Summary of Contents for Miller Electric S-32SL

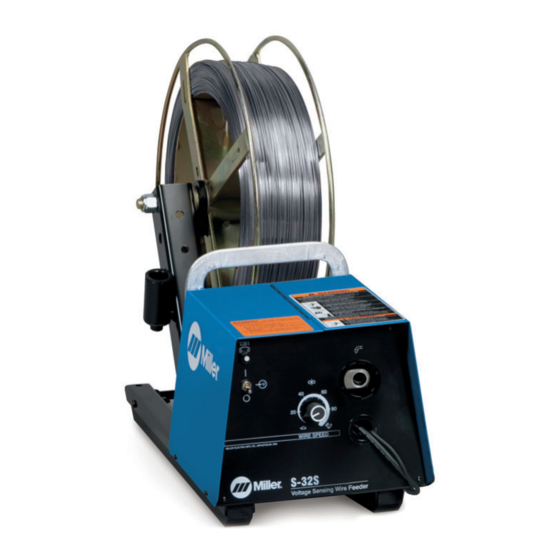

- Page 1 S-32S And S-32SL Visit our website at www.MillerWelds.com OM-1546 090 004M August 2000 Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding Description Wire Feeder...

- Page 2 ISO 9001 Quality System Standard. service information for your particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual catalog sheets.

-

Page 3: Table Of Contents

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage 1-2. Arc Welding Hazards 1-3. Additional Symbols for Installation, Operation, and Maintenance WARNING 1-4. Principal Safety Standards 1-5. EMF Information This product, when used SECTION 1 – CONSIGNES DE SECURITE – LIRE AVANT UTILISATION for welding or cutting, 1-1. -

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. Y Marks a special safety message. Means “Note”; not safety related. 1-2. - Page 6 D Do not use welder to thaw frozen pipes. D Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. D Do not install or place unit on, over, or near combustible surfaces. D Do not install unit near flammables. D Do not overload building wiring – be sure power supply system is properly sized, rated, and protected to handle this unit. -

Page 8: Emf Information

1-5. EMF Information Considerations About Welding And The Effects Of Low Frequency Electric And Magnetic Fields Welding current, as it flows through welding cables, will cause electro- magnetic fields. There has been and still is some concern about such fields. However, after examining more than 500 studies spanning 17 years of research, a special blue ribbon committee of the National Research Council concluded that: “The body of evidence, in the committee’... -

Page 9: Section 1 - Consignes De Securite - Lire Avant Utilisation

SECTION 1 – CONSIGNES DE SECURITE – LIRE AVANT 1-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure présente des risques de danger ! Ceux-ci sont identifiés par des symboles adjacents aux directives. Y Identifie un message de sécurité particulier. Signifie NOTA ;... - Page 10 LES RAYONS DE L’ARC peuvent pro- voquer des brûlures dans les yeux et sur la peau. Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles intenses (ultraviolets et infrarouges) susceptibles de provoquer des brûlures dans les yeux et sur la peau. Des étincelles sont projetées pendant le soudage.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

1-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance Risque D’INCENDIE OU D’EXPLOSION. D Ne pas placer l’appareil sur, au-dessus ou à proxi- mité de surfaces infllammables. D Ne pas installer l’appareil à proximité de produits inflammables D Ne pas surcharger l’installation électrique –... -

Page 12: Principales Normes De Sécurité

1-4. Principales normes de sécurité Safety in Welding and Cutting, norme ANSI Z49.1, de l’American Wel- ding Society, 550 N.W. Lejeune Rd, Miami FL 33126 Safety and Health Sandards, OSHA 29 CFR 1910, du Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402. -

Page 13: Section 2 - Installation

SECTION 2 – INSTALLATION 2-1. Specifications Welding Wire Feed Type Of Power Speed Input Power Source Type Range Standard: 50 To 700 ipm (1.3 To 18 Constant mpm) Open-Circuit/ Voltage (CV) Arc Voltage, Low Speed: Or Constant 25 To 325 ipm 15 To 100 Current (CC) (0.6 To 8.2... -

Page 14: Installing And Aligning Wire Guide And Drive Roll

2-2. Installing And Aligning Wire Guide And Drive Roll Tools Needed: 3/16 in 3/8 in OM-1546 Page 10 Ref. ST-091 547-D / Ref. ST-112 370-C / S-0856 When changing wire size or type, check drive roll and wire guide size (see Parts List). -

