Endress+Hauser Cerabar S PMC71 Operating Instructions Manual

Process pressure measurem

Hide thumbs

Also See for Cerabar S PMC71:

- Operating instructions manual (238 pages) ,

- Technical information (136 pages) ,

- Manual (96 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser Cerabar S PMC71

-

Page 1: Operating Instructions

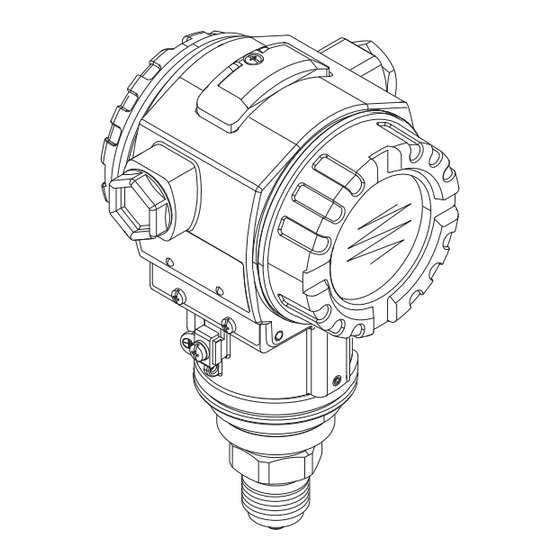

Operating Instructions Cerabar S PMC71, PMP71, PMP75 Process pressure measurement BA00271P/00/EN/18.14 71270361 valid from Software version: 02.20.zz... -

Page 2: Serial Number

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Order code 00X00-XXXX0XX0XXX Ser. No.: X000X000000 TAG No.: XXX000 Serial number www.endress.com/deviceviewer Endress+Hauser Operations App A0023555 Endress+Hauser... - Page 3 Operation via SFX100 ..... . 36 Endress+Hauser operating program ... . 36 Locking/unlocking operation .

-

Page 4: Safety Instructions

Safety instructions Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Safety instructions Designated use The Cerabar S is a pressure transmitter for measuring pressure and level. The manufacturer accepts no liability for damages resulting from incorrect use or use other than that designated. - Page 5 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Safety instructions Notes on safety conventions and icons In order to highlight safety-relevant or alternative operating procedures in the manual, the following conventions have been used, each indicated by a corresponding icon in the margin.

- Page 6 Identification Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Identification Product identification The following options are available for identification of the measuring device: • Nameplate specifications • Order code with breakdown of the device features on the delivery note •...

- Page 7 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Identification Devices for use in hazardous areas are fitted with an additional nameplate. A0021222 Fig. 2: Additional nameplate Approval-specific information Document number for safety instructions or drawing number Devices suitable for oxygen applications or with PVDF process connection are fitted with an additional nameplate.

-

Page 8: Safety Instructions 4

The device complies with the applicable standards and regulations as listed in the EC declaration of conformity and thus complies with the statutory requirements of the EC Directives. Endress+Hauser confirms the successful testing of the device by affixing to it the CE mark. -

Page 9: Incoming Acceptance, Transport, Storage

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Installation Installation Incoming acceptance, transport, storage 3.1.1 Incoming acceptance • Check the packaging and the contents for damage. • Check the shipment, make sure nothing is missing and that the scope of supply matches your order. - Page 10 Installation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART If this is the case, mount the sensor with the pressure compensation (1) pointing downwards. ® • Keep the pressure compensation and GORE-TEX filter (1) free from contaminations and water.

- Page 11 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Installation Pressure measurement in steams ➀ ➃ ➁ ➁ ➂ ➀ P01-PMx7xxxx-11-xx-xx-xx-002 Fig. 6: Measuring arrangement for pressure measurement in steams Cerabar S Shut-off device U-shaped siphon Circular siphon •...

- Page 12 Installation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Level measurement P01-PMP75xxx-11-xx-xx-xx-000 Fig. 8: Measuring arrangement for level • Mount Cerabar S below the lowest measuring point. • Do not mount the device at the following positions: In the fill flow, in the tank outlet or at a point in the container which could be affected by pressure pulses from an agitator.

