Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Paxar 610

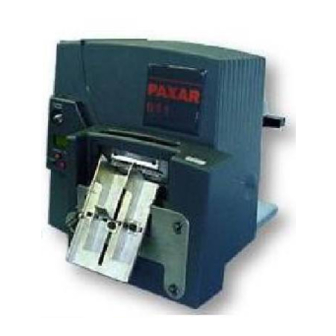

- Page 1 Users Manual 610 / 611 / 612 Printers PAXAR Systems Group Manual Edition 2.1 16 March 2001 Manual Part Number 441397...

- Page 2 This page left blank intentionally.

-

Page 3: Table Of Contents

Status Code Box ... 5 Setting Dip Switches ... 6 DIP Switches... 7 Loading Supplies Loading Labels – 610 / 611 ... 10 Loading Labels – 612 ... 15 Loading Ribbon ... 20 Adjusting the Wide/Narrow Knobs ... 24 Printing Printing... - Page 4 Data Errors... 47 Communication Failures... 52 Data Formatting Errors... 53 Machine Faults... 54 Appendix A - Specifications & Accessories Printer Specifications ... 56 Supply Specifications... 57 Ribbon Specifications ... 58 Accessories... 59 Contacting Paxar Contents Users Manual - 610/611/612 Printers...

-

Page 5: Getting Started

Getting Started The Paxar 610 / 611 / 612 Care Label printers let you print text, graphics, and bar codes on thermal transfer (ribbon) fabric labels. This chapter includes information about Unpacking the printer. Connecting the power cord. Connecting the communications cable. -

Page 6: Audience

The Operator's Handbook is for the person who prints and applies labels. Unpacking the Printer After you unpack the printer, you should have: a 610 / 611 / 612 printer, power cord, communication cable and a ribbon take-up core (may already be on take-up reel). -

Page 7: Establishing Communications

Make sure the printer is off before connecting the cable to the communication port. Your printer is supplied with a parallel printer cable. You may optionally connect your printer to a serial port. To do this, you must purchase a serial interface cable compatible with your computer. -

Page 8: Default Printer Settings

Default Printer Settings These defaults can be changed using Paxar's PCMate software. Print Speed - 4.0 ips (inches per second), Ribbon - High Energy, Supply Type - Black Mark, Contrast - 255, Backfeed - Enabled, Dispense Position - 120 dots, Backfeed Distance - 110 dots. -

Page 9: Button Functions

Feed and Pause: Feed and Clear: Clear: To cancel a single or all queued print jobs, the printer must be in paused mode before Clear is pressed. Status Code Box The status code box displays a three-digit error code to identify any problem the printer may have. -

Page 10: Setting Dip Switches

To change the DIP switch settings, move the switches to the desired position and then turn on the printer. If you select Software Controlled, the parameters in Packet F will override the communication settings. Software Controlled uses the last sent Packet F settings or the defaults. -

Page 11: Dip Switches

Values in bold indicate the default setting (9600 Baud; 8 Data Bits; 1 Stop Bit; No Parity; and Centronics Mode). Communication settings at the printer must match those at the host. Make sure your host is capable of communicating at the speed you select for the printer. - Page 12 Disable On-Demand Enable On-Demand Values in bold indicate the default setting (RTS/CTS Flow Control; Normal Mode; No Verifier; Continuous Supply; Transfer; and Continuous Mode). Shaded DIP switches are not enabled (verifier and feed mode). Getting Started Users Manual - 610/611/612 Printers...

-

Page 13: Loading Supplies

This chapter describes how to load a roll of supply and a ribbon roll. You can use Paxar's fabric label kits containing fabric labels and ribbon. If you switch from black mark to continuous supplies make sure the DIP switches are set correctly. -

Page 14: Loading Labels - 610 / 611

Loading Labels – 610 / 611 For instructions for loading labels for the 612, see page 15. Make sure the printer is configured for the correct supply type. To load a roll of labels: 1. Open the cover. 2. Unlock the printhead by turning the retaining latch. - Page 15 3. Lift printhead assembly using the printhead tab until the assembly locks into place. Make sure you use only approved Paxar supplies. See Appendix A, "Specifications and Accessories" for a list of Paxar supplies or contact your Paxar Representative for 4.

