Decagon Devices AquaLab 4TE Operator's Manual

Water activity meter

Hide thumbs

Also See for AquaLab 4TE:

- Operator's manual (130 pages) ,

- Installation qualification/operational qualification protocols and instructions (15 pages)

Summary of Contents for Decagon Devices AquaLab 4TE

- Page 1 AquaLab Water Activity Meter Operator’s Manual For Series 4TE, 4TEV, DUO Version 4 Decagon Devices, Inc.

- Page 2 Decagon Devices, Inc 2365 NE Hopkins Court Pullman WA 99163 (509)332-2756 fax: (509)332-5158 www.aqualab.com support@decagon.com sales@decagon.com Trademarks AquaLab is a registered trademark of Decagon Devices, Inc. ©2008-2009 Decagon Devices, Inc.

-

Page 3: Table Of Contents

Contents 1. Introduction .........1 About this Manual ........1 Customer Support ........1 Warranty ...........2 Seller’s Liability ..........2 2. About AquaLab ......4 AquaLab Model and Options ....4 AquaLab 4 Instrument Specifications ..4 AquaLab 4 DUO Specifications ....5 How AquaLab Works ........6 AquaLab and Temperature ......6 Chilled Mirror Dewpoint Limitations ..8 3. - Page 4 Configuration Tab ........19 Admin Settings ........25 Data Tab ..........30 6. Cleaning and Maintenance ..32 Cleaning the Block and Sensors ....33 Cleaning Procedure: .......34 Verification of Calibration .......36 7. Verification and Calibration ..37 Water Activity Verification .......37 Verification of Calibration .......38 8.

- Page 5 12. Troubleshooting ....... 62 Diagnostic Screen ........72 13. Support and Repair ....73 Repair Costs ..........74 Loaner Service ......... 74 14. Further Reading ....... 75 Water Activity Theory & Measurement ...75 Food Quality and Safety ......78 Water Activity and Microbiology .....80 Water Activity in Foods ......83 Appendix A ........

-

Page 7: Introduction

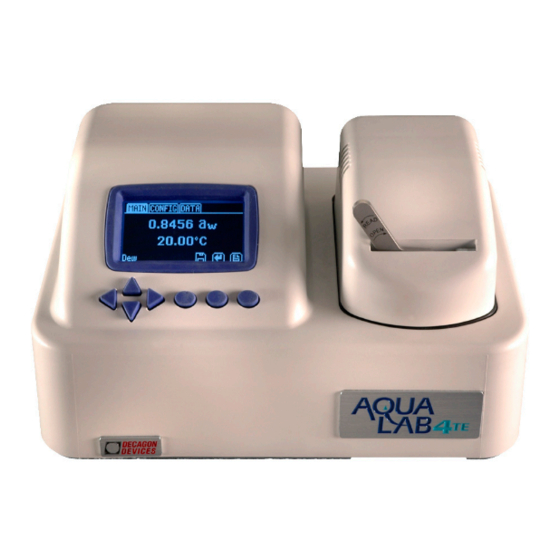

AquaLab 1. Introduction 1. I ntroductIon Welcome to Decagon’s AquaLab Series 4TE, 4TEV, and DUO, the industry standard for measuring water activity (a ). AquaLab is the quickest, most accurate, and most reliable instrument available for measuring water activity. Whether you are researching or working on the production line, AquaLab will suit your needs. -

Page 8: Warranty

AquaLab 1. Introduction Phone 1-800-755-2751 (USA and Canada Only) 1-509-332-2756 International Our Customer Support and Sales Representatives are available Monday thru Friday. 1-509-332-5158 Warranty AquaLab has a 30-day satisfaction guarantee and a three-year war- ranty on parts and labor. Your warranty is automatically validated upon receipt of the instrument. - Page 9 AquaLab 1. Introduction age or injuries to persons (including death), or to property or things of whatsoever kind (including, but not without limitation, loss of anticipated profits), occasioned by or arising out of the installation, operation, use, misuse, nonuse, repair, or replacement of said ma- terial and equipment, or out of the use of any method or process for which the same may be employed.

-

Page 10: About Aqualab

AquaLab 2. About AquaLab 2. About AquaLab AquaLab is the fastest and most accurate instrument for measuring water activity, giving readings in five minutes or less. Its readings are reliable, providing ±0.003 a accuracy. The instrument is easy to clean and checking calibration is simple. AquaLab Model and Options Series 4TE: User-selectable internal temperature control model, uses thermoelectric (Peltier) components to maintain internal tem-... -

Page 11: Aqualab 4 Duo Specifications

AquaLab 2. About AquaLab Sample Temperature Resolution: 0.01° C Sample Dish Capacity: 15ml Full Operating Environment: 5 to 50° C 20 to 80% Humidity Case Dimensions: 26.7 x 17.8 x 12.7cm Weight: 3.1 Kg Case Material: Lustran 433 (ABS) with fire retardant Display: 64 x 128 Graphical Data Communications: RS232A Serial, 9600 to 115200 baud Power: 110 to 220 VAC, 50/60Hz... -