- Page 13 115 (4.53) P01-PMx7xxxx-11-xx-xx-xx-005 Endress+Hauser recommends the use of temperature separators in the event of constant extreme fluid temperatures which lead to the maximum permissible electronics temperature of +85 °C (+185 °F) being exceeded. To minimise the influence of rising heat, Endress+Hauser recommends the device be mounted horizontally or with the housing pointing downwards.

- Page 14 Installation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 3.3.3 Seal for flange mounting ➀ ➁ P01-FMD7xxxx-11-xx-xx-xx-002 Fig. 11: Mounting the versions with flange or diaphragm seal Process isolating diaphragm Seal Warning! The seal is not allowed to press on the process isolating diaphragm as this could affect the measurement result.

- Page 15 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Installation 3.3.5 Wall and pipe-mounting (optional) Endress+Hauser offers a mounting bracket for installing on pipes or walls. mm (in) P01-xMx5xxxx-06-xx-xx-xx-001 Please note the following when mounting: • Devices with capillary lines: mount capillaries with a bending radius of 100 mm (3.94 in).

- Page 16 Installation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 3.3.6 Assembling and mounting the "separate housing" version r ³ 120 (4.72) mm (in) P01-PMx7xxxx-11-xx-xx-xx-011 Fig. 13: "Separate housing" version In the "separate housing" version, the sensor is supplied with process connection and cable fitted.

- Page 17 For the "U1 Prepared for diaphragm seal mount" version in feature 70 "Process connection; Material" in the order code of up to including 40 bar (600 psi)-sensors, Endress+Hauser recommends welding on the diaphragm seal as follows: the total welding depth of the fillet weld is 1 mm (0.04 in) at an external diameter of 16 mm (0.63 in).

-

Page 18: Post-Installation Check

Installation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 3.3.8 Rotating the housing The housing can be rotated up to 380° by loosening the Allen screw. max. 380° P01-PMx7xxxx-17-xx-xx-xx-000 Fig. 15: Aligning the housing – T14 housing: Loosen setscrew with a 2 mm (0.08 in) Allen key. -

Page 19: Wiring

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Wiring Wiring Connecting the device Warning! Risk of electric shock! If the operating voltage is > 35 VDC: Dangerous contact voltage at terminals. In a wet environment, do not open the cover if voltage is present. - Page 20 Wiring Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 4.1.1 Devices with Harting plug Han7D + – – Han7D – P01-xxx7xxxx-04-xx-xx-xx-001 Fig. 18: Left: electrical connection for devices with Harting plug Han7D Right: view of the plug connector at the device 4.1.2...

-

Page 21: Connecting The Measuring Unit

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Wiring Connecting the measuring unit 4.2.1 Supply voltage Note! • All explosion protection data are given in separate documentation which is available upon request. The Ex documentation is supplied as standard with all devices approved for use in explosion hazardous areas. - Page 22 Wiring Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 4.2.3 Load U – 10.5 V U – 11.5 V ➀ ➁ ≤ ≤ Lmax Lmax Lmax Lmax 23 mA 23 mA [ ] Ω [ ] Ω...

-

Page 23: Potential Matching

FieldCare Connecting Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (= Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a notebook. For details refer to TI00405C/07/EN. Note! For the device you need the "ToF Adapter FXA291" as an additional accessory. -

Page 24: Operation

Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation Feature 20 "Output; operation" in the order code provides you with information on the operating options available to you. Versions in the order code Operation 4 to 20 mA HART; external operation, LCD Via on-site display and 3 keys on the exterior of the device 4 to 20 mA HART;... -

Page 25: Operating Elements

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation The following table illustrates the symbols that can appear on the on-site display. Four symbols can occur at one time. Symbol Meaning Alarm symbol – Symbol flashing: warning, device continues measuring. - Page 26 Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 5.2.2 Function of the operating elements – on-site display not connected Press and hold the key or the key combination for at least 3 seconds to execute the corresponding function.

-

Page 27: On-Site Display Not Connected

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation On-site operation – on-site display not connected Note! /M-DAT module see ä 32, "HistoROM®/M-DAT ® To operate the device with a HistoROM (optional)". 5.3.1 Pressure measuring mode... - Page 28 Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 5.3.2 Level measuring mode If no on-site display is connected, the following functions are possible by means of the three keys on the electronic insert or on the exterior of the device: •...

