display.they have the following functions: During normal operation of the controller, the dis- play is in the main menu. If no button is pressed for a Button - scrolling upwards few seconds, the display illumination goes out. - Page 10 adjusted value (not yet confirmed) adjustment channel active area inactive area If more than one item of several can be selected, they will be indicated with checkboxes. When an item has When two values are locked against each other, they been selected, an x appears inside the checkbox.

-

Page 11: Menu Structure

Menu structure the menu items and adjustment values selec- Main menu table are variable depending on adjustments Status already made. the figure only shows an exem- plary excerpt of the complete menu in order to Solar Solar visualise the menu structure. Basic settings Basic settings Arrangement... -

Page 12: Initial Commissioning

Initial commissioning When the hydraulic system is filled and ready for 1. Language: operation, connect the controller to the mains. Î adjust the desired menu language. the controller runs an initialisation phase in which the directional pad flashes red. When the controller is commissioned for the first time or when it is reset, it will run a commissioning menu after the initialisation phase. - Page 13 3. Daylight savings time adjustment: Î activate or deactivate the automatical daylight savings time adjustment. 4. Time: 7. Completing the commissioning menu: Î adjust the clock time. First of all adjust the after the system has been selected, a security enqui- hours, then the minutes. ry appears. If the enquiry is confirmed, the adjust- ments will be saved.

-

Page 14: Basic Systems And Hydraulic Variants

Basic systems and hydraulic variants Variant System the selection of the basic solar system is one of the most important adjustments and is thus requested already in the commissioning menu. First, the basic system is adjusted by means of the number of stores and collectors fields, then the hy- draulic variant. -

Page 15: Overview Of Relay And Sensor Allocation

Overview of relay and sensor allocation System 1 Relay / sensor allocation 10-14 Relay Solar pump Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Sensor Collector 1 Store base Free Free Free Free... - Page 16 System 2 variant 2 Relay / sensor allocation 10-14 Relay 2PV coll. 1 2PV coll. 2 Solar pump Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Opt. function Sensor Collector 1 Store base Free Free Free Collector 2 Free Free...

- Page 17 System 3 variant 2 Relay / sensor allocation 10-14 Solar pump Solar pump Optional Optional Optional Optional Optional Optional Optional Optional Relay store 1 store 2 function function function function function function function function Sensor Collector Store 1 base Free Store 2 base Free Free...

- Page 18 System 4 variant 1 S1 S6 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Optional Optional Pump coll. 1 Pump coll. 2 Relay store 2 function function function function function function function Collector 1 Store 1 base Free Store 2 base Free Collector 2...

- Page 19 System 4 variant 3 S1 S6 Relay / sensor allocation 10-14 Solar pump Solar pump Optional Optional Optional Optional Optional Optional 2PV coll. 1 2PV coll. 2 Relay store 1 store 2 function function function function function function Collector 1 Store 1 base Free Store 2 base...

- Page 20 System 5 variant 1 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Optional Solar pump Relay store 1 store 2 store 3 function function function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Free Free Free...

- Page 21 System 5 variant 3 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Optional Optional Solar pump Relay store 1 store 2 function function function function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Free Free Free...

- Page 22 System 6 variant 2 Relay / sensor allocation 10-14 Solar pump Solar pump Solar pump Optional Optional Optional Optional Optional 2PV coll. 1 2PV coll. 2 Relay store 1 store 2 store 3 function function function function function Collector 1 Store 1 base Free Store 2 base...

- Page 23 System 6 variant 4 S1 S6 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Optional Pump coll. 1 Pump coll. 2 3PV store 1 3PV store 2 Relay function function function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base...

- Page 24 System 7 variant 1 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Solar pump Relay store 1 store 2 store 3 store 4 function function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Store 4 base Free Free...

- Page 25 System 7 variant 3 Relay / sensor allocation 10-14 Solar pump Solar pump Solar pump Solar pump Optional Optional Optional Optional Optional Optional Relay store 1 store 2 store 3 store 4 function function function function function function Collector 1 Store 1 base Free Store 2 base...

