Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Olsen LRF65

- Page 1 Lowboy Rear Flue Model LRFV Lowboy Rear Flue Model with ECM Blower Oil Fired Warm Air Furnaces INSTALLATION, OPERATION & MAINTENANCE MANUAL ECR International 2210 Dwyer Avenue, Utica NY 13501 web site: www.ecrinternational.com P/N 240011511, Rev. C [05/31/2017]...

- Page 2 DIMENSIONS " 4.8cm Table 1 - Dimensions Cabinet Plenum - Openings Flue Furnace Shipping Filter Width Length Height Supply Return (Permanent) Model Height Weight Diameter F x G D x E LRF/ 22" 53-½" 33-⁵/ " 20-½" x 18" 20-½" x 18-⁵/ "...

-

Page 3: Table Of Contents

General ..........................4 Safety Symbols ........................4 Introduction Models LRF/LRFV ....................4 Heat Loss ..........................4 Locating the Unit ......................... 5 Furnace Used In Conjunction With Air Conditioning ..............5 Air Filter ..........................6 Ductwork ..........................6 Combustion and Ventilation Air ....................6 10. -

Page 4: General

1. General 3. Introduction Models LRF/LRFV Furnace installation shall be completed by qualified agency. See Models LRF and LRFV are oil fired forced air lowboy furnaces with glossary for additional information. an output capacity range of 65,000 BTU/hr to 100,000 BTU/hr. •... -

Page 5: Locating The Unit

FIGURE 1a: Evaporator Coil WARNING Fire hazard. Do not install furnace on tiled floors or carpeting. Failure to follow these instructions could result in death or serious injury. 5. Locating the Unit - [See Table 2] • Locate furnace so flue connection to chimney is short, direct and consists of as few elbows as possible. -

Page 6: Air Filter

Manufacturer recommended fan on delay is 30 seconds for LRF100 models and 60 seconds for LRF65/80/90 models. • Flue pipe should connect to chimney so the flue pipe extends into, and terminates flush with the inside surface of chimney •... -

Page 7: 13B. Fan Timer Board And Limit Control (Lrfv) [See Figure

• Limit control is thermally operated and automatically • Accessories requiring 120 VAC power sources such as resets. Limit control is factory installed, pre-set and is not electronic air cleaners and humidifier transformers may be adjustable. powered from electronic fan timer board where provisions have been made for connections, but should have their own •... -

Page 8: Oil Burner Nozzles

18. Oil Burner Nozzles WARNING Furnaces are certified for multiple firing rates. Furnace may be Fire, burn, asphyxiation hazard. Do not start the fired at ideal rate for wide range of structures by manipulating oil burner unless blower access door is secured in place. burner setup and blower settings. -

Page 9: 22B. Circulating Air Blower (Lrfv)

Belt Drive Blower Systems WARNING WARNING Electrical shock hazard. Turn OFF electrical power Improper installation could result in death or serious supply at service panel before opening blower access injury. Belt drive components operate at high speeds door. Failure to do so could result in death or serious and may snag loose clothing resulting in injury or injury. -

Page 10: Operating Instructions (Lrf)

Chart 1. Fan on delay can be set at 30, 60, 90 or 120 seconds. Manufacturer recommended fan on delay is 30 Electrical shock hazard. Turn OFF electrical power seconds for LRF100 models and 60 seconds for LRF65/80/90 supply at service panel before service or maintenance models. -

Page 11: Appendix A - Checkout And Adjustments

(For use with chimney vented units only) Pump Furnace Output Delavan Flow Rate Burner Model Pressure Head Model BTU/Hr Nozzle Setting [USGPH] [PSIG] LRF65 66,000 AFG70MPSS 0.50 / 45°W 0.55 LRFV65 LRF80 78,000 AFG70MPSS 0.50 / 45°W 0.65 LRFV80 LRF90 89,000 AFG70MPSS 0.60 / 60°W... - Page 12 APPENDIX A - CHECK OUT AND ADJUSTMENTS Table A-3 Riello 40F3 Burner Set-Up Riello 40F3 Series Oil Burners (For use with chimney vented units only) Pump Furnace Burner Delavan Head Flow Rate Output Pressure Model Model Nozzle Setting Setting [USGPH] BTU/Hr [PSIG] LRF65RF...

