Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for NIFTYLIFT 120 Series

- Page 1 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS OPERATING AND SAFETY MANUAL MODEL 120H & 120M SERIES TRAILER MOUNTED (T.M) Manufactured by:- NIFTYLIFT LIMITED FINGLE DRIVE STONEBRIDGE MILTON KEYNES BUCKS. MK13 0ER ENGLAND. JULY 1995 TEL.: 01908 223456 120CE.DOC FAX : 01908 312733...

-

Page 2: Table Of Contents

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS TABLE OF CONTENTS 1. INTRODUCTION AND GENERAL INFORMATION Page 1.1 Foreword 1.2 Scope 1.3 Introducing the 120 Trailer Mount (T.M). series 1.4 General Specification 1.5 Identification 2. SAFETY 2.1 Mandatory Precautions 2.2 Environmental Limitations 2.3 Noise &... -

Page 3: Foreword

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS FOREWORD The purpose of these manuals is to provide the customer with proper safety operating and maintenance instructions essential for proper machine operation. All information in these manuals should be READ and fully UNDERSTOOD before any attempt is made to operate the machine. -

Page 4: Scope

SCOPE These operating instructions contain all the necessary information required to allow the safe operation of any Niftylift 120, powered by either electric DC, Diesel or Petrol engine or a combination of these. For further technical information, circuit diagrams and specific instructions for all Maintenance which may need to be carried out by specialist trained personnel, see the associated Workshop and Parts manual for your model of 120 trailer. -

Page 5: General Specification

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS SECTION 1.4 JULY 1995 GENERAL SPECIFICATION FEATURE N120 MAXIMUM HEIGHT - WORKING 40 FT 0 IN 12.3 M MAXIMUM HEIGHT- PLATFORM 36 FT 0 IN 10.3 M MAXIMUM HEIGHT - STOWED 6 FT 3 IN 1.9 M... -

Page 6: Identification

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS SECTION 1 IDENTIFICATION This manufacturers plate is attached to Boom 1 on each machine at the time of manufacture on every Niftylift. Please ensure all sections have been stamped and are legible. -

Page 7: Safety

2.1.2 Always operate the Niftylift in full accordance with the manufacturers operating & safety instructions for that model. 2.1.3 Before use each day and at the beginning of each shift the Niftylift shall be given a visual inspection and functional test including, but not limited to, operating and emergency controls,... - Page 8 2.1.9 Only operate the Niftylift on a firm, level surface. MANDATORY PRECAUTIONS (CONTINUED) 2.1.10 Never position any part of the Niftylift within 10ft (3m) of any electrical power line, conductor or similar above 450 volts. THIS MACHINE IS NOT INSULATED.

- Page 9 Niftylift, which becomes evident during operation. Any problems or malfunctions that affect the safety of operation shall be repaired prior to continued use. 2.1.24 The boom and platform of the Niftylift shall not be used to jack the wheels off the ground. 2.1.25 The Niftylift shall not be used as a crane.

- Page 10 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NEVER START THE NIFTYLIFT IF YOU SMELL GASOLINE, LIQUID PROPANE OR DIESEL FUEL. 2.1.34 The operator shall implement means provided to protect against use by unauthorised persons. 2.1.35 Never remove anything that may affect the stability of the machine such as, but not limited to,...

-

Page 11: Environmental Limitations

OPERATING AND SAFETY INSTRUCTIONS ENVIRONMENTAL LIMITATIONS All "Niftylift" Trailer Mounts are limited to operation as previously described., any slopes must be adjusted by use of the outriggers and jacks. Unless specifically configured otherwise, the machine will have short time rating for operation in extreme temperatures. I.e. Reduced battery cycle times for low temperatures, e.g. -

Page 12: Preparation And Inspection

Carry out the Pre-operational Report before placing machine in service. PREPARATION FOR USE Whilst every effort has been made at the Niftylift factory to ensure your machine arrives in a safe and operable condition it is necessary to carry out a systematic inspection prior to putting the aerial platform into service. -

