Summary of Contents for Smach EFE 2500A

- Page 1 EFE 2500A/AF EFE 4000A/AS/AN SOFT-SERVE AND FROZEN YOGHURT FREEZER USER GUIDE (OPERATING MANUAL) MODEL: EFE 2500A/AF - 4000A/AS/AN – 23.07.2014 Manual Number: V...

-

Page 2: Table Of Contents

14.1.4 Dispensing Head Piston Lifter Assembly: ..............32 14.1.5 Dispensing Head Lifter Rod Assembly: ............... 33 14.1.6 Dispensing Head Assembled ..................33 14.2 BEATER ASSEMBLY ......................34 14.2.1 Seal Assembly:......................34 14.2.2 Inserting the Beater into the Barrel ................34 EFE 2500A /AF - 4000A/AS/AN... - Page 3 14.7 HOPPER COVER ASSEMBLY ....................41 15. POSSIBLE FAILURES AND SOLUTIONS ..................41 16. ELECTRICAL CIRCUIT DIAGRAMS ....................43 16.1 EFE 2500A ........................... 43 16.2 EFE 4000A/AS ........................47 WARRANTY DOCUMENT AND CONDITIONS ................... 51 EFE 2500A /AF - 4000A/AS/AN...

-

Page 4: Congratulations And Thank You

Gıda Makine A.Ş. manufactured especially in Turkey by Smach ® If you encounter a problem with the Smach Soft Serve Ice Cream Machine, please contact your local service technician. Please familiarize yourself with the machine by taking some time to study this manual. If you get to know this little ice-cream factory, it has the potential of making good profit. -

Page 5: Symbols In Manual

He/She is a skilled engineer for the operation of the machine under normal conditions; he/she is able to carry out interventions on mechanical parts and all adjustments, as well as maintenance and repairs. He/She is qualified for interventions on electrical and refrigeration components. EFE 2500A /AF - 4000A/AS/AN... -

Page 6: Contact Details & Help Desk

Tel: +90 236 233 39 29 Fax: +90 236 236 12 59 E-Mail: info@smach.com.tr ® When calling Smach have the following information ready: 1. Freezer Serial Number: Found on body panel 2. A brief description of the problem EFE 2500A /AF - 4000A/AS/AN... -

Page 7: Electrical Connection Notice

7. The fuse must be 220-240V, 50 Hz 16 Amp / 24 Amp or 380-400V, 50 Hz 32 Amp (Before plug the machine, see metallised label on the back of the machine.) EFE 2500A /AF - 4000A/AS/AN... -

Page 8: Warnings & Safety

Therefore please take note and abide by amongst others, the following WARNINGS: The weight of the machine is no less than 170 kg for EFE 2500A and 230 kg for EFE 4000A. The person who carries the machine must be careful while moving the freezer. - Page 9 Failure to follow this procedure may cause severe and costly damage to the refrigeration system. ® Gıda Makine A.Ş will not take any responsibility if the users do not follow NOTICE: Smach all the instructions as described in this User Guide. EFE 2500A /AF - 4000A/AS/AN...

-

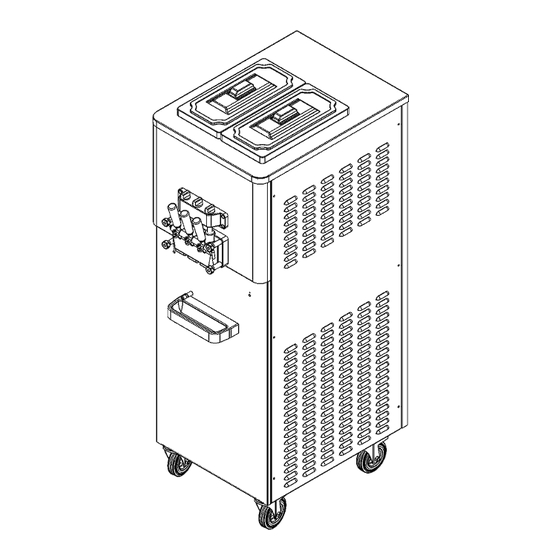

Page 10: Parts Identification

7. PARTS IDENTIFICATION 7.1 Exploded View of Machine 7.1.1. EFE 2500 A/AF Figure 1 The only difference between 2500A and AF is the rotation speed of beater. EFE 2500A /AF - 4000A/AS/AN... - Page 11 15 Front Panel 16 Photo Sensor 17 Selector Switch 18 LED 19 Base 20 Side Panel (Right) 21 Hopper 22 Liquid Level Sensor 23 Air Tube Table 1 (*) Parts marked with this symbol are optional. EFE 2500A /AF - 4000A/AS/AN...

-

Page 12: Efe 4000 A/As

7.1.2 EFE 4000 A/AS Figure 2 EFE 2500A /AF - 4000A/AS/AN... - Page 13 Head Group Head Screws Drip Tray Holder Drip Tray Front Panel Drain Wheel Photo Sensor Side Panel (Right) Barrel Hopper Liquid Level Sensor Air Tube Table 2 (*) Parts marked with this symbol are optional. EFE 2500A /AF - 4000A/AS/AN...

