Table of Contents

Advertisement

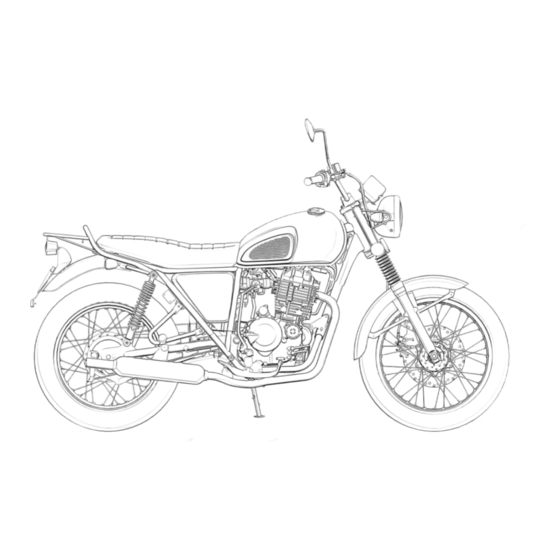

XY400 –2 Maintenance Manual

With the ever increasing varieties of motorcycles, new structures and new techniques have increasingly been applied. To

help shineray users and maintenance personnel better understand the maintenance, adjustment and repair techniques of

XY400-C motorcycle, we prepared this maintenance manual. This manual is expected to facilitate the SHINERAY users and

maintenance personnel and provide technical guidance for them.

The masterstroke of the manual is the XY400-2 motorcycle , and the contents in Chapter 1-Chapter 3 are applicable to the

adjustment of various parts of the motorcycle. Chapter 4-18 describes various constituting parts of the motorcycle respectively.

Chapter 19 contains the electrical system diagram.

The standard maintenance procedures, maintenance precautions and general maintenance knowledge are not covered in

this manual. Any user or maintenance personnel who needs the above information may refer to the related materials

All materials, charts and various data, as well as performance indices referenced herein, are for the latest model in our product

family at the date this manual is printed. SHINERAY Co., Ltd. Shall have the right to, at any time, amend this manual without

prior notice. The copyright of all parts of this manual belongs to China SHINERAY Co., Ltd. and no units or individuals are

allowed to reprint it the without consent of our company.

We hope you will enjoy the comfort and pleasure it brings to you during your driving!

Foreword

1

Foreword

Advertisement

Table of Contents

Summary of Contents for Shineray XY400-2

- Page 1 All materials, charts and various data, as well as performance indices referenced herein, are for the latest model in our product family at the date this manual is printed. SHINERAY Co., Ltd. Shall have the right to, at any time, amend this manual without prior notice.

- Page 2 XY400-C Maintenance Manual Contents Contents 1-12 Overview 13-20 Lubrication system Inspection and adjustment 21-41 Fuel system 42-45 46-50 Removal and installation of engine 51-64 Cylinder head, cylinder and piston 65-75 Clutch and Right crankcase cover Magneto and starting system 76-84 Crankcase, crankshaft and Shift mechanism 85-100 101-109...

- Page 3 XY400-C Maintenance Manual Overview 1. Overview Engine Number Position Bar Tool About Motorcycle Maintenance Maintenance Period Table Technical Data of Main Performance Symbol Descriptions Standard Torque Values Engine Number Position Photo of Complete Vehicle: Frame Number Position: Engine Number Position: Engine Number Frame Number...

- Page 4 XY400–2 Maintenance Manual Overview Maintenance Precautions Whenever reassembling after being disassembled, replace new washers, sealing members, etc. The specified or equivalent lubricating grease (oil) must be applied to or refilled into the specified locations. While fastening bolts or nuts, proceed in diagonal crossing sequence to gradually screw down to the required torque for 2 to 3 tries.

- Page 5 XY400–2 Maintenance Manual Overview In case the fuse is blown, check for the causes and, after Make sure the plastic jacket of the connector is securely being repaired, replace corresponding fuse as per the covering the connector without scaling off. specified capacity.

- Page 6 XY400–2 Maintenance Manual Overview The wire harness shall be clamped at the position without Do not damage the garnish of the wire harness. contacting a rotating part or a removing element. Once the wire harness is damaged, repair it by coiling with plastic adhesive tape.

- Page 7 XY400–2 Maintenance Manual Overview 16. Do not drop or throw the parts and components. Have you learned by heart the method of application? Are the measurement range and polarity in accordance with the instruction manual? 17. In case of rust on the terminals, carry out connection operation after disposing it with abrasive paper, etc.