- Page 29 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation Carry out position adjustment. Setting lower pressure value. Setting upper pressure value. Pressure is present at device. Desired pressure for lower pressure Desired pressure for upper pressure value (EMPTY PRESSURE...

-

Page 30: On-Site Display Connected

Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART On-site operation – on-site display connected If the on-site display is connected, the three operating keys are used to navigate through the operating menu, ä 26, "Function of the operating elements – on-site display connected". - Page 31 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation 5.4.2 Selecting an option Example: select "English" as the language of the menu. On-site display Operation German is selected as the language. A ✓in front of the menu text indicates the active option.

- Page 32 Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART On-site display Operation Use "E" to save the new value and exit the editing mode. See next graphic. P01-xxxxxxxx-19-xx-xx-xx-031 The new value for the damping is now 30.0 s.

- Page 33 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation Note! ® • The HistoROM /M-DAT module may be retrofitted at any time (Order No.: 52027785). ® • The HistoROM data and the data in the device are analysed once a HistoROM /M-DAT is attached to the electronic insert and power is reestablished to the device.

- Page 34 Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART ® Copying configuration data from a HistoROM /M-DAT to a device: Note! The operation must be unlocked. Disconnect device from supply voltage. ® Attach the HistoROM /M-DAT module to the electronic insert. Configuration data from ®...

- Page 35 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation ® Copying configuration data from a HistoROM /M-DAT to a device: Note! The operation must be unlocked. Disconnect device from supply voltage. ® Attach the HistoROM /M-DAT module to the electronic insert. Configuration data from ®...

-

Page 36: Operation Via Sfx100

The operating program FieldCare is an Endress+Hauser Plant Asset Management Tool based on FDT technology. You can use FieldCare to configure all your Endress+Hauser devices, as well as devices from other manufacturers that support the FDT standard. Hardware and software requirements you can find on the www.endress.com ... -

Page 37: Locking/Unlocking Operation

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation Locking/unlocking operation Once you have entered all the parameters, you can lock your entries against unauthorised and undesired access. You have the following possibilities for locking/unlocking the operation: •... -

Page 38: Factory Setting (Reset)

Operation Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 5.8.2 Locking/unlocking operation via on-site display or remote operation Description Locking operation 1. Select INSERT PIN NO. parameter, Menu path: OPERATING MENU OPERATION INSERT PIN NO. 2. To lock operation, enter a number for this parameter between 0 to 9999 that is 100. - Page 39 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Operation Reset code Description and effect 7864 Total reset – Affects the following parameters: – Function group POSITION ADJUSTMENT – Function group BASIC SETUP – Function group EXTENDED SETUP –...

-

Page 40: Commissioning

Commissioning Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Commissioning Warning! • If a pressure smaller than the minimum permitted pressure is present at the device, the messages "E120 Sensor low pressure" and "E727 Sensor pressure error - overrange" are output in succession. -

Page 41: Position Adjustment

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Commissioning Position adjustment Due to the orientation of the device, there may be a shift in the measured value, i.e. when the container is empty or partly filled, the measured value parameter does not display zero. There are three options to choose from when performing position adjustment. -

Page 42: Pressure Measurement

Commissioning Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Pressure measurement 6.4.1 Information on pressure measurement Note! • There is a Quick Setup menu for each of the measuring modes Pressure and Level which guides you through the most important basic functions. With the setting in the MEASURING MODE parameter, you specify which Quick Setup menu should be displayed. - Page 43 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Commissioning On-site operation Digital communication POS. ZERO ADJUST POS. ZERO ADJUST Due to orientation of the device, there may be a shift in Due to orientation of the device, there may be a shift in the measured value.

-

Page 44: Level Measurement

Commissioning Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Level measurement 6.5.1 Information on level measurement Note! • The Pressure and Level operating modes each have a quick setup menu which guides you through the most important basic functions. ä 46, "Quick Setup menu for Level measuring mode". - Page 45 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Commissioning 6.5.2 Overview of level measurement Measuring task LEVEL Measured Description Comment Measured value SELECTION/ variable options display LEVEL MODE The measured variable is LEVEL SELECTION: Via OUTPUT UNIT –...

