Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

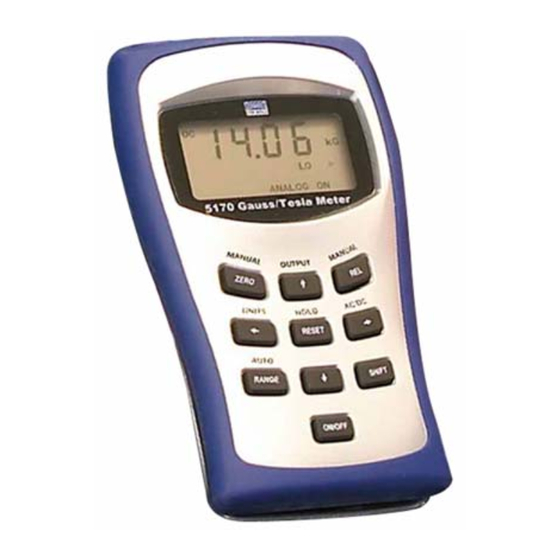

Summary of Contents for Pacific Scientific 5170

- Page 1 Manual UN-01-260 Rev. G Pacific Scientific OECO All rights reserved.

-

Page 2: Table Of Contents

OTHER GENERAL 5180 FILE INFORMATION …....… STATUS BYTE AND REQUEST FOR SERVICE (RQS) …..… SPECIFICATIONS ..............STANDARD EVENT REGISTER ………........… MODEL 5170 / 5180 SPECIFICATIONS ........ MEASUREMENT EVENT REGISTER ……......… STANDARD TRANSVERSE PROBE ........OPERATION EVENT REGISTER ……........… STANDARD AXIAL PROBE ........... - Page 3 List of Tables List of Illustrations Figure 1-1 Flux Lines of a Permanent Magnet......Table 4-1 Common Command Summary....4-10 Figure 1-2 Hall Generator............Table 4-2 SCPI Command Summary......4-13 Figure 1-3 Hall Probe Configurations........Figure 2-1 Standard Transverse Probe........Figure 2-2 Standard Axial Probe..........

- Page 4 Statement regarding improvements to 5100 Series Gaussmeters The 5100 Series Gauss / Tesla Meters now have improved AC performance and several operational improvements as a result of new DSP and microcontroller firmware. Customers with meters manufactured prior to June 2007 and firmware versions below r2.00 and d2.00 should review this manual for changes in specifications.

-

Page 5: Section -1 Introduction

Section 1 Introduction UNDERSTANDING FLUX DENSITY Magnetic fields surrounding permanent magnets or electrical conductors can be visualized as a collection of magnetic flux lines? Lines of force existing in the material that is being subjected to a magnetizing influence. Unlike light, which travels away from its source indefinitely, magnetic flux lines must eventually return to the source. -

Page 6: Measurement Of Flux Density

Section 1 Introduction MEASUREMENT OF FLUX DENSITY A device commonly used to measure flux density is the Hall generator. A Hall generator is a thin slice of a semiconductor material to which four leads are attached at the midpoint of each edge, as shown in Figure 1-2. Figure 1-2 Hall Generator A constant current (Ic) is forced through the material. -

Page 7: Figure 1-3 Hall Probe Configurations

The sensitive area of the Hall generator is generally defined as the largest circular area within the actual slice of the material. This active area can range in size from 0.2 mm (0.008”) to 19 mm (0.75”) in diameter. Often the Hall generator assembly is too fragile to use by itself so it is often mounted in a protective tube and terminated with a flexible cable and a connector. -

Page 8: Product Description

The measurement range is from 0.01 mT (0.1 G or 0.01 kA/m) to 3.000T (30.00 kG or 2388 kA/m) for the 5180, and 2.000T (20.00 kG or 1592 kA/m) for the 5170. The instrument is capable of measuring static (DC) and alternating (AC) magnetic fields. -

Page 9: Specifications

Section 2 Specifications 5170 5180 Ranges: Ultra Low Probe 200 G 300 G 2 kG 3 kG High 20 kG 30 kG Resolution: Ultra Low Probe 1 mG 1 mG 0.1 G 0.1 G 1.0 G 1.0 G High 10 G... - Page 10 SPECIFICATIONS, MODEL 5170 & 5180 GAUSS / TESLAMETER without probe, 23 ±3ºC, RH <85% Probe accuracy must be added to meter accuracy to determine 5170 5180 overall accuracy DC MODE, Low Range: 1.25 + 4 0.8 + 4 Warmup Time To Rated Accuracy: 5 minutes Mid &...

