Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Ricoh B234

-

Page 1: Service Manual

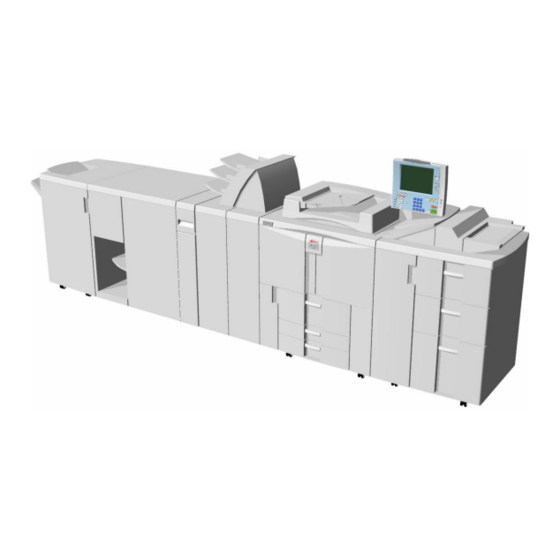

B234/B235/B236 D101/D102/D103 SERVICE MANUAL (Book 1 of 2) 002671MIU MAINFRAME... - Page 5 B234/B235/B236 D101/D102/D103 SERVICE MANUAL BOOK 1 OF 2 MAINFRAME 002671MIU...

- Page 7 It is the reader's responsibility when discussing the information contained within this document to maintain a level of confidentiality that is in the best interest of Ricoh Americas Corporation and its member companies. NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY FASHION AND DISTRIBUTED WITHOUT THE PRIOR PERMISSION OF RICOH AMERICAS CORPORATION.

- Page 9 Ricoh Technical Training Program. Untrained uncertified users utilizing information contained in this service manual to repair or modify Ricoh equipment risk personal injury, damage to property or loss of warranty protection. Ricoh Americas Corporation...

- Page 11 LEGEND PRODUCT COMPANY CODE GESTETNER LANIER RICOH SAVIN B234 DSm790 LD190 Aficio MP9000 8090 B235 DSm7110 LD1110 Aficio MP1110 8110 B236 DSm7135 LD1135 Aficio MP1350 8135 D101 Pro 906EX Pro 906EX Aficio Pro 906EX Pro 906EX D102 Pro 1106EX Pro 1106EX...

-

Page 13: Table Of Contents

Top View....................1-4 Side Views ....................1-4 1.1.5 POWER REQUIREMENTS ...............1-6 1.2 BEFORE YOU BEGIN… ................1-7 1.2.1 B234/B235/B236 OVERVIEW OF OPTIONAL PERIPHERALS ..1-7 1.2.2 D101/D102/D102 OVERVIEW OF OPTIONAL PERIPHERALS ..1-8 Configuration 1: Booklet Finisher B836..........1-8 Configuration 2: Perfect Binder D391 ...........1-9 1.2.3 SPECIAL POINTS ABOUT INSTALLATION ........1-10 1.3 COPIER (B234/B235/B236/D101/D102/D103).........1-11... - Page 14 BOOKLET FINISHER BK5000 (B836)..........1-91 1.10.1 ACCESSORIES .................1-91 1.10.2 INSTALLATION .................1-92 Docking the Booklet Finisher B836 .............1-94 Connecting the Booklet Finisher B836..........1-96 1.11 FINISHER SR5000 (B830) ..............1-97 1.11.1 ACCESSORIES .................1-97 1.11.2 INSTALLATION .................1-98 Docking the Finisher B830..............1-100 Connecting the Finisher B830............1-103 B234/B235/B236/D101/D102/D103...

- Page 15 Seal Check and Removal ..............1-138 Installation..................1-139 1.15.8 BROWSER UNIT (B828) ............1-141 Accessories ..................1-141 Installation..................1-141 1.15.9 VM CARD TYPE C (B861)............1-142 Accessories ..................1-142 Installation..................1-142 1.15.10 FILE FORMAT CONVERTER (B609) ........1-143 Accessories ..................1-143 Installation..................1-143 1.15.11 USB 2.0 HOST INTERFACE (B825) ........1-145 B234/B235/B236/D101/D102/D103...

- Page 16 2.2.2 ADF ....................2-11 2.2.3 FINISHER SR5000 B830 ..............2-11 2.2.4 PUNCH UNIT PU5000 B831 ............2-11 2.2.5 LCIT RT5000 B832................2-12 2.2.6 MULTI-BYPASS TRAY B833 ............2-12 2.2.7 LCIT RT5010 B834................2-12 2.2.8 COVER INTERPOSER TRAY CI5000 B835 ........2-13 2.2.9 BOOKLET FINISHER BK5000 B836..........2-13 B234/B235/B236/D101/D102/D103...

- Page 17 3.4.1 ADF COVERS .................3-16 3.4.2 ADF ORIGINAL TRAY..............3-17 Original Tray ..................3-17 Original Table Cover ................3-17 Bottom Plate ..................3-17 3.4.3 FEED UNIT AND SEPARATION ROLLER........3-18 3.4.4 FEED BELT..................3-19 3.4.5 PICK-UP ROLLER................3-20 3.4.6 ADF SENSORS................3-21 Entrance Sensor and Length Sensor ..........3-21 Registration Sensor ................3-22 B234/B235/B236/D101/D102/D103...

- Page 18 3.8 DEVELOPMENT AND TONER SUPPLY ..........3-64 3.8.1 DEVELOPMENT UNIT REMOVAL..........3-64 Re-installing the Development Unit.............3-65 3.8.2 TONER HOPPER REMOVAL ............3-66 3.8.3 DEVELOPER REPLACEMENT............3-67 Initializing the TD Sensor ..............3-70 3.8.4 CLEANING THE DOCTOR BLADE..........3-71 3.8.5 DEVELOPMENT ENTRANCE, FRONT, REAR SIDE SEALS..3-74 3.8.6 TONER DENSITY SENSOR ............3-75 B234/B235/B236/D101/D102/D103...

- Page 19 CIS Image Position Adjustment: Normal Paper ........3-115 3.10.19 TANDEM FEED TRAY PAPER SIZE CHANGE....3-116 Setting the Paper Size for the Right Tandem Tray ......3-116 Setting the Paper Size for the Left Tandem Tray......3-117 3.10.20 TANDEM TRAY SIDE REGISTRATION ......3-119 B234/B235/B236/D101/D102/D103...

