Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Alliance Laundry Systems UD13F063

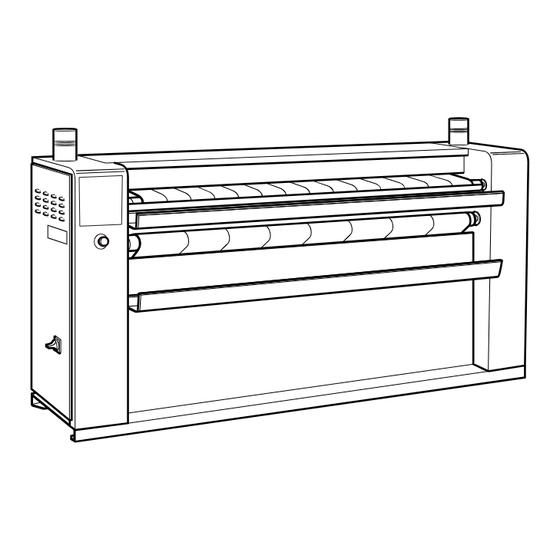

- Page 1 Roll Heated Flatwork Finisher 13 inch (325 mm) Roll Models Refer to Page 4 for Model Identification FWF12C FWF12C Keep These Instructions for Future Reference. (If this machine changes ownership, this manual must accompany machine.) Part No. 1300003ENR8 www.comlaundry.com July 2012...

- Page 3 FOR YOUR SAFETY Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. W053 1300003 (EN) © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT...

-

Page 4: Table Of Contents

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed written consent of the publisher. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 5 Troubleshooting Undesirable Finishes ..........42 Troubleshooting Hot Surface Ignition Module (120 Volt Gas Models Only) .............. 43 Status LED Used to Troubleshoot ........... 43 Ignition System Checks ..............44 1300003 (EN) © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT...

-

Page 6: Introduction

UD13F063 parts distributor. UD13F078 Customer Service UD13F079 For technical assistance, contact your distributor or UD13F126 call the following number: (920) 748-3121 Ripon, Wisconsin © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 7: Safety Information

Refer to the Maintenance section of this manual for the periodic maintenance schedule. Refer to the parts manual for ordering information. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 8 HAUTE TENSION A L’INTERIEUR COUPER L’ALIMENTATION ELECTRIQUE AVANT DE RETIRER CE PANNEAU. SEULEMENT UN TECHNICIEN QUALIFIE PEUT REMMETTRE SOUS TENSION APRES AVOIR REMONTE CE PANNEAU. W812 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

- Page 9 Please read the maintenance book for complete information. Leer el libro de mantenimiento. Bitte die technische Beschreibung lesen. W813 ARRET D’URGENCE – STOP – EMERGENCY FWF138N © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 10: Safety Notice

Be sure that all other safety features, including guards and panels, are in place before operating the finisher. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 11 16. To reduce the risk of fire, DO NOT IRON plastics or articles containing foam rubber or similarly textured rubber-like materials. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 12: Installation

Due to varied requirements, applicable local codes should be thoroughly understood and all pre-installation arranged accordingly. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 13: Overall Dimensions And Connecting Data

(58 mm) 26 in. (660 mm) (542 mm) Model UD13F126 34 in. (860 mm) 2.36 in. (60 mm) 3.94 in. (100 mm) FWF135N FWF135N Figure 2 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 14: Required Materials

32 inch (813 mm) wide door. center of the skid. Refer to Figure 3. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 15: Moving The Finisher With Rollers

6. Place the third roller on the ground ahead of the first two rollers and past the end of the finisher. 8 in. 8" (203 mm) FWF14N FWF14N Figure 4 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 16 9. Level the finisher from right to left and front to back. Verify right to left level by checking the level of the heated roll, not the cabinet. FWF12N FWF12N Figure 6 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 17: Electrical Requirements

In case of servicing (or putting the flatwork finisher out of order), disconnect the flatwork finisher from the main supply by switching off the branch circuit breaker. W816R1 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 18: Electrical Connection

3 x 14 AWG (3 x 2.5 mm 120/60/1 3 x 14 AWG (3 x 2.5 mm 230/50/3 5 x 14 AWG (5 x 2.5 mm 400/50/3 Table 2 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 19: Gas Connection

2 (50.80) 2 (50.80) 2 (50.80) 2.5 (63.50) 2.5 (63.50) 2.5 (63.50) 1,000,000 2 (50.80) 2 (50.80) 2 (50.80) 2.5 (63.50) 2.5 (63.50) 2.5 (63.50) Table 3 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 20: Gas Technical Specifications For Ce Models

(For checking inlet gas pressure) Equipment Shut-Off Valve – Installed within 6 ft. (1.8 m) of finisher Black Iron Pipe 1 inch Gas Connection Figure 8 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 21: Gas Conversion

1. Refer to Table 5, Table 6 and Figure 10 to determine the adjustment and flow rate. 2. Adjust the air shutter according to the requirements for the new type of gas. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 22: Adjustments And Flow Rates For Non-Ce Models

(2.3) (2.7) (1.7) (2.3) (2.7) cu. ft./hr. (m /hr.) 78642 102455 120000 78642 102455 120000 Input Btu/hr. (kW) (22.5) (30) (35) (22.5) (30) (35) Table 6 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 23: Exhaust Requirements

