Summary of Contents for Miller BOBCAT 225 NT

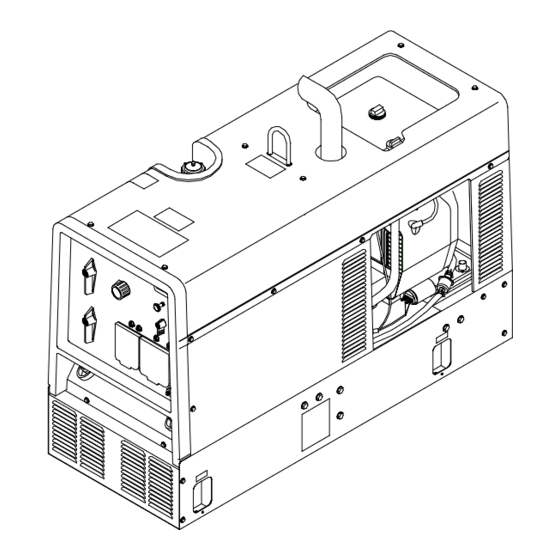

- Page 1 Processes Stick (SMAW) Welding MIG (GMAW) Welding Non-Critical TIG (GTAW) Welding Description Engine Driven Welding Generator Bobcat 225 NT Bobcat 225 NT OM-405 February 1997 Effective with Serial Number KH329624...

- Page 2 1929. This Owner’s Manual is designed to help you get the most out of your Miller products. Please take time to read the Safety precautions. They will help you protect yourself against potential hazards on the worksite. We’ve made installation and operation quick and easy.

-

Page 3: Table Of Contents

Description Standard engine hour meter. Helps maintain WARNING scheduled preventative maintenance. Two-pole alternator design. Produces The Bobcat 225 NT begins a new tradition in The engine exhaust from dependable single-phase welding arc. this product contains portable engine-driven welding generators. The CV setting with fine adjustment. -

Page 5: Safety Precautions - Read Before Using

1. Safety Precautions – Read Before Using Symbol Usage OM-405 - 12/96, safety_rom 12/96 Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. Y Marks a special safety message. This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards. -

Page 6: Engine Hazards

WELDING can cause fire or explo- CYLINDERS can explode if damaged. sion. Welding on closed containers, such as tanks, Shielding gas cylinders contain gas under high drums, or pipes, can cause them to blow up. Sparks pressure. If damaged, a cylinder can explode. Since can fly off from the welding arc. - Page 7 PC boards. READ INSTRUCTIONS. FLYING METAL or DIRT can injure eyes. D Use only genuine MILLER replacement parts. D Wear approved safety glasses with side D Perform engine maintenance and service according to this manual and the engine shields or wear face shield.

-

Page 8: Principal Safety Standards

Principal Safety Standards Safety in Welding and Cutting, ANSI Standard Z49.1, from American Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1, Welding Society, 550 N.W. LeJeune Rd, Miami FL 33126 from Compressed Gas Association, 1235 Jefferson Davis Highway, Suite 501, Arlington, VA 22202. -

Page 9: Signification Des Symboles

1. Consignes de Sécurité – Lire Avant Utilisation Signification des symboles OM-405 – 2/97, safety_rom/fre 12/96 Signifie Mise en garde! Soyez vigilant! Cette procédure présente des risques de danger! Ceux-ci sont identifiés par des symboles adjacents aux directives. Y Identifie un message de sécurité particulier. Ce groupe de symboles signifie Mise en garde! Soyez vigilant! Il y a des risques de danger reliés aux CHOCS ÉLECTRIQUES, aux PIÈCES EN MOUVEMENT et aux PIÈCES CHAUDES. - Page 10 duction d’air pur. Les revêtements et les métaux qui contiennent de tels LES BOUTEILLES peuvent exploser éléments peuvent dégager des vapeurs toxiques lors du soudage. si elles sont endommagées. Les bouteilles contenant des gaz de protection sont à LE SOUDAGE peut causer un incen- haute pression.

- Page 11 LA VAPEUR ET LE LIQUIDE DE LA CHALEUR DU MOTEUR peut REFROIDISSEMENT CHAUD peuvent provoquer un incendie. provoquer des brûlures. D Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces inflammables. D Il est préférable de vérifier le liquide de refroidisse- D Tenir a distance les produits inflammables de ment une fois le moteur refroidi.