- Page 20 PSU-E (ENGINE): A, B ............3-165 3.14.6 PPG, CGB POWER PACKS............3-166 3.14.7 AC DRIVE BOARD ..............3-167 3.15 CONTROLLER BOARDS, HDD ............3-168 3.15.1 CONTROLLER BOX COVER ..........3-168 3.15.2 CONTROLLER BOARD, NVRAM..........3-169 3.15.3 INTERFACE BOARD...............3-170 3.15.4 IPU...................3-171 3.15.5 SD CARD UNIT ...............3-172 B234/B235/B236/D101/D102/D103 viii...

- Page 21 4.1.1 OVERVIEW ..................4-1 4.1.2 RECOVERY METHODS ..............4-1 4.1.3 DOWNLOAD ERROR CODES............4-2 4.1.4 PAPER JAM CODES ................4-5 Copier B234/B235/B236 ...............4-6 Paper Jam Locations – Finisher B830 ..........4-7 Cover Interposer Tray B835..............4-7 Booklet Finisher B836................4-8 Paper Jam Locations – Z-Fold Unit B660 ..........4-8 4.2 SERVICE CALL CONDITIONS ..............4-9...

- Page 22 5.5.1 MAIN MACHINE OUTPUT CHECK: SP5804 ........5-178 Main Machine Output Check (SP5-804) ...........5-178 5.5.2 ADF OUTPUT CHECK: SP6008 ...........5-180 5.5.3 FINISHER OUTPUT CHECK SP6113 (B830) .......5-181 5.5.4 BOOKLET FINISHER OUTPUT CHECK: SP6207 ......5-182 5.5.5 COVER INTERPOSER (B835) OUTPUT CHECK: SP6401..5-182 5.6 SMC LISTS.....................5-184 B234/B235/B236/D101/D102/D103...

- Page 23 PRINTER BIT SWITCH SETTINGS..........5-218 DETAILED DESCRIPTIONS SECTION 6. DETAILED DESCRIPTIONS ............6-1 6.1 COMPONENT LAYOUT ................6-1 6.2 PAPER PATH.....................6-2 6.3 COPY PROCESS..................6-3 6.4 DRIVE LAYOUT ..................6-5 6.5 ELECTRICAL COMPONENT DESCRIPTIONS .........6-6 6.5.1 COPIER ENGINE ................6-6 6.5.2 ADF ....................6-17 6.6 ADF ......................6-18 B234/B235/B236/D101/D102/D103...

- Page 24 Settings Adjustable for Each Original Mode........6-53 6.9.6 RELATION BETWEEN THE SP AND UP SETTINGS.....6-54 6.10 LASER EXPOSURE ................6-56 6.10.1 OVERVIEW ................6-56 6.10.2 LASER EXPOSURE MECHANISM ...........6-57 6.10.3 LD SAFETY SWITCHES ............6-58 6.10.4 MULTI-BEAM LINE EXPOSURE ..........6-59 6.10.5 POLYGON MIRROR MOTOR ...........6-60 B234/B235/B236/D101/D102/D103...

- Page 25 Toner Collection Bottle..............6-107 6.14 PAPER FEED ...................6-109 6.14.1 OVERVIEW ................6-109 6.14.2 DRIVE..................6-111 Tray Components (Example: 3rd Tray)..........6-112 Vertical Paper Path ................6-112 6.14.3 PAPER LIFT – TRAYS 2 & 3 ...........6-113 6.14.4 PICK-UP AND FEED – TRAYS 1, 2, 3 ........6-115 xiii B234/B235/B236/D101/D102/D103...

- Page 26 Fusing Temperature Control at Power On (Cold/Warm Starts)..6-152 Fusing Temperature Control During Standby and in Energy Saver Mode6-153 Fusing Temperature Control During Machine Operation ....6-153 Fusing Temperature Control for Low Power Mode (During and Immediately After)................6-157 Low Speed Mode (CPM Down) ............6-157 B234/B235/B236/D101/D102/D103...

- Page 27 What happens in the off mode ............6-186 Returning to stand-by mode..............6-186 Disabling the off mode ..............6-186 6.19.5 SLEEP MODE .................6-187 Entering sleep stand-by and sleep modes ........6-187 What happens in sleep stand-by and sleep modes ......6-187 Returning to stand-by mode..............6-187 B234/B235/B236/D101/D102/D103...

- Page 28 RING BINDER RB5000 (D392)..........7-20 7.1.15 Z-FOLDING UNIT ZF4000 (B660) ..........7-20 7.1.16 D101/D102/D103 MACHINE CONFIGURATION.......7-21 7.1.17 B234/B235/B236 MACHINE CONFIGURATION .......7-22 Z-FOLDING UNIT (B660) SEE SECTION B660 FOR DETAILED TABLE OF CONTENTS FINISHER (B830) SEE SECTION B830 FOR DETAILED TABLE OF CONTENTS LCIT (B832)

- Page 29 COVER INTERPOSER TRAY (B835) SEE SECTION B835 FOR DETAILED TABLE OF CONTENTS BOOKLET FINISHER (B836) SEE SECTION B836 FOR DETAILED TABLE OF CONTENTS xvii B234/B235/B236/D101/D102/D103...

- Page 31 INSTALLATION PREVENTIVE MAINTENANCE REPLACEMENT AND ADJUSTMENT LCIT B832 LCIT B834 TROUBLESHOOTING Z-FOLDING UNIT B660, FINISHER B830 SERVICE TABLES DETAILED DESCRIPTIONS MULTI BYPASS TRAY B833 SPECIFICATIONS COVER INTERPOSER TRAY B835...

-

Page 33: Important Safety Notices

IMPORTANT SAFETY NOTICES PREVENTION OF PHYSICAL INJURY 1. Before disassembling or assembling parts of the copier and peripherals, make sure that the copier power cord is unplugged. 2. The wall outlet should be near the copier and easily accessible. 3. Note that some components of the copier and the paper tray unit are supplied with electrical voltage even if the main power switch is turned off. -

Page 34: Laser Safety

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL 1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an open flame. 2. Dispose of used toner, developer, and organic photoconductors in accordance with local regulations. (These are non-toxic supplies.) 3. - Page 35 Conventions in this Manual This manual uses several symbols. Symbol What it means Refer to section number See Core Tech Manual for details Screw Connector E-ring Clip ring North America EUR/A Europe/Asia LEFSEF.WMF...