Page 12: How Aqualab Works

AquaLab 2. About AquaLab How AquaLab Works AquaLab uses the chilled-mirror dewpoint technique to measure the water activity of a sample. In an instrument that uses the dewpoint technique, the sample is equilibrated with the head-space of a sealed chamber that contains a mirror and a means of detecting condensa- tion on the mirror. - Page 13 AquaLab 2. About AquaLab There are several advantages in having a temperature-controlled wa- ter activity meter. A few major reasons are: 1. Research purposes. Temperature control can be used to study the effects of temperature on the water activity of a sample, make a comparison of the water activity of different samples independent of temperature, and conduct accelerated shelf-life studies or other water activity studies where temperature control is critical.

-

Page 14: Chilled Mirror Dewpoint Limitations

AquaLab 2. About AquaLab Chilled Mirror Dewpoint Limitations AquaLab’s limitation is its ability to accurately measure samples with high concentrations (typically >1%) of certain volatiles such as etha- nol or propylene glycol, which can condense on the surface of the chilled mirror. -

Page 15: Water Activity Theory

AquaLab 3. Water Activity Theory 3. Water Activity Theory Water is a major component of foods, pharmaceuticals, and cosmet- ics. Water influences the texture, appearance, taste and spoilage of these products. There are two basic types of water analysis: moisture content and water activity. - Page 16 AquaLab 3. Water Activity Theory Fig. 1: Water Activity Diagram—adapted from Labuza Water activity of a system is measured by equilibrating the liquid phase water in the sample with the vapor phase water in the head- space and measuring the relative humidity of the head-space. In the AquaLab, a sample is placed in a sample cup which is sealed inside a sample chamber.

- Page 17 AquaLab 3. Water Activity Theory In addition to equilibrium between the liquid phase water in the sample and the vapor phase, the internal equilibrium of the sample is important. If a system is not at internal equilibrium, one might measure a steady vapor pressure (over the period of measurement) which is not the true water activity of the system.

-

Page 18: Water Potential

AquaLab 3. Water Activity Theory cause condensation. The AquaLab warns the user if a sample is more than 4°C above the chamber temperature, but for high water activity samples the operator needs to be aware that condensation can occur if a sample that is warmer than the block is put in the AquaLab. Water Potential Some additional information may be useful for understanding what water activity is and why it is such a useful measure of moisture... -

Page 19: Sorption Isotherms

AquaLab 3. Water Activity Theory separated from pure water by a semi-permeable membrane, water tends to move from the pure water side through the membrane to the side with the added solute. If sufficient pressure is applied to the solute-water mixture to just stop the flow, this pressure is a measure of the osmotic potential of the solution. - Page 20 AquaLab 3. Water Activity Theory called the sorption isotherm, and is unique for each product. Besides being unique to each product, the isotherm changes depending on whether it was obtained by drying or wetting the sample. These fac- tors need to be kept in mind if one tries to use water content to infer the stability or safety of a product.

-

Page 21: Getting Started

AquaLab 4. Getting Started 4. Getting Started Components of your AquaLab Your AquaLab should have been shipped with the following items: • AquaLab water activity meter • Calibration Certificate • Power cord • RS-232 interface cable • 100 disposable sample cups •... -

Page 22: Preparing Aqualab For Operation

AquaLab 4. Getting Started Preparing AquaLab for Operation After finding a good location for your AquaLab, plug the power cord into the back of the unit. The ON/OFF switch is located on the lower left corner of the AquaLab’s back panel. When the AquaLab is turned on, you should see a model name/number screen and then the main screen as shown below. - Page 23 AquaLab 4. Getting Started If users have been setup on the instrument, the following screen will appear instead of the main screen. (See Chapter 5 for more informa- tion on administrative settings and user setup). Select the appropriate user and login to begin.

-

Page 24: Menus

AquaLab 5. Menus 5. Menus At the top of the display screen there are three tabs: Measurement, Configuration, and Data. These tabs indicate the three menus you can access. To change between the tabs press the right most button below the document icon. The enter icon is the read or enter button. -

Page 25: Configuration Tab

AquaLab 5. Menus Pushing the right or left arrow keys will change the display to a temperature equilibration screen shown below. This screen shows the temperature difference between the sample temperature and the block temperature. Configuration Tab When at the configuration screen, pressing the up and down arrow keys moves the cursor through the various configuration options Press the left and right arrows to page through the options. - Page 26 AquaLab 5. Menus Calibration: Pressing the Enter button when Calibration is highlighted starts the verification process. For more details on the verification procedure refer to Chapter 7. You may also reset the calibration to the fac- tory defaults by highlighting the Defaults option and pressing Enter. This will reset all options to the way they were when the instrument arrived at your location.