- Page 12 DES ÉCLATS DE MÉTAL ou DE LES GAZ D’ÉCHAPPEMENT DES LAITIER peuvent causer des MOTEURS peuvent être mortels. blessures aux yeux. D Utiliser les machines à l’extérieur dans des aires ou- vertes et bien ventilées. Meuler ou extraire le laitier peuvent provoquer des D Si vous utilisez des machines dans un endroit confi- particules volantes.

- Page 13 LIRE LES INSTRUCTIONS. UNE REMORQUE QUI BASCULE peut entraîner des blessures. D Utiliser uniquement des pièces de rechange MILLER. D Utiliser les supports de la remorque ou des blocs D Effecteur la maintenance et la mise en service pour soutenir le poids.

- Page 14 Principales normes de sécurité Safety in Welding and Cutting, norme ANSI Z49.1, de l’American Wel- Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1, ding Society, 550 N.W. Lejeune Rd, Miami FL 33126 de la Compressed Gas Association, 1235 Jefferson Davis Highway, Suite 501, Arlington, VA 22202.

-

Page 15: Definitions

2. Definitions Symbol Definitions Fast Fast/Slow Stop Engine Slow (Idle) (Run, Weld/Power) (Run/Idle) Read Operator’s Start Engine Amperes Volts Manual Engine Oil Fuel Battery (Engine) Engine Check Valve Do not switch while Engine Choke Work Connection Clearance welding Alternating Current Positive Negative Output... -

Page 16: Auxiliary Power Curve

Dimensions, Weights, and Operating Angles Y Do not exceed operating angles while run- Dimensions ning or engine damage will occur. ning or engine damage will occur. Y Do not move or operate unit where it could Height 33-1/2 in (851 mm) tip. - Page 17 Fuel Consumption (Onan-Powered Units) SB-119 455-A Fuel Consumption (Kohler-Powered Units) SB-179 939 OM-405...

-

Page 18: Duty Cycle

Duty Cycle SB-119 454-A Duty cycle is the percentage of 10 minutes that unit can weld at rated load without overheating. Y Exceeding duty cycle can damage unit void warranty. Continuous Welding 100% Duty Cycle at 225 Amperes CC/AC, 210 Amperes CC/DC, 200 Amperes CV/DC Volt-Ampere Curves ST-166 024-A / ST-166 025-A / ST-166 026-A The volt-ampere curve shows the... -

Page 19: Installation

4. Installation Installing Welding Generator install1 1/97 – Ref. ST-800 652 / Ref. ST-800 477-A / ST-158 936-A / S-0854 Generator Base Movement Airflow Clearance Metal Vehicle Frame Y Do not lift unit from end. 18 in Equipment Grounding (460 mm) Terminal 18 in Grounding Cable... -

Page 20: Connecting The Battery

Engine Prestart Checks (Kohler-Powered Units) Ref. ST-801 188-B / Ref. ST-801 221-A Check all fluids daily. Engine must be cold and on a level surface. Unit is shipped with 10W30 engine oil. Full Engine stops if oil pressure gets too low. -

Page 21: Installing Exhaust Pipe

Installing Exhaust Pipe ST-801 681 / Ref. ST-183 175-A Tools Needed: 1/2 in Point exhaust pipe in desired direction. If unit is truck or trailer mounted, point pipe away from direction of travel. Connecting to Weld Output Terminals ST-800 396-A / Ref. ST-183 175-A Tools Needed: 3/4 in Work Weld Output Terminal... -

Page 22: Operating Welding Generator

5. Operating Welding Generator Front Panel Controls Ref. ST-183 175-A Engine Control Switch not crank engine if engine is still turning. Use switch to select weld amperage range when Weld Process Selector switch is in Stick/ To Stop: turn Engine Control switch to Off posi- Use switch to start engine, select speed, and Tig position, or voltage range when switch is in tion. -

Page 23: Operating Auxiliary Equipment

6. Operating Auxiliary Equipment Standard Receptacles Ref. ST-183 175-A Y If unit does not have GFCI re- ceptacles, GFCI- protected extension cord. Auxiliary power decreases as weld current increases. Set Fine Adjust control R1 at 10 for full auxiliary power. 240 V 50 A AC Receptacle RC1 supplies 60 Hz single-phase power at weld/power speed. -

Page 24: Optional Auxiliary Power Receptacles

Optional Auxiliary Power Receptacles Ref. ST-183 175-A / Ref. ST-172 782-A / Ref. ST-172 113 Y If unit does not have GFCI re- ceptacles, GFCI- protected extension cord. Auxiliary power decreases as weld current increases. Set Fine Adjust control R1 at 10 for full auxiliary power. -

