Table of Contents

Advertisement

Quick Links

R

K

AIL

ING

®

By MTH Electric Trains

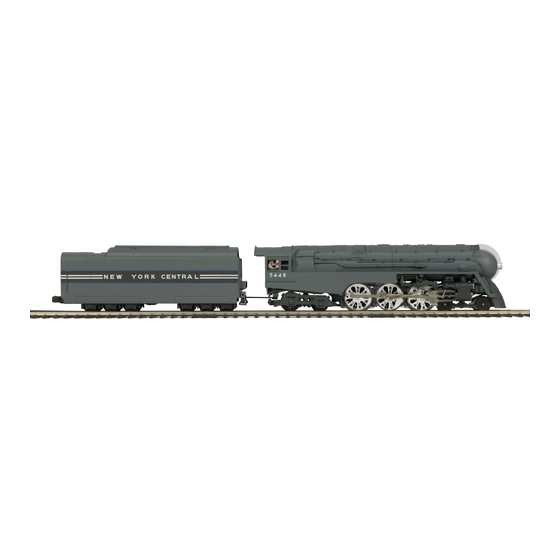

NYC Dreyfuss 4-6-4

STREAMLINED STEAM ENGINE

OPERATING INSTRUCTIONS

Thank you for purchasing the RailKing Die-Cast NYC Dreyfuss 4-6-4 steam engine. The

engine's die-cast body and tender are traditionally sized for operation on any O-27 layout.

The engine is compatible with any standard AC transformer, (see page 25 for a complete

list of compatible transformers and wiring instructions), and is completely compatible with

most 3-rail locomotives, rolling stock and accessories.

The locomotive and tender are equipped with either an electronic whistle or the

ProtoSound Digital Sound and Train Control System which contains several deluxe

features that are simple and fun to operate. Each feature is described among the following

pages which should be read before the engine is operated. For those of you who can't wait

to get started, the Quick Start Operating Instructions found on Page 3 should be read so

that you understand the basics of the operating system. Please note that some features

are only found in the ProtoSound equipped engines and are marked as such. Features not

marked as ProtoSound are available in both versions.

Advertisement

Table of Contents

Summary of Contents for Rail King NYC Dreyfuss 4-6-4

- Page 1 STREAMLINED STEAM ENGINE OPERATING INSTRUCTIONS Thank you for purchasing the RailKing Die-Cast NYC Dreyfuss 4-6-4 steam engine. The engine’s die-cast body and tender are traditionally sized for operation on any O-27 layout. The engine is compatible with any standard AC transformer, (see page 25 for a complete list of compatible transformers and wiring instructions), and is completely compatible with most 3-rail locomotives, rolling stock and accessories.

-

Page 2: Table Of Contents

Table Of Contents QUICK START - BASIC OPERATION (All Models) SMOKE UNIT OPERATION PROTOSOUNDS™ OPERATING INSTRUCTIONS DCRU™ REVERSE UNIT OPERATION (All Models) WHISTLE OPERATION BELL OPERATION SQUEAKING BRAKE SOUNDS ACTIVATING AND TRIGGERING THE SQUEAKING BRAKE SOUNDS TIPS ON USING THE SQUEAKING BRAKE FEATURE PASSENGER STATION PROTO-EFFECTS™... -

Page 3: Quick Start - Basic Operation (All Models)

QUICK START - BASIC OPERATION The RailKing NYC Dreyfuss contains state-of-the-art electronics with several built-in automatic features for incredibly realistic operation. Despite these advanced features, the Dreyfuss is easy to operate with any compatible standard AC transformer. (See the compatiblity chart on page 25) All models are equipped with an operating smoke system that must be primed with smoke fluid before operating. -

Page 4: Smoke Unit Operation

SMOKE UNIT OPERATION The Dreyfuss contains a self-powered smoke unit that outputs a steady stream of smoke through the smoke stack. The ON/OFF switch located under the right side of the locomotive cab must be in the ON position in order for the smoke unit to function. See Fig. 2. The smoke unit is essentially a small Smoke Unit On/Off Switch... -