-

Page 13: Oil Burner Air Adjustment

APPENDIX A - CHECK OUT AND ADJUSTMENTS Table A-5 Carlin EZ-LF Oil Burner Set-Up Carlin EZ-LF Series Oil Burners (For use with chimney vented units only) Pump Flow Furnace Output Burner Delavan Head Bar Pressure Rate Model BTU/Hr Model Nozzle Band Setting [PSIG]... -

Page 14: Start Up

APPENDIX A - CHECK OUT AND ADJUSTMENTS A.3 Start Up Set heat anticipator adjustment in thermostat (if so equipped), by removing "R" or "W" wire to thermostat. Read Use following instructions to set the burner: amperage draw between the two wires. Failure to remove one Shut off electrical power to the furnace. - Page 15 APPENDIX A - CHECK OUT AND ADJUSTMENTS FIGURE 2: UNITED TECHNOLOGIES 1158-120 FAN TIMER BOARD (LRF) FIGURE 3: UNITED TECHNOLOGIES 1168-1 ECM TAP BOARD (LRFV) 240011511 REV. C [05/31/2017]...

-

Page 16: Blower Setup

Heating Blower Set-Up Cooling Capacity Furnace 0.20 in. w.c. 0.50 in. w.c. Blower CFM Range Model Tons @ 0.5 in. w.c. Speed Speed LRF65 100-10T DD 766-1249 LRF80 100-10T DD Medium Low 766-1249 LRF90 100-10T DD Medium Low Medium High 766-1249... - Page 17 APPENDIX A - CHECK OUT AND ADJUSTMENTS Table A-10 Direct Drive Blower Motor Setup - 1/2 HP ECM Variable Speed Constant CFM Motor Dip Switch Adjustment Chart For Input 0.55 USGPH TO 0.85 USGPH SW1 - HEAT SW2 - COOL DIP Switch DIP Switch INPUT...

- Page 18 APPENDIX A - CHECK OUT AND ADJUSTMENTS Table A-11 Direct Drive Blower Characteristics - 1/2 HP ECM Variable Speed Constant CFM Motor - continued COOLING OR HEAT PUMP HEATING SW2 COOL AC SIZE CFM WITH SW3-ADJ CFM WITH SW3-ADJ CFM WITH SW3-ADJ DIP SWITCH POSITION [TONS] DIP SWITCH POSITION A...

-

Page 19: Appendix B - Wiring Diagrams

APPENDIX B - WIRING DIAGRAMS Chimney Vent Furnace Wiring Diagram LRF/LRFV 240011511 REV. C [05/31/2017]... -

Page 20: Direct Vent Furnace Wiring Diagram Lrf/Lrfv

APPENDIX B - WIRING DIAGRAMS Direct Vent Furnace Wiring Diagram LRF/LRFV 240011511 REV. C [05/31/2017]... -

Page 21: Appendix C - Sequence Of Operation And Troubleshooting

APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING Table C-1: 1158-120 Electronic Fan Timer Board (EFT) Detailed Sequence Of Operati on (LRF) Mode Action System Response EFT closes the oil primary control T - T connections. Ignition system and the oil primary control start the furnace. Oil flows as long as the oil Thermostat calls for heat. - Page 22 APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING Table C-2: 1168-1 ECM Tap Board Sequence of Operation (LRFV) Thermostat Input LEDs (LED 1-5, LED 8) Six green LEDs are placed behind their respective thermostat connections (Y1, Y/Y2, G, DH, O, W) and illuminate whenever a call is present.

-

Page 23: Troubleshooting

APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING C.1 Troubleshooting WARNING Electrical shock hazard. Only a trained, experienced service technician should perform troubleshooting procedure. Failure to do so could result in death or serious injury. C.2 Preliminary Steps: Consult Beckett or Riello instruction manuals provided with oil burner for specific information regarding oil burner primary control sequence of operation, diagnostics and troubleshooting. - Page 24 APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING WARNING Electrical shock hazard. Only a trained, experienced service technician should perform troubleshooting procedure. Failure to do so could result in death or serious injury. Table C-3 - System and General Troubleshooting Problem Possible Cause Remedy...