- Page 16 Make sure the supply is straight in the supply path and 8. Tuck the supply under the nibs. Nibs Supply Lever Make sure a few inches of supply are past the front end of the printer. Loading Supplies CAUTION aligned with the printhead.

- Page 17 10. Hold the printhead assembly by the printhead tab while pressing down on the printhead release. 11. Close the printhead by pressing down on the thumb well until you hear it click into place. Users Manual - 610/611/612 Printers Loading Supplies...

- Page 18 You may need to adjust the wide/narrow knobs depending on the width of your supply. See Chapter 4, "Care and Maintenance" for more information. If the printer will be unused for extended periods of time, leave the printhead unlatched. Loading Supplies...

-

Page 19: Loading Labels - 612

Loading Labels – 612 Make sure the printer is configured for the correct supply type. To load a roll of labels: 1. Open the cover. 2. Unlock the printhead by turning the retaining latch. Users Manual - 610/611/612 Printers Loading Supplies... - Page 20 3. Lift printhead assembly using the printhead tab until the assembly locks into place. Make sure you use only approved Paxar supplies. See Appendix A, "Specifications and Accessories" for a list of Paxar supplies or contact your Paxar Representative for 4.

- Page 21 IMPORTANT 6. Before threading the printer, you must set the label length adjustment. Turn the Label Length Adjustment Knob (A) so that the pointer on the turn bar is lined up with the black bar on the Label Length Gauge that corresponds to the length of the label to be printed.

- Page 22 8. Reach under the platen roller and pull the label strip back towards the turn bar (F). Thread the label strip under the guide roller (E) and around the turn bar (F) as shown below. Loading Supplies Users Manual - 610/611/612 Printers...

- Page 23 Continue until the label strip is snug around the turn bar. Lock the printhead down. Note: If the printer is not used for an extended period, the label stock may take a “set” where it goes around the turnbar. After a period of not printing, it is recommended that you feed the material through the printer until the “set”...

-

Page 24: Loading Ribbon

2. Unlock the printhead by turning the retaining latch. 3. Lift printhead assembly using the printhead tab until the assembly locks into place. Make sure you use only approved Paxar supplies. See Appendix A, "Specifications and Accessories" for a list of... - Page 25 Since some supplies are more abrasive to printheads than others, using a ribbon wider than your supply helps protect the printhead. Failure to do this may void your printhead Users Manual - 610/611/612 Printers CAUTION warranty. Loading Supplies...

- Page 26 8. Carefully feed the ribbon under both ribbon rollers and printhead as shown. 9. Tape the ribbon to the take-up core. Do not tape the ribbon to the take-up reel. Loading Supplies Take-up Reel Back Reel Users Manual - 610/611/612 Printers...

- Page 27 11. Rotate the take-up core until the leader is past the printhead. 12. Remove any slack in the ribbon by turning the take-up reel clockwise. 13. Hold the printhead assembly by the printhead tab while pressing down on the printhead release. Users Manual - 610/611/612 Printers Loading Supplies...

-

Page 28: Adjusting The Wide/Narrow Knobs

If you experience ribbon smudging in cold, dry environments, adjust the wide/narrow knobs to the wide setting. For wide supplies, push down and turn the wide/narrow knobs clockwise with a screwdriver. Loading Supplies You must adjust both of the knobs to the same position. Users Manual - 610/611/612 Printers... - Page 29 For narrow supplies, turn the wide/narrow knobs counter-clockwise with a screwdriver until it pops back up. The adjustment is shown in the wide position. Users Manual - 610/611/612 Printers Loading Supplies...

-

Page 30: Printing

Adjust the print positions. Print care symbols and special characters, such as the Euro-Dollar symbol. Printing The host sends online packets containing print jobs to the printer. To print: 1. Turn on the printer. 2. Download a format and a batch. See your System Administrator for more information about downloading packets. -

Page 31: Printer Alignment - Top And Bottom Copy - 612

Printer Alignment - Top and Bottom Copy – 612 The 612 printer must be adjusted so that the copy on the top and bottom of the label lines up correctly. On the base of the unit near the supply roll is an adjustment guide (see the picture on page 17). -

Page 32: Non-Printing Zone

Open (unlock) the printhead before a break period, at the end of each shift, and at the end of each day. Printing 0.375 inch non-print zone Feed close to the edge of your supply. Users Manual - 610/611/612 Printers... -

