Table of Contents

Advertisement

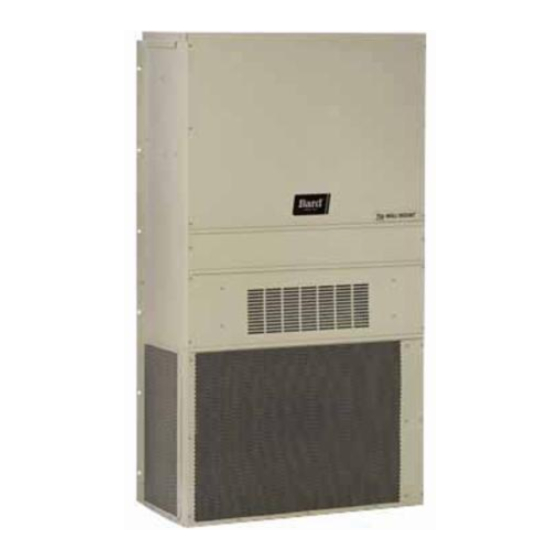

INSTALLATION INSTRUCTIONS

WALL-MOUNTED PACKAGED

H12AA-A

H24AA-A

H36AA-A

H42AA-A

H48AA-A

H60AA-A

H72AA-A

AIR CONDITIONER

Models:

H24LA-A

H36LA-A

H42LA-A

H48LA-A

H60LA-A

H72LA-A

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

H42AA-B

H48AA-B

H60AA-B

H72AA-B

Manual:

Supersedes: 2100-647C

Date:

H42LA-B

H48LA-B

H60LA-B

H72LA-B

2100-647D

7-27-16

Page

1 of 36

Advertisement

Table of Contents

Summary of Contents for Bard H42AA-B

-

Page 1: Installation Instructions

Models: H12AA-A H24AA-A H24LA-A H36AA-A H36LA-A H42AA-A H42LA-A H42AA-B H42LA-B H48AA-A H48LA-A H48AA-B H48LA-B H60AA-A H60LA-A H60AA-B H60LA-B H72AA-A H72LA-A H72AA-B H72LA-B Bard Manufacturing Company, Inc. Manual: 2100-647D Bryan, Ohio 43506 Supersedes: 2100-647C Date: 7-27-16 www.bardhvac.com Page 1 of 36... -

Page 2: Table Of Contents

CONTENTS Start Up ..............17 Getting Other Information and Publications ..3 General.............. 17 Topping Off System Charge ........17 Wall Mount General Information ......4 Safety Practices ..........17 Air Conditioner Wall Mount Model Nomenclature ..4 Important Installer Note ........17 Shipping Damage .......... -

Page 3: Getting Other Information And Publications

GETTING OTHER INFORMATION AND PUBLICATIONS These publications can help when installing the For more information, contact these publishers: furnace. They can usually be found at the local library or purchased directly from the publisher. Be sure to ACCA Air Conditioning Contractors of America consult the current edition of each standard. -

Page 4: Wall Mount General Information

WALL MOUNT GENERAL INFORMATION AIR CONDITIONER WALL MOUNT MODEL NOMENCLATURE – CONTROL MODULES REVISIONS MODEL SERIES (See Spec. Sheet) CAPACITY 12 – 1 Ton COIL OPTIONS VOLTS & PHASE 24 – 2 Ton X – Standard A – 230/208/60/1 COLOR OPTIONS 36 –... -

Page 5: Duct Work

5/8". Any grille that meets with 5/8" louver criteria may be used. It is recommended that Bard Return Air Grille Kit RG2W thru RG5W or RFG2W thru RFG5W be installed when no return duct is used. Contact distributor or factory for ordering information. -

Page 6: Installation

INSTALLATION WALL MOUNTING INFORMATION Clearances Required for Service Access and Adequate Condenser Airflow 1. Two holes for the supply and return air openings must be cut through the wall as shown in Figures LEFT RIGHT DISCHARGE MODELS 3A-D on pages 9-12. SIDE SIDE SIDE... -

Page 7: Figure 1 H12 Unit Dimensions

FIGURE 1 H12AA Unit Dimensions 32.00 30.13 17.00 5.00 5.00 10.00 TOP RAIN FLASHING SHIPPING LOCATION 22.25 25.750 OPTIONAL ELECTRICAL ENTRANCE DRAIN HOSE BACK VIEW 2.50 31.06 14.63 BUILT-IN RAIN HOOD 2° PITCH HEATER & FILTER ACCESS 1.50 19.72 VENTILATION 48.00 ELECTRICAL LOW VOLTAGE... -

Page 8: Figure 2 H24-72 Unit Dimensions

FIGURE 2 Dimensions of Basic Unit for Architectural and Installation Requirements (Nominal) SUPPLY RETURN WIDTH DEPTH HEIGHT MODEL H24A, L 33.300 17.125 74.563 7.88 19.88 11.88 19.88 35.00 10.88 29.75 20.56 30.75 32.06 33.25 31.00 2.63 34.13 26.06 10.55 4.19 12.00 9.00 H36A, L 38.200... -