Page 25: Wiring Optional 240 Volt Plug

Wiring Optional 240 Volt Plug ST-120 813-D Current Available in Amperes 240 V Each 120 V Duplex The plug can be wired for a 240 V, Receptacle* Receptacle 2-wire load or a 120/240V, 3-wire load. See circuit diagram. Plug Wired for 120/240 V, 3-Wire Load When wired for 120 V loads, each duplex receptacle shares a load... -

Page 26: Maintenance (Onan-Powered Units)

7. Maintenance (Onan-Powered Units) Routine Maintenance (Onan-Powered Units) Y Stop engine before maintaining. See also Engine Manual and maintenance Recycle engine label. Service engine more often if used in fluids. severe conditions. 20 h Check and clean spark Check fluid levels. arrestor screen. - Page 27 50 hours Oil Filter ... . MILLER 065 251, Onan 122-0645 Oil Capacity ..1.5 qt (1.4 L) or 1.75 qt (1.6 L) with filter change Fuel Grade .

- Page 28 Servicing Air Cleaner (Onan-Powered Units) aircleaner3 1/97 – ST-156 852 / Ref. ST-183 175-A / S-0759 Y Stop engine. Y Do not run engine without air cleaner or with dirty element. Wrapper (Foam Element) Wash wrapper with soap and water solution.

- Page 29 Changing Engine Oil, Oil Filter, and Fuel Filter (Onan-Powered Units) Ref. ST-800 392-E / ST-800 395-B / Ref. ST-183 175-A / S-0842 Y Stop engine and let cool. Oil Drain Valve 1/2 ID x 12 in Hose Oil Filter Change engine oil and filter accord- ing to engine owner’s manual.

- Page 30 Adjusting Engine Speed (Onan-Powered Units) ST-800 392-E / ST-800 397 After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds ± 2200 100 rpm as follows: Start engine and run until warm. ± 3700 50 rpm Turn Fine Adjust control to 10.

- Page 31 Servicing Optional Spark Arrestor (Onan-Powered Units) Ref. ST-801 682-A / Ref. ST-183 175–A Y Stop engine and let cool. Spark Arrestor Screen Clean and inspect screen. Replace spark arrestor if screen wires are broken or missing. Tools Needed: 1/4 in OM-405...

-

Page 32: Maintenance (Kohler-Powered Units)

8. Maintenance (Kohler-Powered Units) Routine Maintenance (Kohler-Powered Units) Y Stop engine before maintaining. See also Engine Manual and maintenance Recycle engine label. Service engine more often if used in fluids. severe conditions. Check fluid levels. Wipe up spills. See Section 4.2. 20 h 25 h Check and clean optional... - Page 33 ..Champion RC-12YC Oil Filter ... . MILLER 066 698, Kohler 1205001 Use only resistor spark plugs and wires. Oil Capacity ..

- Page 34 Changing Engine Oil, Oil Filter, and Fuel Filter (Kohler-Powered Units) Ref. ST-801 188-B / Ref. ST-183 175-A / ST-800 395 / S-0842 Y Stop engine and let cool. Oil Drain Valve 1/2 ID x 12 in Hose Oil Filter Oil Fill Cap/Dipstick Change engine oil and filter accord- ing to engine owner’s manual.

- Page 35 Adjusting Engine Speed (Kohler-Powered Units) Ref. ST-801 188-B / ST-801 209 After tuning engine, check engine ± 2200 50 rpm speeds with a tachometer (see table). If necessary, adjust speeds ± 3700 50 rpm as follows: Start engine and run until warm. Turn Fine Adjust control to 10.

- Page 36 Overload Protection (Kohler-Powered Units) ST-801 226-B / Ref. ST-801 221-A / Ref. ST-183 175–A Y Stop engine. Fuse F1 (See Parts List) F1 protects the generator excitation circuit. If F1 opens, there will be no/ low weld and auxiliary power out- put.

-

Page 37: Troubleshooting

9. Troubleshooting Welding Trouble Remedy No weld output. Check control settings. Check weld connections. Check fuse F1 and replace if open (see Section 7.4 or 8.6). Be sure all equipment is disconnected from receptacles when starting unit. Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifier SR2. Check plug PLG6 connection. - Page 38 Engine Trouble Remedy Engine will not crank. Check fuse F6, and replace if open (see Section 7.4 or 8.6). Check battery voltage. Check battery connections and tighten if necessary. Check plug PLG4 and plug PLG8 connections. Have Factory Authorized Service Agent check Engine Control switch S2. Engine will not start.