-

Page 37: Installation

INSTALLATION INSTALLATION REVISION HISTORY Page Date Added/Updated/New 09/07/2006 Updated Information – Completing the Installation 46 ~ 47 10/09/2007 Updated Information – Adjusting Image Position Sensor 09/07/2006 Updated Information – Key Counter 11/21/2006 Updated Information – MFP Controller Options 03/23/2007 Updated Information – MFP Controller Options 134 ~ 137 02/01/2007 Updated Information –... -

Page 39: Installation Procedures

3) Directly exposed to heat from a heater 7. Do not place the machine where it will be exposed to corrosive gases. 8. Do not install the machine at any location over 2,000 m (6,500 feet) above sea level. B234/B235/B236/D101/D102/D103... -

Page 40: Machine Level

Within 5 mm (0.2") of level 1. Front to back: Within 5 mm (0.2") of level 2. Right to left: NOTE: The machine legs may be raised or lowered in order to level the machine. Set a carpenter’s level on the exposure glass. B234/B235/B236/D101/D102/D103... -

Page 41: Minimum Space Requirements

NOTE: The controller box door [A] and PSU door [B] on the back of the machine swing open and can be removed. Both doors can be removed to allow the machine to pass through a narrow doorway. ( 1.3.4) B234/B235/B236/D101/D102/D103... -

Page 42: Dimensions

1270 (50) 980 (38.6) 800 (31.5) 600 (23.6) 870 (34.3) 850 (33.5) 540 (21.3) 177 (7) d101i 910 164 (6.5) D101I910.WMF Approximate space required (With Booklet Finisher B836) Meters Feet With A3/DLT LCT B833 11.4 With A4/LT LCT B832 10.4 B234/B235/B236/D101/D102/D103... - Page 43 980 (38.6) 800 (31.5) 870 (34.3) 850 (33.5) 540 (21.3) 860 (33.8) 177 (7) d101i 912 164 (6.5) D101I912.WMF Approximate Space Required (All Options with Ring Binder D392) Meters Feet With A3/DLT LCT B833 12.2 With A4/LT LCT B832 11.2 B234/B235/B236/D101/D102/D103...

-

Page 44: Power Requirements

2. Avoid multi-wiring. 3. Be sure to ground the machine. 4. Never set anything on the power cord. Input Voltage Level Machine Area Europe/Asia B234/D101 208~240V 60 Hz Minimum 220~240V 50/60 Hz Minimum 16A B235/D102 B236/D103 Permissible voltage fluctuation: CAUTION Never turn off the main power switch when the power LED is lit or flashing. -

Page 45: Before You Begin

Before You Begin… BEFORE YOU BEGIN… 1.2.1 B234/B235/B236 OVERVIEW OF OPTIONAL PERIPHERALS B833 B234/235/236 Finisher Copier A4/LT LCT A3/DLT LCT Booklet Finisher Cover Interposer Z-Fold Unit B234I412C.WMF There are many peripherals available for this machine. Install them in this order:... -

Page 46: D101/D102/D102 Overview Of Optional Peripherals

• To prevent the Cover Interposer Tray from falling, always install the next peripheral device in line before installing the tray unit of the Cover Interposer Tray. Cover Interposer Tray (Tray Unit) Booklet Finisher BK5000 (B836) Finisher SR5000 (B830) B234/B235/B236/D101/D102/D103... -

Page 47: Configuration 2: Perfect Binder D391

• To prevent the Cover Interposer Tray from falling, always install the next peripheral device in line before installing the tray unit of the Cover Interposer Tray. Cover Interposer Tray (Tray Unit) Finisher SR5000 (B830) B234/B235/B236/D101/D102/D103... -

Page 48: Special Points About Installation

Item Comments 1.3 Copier • First, install the copier ( section 1.3.2). (B234/B235/B236/D101/D102/D103) 1.4 A3/11"x17" Tray Unit (B331-11) 1.5 LCIT RT5000 (B832) The CIS of the image position sensor unit in the LCT must be calibrated at installation for both LCT 1.6 LCIT RT5010 (B834) -

Page 49: Copier (B234/B235/B236/D101/D102/D103)

COPIER (B234/B235/B236/D101/D102/D103) COPIER (B234/B235/B236/D101/D102/D103) 1.3.1 ACCESSORIES B234I001.WMF 1-11 B234/B235/B236/D101/D102/D103... - Page 50 COPIER (B234/B235/B236/D101/D102/D103) Check the quantity and condition of the accessories in the box against the following list: Description Q'ty 1. Operation Panel..............1 2. Lower Cover - Operation Panel Holder ........1 3. Upper Cover - Operation Panel Holder ........1 4.

-

Page 51: Installation

COPIER (B234/B235/B236/D101/D102/D103) 1.3.2 INSTALLATION CAUTION Rating Voltage for Peripherals Make sure to plug the cables into the correct sockets. “Rating Voltage of Output Connector for Accessory: “Rating Voltage of Output Max. DC 24 V” Connector for Accessory: Max. DC 24 V”... -

Page 52: External Tape And Retainers

COPIER (B234/B235/B236/D101/D102/D103) External Tape and Retainers The installation procedure is not packed with the copier. Always bring this service manual with you. CAUTION Before performing the following procedures, make sure that the machine is unplugged from the power source. B234I006.WMF B234I004.WMF... - Page 53 COPIER (B234/B235/B236/D101/D102/D103) B070I005.WMF B234I024.WMF 3. Remove all tape and retainers from under the ADF [A]. 4. Remove A3 paper [B]. 5. Set the leveling shoes [C] (x 4) under the feet [D], then level the machine. 1-15 B234/B235/B236/D101/D102/D103...

-

Page 54: Internal Tape And Retainers: Paper Trays

COPIER (B234/B235/B236/D101/D102/D103) Internal Tape and Retainers: Paper Trays B234I003.WMF B234I019.WMF 1. Pull out the tandem tray (1st tray) completely, remove the tray lock plate [A] ( x 1) and remove the cushion [B]. 2. Push in the right tray of the tandem tray, then remove the cushion [C]. -

Page 55: Internal Tape And Retainers: Fusing Unit

COPIER (B234/B235/B236/D101/D102/D103) Internal Tape and Retainers: Fusing Unit B234I002.WMF B234I002A.WMF 1. Open the front doors and remove all visible tape and retainers from inside the machine [A]. 2. Press down lever D2 [B], pull out the fusing unit [C], and remove all tape and... -

Page 56: Internal Tape And Retainers: Transfer Unit

COPIER (B234/B235/B236/D101/D102/D103) Internal Tape and Retainers: Transfer Unit B234I002B.WMF 1. Lower the lever C1 [A]. 2. Remove all tape, tags, and retainers [B] from the transfer unit ( x1). B234/B235/B236/D101/D102/D103 1-18... -

Page 57: Internal Tape And Retainers: Drum Cleaning Unit

COPIER (B234/B235/B236/D101/D102/D103) Internal Tape and Retainers: Drum Cleaning Unit 1. Open the right front door. 2. Remove the black screws at x3). 3. Take off the inner cover NOTE: These illustrations show removal using the hex driver provided to the customer. - Page 58 COPIER (B234/B235/B236/D101/D102/D103) 6. Remove the faceplate. B234I110A.WMF 7. Pull the purple handle toward you until the drawer stops. NOTE: The development unit will shift slightly to the right as you pull the drawer out. B234i111.WMFF B234/B235/B236/D101/D102/D103 1-20...