- Page 27 AquaLab 5. Menus Temp Eq: The Temperature Equilibration option allows you to set the level of temperature equilibration desired before the water activity measure- ment begins. The range is 0.5 to 4.0°C. A setting of 4.0°C begins the measurement immediately (assuming the sample is not >4.0°C above or below the block temperature).

- Page 28 AquaLab 5. Menus Mode: Users may choose between single, continuous, or custom mode by pushing the save button. Single Mode Single mode reads the sample once, after which the instrument noti- fies you that it is finished and the water activity and temperature are displayed on the screen.

- Page 29 AquaLab 5. Menus measurement screen. If AquaLab is connected to a computer using AquaLink RG (See Chapter 11), all readings taken during a cus- tom mode test will be downloaded to the AquaLink RG software. On the mode screen, at the top of the page, will appear the current mode settings with the number of tests appearing first, followed by the stability value (∆a ).

- Page 30 AquaLab 5. Menus highlight the number under ∆a , and then use the up and down but- tons to change to any value between 0.0005 and 0.0030. To save the settings and finish, press the save button (to exit without updating, press the cancel button).

-

Page 31: Admin Settings

AquaLab 5. Menus Regional Formatting: Allows you to configure how all Series 4 models will display infor- mation. You may choose the temperature scale (Celsius vs Fahren- heit), the date display (mm/dd/yy vs. dd/mm/yy), the hour format (12 vs 24 hour) and the language. Admin Settings Allows you to create an administrator password as well as create, edit and delete additional users. - Page 32 AquaLab 5. Menus The admin option allows the administrator to grant or block access to some or all of the configuration options in all Series 4 models. For example: If the administrator wanted to make sure that all samples were read at 25°C the administrator would set their temperature to 25°C and then would lock all other users out of that configuration screen.

- Page 33 AquaLab 5. Menus User Setup: Users can be added, edited or deleted from this screen. An alphabet screen will appear where a name can be entered using lower case, upper case and accents. NOTE: User setup is not required for instrument operation. It is in place for users wanting to be compliant with 21 CFR Part 11 or who want to maintain the settings they have selected.

- Page 34 AquaLab 5. Menus “Check” icon button. Press the save icon to save this data record with the name you have specified. NOTE: Pressing the save icon button without giving it a name will save the reading without a name. Beeps: Allows you to set the reading finished notification from 4 beeps to continuous beeps.

- Page 35 AquaLab 5. Menus For the capacitance sensor (TEV Models only) it provides you lid, base, and sample temperatures as well as relative humidity. About: This screen provides important information including the serial number and code version of your instrument.

-

Page 36: Data Tab

AquaLab 5. Menus Data Tab View: This selection will allow you to view your stored measurements. The up/down arrows will move you through the stored data with the most recent measurements at the top of the table. You may also press the left and right arrows to page quickly through the data. - Page 37 AquaLab 5. Menus The information shown is the water activity of the sample, the tem- perature, the time the reading took, the user who ran the test (if setup), the date of the reading, the sensor used (4TEV only), the time the reading was taken, and the sequence number of the stored reading.

-

Page 38: Cleaning And Maintenance

AquaLab 6. Cleaning and Maintenance 6. Cleaning and Maintenance Keeping your AquaLab clean is vital to maintaining the accuracy of your instrument. Dust and sampling debris can contaminate the sampling chamber and must therefore be regularly cleaned out. To clean your instrument, carefully follow these instructions and refer to the labeled diagram below. -

Page 39: Cleaning The Block And Sensors

AquaLab 6. Cleaning and Maintenance Purpose The purpose for the cleaning procedure is to remove grease, dirt and other soluble substances which can absorb/release water during veri- fication, calibration, and/or sample testing. For a smooth and even dew formation, it requires the mirror to be perfectly clean. If there are any contaminants (e.g. -

Page 40: Cleaning Procedure

AquaLab 6. Cleaning and Maintenance previous page) Repeated exposure of cleaning materials or contaminants to the filter may cause inaccurate readings. If the filter appears contami- nated, replace it while being careful not to disturb the sensor behind the filter. Cleaning Procedure: Cleaning your AquaLab is a multi-step procedure which involves washing, rinsing, and drying for each specific area as outlined... - Page 41 AquaLab 6. Cleaning and Maintenance Clean the Mirror Wrap a new Kimwipe around the end of the thin plastic rod (spatula) and moisten it with isopropyl alcohol or Decagon Cleaning Solution. WASH-Swipe the moistened Kimwipe across the mirror once. (A single swipe is usually sufficient to remove con- taminants.) RINSE-Repeat steps a-b using new Kimwipes moisted with distilled water instead of cleaning solution.