- Page 26 System 8 variant 2 Relay / sensor allocation 10-14 Optional Optional Optional Optional Optional Pump coll. 1 Pump coll. 2 Relay store 1 store 2 store 3 function function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Collector 2 Store 4 base...

- Page 27 System 8 variant 4 Relay / sensor allocation 10-14 Optional Optional Optional 2PV coll. 1 2PV coll. 2 Solar pump Relay store 1 store 2 store 3 store 4 function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Collector 2 Store 4 base...

- Page 28 System 9 variant 1 Relay / sensor allocation 10-14 Optional Optional Optional Optional Solar pump Relay store 1 store 2 store 3 store 4 store 5 function function function function Collector 1 Store 1 base Free Store 2 base Store 3 base Store 4 base Store 5 base Free...

- Page 29 System 9 variant 3 Relay / sensor allocation 10-14 Solar pump Solar pump Solar pump Solar pump Solar pump Optional Optional Optional Optional Optional Relay store 1 store 2 store 3 store 4 store 5 function function function function function Collector 1 Store 1 base Free...

-

Page 30: Main Menu

Main menu Status Heating During normal operation, the display of the control- In the Status menu, the status messages for every In the Status / Heating menu, the status of the de- ler shows the main menu. From here, the different menu area can be found. -

Page 31: Meas. / Balance Values

Solar Meas. / Balance values If, for example, s1 is selected, a submenu indicating the minimum and maximum values will open. When the item Chart is selected, a progression chart appears. In the Status / Meas. / Balance values menu, all cur- In this menu, all adjustments for the solar part of the rent measurement values as well as a range of balan- arrangement can be made. - Page 32 the following items in the solar / Basic settings First of all, the basic solar system can be selected ac- menu will adjust to the system selected. cording to the number of stores and collector fields in use. the corresponding numbers are indicated on the display.

- Page 33 Store (1 / 2 / 3 / 4 / 5) In systems with 2 or more stores, the corresponding number of seperate menu items (Store 1 to Store 5) is displayed instead of Store. For each store, an individual ∆t control, a set and a maximum temperature, the priority, a hysteresis, a rise value, a minimum runtime and a minimum pump speed can be adjusted.

-

Page 34: Solar Optional Functions

Loading logic Solar optional functions ding process stops and the controller monitors the increase in collector temperature during the loading break time Load. break. If it increases by 2 K [4° ra], the break time timer starts again to allow the collec- tor to gain more heat. - Page 35 If the menu item Delete function is confirmed by the menu item Relay selec. is available in all opti- at the end of each optional function submenu, the pressing button , a security enquiry appears. the onal functions. therefore, it will not be explained in menu items Funct.

- Page 36 Bypass Depending on whether the bypass is energised by a valve or by a second pump, a corresponding adjust- ment can be made in the menu item Variant. De- pending on the variant, different control logics are applied: Pump: In this version, a bypass pump is placed in front of the collector pump.

- Page 37 CS bypass the Cs bypass function is a different possibility to activate the collector circuit. to enable the use of the Cs bypass function, a Cs10 irradiation sensor has to be connected. When the Cs bypass function is activated, the irra- diation value is the switch-on condition for the col- lector circuit.

- Page 38 Tube collector function this function helps overcome the non-ideal sensor position with some tube collectors. this function operates within an adjusted time frame. It activates the collector circuit pump for an adjustable runtime between adjustable pauses in order to compensate for the delayed temperature measurement.

- Page 39 Target temperature When the Target temperature function is activated, the pump speed control logic changes. the control- ler will remain at the minimum pump speed until the temperature at the allocated sensor exceeds the adjusted target temperature. only then will the standard pump speed control start to operate.

- Page 40 Afterheating suppression the afterheating suppression blocks the conventi- onal afterheating of a store that is currently in solar loading. this function is activated if a previously selected Store is being loaded. solar loading means that store loading is only carried out for energy supply and not for cooling purposes etc.