- Page 59 COPIER (B234/B235/B236/D101/D102/D103) 8. Remove the drum cleaning unit. • Raise the purple lever and pull the cleaning unit to the left until it disengages the lever • Lift the unit out of the drawer Important: Grasp the cleaning unit by its handles as shown and lift it straight B234I113.WMF...

-

Page 60: Pouring Developer

COPIER (B234/B235/B236/D101/D102/D103) Pouring Developer 1. Lift the development unit [A] by its purple handle and hold it level as you remove it. B234i112.WMFF 2. Remove the shipping tape from the inner cover [B]. RIMGI901.BMPP 3. Place the development unit on the spread paper as shown. - Page 61 COPIER (B234/B235/B236/D101/D102/D103) 4. Remove the bracket [A] ( x1). 5. Disconnect the toner hopper [B] 6. Tilt the hopper slightly when you remove it. B234I902.WMFF 7. Pour the developer into the development unit. • Move the toner packet [C] from side...

- Page 62 COPIER (B234/B235/B236/D101/D102/D103) Reinstalling the Development Unit Important: When you reinstall the development unit, handle it carefully. • Never allow the development roller to hit the OPC drum or any other part of the frame of the development unit drawer. • Scratches or other damage to either...

-

Page 63: Operation Panel

COPIER (B234/B235/B236/D101/D102/D103) Operation Panel B234I012.WMF B234I013.WMFMF 1. Remove the right upper cover [A] ( x 4). 2. Pass the harness [B] through the arm [C]. 3. Install the arm [C] ( x 9). 1-25 B234/B235/B236/D101/D102/D103... - Page 64 COPIER (B234/B235/B236/D101/D102/D103) B234I014.WMF B234I015.WMF 4. Pull the harness [A] through the top of the arm and connect it to the operation panel [B] ( x2). 5. Secure the harness clamp [C] on the operation panel ( x 1, M4 x 6 brass pan head).

-

Page 65: Filters, Original Exit Tray

COPIER (B234/B235/B236/D101/D102/D103) Filters, Original Exit Tray B234I017.WMF B234I016.WMF 1. Install the upper cover [A] ( x 3) 2. Install the lower cover [B] ( x 3). 3. Set the drum dust filter [C]. 4. Loosen the bottom knob, adjust the view angle of the operation panel, then tighten the knob. - Page 66 COPIER (B234/B235/B236/D101/D102/D103) B070I506.WMF B234I018.WMF 6. Set the optics dust filter [A]. 7. Loosen the two screws of the bracket [B]. 8. Attach the original exit tray at [C] ( x 2) and [D] ( x 1) 9. Re-tighten the screws of the bracket [B] ( x 2).

-

Page 67: Testing The Copier Breaker Switch

COPIER (B234/B235/B236/D101/D102/D103) Testing the Copier Breaker Switch 1. Plug the copier power cord into its power source. NOTE: Do not turn on the copier. The copier should be off. 2. Use the tip of a small screwdriver to push the breaker test button. -

Page 68: Initializing The Machine

COPIER (B234/B235/B236/D101/D102/D103) Initializing the Machine Important: • Before you do this procedure, make sure that the front doors of the machine are closed. 1. Plug in the power cord and turn the main switch on. 2. Install the toner bottles. -

Page 69: Connecting The Copier Tray Heaters

COPIER (B234/B235/B236/D101/D102/D103) Connecting the Copier Tray Heaters The machine comes from the factory with the tray heaters already installed but disconnected. Tray heater connection is optional. The heaters should be connected if the location has high humidity. Consult with the customer before connecting the tray heaters. - Page 70 COPIER (B234/B235/B236/D101/D102/D103) To supply power 24 hours a day Doing the connection in the previous procedure assures that power is supplied to the machine for the heaters even after the copier is switched off with the main power switch (for example, in auto off mode). However, with only this connection, the heaters do not operate while the copier is operating.

-

Page 71: Completing The Installation

COPIER (B234/B235/B236/D101/D102/D103) 1.3.3 COMPLETING THE INSTALLATION Setting Paper Sizes for the Paper Trays 1. Set the required paper sizes for all paper trays. Unit Name Setting Copier 1st Tray SP5019 002 2nd Tray Automatic side fence detection. 3rd Tray Automatic side fence detection. -

Page 72: Controller Box, Psu Box Removal

COPIER (B234/B235/B236/D101/D102/D103) 1.3.4 CONTROLLER BOX, PSU BOX REMOVAL Remove the controller box and PSU box only if the machine is too large to pass through a narrow door or passageway. Controller Box Removal B234I904.WMFF B234I905.WMFF 1. Open the controller box [A] ( x 3 with washers). -

Page 73: Psu Box Removal

COPIER (B234/B235/B236/D101/D102/D103) PSU Box Removal 1. Open the PSU box [A] ( x 2). B234I906.WMFF 2. Disconnect ground wire [B] ( x 1). 3. Remove duct [C] ( x 3) 4. Disconnect [D] ( x1). 5. Remove the cover x 3). -

Page 74: Transporting The Copier

COPIER (B234/B235/B236/D101/D102/D103) 1.3.5 TRANSPORTING THE COPIER To prevent blockages in the toner supply path, always follow the procedure below before transporting the copier. If this procedure is not done, SC592 (Toner Bank Motor Error) or SC495 (Toner Bottle Unit Error) may be displayed, requiring replacement of the toner transport hose and coil. -

Page 75: After Moving The Copier

COPIER (B234/B235/B236/D101/D102/D103) After Moving the Copier 1. Turn the main power switch on. 2. Load the toner bottles into the toner bank. 3. Start to supply toner from the toner bank to the toner hopper: 1) Select SP2207 002 (Toner Bank Toner Setup). -

Page 76: A3/11"X17" Tray Unit Tk5000 (B331-11)

A3/11"X17" TRAY UNIT TK5000 (B331-11) 1.4.1 ACCESSORIES B331I001.WMF Check the quantity and condition of the accessories in the box against the following list: Description Q'ty 1. A3/DLT Tray ................1 2. Short Connector................ 1 3. Paper Size Decal ..............1 B234/B235/B236/D101/D102/D103 1-38... - Page 77 [C] ( x 4). 4. Remove the fences and adjust their positions for the paper to be loaded: front fence [D] ( x 1), back fence [E] ( x 1), and end fence [F] ( x 1) 1-39 B234/B235/B236/D101/D102/D103...

