Troy-Bilt Storm 7524 Operator's Manual

Snow thrower

Hide thumbs

Also See for Storm 7524:

- Operator's manual (28 pages) ,

- Operator's manual (27 pages) ,

- Operator's manual (28 pages)

Table of Contents

Advertisement

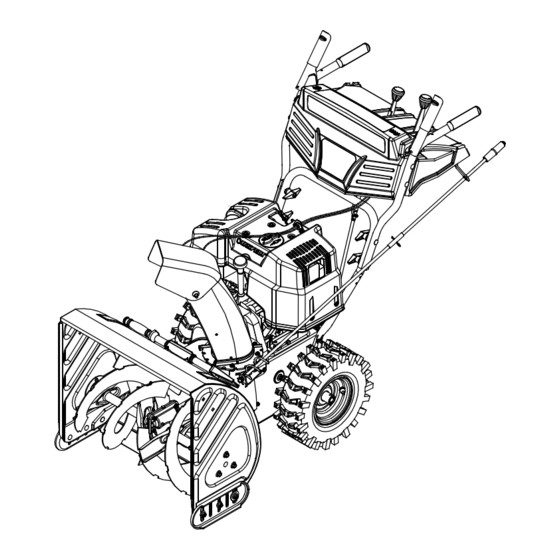

Operator's Manual

Storm

Snow Thrower

Models

7524 & 8526

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTED IN U.S.A.

. 769-00394B.fm

FORM NO

(6/2003)

Advertisement

Table of Contents

Summary of Contents for Troy-Bilt Storm 7524

-

Page 1: Snow Thrower

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019. TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 PRINTED IN U.S.A. -

Page 2: Table Of Contents

. A sample model plate is explained below. For future reference, please copy the model number and the serial number of the equipment in the space below. Copy the model number here: TROY-BILT LLC Copy the serial number here: P. O. BOX 3 6 1 1 3 1 www.troybilt.com... -

Page 3: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 Never run an engine indoors or in a poorly ventilated telephone 1-866-840-6483 for assistance and the name area. Engine exhaust contains carbon monoxide, an of your nearest servicing dealer. odorless and deadly gas. Maintenance & Storage Do not operate machine while under the influence of Never tamper with safety devices.

-

Page 5: Assembling Your Snow Thrower

SECTION 2: ASSEMBLING YOUR SNOW THROWER Unpacking roller guides. Make sure the spring (found at the end of each cable) is attached to its actuator • Remove staples from the top, sides, and ends of bracket. the shipping crate. • Secure the upper handle and lower handle with the •... -

Page 6: Final Adjustments

NOTE: If the tire pressure is not equal in all tires, the unit may pull to one side or the other. Cable Guide Cable WARNING: Maximum tire pressure under any circumstance is 30 psi. Equal tire pressure should be maintained at all times. Excessive pressure (over 30 psi) when seating beads may cause tire/rim assembly to burst with force sufficient to cause serious injury. -

Page 7: Know Your Snow Thrower

If the auger shows any signs of rotating, IMPORTANT: Auger immediately return to the operator’s position and shut Control off the engine. Wait for all moving parts to stop before readjusting the auger control cable. • To readjust the control cable, loosen the hex jam nut on the auger control cable “Z”... -

Page 8: Operating Your Snow Thrower

Always release the traction control before IMPORTANT: Chute Tilt Control changing speeds. The distance snow is thrown can be Auger Control changed by adjusting the angle of the The auger control is located on the left chute assembly. Move chute tilt control handle. -

Page 9: Operating Tips

To Stop Engine • Make certain the auger and drive clutch levers are in the disengaged (released) position. • Run engine for a few minutes before stopping to • Move throttle control up to FAST position. help dry off any moisture on the engine. •... -

Page 10: Making Adjustments

• Use the shovel-shaped end of the clean-out tool to WARNING: The temperature of the muffler remove any snow and ice in the discharge chute. ° • Re-fasten the clean-out tool to the mounting clip on and the surrounding areas may exceed 150 the rear of the auger housing and restart engine. -

Page 11: Skid Shoe

Skid Shoe • Tip the snow thrower forward, allowing it to rest on the auger housing. See Figure 9. The space between the shave plate and the ground can Frame Cover be adjusted by raising or lowering the skid shoes. For close snow removal, as when using on a smooth concrete or asphalt driveway, place the skid shoes in the low position. -

Page 12: Maintaining Your Snow Thrower

SECTION 6: MAINTAINING YOUR SNOW THROWER WARNING: Vent Plug Before lubricating, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come Shear Bolts to a complete stop. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting. -