Page 33: Printing Serial Bar Codes

Printing Serial Bar Codes Currently, the 610 / 611 / 612 printer does not support printing serial (ladder) bar codes. Parallel (Picket Fence) Bar Code Adjusting Print Positions You can adjust the supply, print, and margin positions by using the control panel buttons. -

Page 34: Adjusting The Cut Angle

The range is -99 to 99 dots. Adjusts where data prints horizontally on the supply. Increase the margin position to move print to the right, decrease to move print to the left. The range is -99 to 99 dots. Users Manual - 610/611/612 Printers... -

Page 35: Using The Knife

Depending on the length of your supply, you may lose up to two tags after the last batch. The knife operates when the printer is running. If the Printer is paused, the knife stops cutting. Adjusting the Drop Tray Depending on the model purchased, your printer may have a drop tray stacker. -

Page 36: Care Symbol Font Samples

The following table shows the characters available with Ginetex Font 70 and Font 71. Font 70 can fit five (5) symbols in 22mm (0.88 inches). Nafta Font The following table shows the characters available with Nafta Font 72 and Font 73. Printing Users Manual - 610/611/612 Printers... -

Page 37: Care And Maintenance

Clean the printhead and platen roller Replace a printhead Adjust print contrast Replace a fuse Lubricate the knife Users Manual - 610/611/612 Printers CAUTION Do not use sharp objects to clean the printhead. This may damage the printer and void your warranty. Care and Maintenance... -

Page 38: Clearing Supply Jams

6. Press Feed to position the supply under the printhead. Clearing a Knife Jam If tags are jammed in the knife, the printer displays 760 on the LED. To clear a knife jam, you might have to disconnect the stacker from the knife. -

Page 39: Cleaning

You may have to clean the supply sensor more often if you frequently receive supply error codes. Paxar recommends that you clean the printhead and platen roller at least once a day when the printer is in use. You may need to clean more frequently depending on usage. - Page 40 6. Rub the cotton swab across the supply sensor and remove any build-up. 7. Clean the build-up in the supply path. 8. Let the printer dry and reload your supplies. Care and Maintenance Users Manual - 610/611/612 Printers...

-

Page 41: Replacing The Printhead

The printhead is sensitive to static electricity, which can damage the printhead or reduce its life. Ground yourself by touching some metal, such as the printer's metal base, before touching the printhead. Clean the printhead to remove any salt or oil left from handling prior to operation. - Page 42 4. Press forward and down on the two latches on top of the printhead assembly as shown. The printhead will drop down. 5. Lift the printhead assembly using the printhead tab and push back until the printhead assembly clicks into place. Care and Maintenance Users Manual - 610/611/612 Printers...

- Page 43 However, it is normal to feel some resistance when correctly connecting the cable. 8. Align the new printhead with the tabs. Users Manual - 610/611/612 Printers CAUTION before touching the printhead. Care and Maintenance...

- Page 44 11. Let the printhead dry and reload your supplies. 12. Close the printhead assembly and the cover. 13. Turn on the printer. 14. Press Feed to position the supply under the printhead. Care and Maintenance Users Manual - 610/611/612 Printers...

-

Page 45: Adjusting The Print Contrast

Using a thin screwdriver, turn contrast knob clockwise for darker print; turn counter- clockwise for lighter print. Users Manual - 610/611/612 Printers __________ You only have to turn the contrast adjuster slightly. -

Page 46: Replacing The Fuse

To replace the fuse: 1. Disconnect the printer from the power source. 2. Use a screwdriver to pry open the fuse box in the back of the printer as shown. 3. Remove the old fuse and insert a new one. -

Page 47: Lubricating The Knife

5. Repeat steps 2 – 4 for the other cam. 6. Wipe off any excess grease from the top cover of the knife. 7. Turn on the printer. Users Manual - 610/611/612 Printers Care and Maintenance... -

Page 48: Troubleshooting

Troubleshooting This chapter provides; Information about printing a test label. Solutions to minor printing problems. Explanations of error messages you may receive while using the printer. Troubleshooting Users Manual - 610/611/612 Printers... -

Page 49: Printing A Test Label

Press Feed and Pause simultaneously. Hold for one second and release. Labels similar to these print: The first label shows the printer’s configuration by packer (A – G). The second label shows the model number, software version, stock count, voltage, print contrast, printhead resistance, number of bad dots, installed options, and DIP switch settings. -

