Table of Contents

Advertisement

Westward Operating Instructions and Parts Manual

Operating Instructions and Parts Manual

Please read and save these instructions. Read through this owner's manual carefully before using product. Protect yourself and others by

Please read and save these instructions. Read through this owner's manual carefully before using product. Protect yourself and others by

observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage

observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage

to product or property. Please retain instructions for future reference.

Description

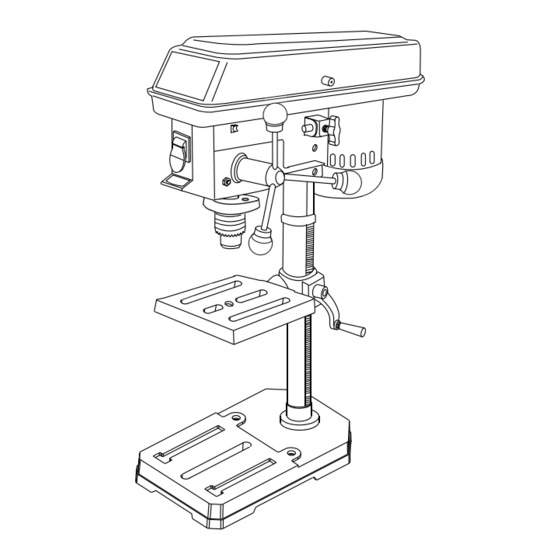

Westward Drill Press feature a heavy cast iron base, column collar, work table and head. Work table height is adjustable using rack

and pinion. Table can be tilted 45° both right and left, and rotates 360° on a vertical axis. Work table surface is precision ground

which features slots for secure, accurate mounting of workpiece and a coolant trough. Other features of the Westward drill press

are an enclosed ball bearing quill assembly, quick belt change and tension mechanism, positive quick-adjust feed depth stop. A

chuck and chuck arbor are included. Westward drill press are ideal for use in home shops, maintenance shops and light industrial

applications. Spindle speeds are adjustable for drilling steel, cast iron, aluminum, wood and plastic.

Unpacking

After unpacking unit, inspect carefully for any damage that may have occurred during transit. Check for loose, missing, or damaged

parts. The drill press is shipped partially assembled. Locate and identify the following assemblies and loose parts: head assembly,

base, column assembly, rack ring and table assembly. Contents of hardware bag includes: Drill chuck, chuck key, rack, feed handles,

worm gear, crank handle, lock handle, hex bolts, 3mm & 4mm hex wrenches and batteries.

IMPORTANT: Many unpainted steel surfaces, such as column and table top, have been coated with a protectant. To ensure proper

fi t and operation, remove coating. Coating is easily removed with mild solvents, such as mineral spirits, and a soft cloth. Avoid

getting solution on paint or any of the rubber or plastic parts. Solvents may deteriorate these fi nishes. Use soap and water on paint,

plastic or rubber components. After cleaning, cover all exposed surfaces with a light coating of oil. Paste wax is recommended for

table top.

WARNING

WARNING

!

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

If any part is missing or damaged, do not plug the drill press in until the missing or damaged part is

replaced, and assembly is complete. Carefully unpack the drill press and all its parts, and compare against the list below.

To protect the drill press from moisture, a protective coating has been applied to the machined surfaces. Remove this

coating with a soft cloth moistened with kerosene or WD-40.

To avoid fi re or toxic reaction, never use gasoline, naphtha, acetone, lacquer thinner or similar highly volatile solvents to

clean the drill press.

REX001

Printed in China

09/06

10",12" Drill Presses

10",12" Drill Presses

1

1KEN3, 1KEN4

1KEN3, 1KEN4

Advertisement

Table of Contents

Need help?

Do you have a question about the 1KEN3 and is the answer not in the manual?

Questions and answers