- Page 41 Cooling mode In the cooling mode menu, different cooling func- In 2-collector systems, separate adjustments can be tions are available. they can be used for keeping the made for each collector field. solar system operational for a longer time during the control logic regards collector cooling operation strong solar irradiation.

- Page 42 Solar / Opt. functions / Add new function... / Cooling mode adjustment channel Description adjustment range / selection Factory setting Variant Cooling logic variant Col. cool, syst. cool., off tcolmax. Collector maximum temperature 70 ... 190 °C [158 ... 374 °F] 100 °C [212 °F] store (1 ...

- Page 43 Solar external heat exchanger this function is used to link loading circuits that are separated by an external heat exchanger. the allocated relay is energised if one of the selec- ted stores is being loaded and there is a temperature difference between the sensor of the corresponding store and the solar flow.

- Page 44 Drainback option a drainback system permits the heat transfer fluid to drain back into the holding tank when solar energy is not collected.the drainback option will initiate the filling of the system when solar loading begins. Note: booster pump a drainback system requires additional components such as a holding tank.

- Page 45 Twin pump the Twin pump function controls the equal distri- bution of pump runtime in systems with two equally usable pumps. If the allocated relay has exceeded its adjusted run- time and the next switch-on process is imminent, the reference relay is switched on instead. all cha- relay reference relay racteristics are adopted.

- Page 46 Heat dump the heat dump function can be used to direct excess heat generated by strong solar irradiation to an ex- ternal heat exchanger (e. g. fan coil) in order to pre- Relay vent the collectors from overheating. the allocated relay is energised with 100 %, if the col- lector temperature reaches the adjusted switch-on temperature.

-

Page 47: Solar Expert Menu

Arrangement Solar expert menu Flow sensor In this menu, all adjustments for the non-solar part of the arrangement can be made. a range of optional functions can be selected and Return sensor adjusted. Example of flow- and return sensor positions Optional functions Solar / Expert adjustment channel Description... - Page 48 When a function has been selected and adjusted, it If the menu item Delete function is confirmed by When a function is selected, a submenu opens in will appear in the Opt. functions above the menu which all adjustments required can be made. pressing button , a security enquiry appears.

- Page 49 Arrangement / Opt. functions / Add new function... / Parallel relay the Parallel relay function can be used to opera- te an allocated parallel relay alongside a selected adjustment channel Description adjustment range / selection Factory setting reference relay. With this function, e. g. a valve can relay relay selection system dependent...

- Page 50 Boiler loading In order to adjust the timer, press button First the individual days of the week or all days of the week can be selected. the last menu item after the list of days is Continue. If Continue is selected, the Edit timer menu opens, in which the time frames can be adjusted.

- Page 51 Arrangement / Opt. functions / Add new function... / Boiler loading adjustment channel Description adjustment range / selection Factory setting relay relay selection system dependent system dependent sensor top top sensor selection system dependent system dependent sensor base Base sensor selection system dependent system dependent tBoiler on...

- Page 52 Heat exchange the heat exchange function can be used for transfer- ring heat from a heat source to a heat sink. Sensor Source the allocated relay is energised when all switch-on conditions are fulfilled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature difference •...

- Page 53 Solid fuel boiler the solid fuel boiler function can be used for trans- ferring heat from a solid fuel boiler to a store. Sensor Solid fuel boiler the allocated relay is energised when all switch-on conditions are fulfilled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature difference Relay...

- Page 54 Circulation Demand + Timer the relay operates when the switch-on conditions of both above mentioned variants are fulfilled. Sensor Relay Circulation the circulation function can be used for controlling a circulation pump. For the control logic, 5 different variants are availa- ble: •...

- Page 55 the time frames can be adjusted in steps of 15 minu- tes. the cursor can be moved along the time line by pressing buttons the beginning of a time frame can be determined by pressing button . the end of a time frame can be determined by pressing button Arrangement / Opt.

- Page 56 Return preheating the return preheating function can be used for transferring heat from a heat source to the heating circuit return. the allocated relay is energised when both switch- on conditions are fulfilled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature Sensor HS Relay...

