Toro 03540 Reelmaster 5200-D Operator's Manual

Two-wheel and four-wheel drive traction units

Hide thumbs

Also See for 03540 Reelmaster 5200-D:

- Service manual (296 pages) ,

- Operator's manual (52 pages) ,

- Operator's manual (44 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Toro 03540 Reelmaster 5200-D

- Page 1 Form No. 3355-138 Rev B Reelmaster® 5200-D/5400-D Two-Wheel and Four-Wheel Drive Traction Units Model No. 03540—Serial No. 260000201 and Up Model No. 03543—Serial No. 260000201 and Up Model No. 03544—Serial No. 260000201 and Up Register your product at www.Toro.com Original Instructions (EN)

-

Page 2: Table Of Contents

5 Installing the Cutting Units....16 or additional information, contact an Authorized 6 Adjusting the Turf Compensation Service Dealer or Toro Customer Service and have Spring ....... 18 the model and serial numbers of your product 7 Adjusting the Lifted Height ready. - Page 3 Checking the Rear Axle Adjusting the Traction Drive for Lubricant ......29 Neutral......49 Checking the Reel to Bedknife Checking and Adjusting the Contact ......30 Traction Linkage ....49 Check the Torque of the Wheel Changing the Transmission Nuts........30 Fluid .........

-

Page 4: Safety

Safety ◊ being driven too fast; ◊ inadequate braking; This machine meets or exceeds CEN standard ◊ the type of machine is unsuitable for its EN 836:1997, ISO standard 5395:1990, and task; ANSI B71.4-1999 specifications in effect at ◊ lack of awareness of the effect of time of production, when ballast is installed ground conditions, especially slopes;... - Page 5 functioning properly. Do not operate unless attached, adjusted properly, and functioning they are functioning properly. properly. • Do not change the engine governor settings or Operation over-speed the engine. Operating the engine at excessive speed may increase the hazard of •...

-

Page 6: Toro Riding Mower Safety

The following list contains safety information storage area free of grass, leaves, or excessive specific to Toro products or other safety grease. information that you must know that is not • Check the grass catcher frequently for wear or included in the CEN, ISO, or ANSI standard. -

Page 7: Sound Pressure Level

• Do not touch the engine, silencer/muffler, or • If major repairs are ever needed or if assistance exhaust pipe while the engine is running or is desired, contact an Authorized Toro soon after it has stopped because these areas Distributor. -

Page 8: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 110-9721 1. Read the Operator’s Manual. 93-6693 1. Crushing hazard of hand—wait for moving parts to stop. 104-2052... - Page 9 104-9296 1. Throttle—slow 4. Reels lowered and on when 7. Reels disabled—lift and lower10. Headlights—Off enabled—forward and backlap 2. Throttle—fast 5. Reels enabled 8. Headlights (optional) 11. Read the Operator’s Manual for further instructions. 3. Reels raised and off 6. Reels disabled—lift only 9.

- Page 10 93-6697 1. Read the Operator’s 2. Add SAE 80w-90 (API GL-5) Manual. oil every 50 hours. 98-9335 1. Cutting/dismemberment hazard, fan—stay away from moving parts. 93-6696 1. Stored energy hazard—read the Operator’s Manual. 98-9342 1. Reel—height of cut 4. Machine speed 2.

- Page 11 93-6692 1. Read the Operator’s Manual—do not prime or use starting uid. 93-6686 93-1263 1. Hydraulic oil 2. Read the Operator’s Manual. 1. Read the Operator’s Manual. 2. To engage the parking brake, connect the brake pedals with the locking pin, push down on both pedals, and pull the brake latch out.

- Page 12 104-9294 1. Read the Operator’s Manual. 3. Warning—Read the 5. Warning—keep bystanders 7. Warning—use a rollover Operator’s Manual. a safe distance from the protection system and wear machine. the seat belt. 2. Do not tow the machine. 4. Cutting hazard of hand 6.