-

Page 39: Electrical Diagrams

10. Electrical Diagrams 10.1 Circuit Diagram For Welding Generator (Onan-Powered Units) SB-180 688 OM-405... - Page 40 10.2 Circuit Diagram For Welding Generator (Kohler-Powered Units) SB-183 459-A OM-405...

-

Page 41: Auxiliary Power Guidelines

11. Auxiliary Power Guidelines 11.1 Selecting Equipment aux_pwr 12/96 – Ref. ST-159 730 / ST-800 577 Auxiliary Power Receptacles – Neutral Bonded To Frame 3-Prong Plug From Case Grounded Equipment 2-Prong Plug From Double In- sulated Equipment Be sure equipment has this symbol and/or wording. - Page 42 11.3 Grounding When Supplying Building Systems ST-800 576-B Equipment Grounding Terminal GND/PE Grounding Cable Use #10 AWG or larger insulated copper wire. Ground Device Y Ground generator to system earth ground if supplying power to a premises (home, shop, farm) wiring system. Use ground device as stated in electrical codes.

- Page 43 11.5 Approximate Power Requirements for Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 44 11.7 Approximate Power Requirements for Contractor Equipment Contractor Rating Starting Watts Running Watts Hand Drill 1/4 in 3/8 in 1/2 in Circular Saw 6-1/2 in 7-1/4 in 8-1/4 in 1400 1400 Table Saw 9 in 4500 1500 10 in 6300 1800 Band Saw 14 in...

- Page 45 11.8 Power Required to Start Motor S-0624 Motor Start Code Running Amperage AC MOTOR VOLTS AMPS Motor HP CODE Motor Voltage PHASE To find starting amperage: Step 1: Find code and use table to find kVA/HP. If code is not listed, multiply running amperage by six to find starting amperage.

- Page 46 11.10 Typical Connections to Supply Standby Power S-0405-A Customer-supplied equipment is required if generator is to supply standby power during emergencies or power outages. Power Company Service Meter 240 V Main and Branch Overcurrent Protection 120/240 Volt Double-Pole, Double-Throw 120 V 60 Hz Transfer Switch Three-Wire...

- Page 47 11.11 Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord. Maximum Allowable Cord Length in ft (m) for Conductor Size (AWG)* Current Load (Watts) (Amperes) 350 (106) 225 (68)

-

Page 48: Stick Welding (Smaw) Guidelines

12. Stick Welding (SMAW) Guidelines 12.1 Stick Welding Procedure stick 12/96 – ST-151 593 Y Weld current starts when Tools Needed: electrode touches work- piece. Y Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. -

Page 49: Electrode And Amperage Selection Chart

12.2 Electrode and Amperage Selection Chart Ref. S-087 985-A 3/32 6010 5/32 & 3/16 6011 7/32 6010 DEEP MIN. PREP, ROUGH HIGH SPATTER 6011 DEEP 1/16 5/64 6013 EP,EN GENERAL 3/32 SMOOTH, EASY, 7014 EP,EN FAST 6013 5/32 LOW HYDROGEN, 7018 3/16 STRONG... - Page 50 12.5 Positioning Electrode Holder S-0060 ° ° ° ° End View of Work Angle Side View of Electrode Angle GROOVE WELDS ° ° ° ° End View of Work Angle Side View of Electrode Angle FILLET WELDS 12.6 Poor Weld Bead Characteristics S-0053-A Large Spatter Deposits Rough, Uneven Bead...

- Page 51 12.8 Conditions That Affect Weld Bead Shape Note Weld bead shape is affected by electrode angle, arc length, travel speed, and thickness of base metal. Correct Angle S-0061 ° - ° Angle Too Large Angle Too Small Drag ELECTRODE ANGLE Spatter Normal Too Long...

-

Page 52: Butt Joints

12.10 Butt Joints S-0662 Tack Welds Prevent edges of joint from drawing together ahead of electrode by tack welding the materials in position be- fore final weld. Square Groove Weld Good for materials up to 3/16 in (5 mm) thick. Single V-Groove Weld °... -

Page 53: Weld Test

12.13 Weld Test S-0057-B Vise Weld Joint Hammer Strike weld joint in direction shown. A good weld bends over but does not break. 2 To 3 in (51-76 mm) 2 To 3 in (51-76 mm) 1/4 in (6.4 mm) 12.14 Troubleshooting – Porosity Porosity –... - Page 54 12.16 Troubleshooting – Incomplete Fusion Incomplete Fusion – failure of weld metal to fuse completely with base metal or a preceeding weld bead. Possible Causes Corrective Actions Insufficient heat input. Increase amperage. Select larger electrode and increase amperage. Improper welding technique. Place stringer bead in proper location(s) at joint during welding.