- Page 57 Function block ∆T function In addition to the pre-defined optional functions, Thermostat function function blocks consisting of thermostat functions, the relay allocated to the function block is switched the relay allocated to the function block is switched timer and differential functions are available. With on, when the adjusted switch-on temperature (th(x) on as soon as the adjusted switch-on temperature the help of these function blocks, further compo-...

- Page 58 Arrangement / Opt. functions / Add new function... / Function block adjustment Description adjustment range / selection Factory setting channel relay relay selection system dependent system dependent thermostat a thermostat a Yes, no th-a on switch-on temperature thermostat a -40 ... 250 °C 40 °C th-a off switch-off temperature thermostat a -40 ...

-

Page 59: Heating

Irradiation switch the Irrad. switch function can be used for operating a relay depending on the measured irradiation va- lue. the allocated relay is switched on if the adjusted ir- radiation value remains exceeded for the adjusted duration. If the irradiation falls below the adjusted value for the adjusted duration, the relay is switched off. -

Page 60: Demands

10.1 Demands In this menu, up to 2 heating demands can be acti- vated and adjusted. Activated demands will be available for selection in the relay allocation channels of the correspon- ding optional functions . This way, several optio- nal functions can demand the same heat source. If, for example the potential-free changeover relay r14 is allocated to Demand ... - Page 61 Summer off: the summer mode becomes active to each room thermostat, a sensor input can be al- week can be selected. the last menu item after the list of days is Continue. If Continue is selected, the when the outdoor temperature exceeds the adjust- located.

- Page 62 Heating / HCs / New HC / Internal adjustment channel Description adjustment range / selection Factory setting HC pump Heating circuit pump system dependent system dependent mixer open relay selection mixer open system dependent system dependent mixer closed relay selection mixer closed system dependent system dependent Flow sensor...

- Page 63 Chimney sweeper function adjustment channel Description adjustment range / selection Factory setting the chimney sweeper function can be used for ena- all days, monday ... sunday, bling a quick access to measurement conditions Days of the week Day selection Continue without menu operation for the chimney sweeper.

-

Page 64: Optional Functions

10.3 Optional functions the menu item Demand is available in all optional at the end of each optional function submenu, the menu items Function and Delete function are heating functions. therefore, it will not be explained in the individual function descriptions. available. - Page 65 Thermal disinfection Due to the flexible control logic, the exact time of thermal disinfection is not predictable. In order to set a fixed time for the disinfection to be run, the st- arting delay must be used: If the starting delay option Starting time is activa- ted, a starting time for the thermal disinfection with starting delay can be adjusted.

- Page 66 DHW heating Boiler mode: If the Boiler mode has been selected, another sensor can be allocated in the channel sensor 2. the switch- on, or the switch-off conditions respectively, then have to be fulfilled at both sensors in order for the relay to be energised.

-

Page 67: Hqm

Heating / Opt. functions / Add new function... / DHW heating adjustment channel Description adjustment range / selection Factory setting Demand Demand relay selection system dependent system dependent loading pump loading pump option Yes, no relay loading pump relay selection system dependent system dependent overrun time... - Page 68 In the adjustment channel Fluid type, the heat the heat quantity measurement deleted will disap- transfer fluid must be selected. If either propylene pear from the list and become available for selection glycol or ethylene glycol is selected, the adjustment in the New HQM menu again.

-

Page 69: Basic Settings

Basic settings SD card In the Basic settings menu, all basic parameters for the controller can be adjusted. normally, these set- tings have been made during commissioning. they can be subsequently changed in this menu. Basic settings the controller is equipped with an sD card slot for sD memory cards. - Page 70 Starting the logging Storing controller adjustments Note: Î Insert the sD card into the slot Î to store the controller adjustments on an sD to safely remove the sD card, always select card, select the menu item Save adjustments. the menu item Remove card... before re- Î...