- Page 78 5. Open the front doors. 6. Pull out the tandem feed tray [A] completely. 7. Push the right tandem tray [B] into the machine. 8. Remove the left tandem tray [C] ( x 2 left, x 3 right). B234/B235/B236/D101/D102/D103 1-40...

- Page 79 A3/11"x17" Tray Unit TK5000 (B331-11) B331I002A.WMF B331I709.WMF 9. From the left tandem tray, remove the front cover [A] ( x 2). 10. Pull out the right tandem tray [B] then remove it. ( x 2). 1-41 B234/B235/B236/D101/D102/D103...

- Page 80 [D], center rail [E], left rail [F]. NOTE: You must use the short, silver screws on the left and right rails. If you use one of the longer screws, it will block the movement of the tray on the rails. B234/B235/B236/D101/D102/D103 1-42...

- Page 81 13. Re-install the front cover [A] ( x 2). 14. Use SP5019 002 to select the paper size for Tray 1 (A3 or DLT). 15. After selecting the paper size, switch the machine off and on to change the indicator on the operation panel. 1-43 B234/B235/B236/D101/D102/D103...

-

Page 82: Lcit Rt5000 (B)

6. Upper Joint Pins ............... 2 7. Philips Screw - M4 x 8 .............. 1 Installation Procedure – English (not shown)........1 NOTE: The tab paper end fence (3) is located in the LCT unit, mounted on hooks behind the front door. B832I101.WMF B234/B235/B236/D101/D102/D103 1-44... -

Page 83: Lcit Rt5000 (B832)

Unplug the power cord before starting the following procedure. 1. Remove the visible tape and other items [A] from the covers and left side of the LCT. 2. Open the LCT door and remove the shipping retainers and tape [B] holding the levers. 1-45 B234/B235/B236/D101/D102/D103... - Page 84 3. Remove the covers [A] from the right upper side. 4. Remove the covers [B] from the right lower side. 5. Install the pins with the grooved rings [C] on the right upper cover. 6. Install the other pins [D] on the right lower cover. B234/B235/B236/D101/D102/D103 1-46...

- Page 85 9. Turn over the ground plate and use the screws to fasten it to the same holes as shown ( x 2). Important! • If you are going to install the Multi Bypass Tray B833, it must be installed before the LCT is docked to the mainframe. ( 1.7) 1-47 B234/B235/B236/D101/D102/D103...

- Page 86 15. Fasten screw [C] to lock the LCT to the side of the copier. 16. Attach connector [D]. 17. Insert the leveling shoes [E] (x 3) under the leveling feet and level the LCT. 18. Attach the appropriate decals to the trays. B832I108.WMF B234/B235/B236/D101/D102/D103 1-48...

-

Page 87: Adjusting Image Position Sensor Strength And Side-To-Side Registration

20 and 40, the CIS may be defective. 9. Exit the SP mode and turn OFF the main power switch. 10. Remove the paper from the machine. 11. Reattach the LCT to the side of the copier. 12. Turn ON the main power switch. 1-49 B234/B235/B236/D101/D102/D103... -

Page 88: Cis Image Position Adjustment: Normal Paper (Lcit)

19. Exit the SP mode. Push [User Tools]> [Adjust Settings for Operators]. 20. Do SP1911 again (CIS Image Position Adjustment: Feed Setting) and reset the values for Trays 4, 5, 6, and 7 to "1" (ON). 2 mm B234I999.WMF B234/B235/B236/D101/D102/D103 1-50... -

Page 89: Lct B832 Tray Heaters

LCIT RT5000 (B832) 1.5.4 LCT B832 TRAY HEATERS Accessories Description 1. Relay Harness ............. 1 2. Heaters ................ 2 3. Cover Plate ..............1 4. Screws ................. 7 5. Harness Clamps ............3 B832I901A.WMF 1-51 B234/B235/B236/D101/D102/D103... -

Page 90: Installation

6. Pass the relay harness [E] through the right side of the LCT and connect it to the heaters ( x2). 7. Attach the cover plate [F] ( x3). 8. Load paper in the bottom paper tray. 9. Push the bottom paper tray into the LCT. 10. Reattach the right cover ( x6). B234/B235/B236/D101/D102/D103 1-52... - Page 91 14. Reconnect the ground wire [C] to the mainframe ( x1). 15. Dock the LCT to the mainframe. • Lock bar ( • Interface cable NOTE: Confirm that neither the relay harness nor ground wire is pinched between the mainframe and the LCT. 1-53 B234/B235/B236/D101/D102/D103...

-

Page 92: Lcit Rt5010 (B)

12. Decals – Paper Size..............1 13. Decals – Paper Size..............1 • Installation Procedure – English (not shown)........1 NOTE: The tab paper end fence (9) is located in the LCT unit, mounted on hooks behind the front door. B834I101.WMF B234/B235/B236/D101/D102/D103 1-54... -

Page 93: Lcit Rt5010 (B834)

1. Remove all the visible strips of tape and packing materials [A] from the covers and left side of the LCT. 2. Open the LCT door and remove the shipping retainers and strips of tape [B] holding the levers. 1-55 B234/B235/B236/D101/D102/D103... - Page 94 3. Remove the covers [A] from the right upper side. 4. Remove the covers [B] from the right lower side. 5. Install the pins with the grooved rings [C] on the right upper cover. 6. Install the other pins [D] on the right lower cover. B234/B235/B236/D101/D102/D103 1-56...

- Page 95 8. Turn over the ground plate and use the screws to fasten it to the same holes as shown ( x 2). Important! • If you are going to install the Multi Bypass Tray B833, it must be installed before the LCT is docked to the mainframe. ( 1.7) 1-57 B234/B235/B236/D101/D102/D103...

- Page 96 16. Insert the leveling shoes [E] (x 4) under the leveling feet and level the LCT. 17. Attach the appropriate decals to the trays. Important! • The CIS inside the LCT must be calibrated. Do this now. ( 1.5.3) B234/B235/B236/D101/D102/D103 1-58...

-

Page 97: Lct B834 Tray Heaters

LCIT RT5010 (B834) 1.6.3 LCT B834 TRAY HEATERS Accessories Description 1. Relay Harness ............. 1 2. Heaters ................ 2 3. Cover Plate ..............1 4. Screws ................. 7 5. Harness Clamps ............2 B834I901A.WMF 1-59 B234/B235/B236/D101/D102/D103... -

Page 98: Installation

6. Pass the relay harness [F] through the right side of the LCT and connect it to the heaters ( x2). 7. Attach the cover plate [G] ( x3). 8. Load paper in the paper trays. 9. Push the trays into the LCT. 10. Reattach the right cover ( x6). B234/B235/B236/D101/D102/D103 1-60... - Page 99 19. Reconnect the ground wire [B] to the mainframe ( x1). 20. Dock the LCT to the mainframe. • Lock bar ( • Interface cable NOTE: Confirm that neither the relay harness nor ground wire is pinched between the mainframe and the LCT. 1-61 B234/B235/B236/D101/D102/D103...