Page 15: Typical Connections

2-3. Typical Connections 2-4. Connecting Welding Gun, Volt Sense Lead, And Weld Cable Tools Needed: 9/16 in CV Welding Power Source With 24 VAC Power CC Welding Power Source Without Contactor External Secondary Contactor Remote Contactor Cord Weld Cable Work Gun Securing Knob Gun Block Gun Outlet Wire Guide... -

Page 16: Connecting Shielding Gas (Optional)

2-5. Connecting Shielding Gas (Optional) Tools Needed: 5/8 in 2-6. Installing Welding Wire And Adjusting Hub Tension Tools Needed: 15/16 in OM-1546 Page 12 Gas Hose With 5/8-18 Right- hand Thread Fittings (Cus- tomer Supplied) Ref. ST-158 789 Retaining Ring Wire Spool Spool Support If necessary, move hub on support... -

Page 17: Threading Welding Wire

2-7. Threading Welding Wire Tighten WOOD Pressure Assembly Adjust- ment Knob Lay gun cable out straight. Open pressure assembly, hold wire tightly, and cut off end. Push wire through guides into gun. Close and tighten pressure assembly. Press gun trig- ger until wire comes out gun. -

Page 18: Section 3 - Operation

SECTION 3 – OPERATION 3-1. Controls OM-1546 Page 14 Selector Switch for Type of Power Source Constant Voltage Constant Current (drooper) CC Wire Speed Control (See Sec- tion 3-2) Power Control Switch Circuit Breaker CB1 CB1 protects wire feeder from over- load. -

Page 19: Wire Speed Control Settings

INCHES PER MINUTE* *Rounded off Wire Speed Setting CC Mode INCHES PER MINUTE* *Rounded off S-32S Models Voltage S-32SL Models Voltage Wire Speed Setting CV Mode INCHES PER MINUTE* Wire Speed Setting CV Mode 105 116 128 140 INCHES PER MINUTE*... -

Page 20: Section 4 - Maintenance & Troubleshooting

SECTION 4 – MAINTENANCE & TROUBLESHOOTING 4-1. Routine Maintenance Replace Unreadable Labels Gun Cable 4-2. Troubleshooting Trouble Wire does not feed; open-circuit voltage Check circuit breaker CB1 and reset (see Section 3-1). available. Check sensing lead connection. Check gun trigger plug connection. Check gun trigger. -

Page 21: Section 5 - Electrical Diagram

SECTION 5 – ELECTRICAL DIAGRAM SB-176 227 Figure 5-1. Circuit Diagram For Wire Feeder OM-1546 Page 17... -

Page 22: Section 6 - Parts List

SECTION 6 – PARTS LIST Hardware is common and not available unless listed. ST-091 506-K Figure 6-1. Main Assembly OM-1546 Page 18... - Page 23 Item Dia. Part Mkgs....097 770 ....+089 818 ....134 464 .

- Page 24 ........MOTOR, 24VDC 2.2A 119RPM (S-32S model) (consisting of) MOTOR, 24VDC 2.2A 54RPM (S-32SL model) (consisting of) ..

- Page 25 NOTE Base selection of drive rolls upon the following recommended usages: 1. V-Grooved rolls for hard wire. 2. U-Grooved rolls for soft and soft shelled cored wires. 3. U-Cogged rolls for extremely soft shelled wires (usually hard surfacing types). 4. V-Knurled rolls for hard shelled cored wires. 5.

- Page 26 Notes OM-1546 Page 22...

- Page 27 Warranty Questions? Call LIMITED WARRANTY – Subject to the terms and conditions below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants 1-800-4-A-MILLER to its original retail purchaser that new Miller equipment sold for your local after the effective date of this limited warranty is free of defects in material and workmanship at the time it is shipped by Miller.

- Page 28 Parts) Circuit Diagrams Welding Process Handbooks File a claim for loss or damage during shipment. 2000 Miller Electric Mfg. Co. 6/00 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters–USA USA Phone: 920-735-4505 Auto-Attended USA &...

Need help?

Do you have a question about the S-32SL and is the answer not in the manual?

Questions and answers