-

Page 71: Manual Mode

Manual mode Note: always adjust the operating mode back to Auto when the control and service work is completed. otherwise normal operation will not be possible. Manual mode In the Manual mode menu, the operating mode of adjustment channel Description adjustment range / selection Factory setting all relays in the controller and in connected modules... -

Page 72: User Code

User code 16.1 Modules In this menu, up to 5 external modules can be regis- In the User code menu, a user code can be entered. tered. each number of the 4-digit code must be individu- all modules connected and acknowledged by the ally adjusted and confirmed. -

Page 73: Inputs

16.2 Inputs In- / Outputs / Inputs adjustment Description adjustment range / selection Factory setting channel s1 ... s12 sensor input selection switch, KtY, pt500, rta11-m, type selecting the sensor type pt1000 pt1000, none offset sensor offset -15.0 ... +15.0 K 0.0 K In this submenu, the type of the sensor connected Imp. -

Page 74: Outputs

16.3 Outputs In order to reduce the number of switching pro- cesses for high-efficiency pumps, the controller is equipped with a relay overrun function that auto- matically comes into effect when the speed control signal is not issued by the relay itself. the correspon- ding relay will then remain switched on for an hour after the switch-off conditions are fulfilled. -

Page 75: Pwm-Profiles

16.4 PWM-Profiles Note: PWM A (e. g. manufacturer WILO) PWM D (e. g. manufacturer WILO) If pWm pumps are used, the lowest adjust- ment value of the minimum speed cannot be lower than 20 %. If a laing pump (pWm C) is used, the pWm start impulse has to be higher than 25% to enable a minimum pump speed of less than 25%. -

Page 76: Troubleshooting

Troubleshooting If a malfunction occurs, a message will appear on the display of the controller. Electric shock! WARNING! upon opening the housing, live parts are exposed. Î Always disconnect the controller from power supply before opening the housing! the controller is protected by a fuse. the fuse holder (which also holds the spare fuse) becomes accessible when the cover is removed. - Page 77 pump is overheated, but no heat transfer from the collector to the store, flow pump starts up very late. and return have the same temperature; perhaps also bubbling in the lines. switch-on temperature diffe- air or gas bubbles in the system? Vent the system;...

- Page 78 the solar circuit pump does not work, although the collector is considerab- stores cool down at night. ly warmer than the store. Collector circuit pump runs during the night? Display illuminated? If not, press button . Display illumi- nated now? Check controller Collector temperature at night there is no current;...

- Page 79 Does the warm water circulation run for a very long time? use the circulation pump with timer and switch-off thermostat (energy efficient circulation). Circulation pump and blocking valve should be switched-off for 1 night; less store losses? Check whether the pumps of the afterheating circuit run at night;...

-

Page 80: Accessories

Accessories 18.1 Sensors and measuring instruments V40 flowmeter the flowmeter V40 is a measuring instrument for detecting the flow of water or water/glycol mixtu- res. after a specific volume has passed, the V40 reed switch sends an impulse to the calorimeter. the heat quantity used is calculated by the calorimeter using these impulses and the measured temperature diffe- rence with the help of pre-defined parameters (gly-... -

Page 81: Index

Index Heat dump ................46 afterheating suppression ..........40 sensor fault, error message .......... 30 Heat exchange..............52 antifreeze, solar optional function ......39 solar external heat exchanger ........43 Heating circuits, internal ..........60 solid fuel boiler ..............53 Balance values .............. - Page 82 Notes...

- Page 83 Notes...

- Page 84 GmbH & Co. KG tecalor GmbH Dr.-stiebel-str. | 37603 Holzminden Fürstenberger str. 77 | 37603 Holzminden tel. 05531 702-0 | Fax 05531 702-480 tel. 05531 99068-700 | Fax 05531 99068-712 info@stiebel-eltron.de info@tecalor.de www.stiebel-eltron.de www.tecalor.de 4 < A M H C M N = j f j d b c >...

Need help?

Do you have a question about the SOM 8 PLUS and is the answer not in the manual?

Questions and answers