- Page 55 12.19 Troubleshooting – Burn-Through Burn-Through – weld metal melting completely through base metal resulting in holes where no metal remains. Possible Causes Corrective Actions Excessive heat input. Select lower amperage. Use smaller electrode. Increase and/or maintain steady travel speed. 12.20 Troubleshooting – Waviness Of Bead Waviness Of Bead –...

-

Page 56: Mig Welding (Gmaw) Guidelines

13. MIG Welding (GMAW) Guidelines 13.1 Typical MIG Process Connections mig 12/96 / ST-800 357-A Y Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a ve- hicle. Place work clamp as close to the weld as possible. Regulator/ Flowmeter Welding... -

Page 57: Typical Mig Process Control Settings

13.2 Typical MIG Process Control Settings Note These settings are guidelines only. Material and wire type, joint design, fitup, position, shielding gas, etc. affect settings. Test welds to be sure they comply to specifications. ST-800 354 Material thickness determines weld parameters. -

Page 58: Holding And Positioning Welding Gun

13.3 Holding And Positioning Welding Gun Note Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam. - Page 59 13.4 Conditions That Affect Weld Bead Shape Note Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed (weld current), and voltage. S-0634 ° Push ° Perpendicular Drag GUN ANGLES AND WELD BEAD PROFILES Short Normal...

- Page 60 13.5 Gun Movement During Welding Note Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads works better. S-0054-A Stringer Bead – Steady Move- ment Along Seam Weave Bead –...

- Page 61 13.8 Troubleshooting – Excessive Spatter Excessive Spatter – scattering of molten metal particles that cool to solid form near weld bead. S-0636 Possible Causes Corrective Actions Wire feed speed too high. Select lower wire feed speed. Voltage too high. Select lower voltage range. Electrode extension (stickout) too long.

- Page 62 13.10 Troubleshooting – Excessive Penetration Excessive Penetration – weld metal melting through base metal and hanging underneath weld. Excessive Penetration Good Penetration S-0639 Possible Causes Corrective Actions Excessive heat input. Select lower voltage range and reduce wire feed speed. Increase travel speed. 13.11 Troubleshooting –...

- Page 63 13.13 Troubleshooting – Burn-Through Burn-Through – weld metal melting completely through base metal resulting in holes where no metal remains. S-0640 Possible Causes Corrective Actions Excessive heat input. Select lower voltage range and reduce wire feed speed. Increase and/or maintain steady travel speed. 13.14 Troubleshooting –...

-

Page 64: Common Mig Shielding Gases

13.16 Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years. The most commonly used shielding gases are listed in the following table. - Page 65 Notes OM-405...

- Page 66 19 20 21 22 13 14 Fig 14-3 48 49 50 Fig 14-2...

-

Page 67: Parts List

Item Part Part Item Description Description Mkgs. Mkgs... . . 181 881 Grommet, neck filler ... 167 730 Cable, bat neg (Onan) . - Page 68 14.2 Panel, Front w/Components (Fig 14-1 Item 43) ST-801 747 Item Part Item Part Description Description Mkgs. Mkgs..184 754 Switch, polarity R3,VR1 046 819 Suppressor 15 Work, Elect 099 255 Terminal, pwr output .

- Page 69 14.3 Generator (Fig 14-1 Item 23) ST-800 798 Item Part Part Item Description Description ... . 013 367 Label, warning moving parts ... 005 614 Holder, brush .

- Page 70 Notes...

- Page 71 Notes...

- Page 72 Notes...

- Page 73 Effective February 7, 1996 (Equipment with a serial number preface of “KD” or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. LIMITED WARRANTY – Subject to the terms and conditions Remote Controls below, Miller Electric Mfg.

-

Page 74: Options And Accessories

Welding Process Handbooks Contact the Delivering Carrier File a claim for loss or damage during ship- for: ment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. PRINTED IN USA 1997 Miller Electric Mfg. Co.

Need help?

Do you have a question about the BOBCAT 225 NT and is the answer not in the manual?

Questions and answers