Page 9: Figure 3A H12 Mounting Instructions

FIGURE 3A H12AA Mounting Instructions SEAL WITH BEAD OF CAULKING RAIN FLASHING ALONG ENTIRE LENGTH OF TOP. SUPPLIED FOAM AIR SEAL WALL WALL STRUCTURE SUPPLY AIR DUCT 17.000 7.031 7.031 2.500 RETURN AIR OPENING 5.000 19.719 10.000 5.000 6.969 17.000 19.719 NOTE: IT IS RECOMMENDED THAT A BEAD OF SILICONE... -

Page 10: Figure 3B H24 Mounting Instructions

Manual 2100-647D Page 10 of 36... -

Page 11: Figure 3C H36 Mounting Instructions

Manual 2100-647D Page 11 of 36... -

Page 12: Figure 3D H42-72 Mounting Instructions

Manual 2100-647D Page 12 of 36... -

Page 13: Figure 4 Electric Heat Clearance

FIGURE 4 Electric Heat Clearance NOTE: SIDE SECTION VIEW OF SUPPLY AIR DUCT FOR WALL MOUNTED UNIT SHOWING 1/4" CLEARANCE TO COMBUSTIBLE SURFACES. WARNING A minimum of 1/4" clearance must be maintained between the supply air duct and combustible materials. This is required for the first 3' of ducting. -

Page 14: Figure 5 Wall Mounting Instructions

FIGURE 5 Wall Mounting Instructions WALL STRUCTURE FACTORY SUPPLIED RAIN FLASHING. MOUNT ON UNIT BEFORE INSTALLATION SUPPLY AIR SUPPLY AIR SUPPLY AIR DUCT OPENING OPENING RETURN AIR RETURN AIR RETURN AIR OPENING OPENING OPENING BOTTOM MOUNTING WOOD OR STEEL SIDING BRACKET. -

Page 15: Wiring - Main Power

FIGURE 7 Common Wall Mounting Installations SUPPLY DUCT MAY BE LOCATED IN AN ATTIC OR BELOW CEILING RAFTERS AS SHOWN RAIN RAIN FLASHING RAFTERS FLASHING RAFTERS FINISHED CEILING SURFACE SUPPLY AIR DUCT SUPPLY AIR DUCT FINISHED CEILING SURFACE W/ GRILLE RETURN AIR RETURN AIR OPENING W/ GRILLE... -

Page 16: Wiring - Low Voltage Wiring

WIRING – LOW VOLTAGE WIRING Filter Switch Adjustment 1. Turn off unit power. Low Voltage Connection 2. Remove upper front door. Front screws on unit top These units use a 24-volt AC low voltage circuit. Tables can be removed for ease of removing upper front 11 and 12 on pages 29 and 30 show the low voltage door. -

Page 17: Start Up

8. Store cylinders in a cool area, out of direct TOPPING OFF SYSTEM CHARGE sunlight. If a leak has occurred in the system, Bard 9. Never heat cylinders above 125°F. Manufacturing recommends reclaiming, evacuating 10. Never trap liquid R-410A in manifold sets, gauge (see criteria above) and charging to the nameplate lines or cylinders. -

Page 18: High Pressure And Low Pressure Switches

HIGH PRESSURE AND LOW PRESSURE The phase monitor in this unit is equipped with two LEDs. If the Y signal is present at the phase monitor SWITCHES and phases are correct, the green LED will light. All H**A/H**L wall mounted air conditioner series If phases are reversed, the red fault LED will be lit and models are supplied with a remote reset for the high compressor operation is inhibited. -

Page 19: Table 1 Sequence Of Operation

TABLE 1 Sequence of Operation Revision "2" Terminal Description Reference Compressor on Output Signal from Jade to MV Economizer Only "A" 24VAC HOT from Terminal 2 Connected to Unit Transformer 24V HOT "R" 24VAC COMMON from Unit Transformer to MV 24V COMMON "C"... -

Page 20: Pressure Service Ports

NOTE: Both high and low pressure switch controls are inherently automatic reset devices. The high pressure switch and low pressure switch cut out and cut in settings are fixed by specific air conditioner unit model. The lockout features, both soft and manual, are a function of the compressor control module. -

Page 21: Figure 8 Fan Blade Setting

SERVICE REMOVAL OF FAN SHROUD FAN BLADE SETTING DIMENSIONS 1. Disconnect all power to the unit. The correct fan blade setting for proper air delivery across the outdoor coil is shown in Figure 8. Refer to 2. Remove screws holding both grilles, one on each Table 2 for unit specific dimension. -

Page 22: Table 3 Cooling Pressure

TABLE 3 Cooling Pressure Air Temperature Entering Outdoor Coil °F Return Air Temp Model Pressure (DB/WB) Low Side 75/62 High Side Low Side H12A 80/67 High Side Low Side 85/72 High Side Low Side 75/62 High Side Low Side H24A/L 80/67 High Side Low Side... -