-

Page 13: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Step Description Qty. – No parts required Connect the Battery Locking hood switch Lock washer Mount the hood latch. Hood latch bracket Bolt (1/4 x 3/4 inch) Flat washer (1/4 inch) Locknut (1/4 inch) Flange-head bolt (5/16 x 5/8 inch) -

Page 14: Connecting The Battery

4. Slide the black, negative battery cable onto the negative battery post and tighten the nut securely. 5. Coat both battery connections with Grafo 112X (skin over) grease (Toro Part No. 505-47), petroleum jelly, or light grease to Figure 2 prevent corrosion and slide the rubber boot over the positive terminal. -

Page 15: Mounting The Hood Latch

Step Mounting the Hood Latch (CE Units Only) Parts needed for this step: Locking hood switch Lock washer Figure 4 Hood latch bracket Bolt (1/4 x 3/4 inch) 1. Locking switch 2. Latch bracket Flat washer (1/4 inch) Locknut (1/4 inch) 4. -

Page 16: Adjusting The Tire Pressure

Step Installing the Cutting Units Parts needed for this step: Cutting unit (sold separately) Procedure 1. Remove the cutting units from the cartons. Assemble and adjust the as described in the Figure 5 cutting unit Operator’s Manual. 1. Floor panel 2. - Page 17 Figure 7 1. Carrier frame 2. Basket guide Figure 9 4. Install a roll pin (Figure 8) into the hole in the 1. Cutting unit mounting 4. Flat washer shaft appropriate side of each cutting unit carrier 2. Carrier frame pivot tube 5.

-

Page 18: Adjusting The Turf Compensation Spring

mounting nuts. Ensure that the washers are the basket bracket and pressing the opposite against the nuts. mounting pin into the pivoting bracket. 9. Detach the lock-up chain from the lift arm and Step secure it to the cross tube on each rear cutting unit with a bolt, flat washer, and locknut (Figure 11). -

Page 19: Adjusting The Lifted Height

spring bracket and front of the washer is 1.25 inches (3.2 cm) (Figure 13). 2. Tighten the hex nuts on the front end of the spring rod until the compressed length (A) of spring is 6.25 inches (32.8 cm) (Figure 13). As the compressed spring length (A) decreases, weight transfer from the front roller to the rear roller increases and the... -

Page 20: Installing Rear Weights

5395:1990, and ANSI B71.4-1999 Standards when equipped with rear weights and 90 lb of calcium chloride ballast is added to rear wheels. Use the chart below to determine the combinations of weights required for your configuration. Order parts from your local Authorized Toro Distributor. Traction Unit... -

Page 21: Installing Ce Decals

Step Installing CE Decals Parts needed for this step: CE decal Blank service decal Procedure 1. Place the CE decal onto the traction unit near the model and serial number plate. 2. Place the blank service decal near the English service decal and write the service information into the blank form in the appropriate language using a permanent marker. -

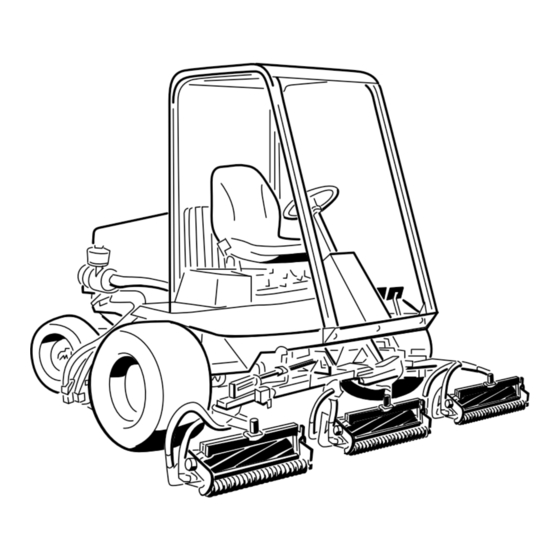

Page 22: Product Overview

Product Overview Figure 16 1. Seat adjusting lever 2. Seat adjusting knob Traction Pedal The traction pedal (Figure 17) controls forward Figure 15 and reverse operation. Press the top of the 1. Operator’s seat 4. Rear cutting units pedal to move forward and the bottom to move 2. -