- Page 100 • The Multi Bypass Unit must be installed on top of the LCT B834 or B832 before the LCT is docked to the mainframe. • If the LCT is already installed, it must be disconnected from the mainframe before installation of the Multi Bypass Unit B833. B234/B235/B236/D101/D102/D103 1-62...

-

Page 101: Multi Bypass Tray (B833)

Be sure to follow the correct tray installation procedure depending on which LCIT will be installed. LCIT Type Mounting Connection • LCIT RT5000 B832 Do the procedure starting on page 1-64. Do the procedure starting on • LCIT RT5010 B834 page 1-68. Do the procedure starting on page 1-66. 1-63 B234/B235/B236/D101/D102/D103... -

Page 102: Lcit Rt5000 B832

2. Remove all other tape and shipping materials. 3. Remove the paper slot cover [B] ( x 2) and discard the screws. 4. Use the edge of a fine tip flathead screwdriver to remove the smaller three covers [C]. B234/B235/B236/D101/D102/D103 1-64... - Page 103 LCT. 8. Align the embossed arrows on the top left cover [E] of the bypass tray with the arrows on the LCT top. 9. Fasten the bypass tray to the right bracket [F] ( x 1). B833I107.WMF 1-65 B234/B235/B236/D101/D102/D103...

-

Page 104: Lcit Rt5010 B834

2. Remove all other tape and shipping materials. 3. Remove the paper slot cover [B] ( x 2) and discard the screws. 4. Use the edge of a fine tip flathead screwdriver to remove the smaller four covers [C]. B234/B235/B236/D101/D102/D103 1-66... - Page 105 10. Align the embossed arrows on the top left cover [G] of the bypass tray with the arrows on the LCT top. 11. Under the top of the LCT, attach the lock screw [H]. 12. Close Tray 1, then reattach the right cover. 1-67 B234/B235/B236/D101/D102/D103...

-

Page 106: Lcit Rt5000 B832/Lcit Rt5010 B834

4. Fasten the bypass tray rear frame [D] to the LCT ( x 1). 5. Fasten the bypass tray front frame [E] to the LCT ( x 1). 6. Connect the bypass tray harness [F] to the LCIT ( x4). 7. Re-attach the cover [B]. B234/B235/B236/D101/D102/D103 1-68... - Page 107 NOTE: Open the LCT front door. Hang the tab sheet fence on the hooks [C] on top of the LCT tab fence. When feeding tab sheets from the bypass tray, follow the decal instructions on the tab fence to install the fence. 1-69 B234/B235/B236/D101/D102/D103...

- Page 108 8. Front Docking Bracket ............1 9. Flat Knob Screw ..............1 10. Screw (M4 x 8)...............4 11. Screw (M3 x 6)...............2 12. Screw (M4 x 12)..............2 13. Knob Screw ................3 14. Base Cover (Tray Unit) ............1 15. Rear Cover ................1 B835I101.WMF B234/B235/B236/D101/D102/D103 1-70...

-

Page 109: Cover Interposer Tray Ci5000 (B835)

Unplug the power cord before starting the following procedure. 1. Remove all the tape and shipping materials from the tray unit [A]. 2. Remove cover [B]. 3. Remove all tape and shipping materials from the transport unit [C]. 1-71 B234/B235/B236/D101/D102/D103... - Page 110 NOTE: These are the docking plates for the next device to be installed in the paper feed line. 7. Attach the black mylar [D] to the relay guide plate [E] of the next finishing device to be installed to the left of the cover interposer tray (Z-folding unit, booklet finisher, or finisher). B234/B235/B236/D101/D102/D103 1-72...

- Page 111 9. Attach the relay guide plate [B] ( x2). 10. Remove the ground plate [C] from the bottom cross-piece ( x2). 11. Turn the ground plate over. 12. Reattach the ground plate with the same screws as shown ( x2). 1-73 B234/B235/B236/D101/D102/D103...

- Page 112 15. Attach the front docking bracket [C] ( x2). 16. If the Z-Folding Unit will be installed, loosen the screws for the rear runner [D] and front runner [E]. 17. Push the runners in and re-fasten them again with the screws. B234/B235/B236/D101/D102/D103 1-74...

- Page 113 22. Push in the locking lever. 23. Check that the top edges of the finisher are parallel with edges of the finisher (or copier) to the right. 24. Fasten the locking lever [A] ( x 1) 25. Close the front door. 1-75 B234/B235/B236/D101/D102/D103...

-

Page 114: Docking The Next Peripheral Device

1) before disconnecting either the cover interposer tray or the next peripheral device to the left, or 2) before doing any maintenance on either the cover interposer tray or the next peripheral device to the left. B234/B235/B236/D101/D102/D103 1-76... -

Page 115: Mounting The Tray Unit

2. Confirm that the connectors [B] are free. 3. Place the tray unit [C] on top of the cover interposer transport unit. 4. Attach the knob screw [D] ( x1). 5. Connect the harness connectors [E] ( 6. Reattach the rear cover. 1-77 B234/B235/B236/D101/D102/D103... - Page 116 12. Hold the lower L-pin [F] as shown, insert it halfway, push it up, then rotate it into its groove. 13. Hold the upper L-pin [G] as shown, insert it halfway, push it down, then rotate it into its groove. B234/B235/B236/D101/D102/D103 1-78...

- Page 117 14. Attach the spacer [A] to the rear of the transport unit ( x2). 15. Set the leveling shoes [B] (x4) under the feet. 16. Turn the nuts to adjust the height of the cover interposer until it is level. 1-79 B234/B235/B236/D101/D102/D103...

- Page 118 17. Screws M3 x 6 ..............8 18. Screws M4 x 6 ..............8 19 Leveling Shoes ............... 3 20. Drive Gear (Black – for B236/D103 135 cpm only) ..1 21. Drive Gear Assembly (Black – for B236/D103 135 cpm only) 1 B660I003A.WMF B234/B235/B236/D101/D102/D103 1-80...