-

Page 11: Standard Transverse Probe

STANDARD TRANSVERSE PROBE Model Number: (5180): STD18-0404 (5170): STH17-0404 Frequency Bandwidth: (5180): 0 to 20 kHz (5170): 0 to 10 kHz Offset change with Temperature: ±300 mG / ºC (typical) Accuracy change with Temperature: -0.05%/ºC (typical) Operating Temperature Range: 0 to +75ºC (+32 to +167°F) Storage Temperature Range: -25 to +75ºC (-13 to +167°F) -

Page 12: Standard Axial Probe

SAD18-1902 2" Axial Probe Flux Density Range: (5180): 0 to ±30 kG (0 to 3 T) 5170 gaussmeter probes (5170): 0 to ±20 kG (0 to 2 T) SAH17-1904 4" Axial Probe SAH17-1902 2" Axial Probe Corrected Linearity: (5180): ±0.5% to ±30kG (5170): ±1.0% to ±20kG... -

Page 13: Low Field Axial Probe

LOW FIELD AXIAL PROBE Model Number: MOS51-3204 Flux Density Range: ±1G (100•T) DC or peak AC Corrected Linearity: ±0.75% of Reading Frequency Bandwidth: 0 to 700 Hz (-3dB) Offset change with Temperature: ±0.02mG / ºC (typical) Accuracy change with Temperature: 0.001 % / ºC (typical) Operating Temperature Range: 0 to +75ºC (+32 to +167°F) Storage Temperature Range: -25 to +75ºC (-13 to +167°F) Figure 2-3... -

Page 14: Zero Flux Chamber

ZERO FLUX CHAMBER MODEL NUMBER: YA111 CAVITY DIMENSIONS: Length: 50.8 mm (2”) Diameter: 8.7 mm (0.343”) ATTENUATION: 80 dB to 30 mT (300 G) PURPOSE: To shield the probe from external magnetic fields during the ZERO or RELATIVE operations. Figure 2-4... -

Page 15: Section - 3 Operating Instructions

Section 3 Operating Instructions OPERATOR SAFETY Do not allow the probe to come in contact with any voltage source greater than 30 Vrms or 60 Vdc Do not connect the auxiliary power connector to an AC power source. Do not exceed 5 Vdc regulated. Do not reverse polarity. -

Page 16: Operating Features

OPERATING FEATURES Display. Liquid crystal display (LCD). Auto Zero. To select AUTO ZERO operation, press the ZERO pushbutton. Unit automatically returns to normal operation. Manual Zero. To select MANUAL ZERO operation, press the SHIFT pushbutton followed by the ZERO pushbutton. Use the LEFT (3) and RIGHT (4) arrow pushbuttons to select digit. Use the UP (5) and DOWN (6) arrow pushbuttons to make fine adjustments as needed. -

Page 17: Instrument Preparation

INSTRUMENT PREPARATION 1) With the power switch turned off apply pressure to the battery compartment cover at the point shown in Figure 3-4. Slide the cover open and remove. 2) Install four AA 1.5V alkaline batteries. The battery compartment is designed to indicate the battery polarity. Reinstall the battery compartment cover. -

Page 18: Power-Up

POWER-UP Press the POWER switch. There will be a momentary audible beep and all display segments will appear on the display. The instrument will conduct a self test before measurements begin. If a problem is detected the phrase “Err” will appear on the display followed by a 3 digit code. -

Page 19: Power-Up Settings

POWER-UP SETTINGS The meter permanently saves certain aspects of the instrument’s setup and restores them the next time the meter is turned on. The conditions that are saved are: RANGE setting (including AUTO range) MODE (AC or DC) UNITS of measure (gauss, tesla or amperemeter) OUTPUT function Other aspects are not saved and default to these conditions: RELATIVE mode (turned OFF) -

Page 20: Low Battery Condition

LOW BATTERY CONDITION The meter is designed to use four standard AA 1.5V alkaline batteries . When the battery voltage becomes too low the battery symbol on the display will flash, as shown in Figure 3-8. Replace the batteries or use an external AC to DC power supply. Figure 3-8 Low Battery Indication Instrument specifications are not guaranteed when a low battery condition exists! -

Page 21: Range Selection

RANGE SELECTION The meter is capable of providing flux density measurements on one of three fixed ranges, or it can be programmed to automatically select the best range for the present flux density. The available ranges are listed in the SPECIFICATIONS section of this manual. The ranges advance in decade steps. The lowest range offers the best resolution while the highest range allows higher flux levels to be measured. -

