Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for North Star 10000 BDG

- Page 1 MODEL 10000 BDG ITEM # 165928 Belt Driven Generator P r o v e n P e r f o r m a n c e M165928A OWNER’S MANUAL 00287 10000 BDG Any Questions, Comments, or Problems? Call Customer Service at 1-800-270-0810...

-

Page 2: Table Of Contents

Thank you for purchasing a NorthStar Belt Driven Generator. Your machine is designed for long life, dependability, and the top performance you demand. Please take time now to read through this manual so you can better understand the machine’s operation, maintenance and safety precautions. -

Page 3: Specifications

SPECIFICATIONS Item Number Ma ximum Output Continuous Output Voltage Phase Frequency Power Factor Minimum Recommended Engine Engine Speed 120V Receptacle 120/240V Receptacle Circuit Breaker Drive Shaft Dimensions Length Width Height Gross Weight #165928 10000 Watts (W) 9600 Watts (W) 120 / 240 Volt (V) Single phase (4-wire) 58.0-63.0 Hertz (H z) 1.0 p.f. -

Page 4: Machine Component Identification

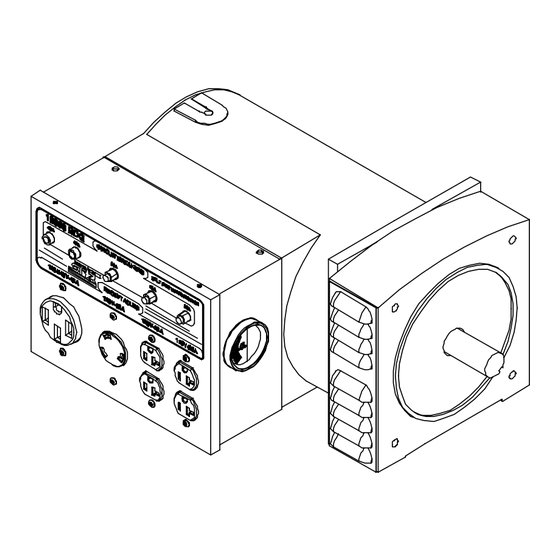

MACHINE COMPONENT IDENTIFICATION Ref. Description 40A Circuit Breakers 30A Circuit Breaker 20A Circuit Breakers Voltmeter 120V 20A Duplex Receptacles 120V 30A Twistlock Receptacle Figure 1 (Ref. 1-7) Ref. Description 120/240V 50A Receptacle 28 mm shaft Grounding screw Mounting feet Fan vents Figure 2 (Ref. -

Page 5: Generator Features

GENERATOR FEATURES References 1-3 Circuit Breakers. • Reference 1 - two 40 amp (A) push-to-reset circuit breakers. • Reference 2 - one 30 amp (A) push-to-reset circuit breaker. • Reference 3 - two 20 amp (A) push-to-reset circuit breakers. Reference 4 - Voltmeter. should be in green area during all generator load conditions. -

Page 6: Installation

ALWAYS remove the spark plug or spark plug wire before working on the engine or generator, this prevents accidental starting. ALWAYS provide adequate ventilation. Do not operate generator in any enclosed or narrow space. Engines consume oxygen and give off deadly carbon monoxide, a poisonous gas. -

Page 7: Installation

Tighten or loosen belt until: d = 0.016 X L If the control box is not located on the correct side for your application, it can be rotated to the opposite side. First remove the fan vents, than remove the four drive end bracket bolts. Rotate the drive end bracket 180°, re-torque bolts to 17 ft•lb. -

Page 8: Extension Cords

The figures given above are for an average load such as a blower or fan. If the electric motor is connected to a hard starting load such as an air compressor, it will require more starting current. If it is connected to a light load or no load such as a power saw, it will require less starting current. -

Page 9: Operating Speed

GROUNDING - All units must be grounded. Drive a 3/4” or 1” copper pipe or rod into the ground close to the generator. The pipe/rod must penetrate moist earth. Connect an approved ground clamp to the pipe. Run a 10 gauge wire from the clamp to the generator ground screw. -

Page 10: Troubleshooting

TROUBLESHOOTING Problem Possible Causes Voltage too low. a) Engine speed too slow. b) Generator is overloaded. c) Belt slippage. (or coupler slippage) Circuit breaker trips. a) Defective load connected to generator. b) Defective receptacle. c) Generator overloaded. Voltage too high. a) Engine speed too high.

Need help?

Do you have a question about the 10000 BDG and is the answer not in the manual?

Questions and answers