Page 23: Table 4A Electrical Specifications H**A Series

TABLE 4A Electrical Specifications H***A Series Single Circuit Multiple Circuit Minimum Maximum Circuit External Fuse or Field Power Ground No. Field Rated Volts Ampacity Circuit Breaker Wire Size Wire Size Maximum Field MODEL Power Minimum... -

Page 24: Table 4B Electrical Specifications H**L Series

TABLE 4B Electrical Specifications H***L Series Single Circuit Dual Circuit Minimum Maximum Circuit External Fuse or Field Power Ground No. Field Maximum Ampacity Circuit Breaker Wire Size Wire Size Rated Volts MODEL Power Minimum External... -

Page 25: Table 5 Recommended Airflow

TABLE 5 Recommended Airflow Nominal Nominal Recommended Factory Speed Model Rated Rated Airflow Range Connection CFM * ESP * H12A 360 - 530 Single H24A, H24L 700 - 950 Single H36A, H36L 1100 1000 - 1300 High H42A, H42L 1350 1250 - 1600 H48A, H48L 1550... -

Page 26: Table 8A H12 Electric Heat

TABLE 8A H12A Electric Heat 240V-1 208V-1 Models (KW) Amps BTUH Amps BTUH 15.0 12760 13.0 9705 20.8 17540 18.1 13275 TABLE 8B H24-72A/L Electric Heat 240V-1 208V-1 240V-3 208V-3 Models (KW) Amps BTUH Amps BTUH Amps BTUH Amps BTUH 15.0 12760 13.0... -

Page 27: Table 9 Optional Accessories

TABLE 9 Optional Accessories Right Hand Units Left Hand Units 901147-A03 EHWA02A-A05LB X 901147-A05 EHW02A-A08LB EHWA02-A05B EHWA02-A10LB EHW02A-A08B EHWA03-A05LB EHWA02A-A10B EHWA03-A10LB EHWA24-A04B EHWA03-A15LB EHWA03-A05B EHW4TA-A05L EHWA03-A08B EHW4TA-B03L Heater Kits EHWA03-A10B EHW4TA-B05L EHWA03-A15B EHWA05-A10LB EHW4TA-A05 EHWA05-A15LB Heater Kits EHW4TA-B03 EHW6TA-A05L EHW4TA-B05 EHW6TA-B03L EHWA05-A10B EHW6TA-B05L... -

Page 28: Table 10 Vent And Control Options

TABLE 10 Vent and Control Options Part Number Description CMC-14 CMC-15 Start Kit (230V 1-Phase) CMC-23 CMC-24 CMC-28 BOP-1A BOP-2 Blank Off Plate EWM1-E Economizer - Bldg. Equipment, Enthalpy EWM1-T Economizer - Bldg. Equipment, DB Temp. EWM2-E Economizer - Bldg. Equipment, Enthalpy EWM2-T Economizer - Bldg. -

Page 29: Chart - Mv Series Controller

TABLE 11 Unit Low Voltage Terminal Connection Chart – MV Series Controller Revision Terminal Description MV Terminal Connection "2" Reference Compressor on Output Signal from Jade to MV "A" on Relay Board "A" 24VAC HOT from Terminal 2 Connected to Unit Transformer to MV "R"... -

Page 30: Chart - Cooling/Heating Thermostat

TABLE 12 Unit Low Voltage Terminal Connection Chart – Cooling/Heating Thermostat Revision Terminal Description Thermostat Connection "2" Reference Compressor on Output Signal from Jade Not Used "A" 24VAC HOT from Terminal 2 Connected to Unit Transformer to Thermostat "R" on Tstat "R"... -

Page 31: Figure 9A H12Aa Wiring Diagram - Top

FIGURE 9A H12AA Wiring Diagram – Top Manual 2100-647D Page 31 of 36... -

Page 32: Figure 9B H24,36*A Wiring Diagram - Top

FIGURE 9B H24,36*A Wiring Diagram – Top Manual 2100-647D Page 32 of 36... -

Page 33: Figure 9C H42,48,60A Wiring Diagram - Top

FIGURE 9C H42,48,60*A Wiring Diagram – Top Manual 2100-647D Page 33 of 36... -

Page 34: Figure 9D H72*A Wiring Diagram - Top

FIGURE 9D H72*A Wiring Diagram – Top Blower Speed Plug Blower Power Plug Freeze Stat Manual 2100-647D Page 34 of 36... -

Page 35: Figure 10 H***A Wiring Diagram - Bottom

FIGURE 10 H***A Wiring Diagram – Bottom Manual 2100-647D Page 35 of 36... -

Page 36: Figure 11 H***A Low Voltage Diagram For Unit And Mv Connections

FIGURE 11 H***A Low Voltage Ladder Diagram for Unit and MV Connections Blk/Wht Filter Light Pin 6 on Vent Plug Low Voltage Pin 9 on Vent Plug Terminal Strip Controller Rd/W Bk/W R on Filter Red/Wht Compressor Switch Control Module Filter Reset Button Org/Blk Red/Wht...

Need help?

Do you have a question about the H42AA-B and is the answer not in the manual?

Questions and answers