-

Page 42: Verification Of Calibration

AquaLab 6. Cleaning and Maintenance Verification of Calibration After you have cleaned the chamber and other parts of your AquaLab, it is important to check the instrument’s performance in order to correct for any linear offset that may have occurred during the clean- ing process. -

Page 43: Verification And Calibration

AquaLab 7. Verification and Calibration 7. Verification and Calibration It is important to verify AquaLab’s water activity calibration against known standards to guarantee optimal performance and accuracy. Decagon recommends verification daily, once per shift or before each use. Water Activity Verification AquaLab uses the chilled-mirror dewpoint technique to determine water activity. -

Page 44: Verification Of Calibration

AquaLab 7. Verification and Calibration produced under a strict quality assurance regime. Please contact Decagon Devices to order additional standards via sales@decagon. com or 1-800-755-2751. Verification Standard Water Activity @ 25°C Distilled Water 1.000 ±0.003 0.5m KCl 0.984 ±0.003 6.0m NaCl 0.760 ±0.003... - Page 45 AquaLab 7. Verification and Calibration water activity range of your sample is changing. Checking the water activity of a standard solution will alert you to the possibility of unit contamination or shifts in the linear offset from other causes. Note: The verification process is the same for both the dewpoint and capacitance sensors in TEV models except that the accuracy for the ca- pacitance sensor is ±...

- Page 46 AquaLab 7. Verification and Calibration to test for water activity readings ranging between 0.713 and 0.621 you should use the 6.0M, NaCl (0.76a )standard for your first veri- fication and the 8.57M LiCl (0.50a ) for the second verification. 6. Prepare a sample cup of the second verification standard and make two readings.

- Page 47 AquaLab 7. Verification and Calibration Repeat Process Measure Verification Standard Correct Clean Sample Not Correct Chamber Clean Sample Chamber Next Correct Re-Read Correct Measure 2nd Standard Standard Correct Not Correct Go to Linear Go to Sampling Offset Procedure Procedure This flowchart is a graphical representation of the directions given above for checking for linear offset.

- Page 48 AquaLab 7. Verification and Calibration Adjust for Linear Offset 1. Once you are certain a linear offset has occurred, toggle to the Configuration tab by pressing the Menu icon button. Calibration is the first option highlighted in the configuration tab. Press the Enter icon button to begin the verification process.

- Page 49 AquaLab 7. Verification and Calibration ing distilled water. Ensure the rim and outside of the cup are clean. Place the sample cup in the AquaLab’s sample chamber. NOTE: The same verification standard may be used to verify and adjust the linear offset. 4.

- Page 50 AquaLab 7. Verification and Calibration temperature for your particular standard (see Appendix B for tem- peratures other than 25°C ). Measure the water activity of a second verification standard accord- ing to the verification procedure described above. If both verifica- tion readings are within ±0.003 a then the instrument is ready to begin testing.

- Page 51 AquaLab 7. Verification and Calibration the Restore Factory Defaults routine. To cancel and return to the main menu, press the Cancel icon button. After pushing the Enter icon button, the following screen will appear: NOTE: For TEV models make sure you have the correct sensor selected. 3.

-

Page 52: Sample Preparation

AquaLab 8. Sample Preparation 8. Sample Preparation Proper sample preparation is an important step in keeping your AquaLab clean and achieving repeatable results. Careful preparation and loading of samples will lengthen time between cleanings and help you avoid downtime. Preparing the Sample 1. -

Page 53: Samples Needing Special Preparation

AquaLab 8. Sample Preparation change the moisture content of the sample. Covering the bottom of the sample cup provides enough sample to get an accurate reading. 4. Make sure the rim and outside of the sample cup are clean. Wipe any excess sample material from the rim of the cup with a clean Kimwipe. -

Page 54: Slow Water-Emitting Samples

AquaLab 8. Sample Preparation Coated and Dried Samples Samples with coatings such as sugar or fat often require multiple readings, because it takes longer for them to equilibrate. If this is the case for your samples, it is not a problem with your instrument; it simply means that your particular sample takes longer than most to equilibrate. -

Page 55: Volatile Samples

AquaLab 8. Sample Preparation For faster reading, it is important to have the water activity of the chamber at or below the water activity of these type of samples. This causes the sample to release water to the vapor phase and equilibrate with the chamber. -

Page 56: Samples Not At Room Temperature

AquaLab 8. Sample Preparation the Series 4, your AquaLab will display an error message indicating the lowest reading it attained on that particular sample. See Chapter 12’s troubleshooting problem #5 for possible solutions. If your sample is not below 0.03 a but is still getting the error mes- sage, refer to Chapter 12 for other possible explanations. -

Page 57: Taking A Reading

AquaLab 9. Taking a Reading 9. Taking a Reading Measurement Steps Once you have verified for cleanliness, calibration and prepared your sample, you are ready to take readings. The process is simple: • Move the chamber lever to the Open position and lift the cham- ber lid. - Page 58 AquaLab 9. Taking a Reading icon and, if enabled, you will hear a series of beeps. Cautions! • Never leave a sample in your AquaLab after a reading has been taken. The sample may spill and contaminate the in- strument’s chamber if the instrument is accidentally moved or jolted.