- Page 8 XY400–2 Maintenance Manual Overview Technical Data of Main Performance Item Data Length 2105mm Width 760mm Height 1130mm Wheelbase 1420mm Min. ground clearance 160mm Complete vehicle weight Non-loaded weight: 151kg, Curb weight: 160kg, Frame type Cradle type Rake angle 28° Front suspension device spring &...

- Page 9 XY400–2 Maintenance Manual Overview Clutch Wet clutch, coil clutch, paper friction wafer Clutch operating system Manual mechanical Variable speed gear 5-speed constant mesh Primary reduction ratio 2.666 Transmission gear ratio Ⅰ 2.615 Ⅱ 1.789 Ⅲ 1.350 Ⅳ 1.120 0.892 Final reduction ratio 2.533 Gear shifting mode Left foot operated to and back type...

- Page 10 XY400–2 Maintenance Manual Overview Standard Torque Values ENGINE Thread diameter Item Quantity Torque value (N.m) Thread locker (mm) Cylinder head cover connecting bolt 8~12 40~50 Cylinder bolt 8~12 Valve adjusting screw nut 8~12 Timing driven sprocket bolt 7~11 Rocker-arm shaft cover 24~28 Magneto flywheel fastening nut 38~45...

- Page 11 XY400–2 Maintenance Manual Overview Name and dimensions Torque value (N.m) 5mm bolt & nut 4.5 ~6 6mm bolt & nut 8 ~12 8mm bolt & nut 18 ~25 10mm bolt & nut 30 ~40 12mm bolt & nut 50 ~60 5mm Screw 3.5 ~5 6mm Screw...

- Page 12 XY400–2 Maintenance Manual Overview Magnetic generator rotor puller: for dismantling magnetic Rubber hanner, Iron hammer, Copper hammer generator rotor Feeler gauge: to measure the clearance of piston, cylinder, Micrometer: to measure the dimensions of piston, valve, etc. piston pin, etc. Dial gauge: to measure the wheel bouncing, cylinder inner Cylinder barometer: to measure the cylinder pressure diameter, etc.

- Page 13 I:Carry out inspection, cleaning, adjustment, lubrication or replacement. C: Cleaning. R: Replacement. A: Adjustment. L: Lubrication. * This item is subject to maintenance by persons from SHINERAY Service Station. If the user has special service tools, maintenance accessories or maintenance ability, it can repair it by itself.

- Page 14 XY400–2 Maintenance Manual Overview Symbol Descriptions Meanings of various symbols in this manual: Explanation Measures to be prompted during operating, inspecting and maintaining. NOTICE: Special instructions or disposal measures given to prevent motorcycle from being damaged. WARNING: Special instructions or measures given to avoid serious damages or personal injuries. Each time reassembled after being removed and disassembled, it must be replaced with a new one.

-

Page 15: Lubrication System

XY400-C Maintenance Manual Lubrication system 2. Lubrication system Maintenance notice Inspection of lubricating oil Troubleshooting Replacement of lubricating oil Lubricating Position of Complete Vehicle Cleaning of Lubricating Oil Strainer Lubrication of Control Lines Cleaning and Replacement of Lubricating Oil Filter Engine Lubrication System Diagram Oil Pump Maintenance notice... -

Page 16: Troubleshooting

XY400-C Maintenance Manual Lubrication system Troubleshooting Lubricating oil contaminated Lubricating oil consumes too fast ● ● 1. Fail to replace lubricating oil according to the There is leakage with the engine; maintenance period table; The piston ring is worn. 2. The pouring orifice thread is damaged thus causing The inlet/exhaust valve guide is worn;... - Page 17 XY400-C Maintenance Manual Lubrication system Engine Lubrication System Diagram Camshaft oil through Cylinder head oil through Crankshaft oil through Cylinder oil through Oil filter Spindle oil through Oil pump Oil strainer Countershaft oil through Right crankcase body oil through Right crankcase cover oil through...

- Page 18 XY400-C Maintenance Manual Lubrication system Left crankcase body oil through Cylinder block, cylinder head, camshaft bearing seat and a camshaft oil through Inspection of lubricating oil Park the motorcycle on a flat surface,look over the engine oil dipstick on the oil pot,if the engine oil level is under the lower scale line, refill the recommended lubricating oil until the oil level reaches the upper-middle limit。...

- Page 19 XY400-C Maintenance Manual Lubrication system dipstick reaches the upper-middle limit. Then insert the oil filter plug and screw it up. Lubricating oil Lubricating oil Replacement of lubricating oil While replacing lubricating oil, it shall be carried out before the engine has cooled down. This will ensure quick and complete discharge of the engine oil inside the crankcase.