-

Page 14: Efe 4000 An

7.1.3 EFE 4000 AN Figure 3 EFE 2500A /AF - 4000A/AS/AN... - Page 15 Selector Switch Beater Seal *Self Service Unit Beater Head Group Head Screws Drip Tray Holder Drip Tray Front Panel Drain Wheel Photo Sensor Side Panel (Right) Barrel Hopper Liquid Level Sensor Air Tube Table 3 EFE 2500A /AF - 4000A/AS/AN...

-

Page 16: Exploded View Of Dispensing Head

O-Ring 89,69 x 5,33 O-Ring 27,2 x 3,53 Middle Piston O-Ring 4,8 x 3,53 O-Ring NBR Dispensing Head Piston Lifter 10 Speed Adjuster 11 Nozzle 12 O-Ring 34,65 x 1,78 13 Lifter Rod Table 4 EFE 2500A /AF - 4000A/AS/AN... -

Page 17: Exploded View Of Self Service Unit

7.3 Exploded View of Self Service Unit Figure 5 PART NAME QUA. Self Service Mounting Unit Self Service Spring Pressure Pin Self Service Screw M30 Self Service Spring Rectangular Reed Sensor Table 5 EFE 2500A /AF - 4000A/AS/AN... -

Page 18: Exploded View Of Air Tube

7.4 Exploded View of Air Tube Figure 6 PART NAME QUA. Outer Air Tube_L Inner Air Tube_L 8 x 2,50 O-Ring 18,70 x 2,62 O-Ring Table 6 EFE 2500A /AF - 4000A/AS/AN... -

Page 19: Exploded View Of Liquid Level Sensor

7.5 Exploded View of Liquid Level Sensor Figure 7 PART NAME QUA. PLS_045 Liquid Level Sensor Body PLS Liquid Level Sensor Float 4,8 x 3,53 mm O-Ring Silicon Yellow Table 7 EFE 2500A /AF - 4000A/AS/AN... -

Page 20: Machines With Air-Cooled Condenser

Attention: The freezer must not be exposed to direct sunlight. If it stands in direct sunlight the performance will decrease. As the air temperature increases the performance decreases. This is true for all refrigeration equipment. EFE 2500A /AF - 4000A/AS/AN... -

Page 21: Machines With Water-Cooled Condenser

Water consumption increases if temperature of entering water is above 20°C. The filter should be cleaned every 3 months. The use of potable water in the cooling system is recommended. EFE 2500A /AF - 4000A/AS/AN... -

Page 22: Control Dial

Both barrel and hopper will be chilled. SOFT / HARD Choose the SOFT / HARD selection depending on the type of Soft-Serve Product you have chosen and the consistency you find more preferable. EFE 2500A /AF - 4000A/AS/AN... -

Page 23: Operating Procedure

® 5. Repairs must be done by the persons who are authorized by Smach , if not, any product failure warrantee will become invalid and void. -

Page 24: Starting The Machine

Then place the air tube and fill the hopper. Fill the hopper, up to the level of upper hole of the air tube. Do NOT fill above the upper hole of the air tube. (Figure 12) Figure 12 EFE 2500A /AF - 4000A/AS/AN... -

Page 25: Dispensing Ice Cream

A specified amount of care and attention is required including but not limited to everything prescribed in this manual. Attention: Because of bacteria population increases very fast, cleaning and sanitizing is vital. Extra attention must be given for cleaning and sanitizing properly. EFE 2500A /AF - 4000A/AS/AN... -

Page 26: Cleaning Procedure

Lubricate the large O-ring and place into the back of the dispense head. 15. Place the dispense head back onto the machine and tighten the screws in a cross- wise manner. Do NOT touch barrel feeder hole during the cleaning process! EFE 2500A /AF - 4000A/AS/AN... - Page 27 For optimal machine-performance, the condenser must be cleaned from dust and dirt regularly by an authorized technician. Dispensing head nozzle must be cleaned and sanitized every 6 hours. For water-cooled machines, the filter must be cleaned every 3 months. Figure 13 EFE 2500A /AF - 4000A/AS/AN...

-

Page 28: Brush Cleaning Procedure

Liquid Level Sensor Pump Cover, Pump Feeder Tube, Air Triple Brush - Ø6 Ø5 Ø2 19506007 Tube, Compression Feed Pipe, Head Nozzle, Head (Back Side), Drip Tray, Hand Brush - 30x35x170 19506008 Pump Table 8 EFE 2500A /AF - 4000A/AS/AN... - Page 29 Make sure all brushes provided with the freezer are available for brush cleaning. Figure 15 Figure 16 Figure 17 EFE 2500A /AF - 4000A/AS/AN...