Page 13: Daily Safety Check List

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS DAILY SAFETY CHECK LIST Before use each day and at the beginning of each shift the aerial platform shall be given a visual inspection and functional test including, but not limited to, the following: 1) Read and fully understand Operating and Safety Manual. -

Page 14: Placard, Decals And Installation

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 3.4 PLACARD, DECALS & INSTALLATION SWL BLANK. (P10799) 200 (KG) (P10803) 40 (KG) (P10804) OUTRIGGER BEAMS (P11547) TRAILER TOWING (P11546) CONTROL (P11498) BASE KEY OP (P10413) EMERGENCY HANDPUMP (P12402) PUSH & RELEASE (P10380) IMPORTANT PART ‘A’... -

Page 15: Placard, Decals And Installation

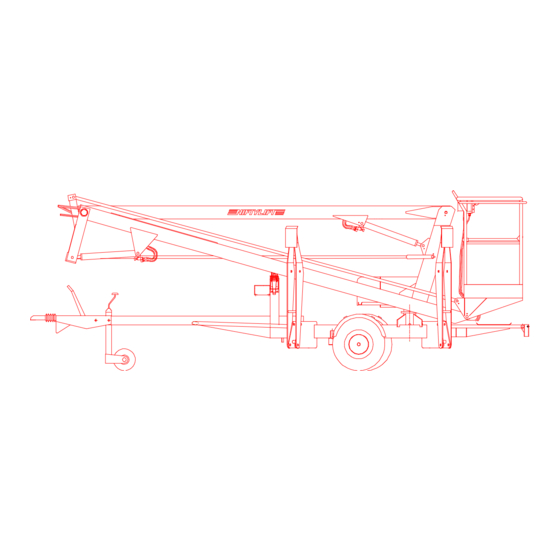

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 3.4 PLACARD, DECALS & INSTALLATION, CONT: BOOM CLAMP (P11549) COUPLING INSTRUCTIONS (P11550) HARNESS POINT (P11554) COMPONENT STABILITY (P11558) TYRE PRESSURE 40 P.S.I. (P11562) NO STEP (LARGE) (P11569) BATTERY DISCONNECT (P12230) TYRE PRESSURE 65 P.S.I. - Page 16 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS THREE VIEW DRAWING D80225...

-

Page 17: Torque Requirements

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 3.5 TORQUE REQUIREMENTS SCREW QUALITY / TIGHTENING TORQUE IN FT LBS (Nm) SIZE 10.9 (10) (14) 18.5 (25) (35) M 10 (49) (69) M 12 (86) (120) M 14 (135) (190) M 16... -

Page 18: Operation

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 4 OPERATION CONTROL CIRCUIT COMPONENTS 4.1.1 Control board:- Situated under the canopy, the control board comprises a p.c.b. (printed circuit board) design which incorporates all of the relays to control the machine operation. - Page 19 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS the carburettor bowl before changing to L.P.G., since the engine will not run satisfactorily if any petrol is in the carburettor bowl.

-

Page 20: Setting Up Procedure

Safety manual and the warning decals on the machine. 2) Position Niftylift on firm, level ground. Never work with base across or adjacent to any slope. Use the manual jacks to level the base of the machine, if necessary using suitable load bearing pads to support the downhill jacks. - Page 21 (dropped) and each jack foot is screwed hard down onto a firm, level surface. All Models 21) Always lower booms fully before adjusting, raising, retracting or moving the outriggers in any way. 22) Never alter, modify or block any of the safety circuits on the Niftylift.

-

Page 22: Ground Control Operation

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 4 OPERATION GROUND CONTROL OPERATION ALWAYS ALLOW THE ENGINE TO WARM UP BEFORE OPERATING. ALL MODELS 1) Ensure all red emergency stops are out. 2) Turn key switch at ground control station to ground (i.e. fully down). - Page 23 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 4.3 GROUND CONTROLS (CONTINUED) Boom Functions A) Push and hold green "Power Control" button. Select lever 1, 2, or 3 for desired function. 1 Operates Lower Boom UP for up: DOWN for down.