Page 23: Brake Pedals

Engine Coolant Temperature Warning Light This light (Figure 19) illuminates and the engine shuts down when the engine coolant reaches a dangerously high temperature. Figure 18 1. Traction speed limiter 5. Parking brake latch 2. Reel control light 6. Locking pin 3. -

Page 24: Hour Meter

Engine Oil Pressure Warning Light This light (Figure 19) indicates dangerously low engine oil pressure. Charge Indicator The charge indicator (Figure 19) illuminates when the system charging circuit malfunctions. Enable/Disable Switch Use the enable/disable switch (Figure 19) in conjunction with the lower mow/raise control lever to operate the reels. - Page 25 Levels Attachments/Accessories A selection of Toro approved attachments and accessories are available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or Distributor or go to www.Toro.com for a list of all approved attachments and accessories.

-

Page 26: Specifications

• Alternate oil: SAE 10W-30 or 5W-30 (all temperatures) Figure 24 Reelmaster 5400 Toro Premium Engine oil is available from your distributor in either 15W-40 or 10W-30 viscosity. 1. Dipstick 2. Oil ll cap See the parts catalog for part numbers. -

Page 27: Checking The Cooling System

Important: Be sure to keep the engine oil level between the upper and lower limits on the oil gauge. Engine failure may occur as a result of over filling or under filling the engine oil. 6. Install the oil fill cap and close the hood. Checking the Cooling System Clean debris off of the screen, oil cooler, and front of the radiator daily and more often if conditions... -

Page 28: Checking The Transmission

2. Remove the floor panel. Alternate fluids: If the Toro fluid is not available, 3. Unscrew the dipstick cap from the transmission other petroleum-based Universal Tractor filler neck (Figure 27) and wipe it with a clean Hydraulic Fluids (UTHF) may be used, provided rag. -

Page 29: Checking The Rear Axle

Checking the Rear Axle Note: Toro will not assume responsibility for Lubricant damage caused by improper substitutions, so use only products from reputable manufacturers who Note: This procedure is for Model 03544 only. will stand behind their recommendation. High Viscosity Index/Low Pour Point Anti-wear... -

Page 30: Checking The Reel To Bedknife Contact

4. Remove each end check plug and add enough lubricant to bring the level up to the bottom of each check plug hole. Under certain conditions, diesel fuel and fuel vapors are highly flammable and explosive. 5. Install all plugs. A fire or explosion from fuel can burn you and others and can cause property damage. -

Page 31: Starting And Stopping The Engine

Stopping the Engine 4. Turn the key in the ignition switch to the On position. The electric fuel pump will begin 1. Move all controls to Neutral, set the parking operation, thereby forcing air out around brake, and move the throttle to the idle the air bleed screw. -

Page 32: Adjusting The Lift Arm Down

Figure 33 1. Reel speed control knobs Note: The reel speed can be increased or decreased to compensate for turf conditions. Adjusting the Lift Arm Down Pressure You can adjust the down pressure spring on each cutting unit lift arm to compensate for different turf conditions. -

Page 33: Towing The Traction Unit

Figure 35 1. Drive shaft 3. Remove the drive shaft. Figure 34 Important: If you do not remove the 1. Spring bracket hex shaft 2. Retaining bracket drive shaft before towing, the transmission input shaft will not be able to rotate, thus not allowing the transmission to maintain 4. -

Page 34: Understanding The Diagnostic Light

are designed to allow assembly only when the • Loop-back is not connected. two halves of the shaft are properly oriented. • The light is burned out. Understanding the • Fuses are blown. Diagnostic Light • It is not functioning correctly. Check the electrical connections, input fuses, and The machine is equipped with a diagnostic light diagnostic light bulb to determine the malfunction. - Page 35 If safety interlock switches are disconnected or damaged the machine could operate unexpectedly causing personal injury. • Do not tamper with the interlock switches. • Check the operation of the interlock switches daily and replace any damaged switches before operating the machine. •...