Page 50: Troubleshooting

Blank labels print or 750 series errors. If you cannot fix a problem, call Technical Support. Troubleshooting Action Turn off the printer, wait fifteen seconds and then turn on the printer. Call Technical Support if the error message reappears. Check supply. Check ribbon. -

Page 51: Error Messages

Some errors numbered 400 – 438 and 500 – 574 are internal software errors. Errors numbered 900 – 999 are hard printer failures. If you cannot clear an error, turn off the printer, wait several seconds and then turn on the printer. Call Technical Support if you receive any error message not listed in this chapter. - Page 52 Option number must be 1, 4, 30, 31, 42, 50, 60, or 61. Copy length is outside the range 0 to 2710. Copy start position must be 1 to 2710. Destination start position must be 1 to 2710. Troubleshooting Users Manual - 610/611/612 Printers...

- Page 53 Data type restriction is outside the range of 1 to 6. Option is not valid for the field. Bar code Intercharacter gap must be 0 to 99 in printer dots. Power up mode must in 0 (online) or 1 (offline).

- Page 54 Amount of row adjustment must be 0 to 999. Duplicate count must be 0 to 999. Bitmap line encoding must be H (hex) or R (run length). Font selector must be 1 to 9999. Font data length must be 68 to 16384. Troubleshooting Users Manual - 610/611/612 Printers...

- Page 55 The number of string that is currently being processed is too long. Too many fields exist in the format. You cannot have more than 1000 fields in the format. Lines, boxes, and constant text fields count as fields. Users Manual - 610/611/612 Printers Troubleshooting...

-

Page 56: Communication Failures

Ask your System Administrator for help. Error Description/Action Printer memory is full. Delete unnecessary formats or graphics from memory. Try run length encoding for large graphics. Parity mismatch. Framing error (baud rate mismatch). This error may appear when you turn off the printer. -

Page 57: Data Formatting Errors

Errors 571 to 618 are data formatting errors. This type of error happens when a field prints incorrectly. Your System Administrator can correct the format, batch, or graphic packet and send the print job again. For errors 571 to 614, the printer will still print, but the data may be incomplete, missing, or wrong. -

Page 58: Machine Faults

Waiting to dispense label. Press Feed. Verifier failure. Call Technical Support. The printhead has less than four bad spots. The printer can shift bar code fields to avoid bad dots. Press Clear to continue printing. Print a test label to confirm the number of bad dots. - Page 59 Resend the packets. If the problem continues, call Technical Support. The printer is not initialized. Call Technical Support. The printer job queue is full. Turn off the printer. Wait 15 seconds and turn it back on. Resend the packets. If the problem continues, call Technical Support.

-

Page 60: Appendix A - Specifications & Accessories

115 Vac, 60Hz, 100 Vac, 50/60 Hz, 230 Vac, 50Hz For Thermal Transfer (ribbon) 40 to 95 F (4 to 35 C) Thermal at 4 inches (102 mm) wide 300 dpi (11.8 dots per mm) Thermal Transfer (ribbon) 4.0 inches (102 mm) per second Users Manual - 610/611/612 Printers... -

Page 61: Supply Specifications

Fabric Label Kits: Paxar Systems: Paxar Europe: Sizes: Contact your Paxar Representative for more Information about kits and approved supplies. Additional configurations may be available. If you experience label jamming with narrow Supplies separately from the printer in a dry,... -

Page 62: Ribbon Specifications

4.1 inches (105 mm) Inches (6.35 mm) wider than your fabric. Ribbon Length: 23,600 inches (600 meters) Contact your Paxar Representative for more Information about approved ink products. Additional configurations may be available. Appendix A - Specifications & Accessories ________ For best results, use a ribbon that is 0.25... -

Page 63: Accessories

When ordering spare parts in the U.S.A. 1-800-96PAXAR or (570) 888-6641 Fax: (570) 888-7416 For Machine Service or Technical Support in the U.S.A. (570) 888-9116 Fax: (570) 888-7416 For International assistance, call your Paxar Representative www.paxar.com Users Manual - 610/611/612 Printers Contacting Paxar...

Need help?

Do you have a question about the 610 and is the answer not in the manual?

Questions and answers