Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Vivax cool ACP-09CH25GEK/I

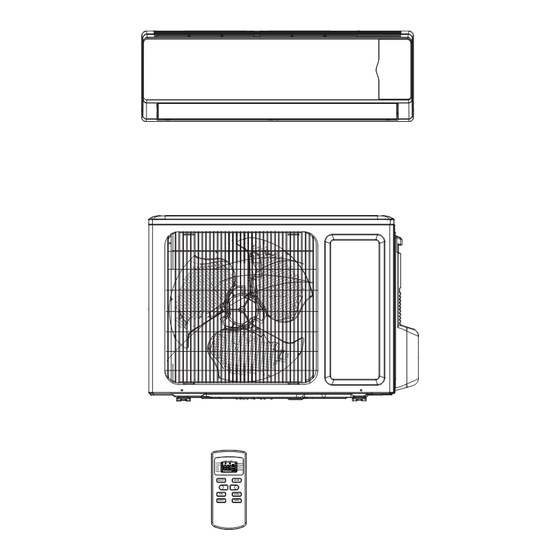

- Page 1 Service manual ACP-09CH25GEK RoHS...

- Page 4 ACP-09CH25GEK/I ACP-09CH25GEK/O T-ON T-OFF AUTO SWING COOL SLEEP LOCK SPEED HEAT ON/OFF MODE SWING SLEEP TIMER...

- Page 5 Installing, starting up, and servicing air conditioner can be Make sure the outdoor unit is installed on a stable, level hazardous due to system pressure, electrical components, surface with no accumulation of snow, leaves, or trash and equipment location, etc. beside.

- Page 6 ACP-09CH25GEK ACP-09CH25GEK/I...

- Page 7 ACP-09CH25GEK/O...

- Page 8 Condition Condition Indoor:DB20 Indoor:DB27 WB19 Indoor air flow: Super High Indoor air flow: Super High Pipe length:4m or 5m Pipe length:4m or 5m 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 Outdoor temp.( Outdoor temp.( )

- Page 10 Model: ACP-09CH25GEK/O...

-

Page 11: Indoor Unit

INDOOR UNIT OUTDOOR UNIT HEAT EXCHANGER (EVAPORATOR) COOLING HEATING... - Page 12 ACP-09CH25GEK/I...

- Page 13 ACP-09CH25GEK/O...

-

Page 14: Top View

TOP VIEW Part Name Neutral wire of Health function PG motor Neutral wire Live wire of Health function 4-way valve control terminal Outdoor fan Auto button Up&down swing control terminal Interface feedback from indoor fan Display control terminal 1 Display control terminal 2 Interface of pipe temperature sensor Interface of ambient... - Page 15 ON/OFF Press it to start or stop operation. MODE Press it to select operation mode(AUTO/COOL/DRY/FAN/HEAT). : Press it to decrease temperature setting. : Press it to increase temperature setting. Press it to set fan speed. SWING Press it set swing angle. SLEEP TIMER Press it set auto-on/auto-off timer.

-

Page 16: Replacement Of Batteries

SLEEP: Press this button to go into the SLEEP operation mode. Press it again to cancel. This function is available in COOL , HEAT (Only for models with heating function) or DRY mode to maintain the most comfortable temperature for you. TIMER: Press this button to initiate auto-on/auto-off timer. -

Page 17: Temperature Parameters

1 Temperature Parameters Indoor preset temperature (Tpreset) Indoor ambient temperature (Tamb.) 2 Basic functions ( The temperature in this manual is expressed by Centigrade. If Fahrenheit , is used, the switchover between them is Tf=TcX1.8+32.) Once the unit is energized, the compressor shall never be restarted except 3mins interval at least. For the first energization, if the unit is at off status before power failure, the compressor can be restarted without 3-min delay. -

Page 18: Heating Mode

(2)Dry Mode Dry Conditions and Process When Tamb. Tpreset+2 , the unit will run in dry an d cooling mode, in that case the compressor and outdoor fan will run and the indoor fan will run at low speed. When Tpreset-2 Tamb. -

Page 19: Fan Mode

Defrosting Conditions and Process The unit with intelligent defrosting function can defrost accor ding to frosting conditions. Dual8 displays H1. Protection Function High Temp Resistance Protection If it is detected that the evaporator tube temperature is superheating, the outdoor fan will stop working. When the tube temperat ure resumes to normal condition, the outdoor fan will resume running. - Page 20 (6)Dry Function This function can be set in cooling or dry mode. (7)Automatic Control of Fan Speed In this mode, the indoor fan will automatically select high, medium or low speed with the change of ambient temperature. (8)Up & Down Swing After energization, up &...