- Page 36 ECU problem. If this occurs, contact your Toro Distributor for assistance. 7. The “outputs displayed” LED, on lower right column of Diagnostic ACE, should be Important: The Diagnostic ACE display illuminated.

- Page 37 Diagnostic ACE Logic Grid Figure 40...

-

Page 38: Hydraulic Valve Solenoid

Hydraulic Valve Solenoid before continuing operation. Serious damage Functions could occur if you operate the machine with a malfunction. Use the list below to identify and describe the Mowing different functions of the solenoids in the hydraulic manifold. Each solenoid must be energized to Start the engine and move the throttle to the Fast allow function to occur. -

Page 39: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval After the rst operating • Torque the wheel lug nuts to 75 to 80 ft-lb (102 to 108 N⋅m). hour •... - Page 40 Maintenance Service Maintenance Procedure Interval • Check the fuel lines and connections for deterioration, damage, or loose connections. • Replace the fuel lter canister. Every 400 hours • Replace the fuel prelter. • Check the traction linkage movement. • Check the engine RPM (idle and full throttle). •...

-

Page 41: Daily Maintenance Checklist

Daily Maintenance Checklist Duplicate this page for routine use. Maintenance Check Item For the week of: Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check the safety interlock operation. Check the brake operation. Check the engine oil and fuel level. Drain the water/fuel separator. Check the air lter restriction indicator. -

Page 42: Service Interval Chart

Service Interval Chart Figure 41 1. Read the Operator’s Manual. If you leave the key in the ignition switch, someone could accidently start the engine and seriously injure you or other bystanders. Remove the key from the ignition before you do any maintenance. Lubrication Greasing the Bearings and Bushings... - Page 43 Figure 45 • 1 fitting on the traction control linkage at the transmission (Figure 46) Figure 43 • 1 fitting on the drive shaft support bearing (Figure 46) • 5 fittings on the lift arm pivots (Figure 44) • 3 fittings on the rear axle drive shaft (Figure 46) •...

-

Page 44: Engine Maintenance

Note: When operating the machine in extremely Figure 49 dusty conditions, an optional extension tube (Toro Part No. 43-3810), which raises precleaner bowl above the hood, thus, lengthening the time Engine Maintenance between precleaner bowl servicing, is available from your local authorized Toro Distributor. -

Page 45: Servicing The Engine Oil And Filter

1. Remove the drain plug (Figure 52) and let the oil flow into a drain pan. Figure 52 1. Engine oil drain plug 2. When the oil stops, install the drain plug. Figure 51 3. Remove the oil filter (Figure 53). 1. -

Page 46: Fuel System Maintenance

Draining the Fuel Tank 3. Hold the injection pump lever arm (Figure 54) against the high idle stop and tighten the cable Drain and clean the fuel tank every 2 years. Also, connector. drain and clean the tank if the fuel system becomes Note: When tightened, the cable connector contaminated or if the machine is to be stored for must be free to swivel. -

Page 47: Replacing The Fuel Filter

Replacing the Fuel Filter Bleeding Air from the Fuel Canister Injectors Note: This procedure should be used only if the Replace the filter canister after every 400 hours of operation. fuel system has been purged of air through normal priming procedures and the engine will not start; 1. -

Page 48: Servicing The Battery

Rinse it with clear water. Coat the Optional Lighting battery posts and cable connectors with Grafo 112X (skin-over) grease (Toro Part No. 505-47) or Important: If you add optional lighting petroleum jelly to prevent corrosion. to the machine, use the following schematic... -