Page 22: Hold Mode Selection

HOLD MODE SELECTION In some applications it may be desirable to hold a reading that is either greater than or less than all previous readings, or which has the greatest peak value whether positive or negative. The MAX HOLD function holds the reading that is arithmetically greater than all previous readings. For instance a reading of +125.0 is greater than +99.0 or -150.0. -

Page 23: Min / Max Hold Usage

If the reading exceeds the range limit the 5180 meter will hold a flashing value of “2999” (gauss or tesla mode), “2387” (ampere meter mode) or the maximum value allowed in the RELATIVE mode. The 5170 meter will hold a flashing value of "1999" (gauss or tesla mode), "1592"... -

Page 24: Zero Function

ZERO FUNCTION “Zeroing” the probe and meter is one of the most important steps to obtaining accurate dc flux density measurements. The ideal Hall generator produces zero output in the absence of a magnetic field, but actual devices are subject to variations in materials, construction and temperature. -

Page 25: Automatic Zero Function

AUTOMATIC ZERO FUNCTION The meter provides two methods to zero the probe. The first is completely automatic. Prepare the probe for zeroing, then press the ZERO pushbutton. The “ZERO” icon will flash and actual dc flux density readings will appear on the display. -

Page 26: Manual Zero Function

MANUAL ZERO FUNCTION The second zeroing method is a manual adjustment. This feature also allows the user to set the “zero” point to something other than zero, if desired. Position the probe for zeroing, then press the "SHIFT" pushbutton followed by the "ZERO" pushbutton. The “ZERO” icon will flash and actual DC flux density readings will appear on the display. -

Page 27: Relative Mode

RELATIVE MODE The RELATIVE mode allows a specific flux density value to be subtracted from all incoming readings. When the RELATIVE mode is active, all incoming readings are "relative" to an offset selected by the user. For example, if the displayed value is +100 gauss when RELATIVE mode is activated, and the flux density at the probe changes to +150 gauss the displayed value will be +50.0 gauss. -

Page 28: Automatic Relative Mode

AUTOMATIC RELATIVE MODE In the automatic relative mode, the present flux density as seen by the probe is used as the relative offset value. Prepare the probe and select an appropriate range and mode (AC or DC) as needed (AUTO RANGE is deactivated when RELATIVE MODE is used). -

Page 29: Manual Relative Mode

MANUAL RELATIVE MODE The second method by which to set a relative value is a manual adjustment. In some cases the user will wish to set an absolute relative value. To do this, insert the probe in the "zero flux chamber" provided with this meter. To manually assign a relative offset value, press the SHIFT key followed by the REL key. -

Page 30: Analog Output Function

ANALOG OUTPUT FUNCTION The 5180 meter is capable of providing an analog voltage signal proportional to the present flux density level. Calibration is set to 3.0V full scale DC or 3.0VRMS AC, depending upon the mode of operation. This signal, available at the BNC connector, can be connected to a voltmeter, oscilloscope, recorder, data logger, or external analog to digital converter. -

Page 31: Analog Output Usage

ANALOG OUTPUT USAGE See the SPECIFICATIONS section for frequency range and accuracy of the analog output. The analog output signal is calibrated to 3VDC or 3VRMS depending on the selected mode. The analog output voltage is proportional to the flux density being measured depending on the meters current range. For instance, when in the 30mT DC range a reading of 12.3mT relates to an analog output voltage of 1.23VDC. -

Page 32: Figure 3-21 Adjusting The Dc Offset Of The Analog Output

When both the ANALOG OUTPUT and AUTO RANGE features are active the following condition can occur. Suppose the present range is 3kG and the present reading is +2.8kG. The analog output will be +2.8VDC. The signal then increases to +3.2kG, which would force an automatic change to the 30kG range setting. The analog output will now be +0.32VDC because of the range change. -

Page 33: Sources Of Measurement Errors

SOURCES OF MEASUREMENT ERRORS When making flux density measurements there are several conditions that can introduce error: 1) Operating the meter while the LOW BATTERY symbol appears. Instrument specifications are not guaranteed when a low battery condition exists! 2) Failure to zero the error signals from the meter, probe, and nearby sources of magnetic interference. 3) Subjecting the probe to physical abuse. -