Page 13: Servicing Your Snow Thrower

excessive wear, cracks, or loose fit on the friction wheel drive hub. Handle Panel • Also engage the traction control and check if the friction wheel is making contact with friction plate. Refer to Figure 10. If it does not make contact, adjust the traction drive cable and recheck the friction wheel. -

Page 14: Belt Replacement

• To remove the shave plate, remove the carriage bolts, belleville washers and hex nuts which attach Friction Wheel the shave plate to the snow thrower housing.See Figure 15. • Reassemble the new shave plate, with heads of carriage bolts to the inside of the housing. Tighten securely. -

Page 15: Off-Season Storage

Changing Friction Wheel Rubber • Lightly tap the hex nut to dislodge the ball bearing from the right side of frame. Remove the hex nut and The rubber on the friction wheel is subject to wear and bell washer from left end of shaft. should be checked after 25 hours of operation, and •... -

Page 16: Troubleshooting

SECTION 9: TROUBLESHOOTING Problem Cause Remedy Engine fails to start. Fuel tank empty, or stale fuel. Fill tank with fresh gasoline. Blocked fuel line. Clean the fuel line. Choke not in ON position Move switch to ON position Faulty spark plug. Clean, adjust gap or replace. -

Page 17: Parts List

SECTION 10: PARTS LIST FOR MODELS STORM 7524 & STORM 8526 32 20 Ref. No. Part No. Part Description Ref. No. Part No. Part Description 731-2635 Mount, Chute Clean-out Tool 712-0798 Hex Nut 3/8-16 731-2643 Chute Clean-out Tool 712-3068 Hex Nut 5/16-18 684-04002 26”... - Page 18 Models Storm 7524 & Storm 8526 Drive Clutch Cable Auger Clutch Cable Auger Clutch Cable...

- Page 19 Models Storm 7524 & Storm 8526 Ref. No. Part No. Part Description Ref. No. Part No. Part Description 710-1652 TT Screw, 1/4-20 x .625 715-0249 Roll Pin 784-5688 Drive Cable Guide Bracket 714-0143 Klik Pin 684-0042C Friction Wheel Assembly 784-5687A...

- Page 20 Models Storm 7524 & Storm 8526...

- Page 21 Models Storm 7524 & Storm 8526 Ref. Ref. Part No. Part Description Part No. Part Description 736-0451 Saddle Washer 731-04067 Handle Panel (8526) 731-04059 Handle Panel (7524) 720-0284 Knob 710-1003 Special B Screw (8526) 710-0449 Carriage Screw 5/16-18, Gr. 5...

- Page 22 Models Storm 7524 & Storm 8526 Ref. Part No. Description Ref. Part No. Description 05896A Idler Brkt. 748-0360 Pulley Adapter 710-1245B Hex Hd. Cap Screw 5/16-24 Thd. 754-0346 V-Belt 3/8 710-0230 Hex Hd. Cap Screw 1/4-28 Thd. 754-0430B Belt 710-0627 Hex Hd.

- Page 23 Models Storm 7524 & Storm 8526 Ref. Part No. Description 710-04071 Carriage Screw 710-0262 Carriage Bolt 5/16-18 x 1.75” 710-0805 Hex Bolt 5/16-18 x 1.5” 710-0895 HiLo Screw 1/4-15 x .75” 710-3015 Hex Screw 1/4-20 x .75” 712-0429 Hex Lock Nut...

- Page 24 Model Storm 7524 Ref. Part No. Description 618-0414A Auger Gearbox Ass’y Comp. 618-0123 Housing Assembly, RH 618-0418 Housing Assembly, LH 710-0642 Screw, 1/4-20 x .75 711-0908A 24” Auger Axle 714-0161 Hi-Pro Key 715-0143 Spirol Pin 717-0526 Worm Shaft .75 O.D.

- Page 25 Model Storm 8526 Ref. Part No. Description 618-0415A Auger Gearbox Ass’y Comp. 618-0123 Housing Assembly, RH 618-0418 Housing Assembly, LH 710-0642 Screw, 1/4-20 x .75 711-0909A 26” Auger Axle 714-0161 Hi-Pro Key 715-0143 Spirol Pin 717-0526 Worm Shaft .75 717-0528A Worm Gear 20T 718-0186 Thrust .75 x .415...

-

Page 26: Troy-Bilt Llc

MANUFACTURER’S LIMITED WARRANTY FOR: The limited warranty set forth below is given by Troy-Bilt LLC d. Troy-Bilt does not extend any warranty for products sold with respect to new merchandise purchased and used in the or exported outside of the United States, its possessions United States, its possessions and territories.