Page 49: Drive System Maintenance

Figure 61 1. Traction adjustment cam Figure 60 The engine must be running so the final adjustment of the traction adjustment cam can be performed. This could cause Note: Make sure a good ground is achieved to personal injury. prevent damage to machine. Keep hands, feet, face, and other body parts away from the muffler, other hot Drive System... -

Page 50: Changing The Transmission

Changing the Transmission first, thereafter. Fluid Only the Toro replacement filter (Part No. 110-4146) can be used in the hydraulic system. Change the transmission fluid after every 800 Important: Use of any other filter may void hours of operation or annually, whichever occurs the warranty on some components. -

Page 51: Changing The Rear Axle

5. Ensure that the filter mounting area is clean. of the steering tires. If the toe-in is not within specifications, adjust it as described below for your 6. Install the filter by hand until the gasket model. contacts the mounting surface, then rotate it an additional 1/2 turn. -

Page 52: Cooling System Maintenance

Figure 66 1. Tie rod Figure 67 1. Screen 4. Rotate the detached ball joint inward or outward 1 complete revolution. Tighten the 4. Clean the screen thoroughly with compressed clamp at the loose end of the tie rod. air. 5. -

Page 53: Belt Maintenance

Figure 68 1. Brake cables Figure 69 3. Tighten the rear nut to move the cable 1. Alternator belt 2. Brace backward until brake pedals have 1/2 to 1 inch (1.25 to 2.5 cm) of free travel. 3. Loosen the bolt securing the brace to the 4. -

Page 54: Hydraulic System Maintenance

Green zone. When the indicator is in the Red zone, the change the hydraulic filter. Use the Toro replacement filter (Part No. 75-1310). Important: Use of any other filter may void the warranty on some components. -

Page 55: Checking The Hydraulic Lines And Hoses

1. Hydraulic lter Use the hydraulic system test ports to test the pressure in the hydraulic circuits. Contact your local Toro distributor for assistance. 3. Remove the filter. 4. Lubricate the gasket on the new filter with Use Test Port #1 (Figure 73) to assist in troubleshooting the hydraulic circuit for the front hydraulic oil. -

Page 56: Cutting Unit System Maintenance

Figure 74 Figure 73 1. Center cutting unit adjustment valve 1. Test port #1 2. Test port #2 2. Loosen the setscrew on the valve and rotate the valve approximately 1/2 turn clockwise. Cutting Unit System 3. Verify the lift rate adjustment by raising and Maintenance lowering the cutting unit several times. -

Page 57: Backlapping The Cutting Units

Note: When backlapping, the front units all 2. Loosen the setscrew on the valve and rotate the valve approximately 1/2 turn clockwise. operate together, and the rear units operate together. 3. Verify the lift rate adjustment by raising and lowering the cutting unit several times. Adjust 1. - Page 58 Enable/Disable switch to the Disable position, and stop the engine. After completing adjustments, repeat steps 5 through 10. 12. Repeat the procedure for all cutting units you want to backlap. 13. When finished, return the backlap switch to the Off position, lower the seat, tighten both locking bolts securely, and wash all lapping compound off of the cutting units.

-

Page 59: Storage

B. Clean the battery, terminals, and posts with a wire brush and baking soda solution. C. Coat the cable terminals and battery posts with Grafo 112X skin-over grease (Toro Part No. 505-47) or petroleum jelly to prevent corrosion. D. Slowly recharge the battery every 60 days for 24 hours to prevent lead sulfation of the battery. -

Page 60: Schematics

Schematics Hydraulic Schematic (Rev. -) - Page 61 Electrical Schematic (Rev. -)

- Page 64 (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

Need help?

Do you have a question about the 03540 Reelmaster 5200-D and is the answer not in the manual?

Questions and answers