-

Page 119: Z-Folding Unit Zf4000 (B660)

6. Open the right vertical transport cover [H] completely (2 steps). 7. Remove four spacers [I] by pulling on the string. NOTE: It may be necessary to remove the front inner cover if the string fails to remove the “U” shaped piece [I]. 1-81 B234/B235/B236/D101/D102/D103... -

Page 120: Replacing The Gear For B236/D103 (135 Cpm) Only

Z-FOLDING UNIT ZF4000 (B660) Replacing the Gear for B236/D103 (135 cpm) only Important: • This procedure is not required for the B234/D101 (90 cpm) or B235/D102 (110 cpm). • Do this procedure only for the B236/D103 (135 cpm). The gear... -

Page 121: Attaching The Brackets

Z-Folding Unit ZF4000 (B660) Attaching the Brackets B830/B836 B660I004A.WMF B234/B235/B236/D101/D102/D103 1. Attach the long connection bracket [A] to the unit (3000-Sheet Finisher B830 or Booklet Finisher B836) to the left of the Z-folding unit ( x4 M4x10). NOTE: Use the long screws provided with the Z-fold unit accessories. -

Page 122: Preparing For Docking

NOTE: The spacers align the top of the Z-folding unit with the edge of the Copier. 5. Reattach the top cover [B] ( x 4). NOTE: Make sure that the top cover is level with the tops of the rear and front spacers. B234/B235/B236/D101/D102/D103 1-84... - Page 123 6. Replace the entrance guide plate [A] with the longer guide plate [B] provided with the accessories ( x 2). Important: Attach the mylar as shown in the illustration only to the guide plate provided with the Cover Interposer Tray B835. 1-85 B234/B235/B236/D101/D102/D103...

-

Page 124: Testing The Breaker

• Confirm that the power cord is securely connected to the power supply. • Push the test button again. • If the breaker switch does not snap to the off position, the breaker switch must be replaced. 6. Reset the breaker switch to the on position. B234/B235/B236/D101/D102/D103 1-86... -

Page 125: Docking The Z-Folding Unit To The Cover Interposer Tray Or Copier

The Z-Folding Unit is docked to the Cover Interposer Tray B835, or to the Copier if the cover interposer tray is not used. Z-Fold Unit Cover Interposer Tray B835 B660I202.WMF 1. Attach the rear docking bracket [A]. 2. Attach the front docking bracket [B]. 3. Connect the Z-folding unit. 1-87 B234/B235/B236/D101/D102/D103... - Page 126 Z-FOLDING UNIT ZF4000 (B660) Z-Fold B660 Copier B660I201.WMF 1. Remove the connector plate [A]. 2. Attach the rear docking bracket [B]. 3. Attach the front docking bracket [C]. 4. Connect the Z-folding unit. B234/B235/B236/D101/D102/D103 1-88...

-

Page 127: Connecting The Z-Folding Unit B660

[C]. 11. Connect the Z-Folding unit to the copier. 12. Connect the Z-Folding unit power cord to the Z-folding unit and connect the other end of the cord to the power ac supply. 1-89 B234/B235/B236/D101/D102/D103... - Page 128 15. Reattach the bracket [C] ( x 1). CAUTION With the support retracted, the Z-folding unit tips easily! 16. Attach the I/F cable to the cover interposer tray (or Copier). 17. Connect the power cord to the Z-folding unit. B234/B235/B236/D101/D102/D103 1-90...

-

Page 129: Booklet Finisher Bk5000 (B836)

4. Output Tray................1 5. Joint Bracket ................1 6. Spacers (attached to base plate with screws)......2 7. Leveling Shoes ................. 3 8. Tapping Screw (M4 x 14)............4 9. Tapping Screw (M3 x 6)............8 B836I101.WMF 1-91 B234/B235/B236/D101/D102/D103... -

Page 130: Installation

2. Remove the tape from the interface connector [A]. 3. Open the small front door [B]. 4. Remove all tapes and packing materials. 5. Open the large front door [C]. 6. Pull the jogger unit [D] out of the finisher. 7. Remove all tapes and retainers. B234/B235/B236/D101/D102/D103 1-92... - Page 131 8. Remove the strip from the sponge cushion [A]. 9. Attach the cushion to the finisher as shown. 10. Use a short screwdriver to attach the grounding plate [B] ( x 2, M3 x 6). B836I105.WMF 11. Attach the output tray [C]. B836I107.WMF 1-93 B234/B235/B236/D101/D102/D103...

-

Page 132: Docking The Booklet Finisher B836

• Copier (if neither Z-folding unit nor cover interposer tray is installed). Booklet Finisher B836 Z-Folding Unit (B660) 1. Fasten the joint bracket to the Z- Folding Unit B660. ( x4 M4x10) 2. Dock the finisher. (Go to page 1-96.) B836I202.WMF B234/B235/B236/D101/D102/D103 1-94... - Page 133 M4x14) 2. Dock the finisher. (Go to page 1-96.) B836I201.WMF Booklet Finisher B836 Copier 1. Remove the connector cover 2. Fasten the joint bracket to the Copier x4 M4x14). 3. Dock the finisher. (Go to page 1-96.) B836I104.WMF 1-95 B234/B235/B236/D101/D102/D103...

-

Page 134: Connecting The Booklet Finisher B836

7. Fasten the locking lever [A] ( x 1) 8. Close the front door. 9. Set the leveling shoes [E] (x3) under the feet. 10. Turn the nuts to adjust the height of the finisher until it is level. B234/B235/B236/D101/D102/D103 1-96... -

Page 135: Finisher Sr5000 (B830)

8. Tapping Screws – M3 x 6.............. 8 9. Tapping Screws – M4 x 8.............. 2 10. Support Plate Pocket ..............1 11. Support Plate ................1 12. Side Tray..................1 13. Support Plate for Proof Tray ............1 B830I101.WMF 1-97 B234/B235/B236/D101/D102/D103... -

Page 136: Installation

1. Unpack the finisher and remove all tapes and shipping retainers. 2. Open the front door and remove the shipping retainers. 3. Remove the brackets, tags, and wires in this order: [A] [B] [C] ( x 2 each). B234/B235/B236/D101/D102/D103 1-98... - Page 137 B830I105.WMF 7. Install the entrance guide plate [G] ( x 2) (M3 x 6). 8. Insert the shift tray [H] properly into the grooves and fasten it ( x 4) (M3 x 6). B830I109.WMF 1-99 B234/B235/B236/D101/D102/D103...

-

Page 138: Docking The Finisher B830

• Copier (if Booklet Finisher B836, Z-Folding Unit B660, and Cover Interposer Tray B835 are all not installed.) Finisher B830 Booklet Finisher B836 1. Fasten the joint bracket to the Booklet Finisher B836. 2. Dock the finisher. (Go to page 1-103.) B830I205.WMF B234/B235/B236/D101/D102/D103 1-100... - Page 139 Folding Unit B660. 2. Dock the finisher. (Go to page 1-103.) B830I204.WMF Finisher B830 Cover Interposer Tray B835 1. Fasten the joint bracket to the Cover Interposer Tray B835. 2. Dock the finisher. (Go to page 1-103.) B830I203.WMF 1-101 B234/B235/B236/D101/D102/D103...