Page 5: Protosounds™ Operating Instructions

occurs, we recommend that you inspect and/or replace the wick taking care to not run the engine without fluid in the future. You can inspect the wick to see if it needs replacement by removing the smoke unit inspection cover as seen in Fig. 4. After removing the screws lift the inspection plate away and inspect the wick. -

Page 6: Dcru Reverse Unit Operation (All Models)

DCRU REVERSE UNIT OPERATION (All Models) As mentioned in the Basic Operating section, the engine is controlled by a DCRU reverse unit that contains the standard forward-neutral-reverse states found on most reverse units. However, as described earlier, when power is first applied to the track, the reverse unit begins in RESET or what seems like a neutral state. -

Page 7: Whistle Operation

DCRU MANUAL LOCKOUT (Engines w/o ProtoSound) Engines not equipped with ProtoSounds can be manually locked into Forward, Neutral or Reverse by sliding the lockout switch to the “OFF” position after entering the desired reverse unit state (See Figure 7 on page 14). To operate the engine in automatic mode again, simply slide the switch back to the “ON”... -

Page 8: Squeaking Brake Sounds

SQUEAKING BRAKE SOUNDS ProtoSounds is now equipped with operator controlled squeaking brake sounds. Once activated, this easy to use feature plays the sound of squeaking brakes whenever the transformer throttle is reduced from high voltage to low voltage simulating the application of the brakes as you enter curves or slow down for crossings and passenger stations. -

Page 9: Tips On Using The Squeaking Brake Feature

Note: Once the brake feature is activated and the engine is running, it is possible that the brake sounds may not occur if the transformer throttle setting is not set high enough before throttling down. We recommend that after activating the brake feature, you run the engine at no less than 14 volts before throttling down to approximately 8 volts or less to ensure that the brake sounds occur. -

Page 10: Activating And Triggering Passenger Station Sounds

sounds, conductor voices and general train station ambient sounds. Each is described in more detail in the following sections. ACTIVATING AND TRIGGERING PASSENGER STATION ANNOUNCEMENTS Before PFA can be heard the feature must be activated first. Activation is accomplished by holding down the bell button for three or more seconds as described in the Activating and Triggering The Squeaking Brake Sounds section found earlier on page 8. - Page 11 The operator now interrupts the transformer throttle again to enter Event 3 (Reverse) the next reverse unit phase; reverse. In an effort to enhance realism, PFA has disabled the reverse phase so that it doesn’t power the motors and cause the engine to move backward.

-

Page 12: Tips On Using The Fys Features

TIPS ON USING THE PFA FEATURES PFA is a unique feature of ProtoSounds that is completely controlled by the operator. You decide how, when or if you want to utilize the feature. By reviewing following tips you should find solutions or suggestions to the various operating scenarios you might encounter when using PFA. -

Page 13: Optional Proto-Coupler Operation

OPTIONAL PROTO-COUPLER OPERATION Your Dreyfuss locomotive can be upgraded with coil-wound ProtoCouplers™ which can be mounted on the tender and locomotive for remote controlled coupler operation. (See your MTH or RailKing dealer) Because it is controlled through ProtoSound’s microprocessor, it doesn’t require an uncoupling track section or modification to your layout to function. -

Page 14: Replacing The Protosound Battery

REPLACING THE PROTOSOUND BATTERY The battery, located in the engine’s tender (see Figure 10 on page 20 for the location of the tender mounting screws), is a rechargeable NiCad type which is continually charged from the track when power is applied. NiCad batteries are a dry battery and should not leak or cause any damage to your locomotive and will last up to five years or longer. -

Page 15: Using "Reset" To Program Protosounds

USING “RESET” TO PROGRAM PROTOSOUNDS™ As mentioned earlier, there are several programmable options in each ProtoSound-equipped engine that can be remotely set from any compatible standard transformer equipped with a whistle button. For a list of compatible transformers, see the chart on page 25. -

Page 16: Programming For A Separate Bell Button Controller

50% steam chuffing volume, pushing it a third time will give you 25% steam chuffing volume and pushing it a fourth time will give you no steam chuffing sounds. The microprocessor will immediately play the sound level each time the whistle button is pushed so that you can decide if it is acceptable. -