- Page 25 APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING Table C-3: System and General Troubleshooting continued Problem Possible Cause Remedy If cad cell is dirty, clean it. Determine why cad cell is getting dirty. If cad cell is poorly aimed, realign it. Furnace starts, but cuts out requiring manually NOTE: Photocell should have resistance of 100 KΩ...

- Page 26 APPENDIX C - SEQUENCE OF OPERATION AND TROUBLESHOOTING Table C-3: System and General Troubleshooting continued Problem Possible Cause Remedy Adjust oil burner combustion air band and draft regulator to gain highest Insufficient combustion air practical CO2 or lowest practical O2 content in flue gases. adjustment at oil burner, or improper draft pressure.

-

Page 27: Appendix D - Home Owners Reference Table

APPENDIX D - HOMEOWNER’S REFERENCE TABLE Model No. Serial No. Date Installed Contractor Contact Address Postal Code Telephone No. After Hours No. Fuel Supplier Fuel Oil Supplier Contact Telephone No. After Hours No. 240011511 REV. C [05/31/2017]... -

Page 28: Parts Listing: Chimney Vent Models Lrf/Lrfv

109009624AD Base Panel Assembly 550003225 Rear Panel 109009626AD Blower Door 109009809AD Front Panel 109009786AD Logo Bezel 28479 Logo Label Olsen 28563 Logo Label Airco 28564 Handle (2 per unit) 28673 Top Panel 109008787AD Blower Division Panel 3002357 Inner Front Panel... - Page 29 PARTS LISTING Parts Listing: Chimney Vent Models LRF/LRFV - CONTINUED Ref. No. Description Part No. Blower Assembly - Direct Drive ECM Motor (includes 39) 550003218 Blower Housing and Wheel 100-10T Direct Drive 240010315 Blower Motor 1/2 HP ECM Programmed 102000186 Motor Mounting Band TR6884B 17811 Motor Mounting Arms...

-

Page 30: Parts Listing: Direct Vent Models Lrf/Lrfv

PARTS LISTING Parts Listing: Direct Vent Models LRF/LRFV Ref. No. Description Part No. All parts are same as listed for chimney vent models secept as listed below. Cleanout Cover w/ Pressure Tap for Direct Vent (Includes one item 19) 550003409 Oil Burner Assembly, Beckett NX56LQ 0.50-60°W 550003406 Oil Burner Assembly, Riello 40BF3 0.55-80°B (0.55/0.65 USGPH Firing Rates) -

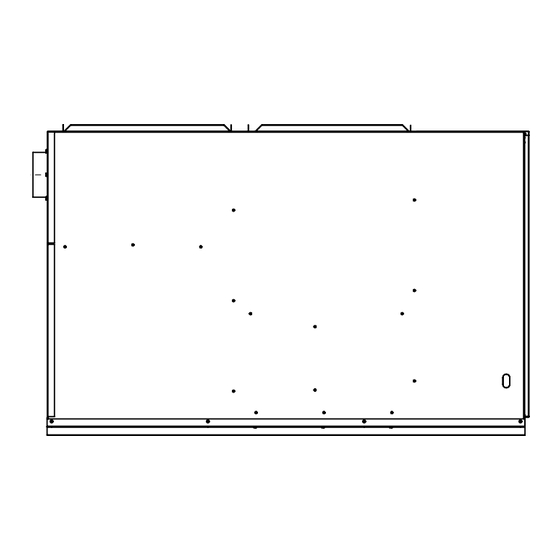

Page 31: Parts Diagram

PARTS LISTING Model LRF/LRFV Diagram 240011511 REV. C [05/31/2017]... - Page 32 ECR International 2210 Dwyer Avenue, Utica NY 13501 web site: www.ecrinternational.com...

Need help?

Do you have a question about the LRF65 and is the answer not in the manual?

Questions and answers