- Page 59 AquaLab 9. Taking a Reading • physical temperature of the instrument should be between 15 - 50°C. Between these ambient temperatures, AquaLab will measure samples of similar temperature quickly and accurately. The AquaLab Series 4TE has temperature control capabilities that enable it to read samples at temperatures different from am- bient temperature, but no higher than 50°C.

-

Page 60: Duo Operation (Optional)

4TE, but then it uses preloaded product specific isotherm models to calculate moisture content and present it on the screen with the water activity. For information about upgrading your Series 4TE to a Series 4TE DUO, please contact Decagon Devices. -

Page 61: Obtaining Product Isotherm Models

AquaLab 10. Duo Operation (Optional) Obtaining Product Isotherm Models Since the isotherm relationship for each product is unique, each prod- uct’s isotherm model must be determined experimentally. This only needs to be done once, but must be done prior to testing moisture con- tent with the DUO. - Page 62 AquaLab 10. Duo Operation (Optional) allowing the user to control and organize their product models. The AquaLink RG software can also download data (including moisture content) from the instrument, present the data in table form, filter the data, and print reports. Measuring Moisture Content With the product models loaded into the instrument, the Series 4TE DUO can generate moisture content and water activity simul-...

- Page 63 AquaLab 10. Duo Operation (Optional) • A list of available models will be listed by name. • Select the model for the product to be analyzed. Selecting “None” will not select any model. Taking a Reading • Readings are taken with the DUO the same as outlined in Chap- ter 9.

- Page 64 AquaLab 10. Duo Operation (Optional) nates the need to return to the configuration screen to change products. When the tab at the top shows “Measurement”, no model is selected and only water activity will be displayed on the screen. • Place a sample in the chamber and begin testing by sliding the lever left to the read position.

- Page 65 AquaLab 10. Duo Operation (Optional) • The test can be saved to the instrument’s memory by pressing the button under the save icon. An annotation can be added if desired. If autosave has been selected, the data will already be saved but without any annotation.

-

Page 66: Computer Interface

If you are interested in purchasing the full version of AquaLink RG, contact Decagon or your local distributor. If you have purchased the AquaLab 4TE DUO you will automatically receive the full version of AquaLink RG with your manual. - Page 67 AquaLab 11. Computer Interface • At the prompt, choose a name for this program (AquaLab is a good one) and choose an arbitrary icon above to represent it. In future downloads, you will be able to click on this icon in have it already set up for you to download.

-

Page 68: Troubleshooting

AquaLab 12. Troubleshooting 12. Troubleshooting AquaLab is a high performance, low maintenance instrument, de- signed to have few problems if used with care. Unfortunately, some- times even the best operators using the best instruments encounter technical difficulties. Below is quick reference guide that will direct you to detailed solutions of some problems that may occur. - Page 69 AquaLab 12. Troubleshooting Troubleshooting Quick Guide (Continued) If this problem occurs: Refer to: Verification is not correct ..........Problem #7 Screen displays “Missing bootstrap loader” ....Problem #8 Screen displays “Firmware is corrupted” ...... Problem #9 DUO Model--Test was run with wrong model..Problem #10 DUO Model--%MC displayed is not correct.

- Page 70 AquaLab 12. Troubleshooting is on the right side of that panel. Press in on the release tab and pull the fuse-holder out. Pull the broken fuse(s) out and replace with a 1.25 Amp 250V fuse. Caution: Do not use any other kind of fuse or you will risk dam- age to your instrument as well as void your warranty.

- Page 71 AquaLab 12. Troubleshooting A fan blade in the block chamber may be broken or bent. If even salt standards take a long time to read, and the sample chamber is clean, you may have a broken chamber fan blade. This is especial- ly likely if you have just cleaned the chamber.

- Page 72 AquaLab 12. Troubleshooting SOLUTION: Your sample’s temperature is too high for the instrument to equili- brate with it in a reasonable amount of time. The instrument and sample need to be in temperature equilibrium before accurate measurements can be made. Therefore, very cold samples will take a very long time to measure for the same reason.

- Page 73 AquaLab 12. Troubleshooting PROBLEM: Message on screen displaying dew point sensor failure. SOLUTION: The Cooler is damaged and will need to be serviced by Decagon. See Chapter 12 for detailed instructions. PROBLEM Verification is not correct. SOLUTIONS: The sample chamber and mirror need to be cleaned. See Chap- ter 6 for detailed cleaning instructions.