IMPORTANT: Outlet ducts used for the finisher’s up air. exhaust may under no circumstances be shared with other devices. The maximum static back pressure is 1.6 W.C.I. (4 mbar). © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 24: Individual Venting

2 in. (51 mm) MINIMUM CLEARANCE 2 in. (51 mm) MINIMUM CLEARANCE 31.62 in. (803 mm) WALL NO SCREEN OR CAP AIR OUT FWF83N Figure 11 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 25: First Start-Up

FWF112N Figure 14 and Figure 15. Figure 15 c. Turn roll with crank handle. Refer to Figure 16. FWF110N FWF110N Figure 13 FWF113N FWF113N Figure 16 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 26 7. Turn the circuit breaker to position 1 (ON). 8. On electromechanical models, press the green Power On button and hold for 1 to 2 seconds. On microprocessor models, press START keypad. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 27: Operation

Decrease Preset Temperature Keypad Right Exhaust Outlet Display Preset Temperature Keypad Input Tray Temperature Display Output Tray Speed Display Right Side of Finisher Increase Ironing Speed Keypad Figure 19 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 28: Pre-Operating Procedures

If finisher does not stop, press STOP keypad, discontinue use and call a qualified service person. 5. Press START keypad. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 29 STOP keypad. Finisher will stop automatically when the temperature of the cylinder is less or equal to the programmed stop temperature (default is 176 F [80 C]). © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 30: Operating Instructions For Electromechanical Models Through September 2003

Return Ribbons Heat Indicator Light Right Exhaust Outlet Power Off Button Input Tray Power On Button Output Tray Heat Switch Right Side of Finisher Figure 20 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 31: Pre-Operating Procedures

16. Press the red Power Off button to shut down the Mark 2: from 266°F (130°C) to 320°F (160°C) finisher. Mark 3: from 320°F (160°C) to 356°F (180°C) © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 32: Regulating The Cylinder Heat

When heating is activated, the decimal point on the temperature display lights up. When only one resistor group is activated, the decimal point will blink. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 33: Breakdown Procedures

When there is an internal problem with the control, the service person immediately. alarm sounds for one minute and display shows AL3. Alarm is cancelled by restarting finisher or turning finisher on and off. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 34: Thermal Warning Fan

(refer to Gas Connection section). • Ignition electrode is faulty. Replace ignition electrode. To cancel alarm without re-igniting burner, press Stop keypad to stop finisher. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 35: Maintenance

FWF4N position 0 (OFF). Screws Pick-Up Table Feeding Ribbons Figure 22 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 36: Return Ribbon Tension Adjustment

8. Replace both side panels on the finisher. IMPORTANT: Do not over-tighten the return ribbons as this will cause rapid deterioration. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 37: Press-Roller Pressure Adjustment

8. Replace both side panels on the finisher. PRESS-ROLLER TENSION SYSTEM FWF6N FWF6N Drive-Roller Sprocket Tension Pin Tension Spring Tension Bracket with Holes Drive Chain Figure 24 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 38: Thermostat Inspection

7. Replace the top panel on the finisher. FWF8N Thermostat Holder FWF9N Scrapers FWF9N Thermostat Ironing Cylinder Press-Roller Figure 25 Guide Ribbons Paraffin Wax Return Ribbons Figure 26 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 39: Removing Rust From Ironing Cylinder

Refer to Figure 23 and follow the procedures to adjust the tension on the return ribbons. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 40: Replacement Of Feeding Ribbons

Refer to Figure 28. FWF25N Screw Top Panel Feeding Ribbon Figure 30 FWF23N Top Panel Roller Pin Feeding Roller Adhesive Strip Figure 28 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 41 1/5 inch (5 mm). 7. Remove bearing by pressing left. Refer to Figure 32. FWF27N Feeding Ribbon Roller Bearing Figure 32 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

-

Page 42: Replacement Of Return Ribbons

NOTE: Do not release bottom portion of return ribbon. FWF28N Tension Screw Bracket Figure 33 FWF30N Guide Ribbons Flap of Return Ribbon Return Ribbon Guide Figure 35 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 43: Replacement Of Supporting Rollers

14. Hook the tension spring back onto the tension pin. 15. If necessary to increase or decrease the tension of the return ribbons, refer to Adjustment of Return Ribbons section. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 44: Troubleshooting Undesirable Finishes

Synthetic Fibers 10-15% Artifical silks, acetate and 10-15% acetate fiber Rayon 10-15% Silk 10-15% Wool (iron between moist cloth) 10-15% Polyester 10-15% Poly-Cotton Blend 20-25% Cotton 40-45% © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 45: Troubleshooting Hot Surface Ignition Module (120 Volt Gas Models Only)

Start a new call for heat and if the three- interrupted (thermostat satisfied or system power flash signal returns, replace the ignition module. switched off), the LED goes off and the status information is lost. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) -

Page 46: Ignition System Checks

5A. position, restore to the correct position. • Replace the igniter and sensor or igniter- sensor with an identical unit if the insulator is cracked. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN) - Page 47 Remove valve lead at ignition module. If valve closes, recheck temperature controller and wiring; if not, replace gas control. Troubleshooting ends. REPEAT PROCEDURE UNTIL TROUBLE-FREE OPERATION IS OBTAINED. FWF64N Figure 37 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1300003 (EN)

Need help?

Do you have a question about the UD13F063 and is the answer not in the manual?

Questions and answers