Table of Contents

Advertisement

Operator's Manual

COOL ARC

WATER COOLER

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10117-A

| Issue D ate Mar-15

© Lincoln Global, Inc. All Rights Reserved.

®

55 & COOL ARC

®

55 ALUMINUM

For use with machines having Code Numbers:

11859, 12377

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric COOL ARC 55

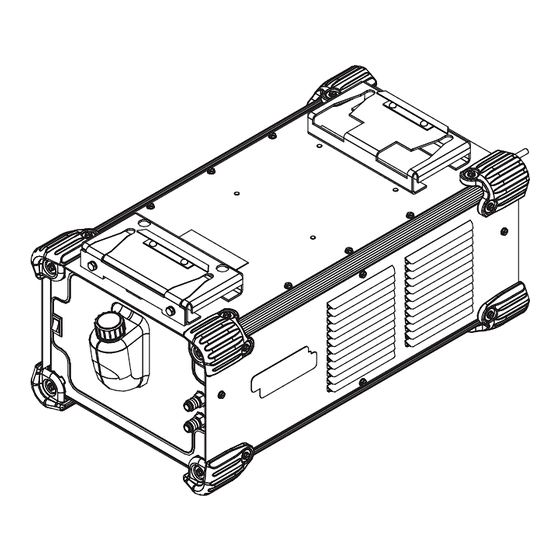

- Page 1 Operator’s Manual ® ® COOL ARC 55 & COOL ARC 55 ALUMINUM WATER COOLER For use with machines having Code Numbers: 11859, 12377 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10117-A | Issue D ate Mar-15...

-

Page 2: Safety Precautions

THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. Use LINCOLN ELEC TRIC. corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Material Safety PLEASE EXAMINE CARTON AND EQUIPMENT FOR DAMAGE Data Sheet (MSDS) and the warning IMMEDIATELY... - Page 3 American Welding Society, P.O. Box 351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” ELECTRIC AND booklet E205 is available from the Lincoln Electric Company, 22801 MAGNETIC FIELDS MAY St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER TABLE OF CONTENTS Page Installation..........................Section A Technical Specifications.......................A-1 Safety Precautions ........................A-2 Unpacking the COOL ARC ® 55 ....................A-2 Installation on Power Source ....................A-2 Location and Mounting ......................A-2 Filling the Coolant Reservoir ....................A-3 Coolant “In”... -

Page 7: Installation

NOT used. Lincoln Electric Low Conductivity Coolant For Use Below Freezing: 50% water and 50% pure ethylene may be used in MIG and TIG systems glycol (reagent or industrial grade) (but NOT aluminum push-pull) where mixture. -

Page 8: Safety Precautions

55 can be used as a stand alone unit or mounted directly to the bottom of the Power Wave “S” series power source. Always place the Cool Arc 55 on a level surface to avoid causing the machine to topple over. -

Page 9: Filling The Coolant Reservoir

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER INSTALLATION FILLING THE COOLANT RESERVOIR: CAUTION Recommended Coolant • For Use Above Freezing: Clean tap, distilled or de-ionized DO NOT USE OIL BASED COOLANTS OR COOLANTS THAT CONTAIN RUST water. -

Page 10: Coolant "In" And "Out" Connections

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER INSTALLATION COOLANT "IN" AND "OUT" CONNECTIONS INPUT POWER CONNECTION The fittings located on the COOL ARC ® 55 are two female Quick Plug the input power cord on the COOL ARC ®... -

Page 11: Installation Of Water Cooled Accessories

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER INSTALLATION INSTALLATION OF WATER COOLED ACCESSORIES After following the installation instructions above, the COOL ARC ® 55 is ready for connection to a water-cooled accessory. K529-10 POWER INPUT CABLE WITH WATER AND GAS HOSES This cable assembly includes a (1) power cable, (1) control WATER COOLED TIG TORCH AND MIG GUN cable, (1) gas hose and (2) water hoses to connect a power... -

Page 12: Operation

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER OPERATION SAFETY PRECAUTIONS RECOMMENDED PROCESSES AND EQUIPMENT Recommended Processes, Equipment and Accessories. The WARNING COOL ARC ® 55 is designed for use with water-cooled TIG, MIG, PAC (Plasma Arc Cutting) and PAW (Plasma Arc Welding) guns ELECTRIC SHOCK and torches. -

Page 13: Cooling Efficiency

• Do not operate cooler without coolant in reservoir. Never run pump dry. FIGURE B.1 Coolant Circulation Diagram ROOM AIR IN HEAT EXCHANGER PUMP RESERVOIR FIGURE B.2 WELDING GUN OR TORCH COOLANT OUT COOLANT IN HEAT IN PUMP HEAT HEAT EXCHANGER RESERVOIR COOL ARC 55... -

Page 14: Accessories

MIG or TIG hook-up kits provided by disconnect on the other. Most wire feeders have female quick Lincoln Electric. Refer to Magnum accessory literature sheets. disconnects and this kit allows direct hook up between the water cooler and the wire feeder. -

Page 15: Maintenance

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER MAINTENANCE SAFETY PRECAUTIONS PUMP MAINTENANCE WARNING The pump head has a "built in" strainer on the inlet side of the pump. It is recommended to clean or replace the pump's inlet strainer at least Have qualified personnel do the maintenance work. -

Page 16: Coolant Treatment Recommendation

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER MAINTENANCE COOLANT TREATMENT RECOMMENDATION PUMP INLET STRAINER This procedure is intended to provide a means of reducing the objectionable amount of fungal and bacterial contamination that Poor cooler performance can usually be traced to a partially or has occurred in COOL ARC ®... -

Page 17: Service The Pump Inlet Strainer

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER MAINTENANCE Removing Coolant: Add coolant: a. Drain coolant from the reservoir using clean siphoning a. Add 2.375 gallons of coolant, either the recommendations off equipment the water cooled accessory or if none, see the design speci- b. -

Page 18: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 19 COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Cooler does not operate with power switch 1. Input cord unplugged. "ON".

- Page 20 COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER DIAGRAMS...

- Page 21 COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER DIAGRAMS...

- Page 22 COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER NOTES...

- Page 23 COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM WATER COOLER NOTES...

- Page 24 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the COOL ARC 55 and is the answer not in the manual?

Questions and answers