Page 34: More Details On Ac Mode Operation

6) Flux density can vary considerably across the pole face of a permanent magnet. This can be caused by internal physical flaws such as hairline cracks or bubbles, or an inconsistent mix of materials. Generally the sensitive area of a Hall generator is much smaller than the surface area of the magnet, so the flux density variations are very apparent. -

Page 35: More Details On Dc Mode Operation

An AC reading, being a true RMS value, has no polarity. However, when using the RELATIVE function in AC mode, a negative value may be displayed. A negative AC reading means that the present reading is less than the RELATIVE value. An unsigned value means the present reading is greater than or equal to the RELATIVE value. For example, if the original RELATIVE value was 100mT and the present field is 80mT, the result will be -20mT. -

Page 36: Section - 4 Remote Operation

Section 4 Remote Operation USB INTERFACE CONNECTION NOTE: Ensure that sleep mode is disabled prior to remote operation. Prior to using the remote operation capability of the meter, the USB driver software must be installed on a computer. This software was supplied on the User’s Manual CD for the meter, however newer software may be available. Please visit the F.W. -

Page 37: Error Buffer

ERROR BUFFER Errors are generated by a variety of sources, such as hardware errors or errors in the command syntax. If an error occurs a message is stored in an ERROR BUFFER. The message can be retrieved by a specific command discussed later in this section. STATUS REGISTERS There are four register sets that indicate the status of the instrument, such as errors or the present state of the meter. -

Page 38: Information For Remote Operation

Information for Remote Operation of 5180 Gaussmeter There are 2 DLL files which should be installed when you run the setup program from the 5180 User manual CD. They are libusb0.dll and usb5100.dll. They should have installed to your system when you ran the installation from the CD. Note: These files allow communication with the 5180 by higher level programming languages such as various types of C, C++ or C#, VisualBasic or development programs like LabView, Agilent VEE or TestPoint which can make calls to a DLL file. -

Page 39: Other General 5180 File Information

• Usb5100.DLL exports many functions that actually do the USB connection and communication with the 5180 meter. This is the DLL that provides the functions used by the Pacific Scientific OECO manufacturing test & calibration system. It calls functions that are exported by libusb0.dll. The functions in this DLL should be able to be called by most higher level programming languages using the methods described earlier in this document. -

Page 40: Status Byte And Request For Service (Rqs)

STATUS BYTE AND REQUEST FOR SERVICE (RQS) A bit in the STATUS BYTE called RQS (request for service) sets whenever an event occurs that requires the attention of the computer. The RQS bit can set if any of the summary bits from the MEASUREMENT EVENT, OPERATION EVENT, STANDARD EVENT or QUESTIONABLE EVENT registers are set, or if an error message exists. - Page 41 OSB – Operation Summary Bit: If any of the bits in the OPERATION EVENT register set, and their respective enable bits are set, the Operation Summary Bit (OSB) will set. ESB – Event Summary Bit: If any of the bits in the STANDARD EVENT register set, and their respective enable bits are set, the Event Summary Bit (ESB) will set.

-

Page 42: Standard Event Register

STANDARD EVENT REGISTER If any of these bits set, and their respective enable bits are set, the Event Summary Bit (ESB) will set in the STATUS BYTE. PON–Power On: Indicates that the meter was turned off and on since the last communication. CME –... -

Page 43: Measurement Event Register

MEASUREMENT EVENT REGISTER If any of these bits set, and their respective enable bits are set, the Measurement Summary Bit (MSB) will set in the STATUS BYTE. ROF – Reading Overflow: Indicates that the present reading exceeds the present measurement range. RAV –... -

Page 44: Common" Command Syntax

“COMMON” COMMAND SYNTAX The “common” commands are recognized and acted upon in a similar manner by all instruments that follow the IEEE488.2 standard, whether a DVM, scope, frequency meter, gaussmeter, etc. These are the syntax rules: 1) A common command always begins with an asterisk character (*) followed by a three or four character acronym and possibly one other parameter. - Page 45 4-10...

- Page 46 *CLS – CLEAR STATUS Clears the MEASUREMENT EVENT, OPERATION EVENT, STANDARD EVENT and QUESTIONABLE EVENT registers, but not their enable registers. It also clears the error buffer. *ESE <NRf> – PROGRAM STANDARD EVENT ENABLE REGISTER A set bit in the STANDARD EVENT ENABLE register allows its corresponding event to set the ESB (event summary bit) in the STATUS BYTE register.