-

Page 30: Sanitizing Procedure

13.3 SANITIZING PROCEDURE After cleaning procedure, hopper, barrel and all the removable parts must ® be sanitized. It is recommended to use approved “SMACH Sanitizer” ® during disinfection. (Please contact SMACH to provide approved ® “SMACH Sanitizer”.) ® The SMACH sanitizer is based on alcohol and QAC. -

Page 31: Step-By-Step Assembly Procedure

Place a small amount of lubricant onto your middle and index finger and evenly coat the piston’s entire surface. The coating must be all-encompassing but must not be too thick; a very thin layer will suffice. EFE 2500A /AF - 4000A/AS/AN... -

Page 32: Dispensing Head Piston Assembly

If the piston does not move freely, a little more Lubricant is required. In that case, remove the piston, add a little more lubricant as prescribed above and re-insert. EFE 2500A /AF - 4000A/AS/AN... -

Page 33: Dispensing Head Piston Lifter Assembly

Figure 24 Figure 25 14.1.4 Dispensing Head Piston Lifter Assembly: Figure 26 EFE 2500A /AF - 4000A/AS/AN... -

Page 34: Dispensing Head Lifter Rod Assembly

14.1.5 Dispensing Head Lifter Rod Assembly: Figure 27 Figure 28 14.1.6 Dispensing Head Assembled: Figure 29 EFE 2500A /AF - 4000A/AS/AN... -

Page 35: Beater Assembly

When it is pushed in, the beater seal will push it out a few millimeters like a spring. Do not be concerned about this, as you place the dispensing head on, the dispense head will push it into position. EFE 2500A /AF - 4000A/AS/AN... -

Page 36: Fitting The Assembled Dispensing Head

UP position so Soft-Serve liquid does not run out. 14.3.2 Tightening the Screws: Tighten the 4 Dispense Head Screws in a cross order (i.e., left-hand top and right-hand bottom and then right-hand top and left-hand bottom. Figure 36 Figure 37 EFE 2500A /AF - 4000A/AS/AN... -

Page 37: Assembly Of The Aeration Tube

Figure 38 Grease and fit the o-rings to the slots on the inner and outer aeration tubes. Figure 39 Slip two parts to each other. Select the suitable hole size by turning the inner tube. EFE 2500A /AF - 4000A/AS/AN... - Page 38 The MEDIUM HOLE will result in an average air percentage and yield a medium overrun. The LARGE HOLE for will decrease the air percentage and yield a lower overrun. The LARGE HOLE setting may also be required for high-viscosity (thick) liquid mixes. EFE 2500A /AF - 4000A/AS/AN...

-

Page 39: Assembly Of Hopper Agitator To The Machine

14.5 ASSEMBLY OF HOPPER AGITATOR TO THE MACHINE Figure 41 Figure 42 EFE 2500A /AF - 4000A/AS/AN... - Page 40 Figure 43 Lubricate the Agitator Seal and place it on the Agitator shaft. Check the position of the seal. It must be placed as shown in the picture. EFE 2500A /AF - 4000A/AS/AN...

-

Page 41: Liquid Level Sensor Assembly

Place the liquid level sensor float on the body. Make sure the float is placed correctly. The up side of the float is marked as shown in the picture. After placing float, place the O-Ring to the groove. Figure 46 Figure 47 EFE 2500A /AF - 4000A/AS/AN... -

Page 42: Hopper Cover Assembly

Attention: DO NOT ALLOW ANY TECHNICAL MAINTENANCE OR REPAIRS BEFORE DISCONNECTING THE FREEZER FROM THE POWER SUPPLY. If the solutions listed below in the Trouble Shooting guide do not resolve your operational problems, call an authorized service agent for further assistance. EFE 2500A /AF - 4000A/AS/AN... - Page 43 Tighten Disphense head screws evenly tightened sufficiently or are and properly tightened unevenly Mix leaks from the Drip Beater-seal is missing Drain the machine and add Beater-Seal Tube Beater-seal is worn Drain the machine and replace beater- seal. EFE 2500A /AF - 4000A/AS/AN...

-

Page 44: Electrical Circuit Diagrams

16. ELECTRICAL CIRCUIT DIAGRAMS 16.1 EFE 2500A/AF Figure 48 EFE 2500A /AF - 4000A/AS/AN... - Page 45 Figure 49 EFE 2500A /AF - 4000A/AS/AN...

- Page 46 Figure 50 EFE 2500A /AF - 4000A/AS/AN...

- Page 47 Figure 51 EFE 2500A /AF - 4000A/AS/AN...

-

Page 48: Efe 4000A/As

16.2 EFE 4000A/AS/AN Figure 52 EFE 2500A /AF - 4000A/AS/AN... - Page 49 Figure 53 EFE 2500A /AF - 4000A/AS/AN...

- Page 50 Figure 54 EFE 2500A /AF - 4000A/AS/AN...

- Page 51 Figure 55 EFE 2500A /AF - 4000A/AS/AN...

-

Page 52: Warranty Document And Conditions

ORTA OLCEKLI SANAYI BOLGESI MANISA Tel: +90 236 233 39 29 / +90 236 233 62 04 Fax: +90 236 236 12 59 WARRANTY MODEL NO: EFE 2500A / 4000A/AS International Warranty Period: 1 Years Invoice Date/No: Delivery Date: SEAL&SIGNATURE ®...

Need help?

Do you have a question about the EFE 2500A and is the answer not in the manual?

Questions and answers