Table of Contents

Advertisement

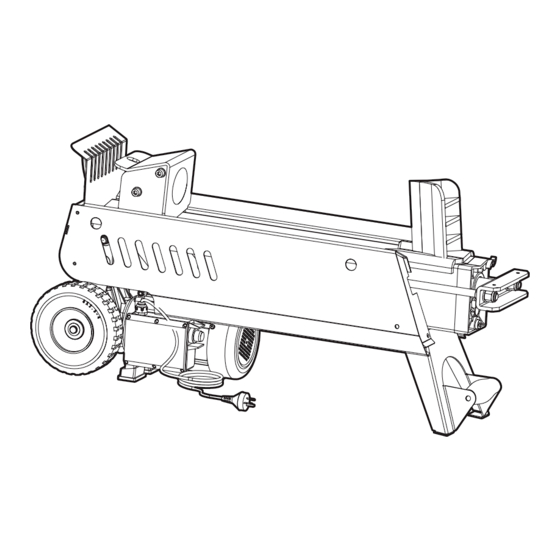

9-Ton Log Splitter

model number 060-3772-0

Please read and understand this manual before beginning

any use or assembly of the product, and make sure all

parts are present.

Questions?

If you have any questions or need replacement parts,

please call our toll-free helpline at 1-866-523-5218.

w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 1

YW_060_3772_0_9TElectricLogSplitter

PANTONE

PANTONE

PROCESS

388

3145

WO

w01a

w01b

02

12/01/16

12/05/16

mm/dd/yy

Date

xxxxxx

PA

PA

Artist

978343

CTC Generic

PANTONE

COOL GRAY 11

BLACK

w02a

03

w02b

04

05

w03a

12/16/16

mm/dd/yy

12/20/16

mm/dd/yy

mm/dd/yy

12/29/16

xxxxxx

xxxxxx

xxxxxx

PA

PA

Cindy

AD8343

LITHO

FLEXO

PANTONE

000

w07a

06

07

mm/dd/yy

mm/dd/yy

02/08/17

xxxxxx

xxxxxx

Alexa

Instruction

Manual

2017/3/6 22:26:43

Advertisement

Table of Contents

Summary of Contents for Yardworks 060-3772-0

- Page 1 9-Ton Log Splitter model number 060-3772-0 Please read and understand this manual before beginning any use or assembly of the product, and make sure all Instruction parts are present. Manual Questions? If you have any questions or need replacement parts, please call our toll-free helpline at 1-866-523-5218.

- Page 2 060-3772-0 | contact us 1.866.523.5218 Specifications Important Safety Instructions Symbols Parts List Exploded View Parts Location Important Information Before Assembly Assembly Operation Maintenance Storage Troubleshooting Environmental Protection Warranty w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 2 2017/3/6 22:26:43...

- Page 3 060-3772-0 | contact us 1.866.523.5218 Product Name 9-Ton Log Splitter Model Number 060-3772-0 Motor 120 V 60 Hz 15 A 1 3/4 HP Log Capacity (Diameter) 12 1/2" (32 cm) Log Capacity (Length) 20 1/2" (52 cm) Splitting Force...

-

Page 4: Personal Safety

060-3772-0 | contact us 1.866.523.5218 IMPORTANT! READ AND UNDERSTAND power supply when it is not in use, and ALL INSTRUCTIONS. before making adjustments, changing parts, Failure to follow safety instructions may cleaning, or servicing the log splitter. result in electric shock, fire, and/or serious •... -

Page 5: Safe Operation

060-3772-0 | contact us 1.866.523.5218 • environments. Do not use the log splitter Inspect the log before loading it on the in wet or damp conditions, and do not log splitter. Ensure there are no nails or expose it to rain. In order to avoid potential foreign objects in the logs to be split. -

Page 6: Symbols

060-3772-0 | contact us 1.866.523.5218 Symbol Name Designation/Explanation Symbol Name Designation/Explanation User must read and Always pay attention to Avoid Read the understand the instruction the movement of the log injury from instruction manual and all labels pusher. Keep hands and unexpected manual. - Page 7 060-3772-0 | contact us 1.866.523.5218 Item Description Snap washer Washer Valve rod O-ring Safety valve spring basis O-ring Safety valve spring Safety valve core Cylinder cover-left Valve sleeve O-ring Safety valve core adjusting spring Adjusting spring basis Stud...

- Page 8 060-3772-0 | contact us 1.866.523.5218 Item Description Screw Steel ball Valve Valve rod restoring spring O-ring Valve base Intake hose Connection hose Cylinder cover guard Lever nut Lever head Lever Carriage nut Separating plate Bolt Washer Body cover-right...

- Page 9 060-3772-0 | contact us 1.866.523.5218 Item Description Plastic insert-upper Drawing weldment Plastic insert-lower Thin nut Spring washer Support leg Bolt Handle Sleeve O-ring O-ring Gear shaft snap washer Steel ball Bolt Spring washer Bolt Pump cover Sleeve bearing...

- Page 10 060-3772-0 | contact us 1.866.523.5218 w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 10 2017/3/6 22:26:44...

- Page 11 060-3772-0 | contact us 1.866.523.5218 Item Description Log pusher Work table Wedge Support leg Log retaining plates Motor Pushbutton switch Pushbutton box Wheels (for minor moving only) Hydraulic control lever Control lever guard Bleed screw Oil drain bolt with dipstick Maximum pressure limiting screw w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 11...