- Page 20 XY400-C Maintenance Manual Lubrication system CAUTION Application of engine oil of poor quality will have an impact on the functional performance and life span of the motorcycle engine. Cleaning of Lubricating Oil Strainer It shall be carried out while replacing lubricating oil. While cleaning, you should unscrew the oil drain plug to drain the waste engine oil, and flush the strainer with cleaning agent;...

-

Page 21: Oil Pump

XY400-C Maintenance Manual Lubrication system Oil Pump In case of failure, the oil pump needs to be removed for repair or replacement. This section includes the following contents: Steps and illustration for oil pump removal; Steps and illustration for oil pump installation; Disassembly and assembly of oil pump, etc. - Page 22 XY400–2 Maintenance Manual Lubrication system Steps for oil pump installation: The installation procedures are the removal procedures in reverse order. Pay attention to the following points during the installation: 1、 The spare parts shall be clean and intact; 2、 Install clutch assembly, and the retaining nut M18 shall be coated with thread retaining adhesive LOCTITE243; tightening torque: 114N.m -126N.m;...

-

Page 23: Inspection And Adjustment

XY400–2 Maintenance Manual Inspection and adjustment 3. Inspection and adjustment Maintenance notice Running system Check-up of spark plug Clutch control line Machine oil checking Driving chain Oil output tank Battery Checking Timing phase Replacement of Fuse Cylinder pressure Brake lamp adjustment Timing chain tension Headlamp dimming Valve clearance... - Page 24 XY400–2 Maintenance Manual Inspection and adjustment revealed at the crack point. Explanation: Unless expressly stated or indicated in the maintenance period table, check and adjust all parts of the XY400-C motorcycle according to the contents hereof before using it. Technical specifications ●...

- Page 25 XY400–2 Maintenance Manual Inspection and adjustment Check-up of spark plug Machine oil checking ①Remove the spark plug cap. Remove the spark plug Check oil level weekly. Always keep oil level between with a socket wrench. Visually check whether there is the HI and LO mark.

- Page 26 XY400–2 Maintenance Manual Inspection and adjustment Refilling method: Remove the oil filler plug, refill the Cleaning of Lubricating Oil Strainer engine oil slowly with a funnel until the oil level in the It shall be carried out while replacing lubricating oil. engine oil dipstick reaches the upper-middle limit.

- Page 27 XY400–2 Maintenance Manual Inspection and adjustment Timing phase It shall be carried out when the vehicle is new or there is any question about the timing phase. Remove the cylinder head cover Turn the crankshaft pulley Counterclockwise to align Notice the scale line “I”...

- Page 28 XY400–2 Maintenance Manual Inspection and adjustment include: While aligning Incorrect valve clearance adjusted Valve leakage Cylinder head sealing gasket ablated Piston ring or cylinder worn Piston ring worn The main reasons for excessive pressure include: The boss is in the center of the hole Presence of accumulated carbon inside the combustion chamber or on the piston top...

-

Page 29: Valve Clearance

XY400–2 Maintenance Manual Inspection and adjustment the crankcase. Insert the tensioner 4 locking key if there is too small gap or even no gap at all, closing into the tail end of the new chain tensioner, turn and of the valve will be hindered, which will cause many retract the front end of the tensioner and lock it, then problems such as engine stall, power loss, etc. -

Page 30: Air Filter

XY400–2 Maintenance Manual Inspection and adjustment Air filter compressing stroke but exhaust/intake stroke. In this Cleaning and replacement of air filter case, continuously turn the flywheel clockwise for 360 Remove the left side covers Handle it carefully to degrees to the top dead center position of the avoid scraping. -

Page 31: Idle Speed

XY400–2 Maintenance Manual Inspection and adjustment Idle speed Notice Check and adjust the idle speed after all other items of the engine have been adjusted to the specified ranges. For this model, the idle speed is controlled by an ECU. Maintaining &... -

Page 32: Brake System

XY400–2 Maintenance Manual Inspection and adjustment Brake system Fine adjustment: Check the front brake handle free stroke. Pull open the rubber lagging, unscrew the The brake handle free stroke 10-20mm. retaining nut A, and turn the adjusting solenoid to adjust to a satisfied free stroke. - Page 33 XY400–2 Maintenance Manual Inspection and adjustment Bleed air from the deflating valve of the vacuum hose and all connecting pieces for leakage. pump’s caliper Notice Open the cover of brake cylinder cover and refill The brake fluid shall be DOT 3 non-petroleum brake fluid.

Need help?

Do you have a question about the XY400-2 and is the answer not in the manual?

Questions and answers