- Page 23 Space to the ceiling 15cm Above Space to the wall 15cm Above 15cm Above Space to the wall 300cm Above Above Air outlet side Space to the floor The dimensions of the space necessary for correct ● installation of the appliance including the minimum permissible distances to adjacent structures Space to the obstruction Air inlet side...

- Page 24 Wall Wall Mark on the middle of it Gradienter Space Space to the to the wall wall 150mm 150mm above above Right Left Ф 55mm Ф 55mm (Rear piping hole) (Rear piping hole) Outdoor Indoor Wall pipe Seal pad Φ outlet pipe of indoor unit outlet pipe of...

- Page 25 External connection Gas side pipe electric wire Liquid side piping Tailing 2 Gas side piping Tailing 1 insulation Liquid side Piping insulation Fig.3 Finally wrap it Water drainage pipe with tape Left Left rear Right Fig.4 Right rear Fixing hook Mounting plate Mounting...

-

Page 26: Items To Be Checked

Manifold Valve Multimeter Manometer -76cmHg Hi handle Lo Handle Charging hose Low pressure valve Vacuum pump Fig.6 Drain-water hole Bottom frame Drain connecte r Hose (available commercially , inner dia. 16mm ) Items to be checked Possible malfunction Has it been fixed firmly? The unit may drop, shake or emit noise. - Page 27 Fig. a Fig. b Air filter Healthy filter Fig. c...

- Page 28 ACP-09CH25GEK/I...

- Page 29 ACP-09CH25GEK/I...

- Page 31 ACP-09CH25GEK/O...

- Page 32 ACP-09CH25GEK/O...

- Page 34 Display Method of Indoor Unit Indicator lamp(During blinking,ON for No. Malfunction Name 0.5S and OFF for 0.5S) A/C Status Possible Causes Error Code Operation COOL HEAT Lamp Lamp. Lamp. The unit will stop operation 1.The wiring terminal between indoor as it reaches the temperature ambient temperature sensor and controller point.During cooling and drying is loosened or poorly contacted;...

- Page 35 Start Is the wiring terminal between temperature sensor and the controller loosened or poorly contacted? Insert the temperature sensor tightly Malfunction is eliminated. Is there short circuit due to trip over of the parts Make the parts upright Malfunction is eliminated.

- Page 36 Possible causes: 1. There is no jumper cap on the controller; 2. Jumper cap is not inserted properly and tightly; 3. Jumper cap is damaged; 4. Controller is damaged. See the chart below: C5 is displayed on the unit. Install a matching Is there jumper cap on the jumper cap .

- Page 37 Possible causes: 1. Fan motor is locked; 2. The.feedback.terminal of PG motor is not connected tightly; 3. The control terminal of PG motor is not connected tightly; 4. Motor is damaged; 5. Malfunction of the rotation speed detection circuit of the mainboard. See the chart below: “H6”is...

- Page 38 “ U 8 ” is displayed on the unit . Re - energize 1 minute after de - erergization The unit returns to normal Conclusion : U 8 is displayed due to Is “ U 8 ” still instant energization after de - displayed ? energization while the capacitor discharges slowly .

- Page 39 Appendix 1: Resistance Table for Indoor and Outdoor Ambient Temperature Sensors (15K) Temp. Temp. kΩ kΩ Temp. kΩ Temp. kΩ Resistance Resistance Resistance Resistance 138.1 18.75 3.848 1.071 128.6 17.93 3.711 1.039 121.6 17.14 3.579 1.009 16.39 3.454 0.98 108.7 15.68 3.333 0.952...