- Page 74 AquaLab 12. Troubleshooting PROBLEM: Message on screen displays the following: SOLUTION: The instrument cannot download new firmware updates. To down- load new firmware to the Series 4 models, or to stop this message from displaying, the instrument must be serviced by Decagon. PROBLEM: Message on screen displays the following: SOLUTION:...

- Page 75 AquaLab 12. Troubleshooting DUO PROBLEM: Test was run with wrong model. SOLUTION: On the measurement screen, toggle to the correct model using the up and down arrow keys. The moisture content value will be updated to correspond with the model selected. If the correct model is not available, the model may not be load- ed on the instrument.

- Page 76 If no models appear in moisture content screen, models will need to be reloaded using AquaLink RG software. If moisture content is not an active selection, the DUO fea- ture may not be active. Content Decagon Devices to learn how to activate the DUO feature. DUO PROBLEM:...

- Page 77 AquaLab 12. Troubleshooting SOLUTION: When a moisture content reading is not shown, the water activ- ity or temperature for that reading is beyond the scope of the moisture sorption isotherm. This can happen under the follow- ing conditions: The isotherm equation calculates a moisture content that is less than 0% or greater than 100% with the given water activity.

-

Page 78: Diagnostic Screen

AquaLab 12. Troubleshooting Diagnostic Screen If, after cleaning your instrument and reading the other trouble- shooting hints, you have reason to believe that one of the compo- nents of your AquaLab may be causing measurement error, you may access a screen that will display values for component perfor- mance. -

Page 79: Support And Repair

AquaLab 13. Support and Repair 13. Support and Repair NOTE: If you purchased your AquaLab from one of our international distributors, please contact them. They will be able to provide you with local support and service. When encountering problems with your AquaLab (that can’t be re- solved with the help of this manual), please contact Decagon Cus- tomer Support at support@decagon.com, 800-755-2751 (US and Canada), 509-332-2756 (International) or fax us at (509) 332-5158. -

Page 80: Repair Costs

Tape the box in both directions for added support. Include the RMA number in the attention line on the shipping label. Ship to: Decagon Devices Inc. ATTN: RMA (insert your RMA #) 2365 NE Hopkins Court Pullman, WA 99163 Repair Costs Manufacturer’s defects and instruments within the three-year warranty... -

Page 81: Further Reading

AquaLab 14. Further Reading 14. Further Reading Water Activity Theory & Measurement Bousquet-Ricard, M, G. Qualyle, T. Pharm, and J.C. Cheftel. (1980). Comparative study of three methods of determining water activity in intermediate moisture foods. Lebensmittel-Wissenschaf- tund-Technologie.13:169-173. Chirife, J., G. Favetto, C. Ferro-Fontan, and S. Resnik. (1983). The water activity of standard saturated salt solutions in the range of intermediate moisture foods. - Page 82 AquaLab 14. Further Reading Labuza, T.P . and R. Contreras-Medellin. (1981). Prediction of moisture protection requirements for foods. Cereal Foods World. 26(7):335-343. Labuza, T.P., K. Acott, S.R. Tatini, and R.Y. Lee. (1976). Water activity determination: A collaborative study of different methods. Journal of Food Science.

- Page 83 AquaLab 14. Further Reading opment and Industrial Pharmacy. 16(8):1399-1409. Stamp, J.A., S. Linscott, C. Lomauro, and T.P. Labuza. (1984). Measurement of water activity of salt solutions and foods by several electronic methods as compared to direct vapor pressure measure- ment. Journal of Food Science. 49:1139-1142. Stoloff, L.

-

Page 84: Food Quality And Safety

AquaLab 14. Further Reading ences on Food Quality. Rockland, L.B. and G.F. Stewart (ed.) Aca- demic Press, New York. pp. 1-61. Vega, M.H. and G.V. Barbosa-Canovas. (1994). Prediction of water activity in food systems: A review on theoretical models. Revista Es- panola De Ciencia Y Tecnologia De Alimentos. - Page 85 AquaLab 14. Further Reading Chirife, J. and M.P. Buera. (1996). Water activity, water glass dy- namics, and the control of microbiological growth in foods. Critical Reviews in Food Science and Nutrition. 36(5):465-513. Franks, F. (1982). Water activity as a measure of biological viability and quality control.

-

Page 86: Water Activity And Microbiology

AquaLab 14. Further Reading Rockland, L.B. and S.K. Nishi. (1980). Influence of water activity on food product quality and stability. Food Technology. 34:42-59. Seow, C.C., T.T. Teng, and C.H. Quah. (1988). Food Preservation by Moisture Control. Elsevier, New York. Taoukis, P., W. Breene, and T.P. Labuza. (1988). Intermediate mois- ture foods. - Page 87 AquaLab 14. Further Reading of temperature, water activity, and incubation time on production of aflatoxins and cyclopiazonic acid by an isolate of Aspergillus fla- vus in surface agar culture. Applied and Environmental Microbiol- ogy. 63:1048-1053. Hocking, A.D. and B.F. Miscamble. (1995). Water relations of some Zygomycetes isolated from food.