- Page 46 Commissioning Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 6.5.3 Quick Setup menu for Level measuring mode Note! • Some parameters are only displayed if other parameters are appropriately configured. For example, the EMPTY CALIB. parameter is only displayed in the following cases: –...

- Page 47 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Commissioning On-site operation Digital communication LEVEL SELECTION LEVEL SELECTION Select level mode. For an overview see ä 45. Select level mode. For an overview see ä 45.

-

Page 48: Maintenance

Maintenance Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Maintenance ® Keep the pressure compensation and GORE-TEX filter (1) free from contaminations and water. P01-PMC71xxx-17-xx-xx-xx-001 Cleaning instructions Endress+Hauser offer flushing rings as accessories to clean process isolating diaphragms without taking the transmitters out of the process. -

Page 49: Trouble-Shooting

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Trouble-shooting Messages The following table lists all the possible messages that can occur. The device differentiates between the error types "Alarm", "Warning" and "Error". You may specify whether the instrument should react as if for an "Alarm" or "Warning" for "Error" messages. - Page 50 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 115 (E115) Error Out of B>Sensor overpressure – Overpressure present. – Reduce pressure until message specification disappears.

- Page 51 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 604 (W604) Warning Funktion C>Linearisation table not – The linearisation table consists of – Add to linearisation table. If check (C) valid.

- Page 52 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 706 (W706) Warning Maintenance C>Configuration in – Configuration (parameters) in the – Copy data from the device to the HistoROM.

- Page 53 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 716 (E716) Error Failure (F) B>Process isolating – Sensor defect. – Replace Sensor. diaphragm broken –...

- Page 54 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 726 (E726) Error Out of C>Sensor temperature error - – Electromagnetic effects are – Block off electromagnetic effects...

- Page 55 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 736 (A736) Alarm Failure (F) B>RAM error – Fault in the main electronics. – Briefly disconnect device from the power supply.

- Page 56 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Code Error type/ Corresponds Message/description Cause Measure Prio NA 64 NE 107 rity 746 (W746) Warning Funktion C>Sensor connection error - – Electromagnetic effects are – Wait a few minutes.

-

Page 57: Response Of Outputs To Errors

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting 8.1.1 On-site display error messages If the device detects a defect in the on-site display during initialization, the following error messages can be displayed: Message Measure Initialization, VU Electr. Defect A110 Exchange on-site display. - Page 58 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART 8.2.1 Configuring current output for an alarm You can configure the current output for the event of an alarm by means of the OUTPUT FAIL MODE, ALT. CURR. OUTPUT and SET MAX. ALARM parameters. These parameters are displayed OUTPUT).

-

Page 59: Confirming Messages

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Confirming messages Depending on the settings for the ALARM DISPL. TIME and ACK. ALARM MODE parameters, the following measures should be taken to clear a message: Settings Measures –... -

Page 60: Repair

Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Repair The Endress+Hauser repairs concept provides for measuring devices to have a modular design and also the customer may carry out repairs ( ä 60, "Spare Parts"). Note! •... -

Page 61: Software History

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Trouble-shooting Software history Date Software version Changes software Documentation Operating Instructions Description of Instrument Functions 11.2003 01.00.zz Original software. BA271P/00/EN/10.03 — 52020517 Compatible with: – ToF Tool Field Tool Package, version 1.04.00 or higher –... - Page 62 Trouble-shooting Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Date Software version Changes software Documentation Operating Instructions Description of Instrument Functions 06.2006 02.10.zz – New "Level Easy Pressure" and "Level Easy Height" level BA271P/00/EN/07.06 BA274P/00/EN/07.06 modes implemented. New LEVEL SELECTION parameter...

-

Page 63: Technical Data

Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Technical data Technical data For technical data, please refer to TI00383P. Endress+Hauser... - Page 64 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Index Index Numerics 4...20 mA test signal......21 Pipe mounting .

- Page 65 Cerabar S PMC71, PMP71, PMP75 with 4 to 20 mA HART Index Endress+Hauser...

- Page 66 www.endress.com/worldwide BA00271P/00/EN/18.14 71270361 CCS/FM+SGML 9 71270361...

Need help?

Do you have a question about the Cerabar S PMC71 and is the answer not in the manual?

Questions and answers