-

Page 24: Platform Control Operation

OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS PLATFORM CONTROL OPERATION NEVER START THE NIFTYLIFT IF YOU SMELL GASOLINE, LIQUID PROPANE OR DIESEL. THESE FUELS ARE FLAMMABLE. BEFORE OPERATING THE NIFTYLIFT ENSURE THAT EACH OPERATOR HAS READ AND FULLY UNDERSTOOD THE OPERATING MANUAL. - Page 25 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS PLATFORM CONTROLS 4.4.2 PLATFORM PUSHBUTTON CONTROLS STATION (BI-ENERGY MODEL SHOWN) Boom Functions Select lever 1, 2, or 3 for desired function. 1 Operates Lower Boom UP for up: DOWN for down.

- Page 26 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS PLATFORM CONTROLS 4.4.3 Starting the Engine from the Platform NEVER START THE NIFTYLIFT IF YOU CAN SMELL GASOLINE, LIQUID PROPANE OR DIESEL. THESE FUELS ARE HIGHLY FLAMMABLE. ****FOR COLD START PROCEDURES SEE SECTION 4.1.

-

Page 27: Boom Controls

3) Turn engine over until it fires. NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS BOOM CONTROLS DO NOT OPERATE THE NIFTYLIFT WHILST ELEVATED UNLESS ON A FIRM, LEVEL SURFACE FREE FROM ANY POSSIBLE OBSTRUCTIONS OR HAZARDS BOTH AT GROUND LEVEL AND OVERHEAD. -

Page 28: Batteries And Charging

NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS BATTERIES AND CHARGING BATTERIES SHALL BE RECHARGED IN A WELL VENTILATED AREA FREE OF FLAME, SPARKS OR OTHER HAZARDS WHICH MAY CAUSE EXPLOSION. HIGHLY EXPLOSIVE HYDROGEN GAS IS PRODUCED DURING THE CHARGING PROCESS. - Page 29 4.7.1 TRANSPORTING * The maximum weight of a Niftylift N120 is 2794 lbs (1270 kgs) * Always ensure the truck or trailer you are loading or towing the Niftylift with can carry it legally. * If loading by crane, the use of shackles and an adequately rated spreader beam, with four leg slings, is MANDATORY.

- Page 30 OPERATING AND SAFETY INSTRUCTIONS NIFTYLIFT T.M SERIES OPERATING AND SAFETY INSTRUCTIONS 4.7.2 TOWING THE MAXIMUM TOWING SPEED OF A NIFTYLIFT IS 45 MPH (72 KMPH) WITH A VEHICLE THAT COMPLIES WITH ALL ROAD TRAFFIC REGULATIONS. SPEEDING MAY RESULT IN DEATH OR SERIOUS INJURY.

- Page 31 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS 1) To operate the trailer parking brakes pull the handbrake lever upwards and backwards. The spring loaded mechanism will engage and stay in the operated position until re-set. 2) To dis-engage the parking brakes, firmly grasp the handbrake lever and pull upwards. Depress the ratchet release button in the end of the handbrake lever and return the lever to the horizontal position.

- Page 32 NIFTYLIFT T.M. SERIES OPERATING AND SAFETY INSTRUCTIONS...

-

Page 33: Emergency Controls

Fit 1/2 inch drive socket on to end of swing worm gear and crank round manually. 5.5 INCIDENT NOTIFICATION It is a mandatory requirement that any accident or incident involving a Niftylift, regardless of whether any party received injury or property was damaged, be reported by telephone directly to... -

Page 34: Responsibilities

6.1 CHANGES IN OWNERSHIP When a change of ownership of a Niftylift occurs, it shall be the responsibility of the seller to notify Niftylift direct of the unit, model and serial number and the name and address of the new owner within 60 days.

Need help?

Do you have a question about the 120 Series and is the answer not in the manual?

Questions and answers