- Page 88 AquaLab 14. Further Reading growth and survival of Listeria monocytogenes Scott A. Journal of Food Protection. 55:414-418. Nakajo, M. and Y. Moriyama. (1993). Effect of pH and water activ- ity on heat resistance of spores of Bacillus coagulans. Journal of the Japanese Society for Food Science and Technology.

-

Page 89: Water Activity In Foods

AquaLab 14. Further Reading and humectant. Letters In Applied Microbiology. 19:76-78. Tapia de Daza, M.S., Y. Villegas, and A. Martinez. (1991). Minimal water activity for growth of Listeria monocytogenes as affected by solute and temperature. International Journal of Food Microbiol- ogy. - Page 90 AquaLab 14. Further Reading water activity, and temperature and suitability of media for its recov- ery. Applied and Environmental Microbiology. 62:2735-2740. Duffy, L.L., P.B. Vanderlinde, and F.H. Grau. (1994). Growth of Listeria monocytogenes on vacuum-packed cooked meats: Effects of pH, a w, nitrite and ascorbate. International Journal of Food Micro- biology.

- Page 91 AquaLab 14. Further Reading patties supplemented with wheat germ protein flour. Journal of Food Science. 61:418-421. Shimasaki, T., K. Miake, Y. Tsukamasa, M.A. Sugiyama, Y. Minegi- shi, and H. Shinano. (1994). Effect of Water Activity and Storage Temperature on the Quality and Microflora of Smoked Salmon. Nippon Suisan Gakkaishi.

- Page 92 AquaLab 14. Further Reading Pisecky, J. (1992). Water activity of milk powders. Milchwissenschaft. 47:3-7. Tornadijo, E., J.M. Fresno, J. Carballo, and S.R. Martin. (1993). Study of Enterobacteriaceae throughout the manufacturing and rip- ening of hard goats’ cheese. Journal of Applied Bacteriology. 75:240- 246.

- Page 93 AquaLab 14. Further Reading Jimenez, M., M. Manez, and E. Hernandez. (1996). Influence of water activity and temperature on the production of zearalenone in corn by three Fusarium species. International Journal of Food Mi- crobiology. 29:417-421. Kiranoudis, C.T., Z.B. Maroulis, E. Tsami, and K.D. Marinos. (1993).

- Page 94 AquaLab 14. Further Reading Zeb, A., R. Khan, A. Khan, M. Saeed, and S.A. Manan. (1994). Influence of crystalline sucrose and chemical preservatives on the water activity and shelf stability of intermediate banana chips. Sar- had Journal of Agriculture. 10:721-726. Zhang, X.W., X.

- Page 95 AquaLab 14. Further Reading Ramanathan, S. and S. Cenkowski. (1995). Sorption isotherms of flour and flow behaviour of dough as influenced by flour compac- tion. Canadian Agricultural Engineering. 37:119-124. Roessler, P.F. and M.C. Ballenger. (1996). Contamination of an un- preserved semisoft baked cookie with a xerophilic Aspergillus spe- cies.

- Page 96 AquaLab 14. Further Reading Sarhad Journal of Agriculture. 8:23-28. Ferragut, V., J.A. Salazar, and A. Chiralt. (1993). Stability in the conservation of emulsified sauces low in oil content. Alimentaria. 30:67-69. Ibarz, A., J. Pagan, and R. Miguelsanz. (1992). Rheology of clarified fruit juices: II.

- Page 97 AquaLab 14. Further Reading Enigl, D.C. and K.M. Sorrels. (1997). Water Activity and Self-Pre- serving Formulas. In: Preservative-Free and Self-Preserving Cosmet- ics and Drugs: Principles and Practice. Kabara, J.J. and D.S. Orth (ed.) Marcel Dekker, pp. 45-73. Hageman, M.J. (1988). The role of moisture in protein stability. Drug Development and Industrial Pharmacy.

- Page 98 AquaLab 14. Further Reading Bell, L.N. (1995). Kinetics of non-enzymatic browning in amor- phous solid systems: Distinguishing the effects of water activity and the glass transition. Food Research International. 28:591-597. Brake, N.C. and O.R. Fennema. (1993). Edible coatings to inhibit lipid migration in a confectionery product.

-

Page 99: Preparing Salt Solution

AquaLab Appendix A Appendix A Preparing Salt Solution If you choose to mix a saturated salt solution for use as a verification standard, we recommend that you use the approved AOAC method. This method is as follows: 1. Select a reagent-grade salt and place it in a test container to a depth of about 4cm for more soluble salts (lower a ), to a depth of about 1.5 cm for less soluble salts (high a... - Page 100 AquaLab Appendix A Table 2: Water Activity of Selected Salt Solutions Saturated at 20° C at 25° C Solution Lithium 0.113 ± 0.003 0.113 ± 0.003 Chloride Magnesium 0.331 ± 0.002 0.328 ± 0.002 Chloride Potassium 0.432 ± 0.003 0.432 ± 0.004 Chloride Magnesium 0.544 ±...

