Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

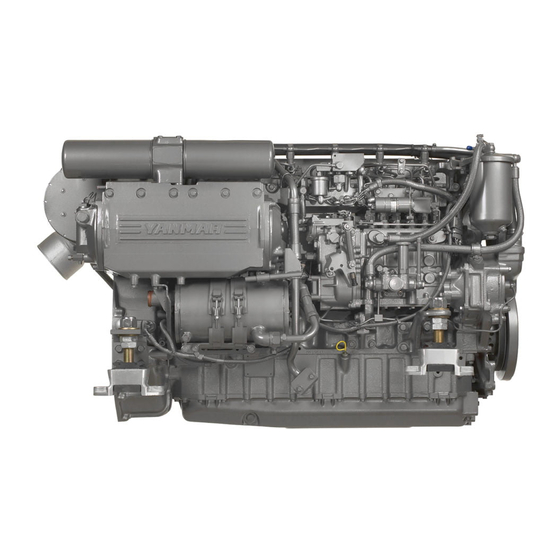

Summary of Contents for Yanmar 6LY2-STE

- Page 1 HINSI-H8-011-1 SERVICE MANUAL MARINE DIESEL ENGINE 6LY2-STE 6LY2A-STP 6LYA-STP...

Need help?

Do you have a question about the 6LY2-STE and is the answer not in the manual?

Questions and answers