-

Page 12: Intended Use

060-3772-0 | contact us 1.866.523.5218 NOTE: The safe use of this product requires an understanding of the information on the product and this operator’s manual as well as knowledge of the project you are attempting. Before use of this product, familiarize yourself with all operating features and safety rules. -

Page 13: Unpacking Instructions

060-3772-0 | contact us 1.866.523.5218 UNPACKING INSTRUCTIONS This log splitter is shipped completely assembled with the exception of installing the wheels and the rubber feet. • Carefully remove the log splitter and its accessories from the box. • Check and make sure all parts and accessories are included before using the log splitter for the first time. -

Page 14: Electrical Requirements

060-3772-0 | contact us 1.866.523.5218 ELECTRICAL REQUIREMENTS • Use a standard 120 V (±10%) 60 Hz (±1 Hz) AC only electrical supply that has under- voltage, over-voltage, and over-current protection devices as well as a residual current device (RCD) with a maximum residual current rated at 0.03 A for the log splitter. -

Page 15: Assembling The Wheels

060-3772-0 | contact us 1.866.523.5218 CAUTION! To avoid possible electric shock, switch off the power supply at the main fuse or circuit breaker box before assembling, servicing, or cleaning the log splitter. 1. ASSEMBLING THE WHEELS • Remove the wheel nut and washer from Axle the axle. -

Page 16: Check The Oil

060-3772-0 | contact us 1.866.523.5218 CAUTION! • Before using the log splitter, make sure that the work area is clear of obstructions, clutter, children, and pets. Work only in an area with ample lighting. • Dress properly. Wear rubber gloves and non-skid, steel-toed footwear. - Page 17 060-3772-0 | contact us 1.866.523.5218 2. LOOSEN THE BLEED SCREW • Turn the bleed screw 3 full turns. • Leave the bleed screw in a vertical position aligned behind the wedge or in a horizontal position aligned with the work table in order to avoid being sheared off by the split log during operation.

- Page 18 060-3772-0 | contact us 1.866.523.5218 WARNING! • Do not place the log at an angle against the wedge to split the log on the upper part (fig. 2). Doing so can break the wedge or damage the machine.

- Page 19 060-3772-0 | contact us 1.866.523.5218 WARNING! Do not crouch on the ground, sit down on a log beside the splitter, or kneel down by the log splitter (fig. 5). Always keep your hands and body out of the splitting or operating zone while using the log splitter.

-

Page 20: Freeing A Jammed Log

060-3772-0 | contact us 1.866.523.5218 f. Stop the log splitter by simultaneously releasing the hydraulic control lever and the switch (fig. 7). Wait for the log pusher to return to its starting position. g. Repeat steps b through f for the other logs. -

Page 21: Replacing The Hydraulic Oil

060-3772-0 | contact us 1.866.523.5218 WARNING! To avoid possible electric shock, always disconnect log splitter from the power supply and tighten the bleed screw before cleaning, making adjustments, or conducting maintenance work on the log splitter. REPLACING THE HYDRAULIC OIL Replace the hydraulic oil in the log splitter after every 150 hours of use. - Page 22 060-3772-0 | contact us 1.866.523.5218 • Wipe the dipstick clean and insert it back into the oil tank to check for the oil level. • Remove the dipstick and check for oil level. The level of the refilled oil should be between the 2 grooves of the dipstick.

-

Page 23: Sharpening The Blade

060-3772-0 | contact us 1.866.523.5218 SHARPENING THE BLADE After using the log splitter for some time, sharpen the blade or wedge using a fine-toothed file. Smooth out any burns or crushed areas along the cutting edge. CLEANING • Clean the log splitter using a clean, damp cloth. Use a soft brush on the splitting area and the motor ventilation area to remove any wood debris. -

Page 24: Cylinder

060-3772-0 | contact us 1.866.523.5218 Problem Possible Reason Solution Refer to the Operation section for The log is not positioned correctly. instructions on proper log loading. The size or hardness of the log Reduce the size of the log before exceeds the capacity of the machine. -

Page 25: Warranty

WARRANTY For TWO YEARS from the date of purchase within Canada, YARDWORKS CANADA will, at its option, repair or replace for the original purchaser, free or charge, any part or parts found to be defective in material or workmanship. - Page 26 w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 26 2017/3/6 22:26:46...

- Page 27 w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 27 2017/3/6 22:26:46...

- Page 28 Imported by YardWorks Canada Toronto, Canada M4S 2B8 w09a_YW_060_3772_0_9TElectricLogSplitter_GB.indd 28 2017/3/6 22:26:46...

Need help?

Do you have a question about the 060-3772-0 and is the answer not in the manual?

Questions and answers

Why does the hydraulic ram stop retracting 6” from closing

The hydraulic ram on Yardworks part number 060-3772-0 may stop retracting 6 inches from closing due to a lower maximum pressure setting caused by the limiting screw. This restricts full ram movement.

This answer is automatically generated

can i order part number 54 front cover ours cracked and will not hold transmission fluid leaks and squirts out

this is part i need

She I not working. She keeps tripping out the motor.

The Yardworks 060-3772-0 motor could trip out if pressure is applied for more than 5 seconds, causing the pressurized oil to overheat and potentially damage the motor.

This answer is automatically generated

My log splitter is leeks hydraulic fluid through electrical box, I m looking for shaft seal ,or pump housing for 9 ton splitter #060-3772-0