- Page 40 Appendix 2: Resistance Table for Indoor and Outdoor Tube Temperature Sensor (20K) kΩ Temp. kΩ Temp. kΩ Temp. kΩ Temp. Resistance Resistance Resistance Resistance 181.4 25.01 5.13 1.427 171.4 23.9 4.948 1.386 162.1 22.85 4.773 1.346 153.3 21.85 4.605 1.307 20.9 4.443 1.269...

- Page 41 Appendix 3: Resistance Table for Outdoor Discharge Temperature Sensor (50K) kΩ kΩ kΩ Temp. kΩ Temp. Temp. Resistance Temp. Resistance Resistance Resistance 853.5 18.34 4.754 799.8 93.42 17.65 4.609 89.07 16.99 4.469 703.8 84.95 16.36 4.334 660.8 81.05 15.75 4.204 620.8 77.35 15.17...

- Page 42 1.Remove the filter Open the front panel. panel Loosen the clasp of the filter. clasp Take out the filter. filter 2.Remove the horizontal louver Remove the axile bush on the horizontal louver. axile bush...

- Page 43 Pull the horizontal louver outward to remove it. horizontal louver 3. Remove the panel Push the rotor shaft on both sides of the panel to make it separate from the groove. rotor shaft Remove the panel. panel 4.Remove the electric box cover Loosen the screws of the electric box cover.

- Page 44 electric box cover 2 Remove the electric box cover. 5.Remove the front case Open the screw cap on the front case. Remove the screws fixing the front case. screw clasps Loosen the clasps of the front case. left middle right front case Remove the front case.

- Page 45 6.Remove the vertical louver Loosen the clasp connecting the vertical louver and bottom case subassembly. clasp Remove the vertical louver. vertical louver 7.Remove the electric box heat exchanger thermistor Disconnect the indoor tube temperature sensor. screw Remove the screws of the electric box. screws ground wire Remove the screws at the joint of the...

- Page 46 Loosen the clasp at the joint of the electric box cover and the electric box. clasp fan motor signal wire Disconnect the plug of the motor. Disconnect the plug of step motor. plug of step motor Remove the 2 screws of the display. screws electric box Remove the electric box.

- Page 47 8.Remove pipe clamp of connecting pipe pipe clamp auxiliary piping screws Remove the screws of the pipe clamp of connecting pipe. pipe clamp Remove pipe clamp of connecting pipe. 9.Remove the evaporator Remove the screws at the joint of the evaporator and bottom case.

- Page 48 heat Remove the evaporator. exchanger 10.Remove motor and cross flow fan step motor Remove the screw of the step motor and remove the step motor. motor clamp Remove the screw of the motor clamp. Remove the press plate.

- Page 49 cross flow blade motor Remove the cross flow blade and motor. O-gasket sub-assy of bearing ring of bearing Remove the rubber cushion of the bearing. cross flow blade Remove the screws at the joint of the motor cross flow blade and the motor. Take down the motor.

- Page 50 ACP-09CH25GEK/O 1. Before disassembly 2. Remove big handle Remove the connection screw fixing the big handle big handle and then remove the handle. 3. Remove top panel top panel Remove connection screws connecting the top panel with the front panel and the right side plate, and then remove the top panel.

- Page 51 4. Remove front grille Remove connection screws between the front grille and the front panel. Then remove the front grille. front grille 5. Remove front panel Remove connection screws connecting the front panel with the chassis and the motor support, and then remove the front panel.

- Page 52 8. Remove motor and motor support motor support Remove the 4 tapping screws fixing the motor and disconnect the leading wire insert of the motor. Then remove the motor. Remove the 2 tapping screws fixing the motor support and lift the motor support to remove it. motor 9.

- Page 53 12. Remove magnet coil magnet coil Remove the screw fixing the magnet coil and then remove the coil. 13. Remove valves and 4-way valve subassembly 4- wa y valv e Unsolder welding joint connecting the capillary, the valve and the outlet pipe of condenser to remove the capillary.

Need help?

Do you have a question about the ACP-09CH25GEK/I and is the answer not in the manual?

Questions and answers