-

Page 47: Scpi Command Syntax

SCPI COMMAND SYNTAX The SCPI commands go one step farther than IEEE488.2 and provide a language protocol and defines a standard set of commands to program most aspects of the instrument. These are the syntax rules: 1) The first character of any command string is a colon (:). 2) The commands are not case sensitive. -

Page 48: Scpi Commands

SCPI COMMANDS In the following discussion the commands are written such that the short form of the command is written in UPPER CASE letters and the remainder of the command is written in lower case letters. Either form can be used. If parameters are required they will appear within <>... - Page 49 Table 4-2 SCPI Commands 4-14...

-

Page 50: Error Messages And Commands

ERROR MESSAGES AND COMMANDS If an error occurs a message is placed in the error buffer. The message will contain a number, a comma (,) and a brief description of the error. Negative () numbers are used for SCPI defined messages while positive (+) numbers relate specifically to the meter. -

Page 51: Status Commands

STATUS COMMANDS The STATUS commands control and query the MEASUREMENT EVENT, OPERATION EVENT and QUESTIONABLE EVENT registers. :STATus:MEASurement:EVENt? :STATus:OPERation:EVENt? :STATus:QUEStionable:EVENt? Returns the contents of the specified EVENT register, then clears the register contents. :STATus:MEASurement:ENABle <NRf> :STATus:OPERation:ENABle <NRf> :STATus:QUEStionable:ENABle <NRf> Programs the specified EVENT ENABLE register with the value <NRf>. <NRf> is an ASCII string representing an integer mask. For instance a value of 45 decimal is the same as binary 00101101, thus setting bits 5, 3, 2 and 0 in the enable register. -

Page 52: Mode Commands

MODE COMMANDS These commands select readings in either GAUSS, TESLA or AMPMETERS, and flux density readings for either static fields (dc) or alternating fields (ac). See Section3 for more information. :UNIT:FLUX:AC:GAUSs Specifies ac flux density readings in gauss. :UNIT:FLUX:AC:TESLa Specifies ac flux density readings in tesla. :UNIT:FLUX:AC:AM Specifies ac flux density readings in ampmeters. -

Page 53: Range Commands

RANGE COMMANDS These commands select either a fixed range or AUTO range. See Section 3 for more information. :SENSe:FLUX:RANGe:AUTO Selects the AUTO RANGE function. :SENSe:FLUX:RANGe <n> Selects a fixed range <n>, where n = 0 for 300 G / 30 mT / 23.88 kA/m 1 for 3 kG / 300 mT / 238.8 kA/m 2 for 30 kG / 3 T / 2388 kA/m :SENSe:FLUX:RANGe? -

Page 54: Hold Commands

HOLD COMMANDS These commands select one of the HOLD modes or resets the presently held reading. See Section3 for more information. :SENSe:HOLD:STATe <n> Selects the HOLD function, where <n> is a single ASCII digit, as follows: 0 = All HOLD modes turned off. 1 = MIN HOLD on. -

Page 55: Zero Command

ZERO COMMAND This command initiates an automatic ZERO operation. See Section3 for more information. :SYSTem:AZERo Automatic zeroing is initiated upon receipt of this command. RELATIVE COMMANDS These commands control the RELATIVE function. See Section 3 for more information. :SYSTem:ARELative:STATe <n> The relative function is turned off when <n>... -

Page 56: Analog Output Command

ANALOG OUTPUT COMMAND This command enables or disables the ANALOG OUTPUT. See Section3 for more information. :SYSTem:OUT <n> Enables or disables the ANALOG OUTPUT, where <n> is a single ASCII digit, as follows: 0 = Analog output turned off. 1 = Analog output turned on. 2 = Analog output turned on. -

Page 57: Operation Complete Status

USING THE OPERATION COMPLETE STATUS There are several ways to determine if the meter has executed a command. If the command string contains a query command the program can simply wait for the meter to transmit its response. But if the query command contains an error the command may never be executed. -

Page 58: Model 5100 Error Codes

MODEL 5100 ERROR CODES THAT MAY BE DISPLAYED IF THERE IS A PROBLEM Description of Error Error Code Possible problem Invalid calibration data Meter not calibrated or data corrupt Probe EPROM read error Probe EPROM missing or defective Probe CRC failed Probe EPROM defective Incorrect probe current Probe EPROM error or meter malfunction... -

Page 59: Warranty

Pacific Scientific OECO’s satisfaction to be defective. If it is determined that the defect has been caused by misuse or abnormal conditions of operation, repairs will be billed at cost after submitting an estimate to the purchaser.

Need help?

Do you have a question about the 5170 and is the answer not in the manual?

Questions and answers