Page 17: Programming For Optional Protocoupler Operation

repeat the above procedure but keep pressing the whistle button in Feature 25 until ProtoSounds only dings once instead of twice. Note: If you didn’t set the “Separate Bell Button Operation" in Feature 20 before setting the “Whistle In Neutral" option, then your bell will not function until you set the “Separate Bell Button"... -

Page 18: Activating Remote Lock-Out Control

ProtoSound equipped engines feature a RESET setting that allows the operator to remotely “lock” the engine into forward, neutral or reverse. This is especially useful on layouts that feature “blocked” track sections. The lockout feature comes from the factory in the OFF position, meaning it is not active when you first take the engine out of the box. -

Page 19: Reverse Unit Lock-Out Operation

REVERSE UNIT LOCK-OUT OPERATION ProtoSound’s unique design eliminates the need for a lock-out switch on the locomotive by allowing the customer to lock the engine into any directional state (forward, neutral or reverse) from the transformer. This will allow users to run the engine on layouts equipped with block signals or stop stations which would normally cycle the engine back into neutral. -

Page 20: Oil & Lubrication Instructions

OIL & LUBRICATION INSTRUCTIONS In order for the engine to perform correctly and quietly, it is important that both the locomotive and tender be lubricated before operation. Lubrication should include all side-rods and linkage components to prevent them from squeaking. Use light household FrontChassis MountingScrews G-(Grease) -

Page 21: Traction Tire Replacement Instructions

TRACTION TIRE REPLACEMENT INSTRUCTIONS Your Dreyfuss locomotive is equipped with two neoprene rubber traction tires. While these tires are extremely durable and long-lasting there may arise a time where they will need to be replaced. Should this occur, you will need to remove the main side rod on the 6-wheel drive train in order to slip the new tire over the wheel. -

Page 22: Trouble Shooting Protosound™ Problems

TROUBLE SHOOTING PROTOSOUND™ PROBLEMS Although ProtoSounds has been designed and engineered for ease of use, some questions may arise during initial operation. The following table should answer most questions. If you find that your problem can’t be resolved with this manual, contact MTH ProtoSound Electronics (9693-A Gerwig Lane, Columbia, MD 21046) for additional assistance. - Page 23 LOCK-OUT PROBLEMS REMEDY I can't get the engine to run after I The engine is Locked-Out into the neutral position. Follow the unlocking procedure power up the transformer. It sits still on page 19. with the steam compressor running. The engine won't lockout into You are waiting too long to turn the throttle back on after the short whistle blast Forward, Neutral or Reverse even sounds.

- Page 24 REMEDY BRAKE SOUND PROBLEMS When the transformer is throttled The brake feature has not been activated. See page 6 for information on down, the brake sounds won't play. activating the brake sound feature. The throttle voltage setting on the transformer is either not starting high enough or ending low enough to trigger the brake sounds.

-

Page 25: Transformer Compatibility And Wiring Chart

TRANSFORMER COMPATIBILITY AND WIRING CHART ProtoSounds™ is designed to work with any “Standard” AC transformer that uses a “Pure Sine-Wave” format. The chart below lists the many Lionel® compatible transformers, such as the Lionel KW and ZW models. In addition, the chart details how the terminals on these compatible transformers should be attached to your layout. -

Page 26: Protosound Reset Feature Chart

PROTOSOUND RESET FEATURE CHART The following chart lists the available features found in your ProtoSound equipped engine. The default settings are listed for each feature as well as the operation of the feature. You can reset all features to their original factory settings by accessing Feature 18 in RESET RESET # OPERATION DEFAULT SETTING... -

Page 27: Service And Warranty Information

SERVICE AND WARRANTY INFORMATION HOW TO GET SERVICE UNDER THE TERMS OF THE LIMITED ONE YEAR WARRANTY For warranty repair, do not return your product to the place of purchase. Instead, follow the instructions below to obtain warranty service as our dealer network is not prepared to service the product under the terms of this warranty.

Need help?

Do you have a question about the NYC Dreyfuss 4-6-4 and is the answer not in the manual?

Questions and answers