-

Page 101: Temperature Correction

AquaLab Appendix B Appendix B Temperature Correction of Decagon’s Verification standards Temp. 0.5m 6.0m 8.57m 13.4m (°C) NaCl LiCl LiCl 15.0 1.000 0.984 0.761 0.492 0.238 20.0 1.000 0.984 0.760 0.496 0.245 25.0 1.000 0.984 0.760 0.500 0.250 30.0 1.000 0.984 0.760 0.504... -

Page 102: Aqualab Calibration Standards

AquaLab Appendix C Appendix C AquaLab Verification Standards Application Note Using AquaLab is easier then ever. Pre-packaged standard salt solu- tions are immediately available for performance verification, saving you time and money. Validation and documentation for GMP and GLP has also become easier. Operate your instrument with certainty and insure the quality of your food product by using low cost preci- sion salt solutions. - Page 103 AquaLab Appendix C verified by an independent third party and are shelf stable for one year. Order your calibrtion salt standard of similar water activity today. Uncertainties Using Saturated Salt Solutions The water activity values listed in our operator’s manual for satu- rated salts were reprinted from Greenspan (1977).

- Page 104 AquaLab Appendix C better standards than saturated salts. Robinson and Stokes (1965) give activity coefficient for various salt solutions. These can be used to compute the water potential, or partial specific Gibbs free energy, of the water in the solution using; Ψ...

- Page 105 AquaLab Appendix C NaCl (Lang, 1967) and KCl (Campbell and Gardner, 1971) and no other terms have any temperature dependence. A further advantage of unsaturated salts is that there is no solid phase present to affect the water activity of the solution. Salt in saturated solutions can exist in different states and result in uncertainty in the water activity values.

- Page 106 AquaLab Appendix C the value listed above. If it within ±0.003, place your second solu- tion in the drawer for testing. It should read the value ±0.003 listed in the table above. If the readings are within the expected values your verification is complete.

-

Page 107: Declaration Of Conformity

2008 This is to certify that the AquaLab water activity meter, manufac- tured by Decagon Devices, Inc., a corporation based in Pullman, Washington, USA meets or exceeds the standards for CE compli- ance as per the Council Directives noted above. All instruments are built at the factory at Decagon and pertinent testing documenta- tion is freely available for verification. -

Page 108: Certificate Of Traceability

AquaLab Certificate of Traceability Certificate of Traceability Decagon Devices, Inc 2365 NE Hopkins Court Pullman WA 99163 Tel: (509) 332-2756 Fax: (509) 332-5158 support@decagon.com This is to certify that AquaLab water Activity Meters are manufac- tured utilizing temperature standards with calibration traceable to... - Page 109 AquaLab Certificate of Traceability Index About 1, 29 Accuracy 51 Admin 26 Administrator password 25 AquaLab and water activity 4, 5 AquaLab models 4 AquaLink RG 60 Auto save 27 Barrier 48 Beeps 28 Binding 12 Calibration 20, 38 Capillaries 13 Cautions 52 Certificate of Traceability 102 Chemical reactivity 14...

- Page 110 AquaLab Customer support 1 Custom mode 22 Data 18 Declaration of Conformity 101 Dehydrated 48 Delete 31 Diagnostics 28, 72 DUO 14, 54 Equilibrate 48, 50 Equilibrium 6 Error message 50 Fax 2 Fuse 63 Gibbs 12 Homogeneous 46 Hyperterminal 60 Infrared thermometer 10 Isotherm model 55 LCD 51...

- Page 111 AquaLab Location 15 Loss on drying 9 Matrix 13 Measurement 18 Menus 18 Microbial 13 Microbial growth 14 Moisture content 54 Multi-component 11 Notification 28 Operation 16 Original calibration 44 Osmotic 12 Performance 36, 37 Perishability 9 Pharmaceuticals 9 Phone 1, 2 Photo detector 6 Physical temperature 53 Pressure 12...

- Page 112 AquaLab Salt standard 38 Sample preparation 46 Saturation 10 Seller’s liability 2 Serial number 29 Sorption isotherm 14 Specifications 4 Spreadsheet 61 Technical difficulties 62 Temperature 6, 20 Temperature effects 11 Temperature fluctuations 7 Thermodynamic property 12 Time 24 Troubleshooting 18 Users 17, 27 Vapor equilibrium 46 Vapor phase 10...

- Page 113 AquaLab...

Need help?

Do you have a question about the AquaLab 4TE and is the answer not in the manual?

Questions and answers