- Page 140 FINISHER SR5000 (B830) Finisher B830 Copier B234 1. Remove the connector cover 2. Fasten the joint bracket to the Copier. 3. Dock the finisher. (Go to page 1-103.) B830I201.WMF B234/B235/B236/D101/D102/D103 1-102...

-

Page 141: Connecting The Finisher B830

7. Fasten the locking lever [A] ( x 1) 8. Close the front door. 9. Set the leveling shoes [E] (x4) under the feet. 10. Turn the nuts to adjust the height of the finisher until it is level. 1-103 B234/B235/B236/D101/D102/D103... -

Page 142: Punch Unit Pu5000 (B831)

4. Spacer (2 mm) ................ 1 5. Knob ..................1 6. Step Screw ................1 7. Screw (M4 x 6) Black .............. 1 8. Screw (M3 x 10)..............2 9. Spring ..................1 10. Sensor Arm and Sensor............1 B831I101.WMF B234/B235/B236/D101/D102/D103 1-104... -

Page 143: Installation

5. Remove the inner cover [C] ( x 3). 6. Behind the inner cover at [D] and [E], press the lock tab to the right to release the inner cover from the frame. 7. Remove the plastic knockouts [F]. 1-105 B234/B235/B236/D101/D102/D103... - Page 144 8. Remove the paper guide [A] ( x 4). 9. Install the sensor arm [B] ( x 1, small step screw (M3 x 4). NOTE: Make sure that the sensor arm swings freely on the step screw. 10. Attach the spring [C]. B234/B235/B236/D101/D102/D103 1-106...

- Page 145 NOTE: These extra spacers can be used to adjust the position of the punch holes (front to rear, across the page). 13. At the front, fasten the punch unit knob [C] ( x 1). 1-107 B234/B235/B236/D101/D102/D103...

- Page 146 17. Slide the punch waste collection hopper [D] into the finisher. 18. Re-attach the inner cover and rear cover. 19. Close the front door and re-connect the finisher to the machine. B234/B235/B236/D101/D102/D103 1-108...

-

Page 147: Skew And Side-To-Side Adjustment

• Skew appears when the paper rotates away from the direction of paper feed. • If side-to-side registration shifts, the sheet remains straight but shifts left or right away from center. Side-to-Side Registration Shift Skew Feed Direction B234I912.WMF 1-109 B234/B235/B236/D101/D102/D103... -

Page 148: Where Skew And Side-To-Side Registration Are Measured

Important! Only one scale is read, depending on the type of paper. Be sure to read the correct scale for the paper size. Rear DLT (11" x 17") size paper only Front A3 size paper only B234/B235/B236/D101/D102/D103 1-110... -

Page 149: Where Skew And Side-To-Side Registration Are Adjusted

• If both the finisher (B830) and booklet finisher (B836) are installed, the adjustment can be done at First, do the adjustment at , and do another test. If there still a problem with skew or side-to-side registration, do the adjustment at B836 B830 B234I920.WMF 1-111 B234/B235/B236/D101/D102/D103... -

Page 150: System Configuration

±2 mm on the rear scale. No deviation in side-to-side registration. Deviation in side-to-side registration. The leading edge and trailing edge exit at the same point, but that point deviates more than ±2 mm from center on the rear scale. B234/B235/B236/D101/D102/D103 1-112... - Page 151 Deviation is more than 2 mm. Adjustment is necessary. Scale: 2 mm Example: Skew at Front Scale (A3) B234I914.WMF There is some deviation but no adjustment is necessary. Deviation is more than 2 mm. Adjustment is necessary. LE: Leading Edge TE: Trailing Edge 1-113 B234/B235/B236/D101/D102/D103...

- Page 152 Deviation is more than 2 mm. Adjustment is necessary. Example: Side-to-Side Shift at Front Scale (A3) B234I916.WMF There is some deviation but no adjustment is necessary. Deviation is more than 2 mm. Adjustment is necessary. LE: Leading Edge TE: Trailing Edge B234/B235/B236/D101/D102/D103 1-114...

-

Page 153: How To Adjust Skew, Side-To-Side Registration

4. If the leading/trailing edges are exiting at the same point slightly left or right of center, there is some deviation in the side-to-side registration. If the deviation is within 2 mm, no adjustment is necessary. -or- If the deviation is more than 2 mm, do the side-to-side registration adjustment (see below). 1-115 B234/B235/B236/D101/D102/D103... - Page 154 2) Insert one spacer [E] or [F]. 3) Do some more test prints to check the adjustment. If skew is still present, insert another spacer at the same location. B234I993.WMF B234/B235/B236/D101/D102/D103 1-116...

- Page 155 If the deviation from center was toward the front of the machine, slide the bracket to the front and fasten it with the screw. -or- If the deviation from center was toward the back of the machine, slide the bracket to the rear and fasten it with the screw. 1-117 B234/B235/B236/D101/D102/D103...

- Page 156 • Move the plate on the scales [C] and [D] by the same amount as the adjustment done above on the long bracket. • Retighten the screws. 4. Do some more test prints and repeat the adjustment until it is correct. B234/B235/B236/D101/D102/D103 1-118...

-

Page 157: Key Counter

6. Tapping Screws M4 x 8 ............3 7. Machine Screws M3 x 20............2 8. External Screw M3 x 20 ............1 9. Machine Screw (Flathead) M4 x 16 ........1 10. Extension Cable (for LCT Installation) ........1 11. Extension Cable Clamps (for LCT Installation) ......6 1-119 B234/B235/B236/D101/D102/D103... -

Page 158: Installation

[C] 2. Fasten the key counter holder [C] through the bracket plate to the counter plates [A] ( x 2). 3. Fasten the cover [D] to the key counter bracket [B] ( x 2). B234/B235/B236/D101/D102/D103 1-120... -

Page 159: Attaching The Key Counter To The Copier

5. Fit the keyhole of the key counter bracket [E] over the head of the shoulder screw, then slide it back. 6. Fasten the key counter assembly [F] to the copier ( x 1). 7. Do the User Tool and SP mode settings described at the end of this section. 1-121 B234/B235/B236/D101/D102/D103... -

Page 160: Attaching The Key Counter To The Lct

2. Remove the LCT right cover [B] ( x 6). 3. Remove the LCT rear cover [C] ( x 3). 4. On the right side of the LCT, attach 2 clamps [D]. 5. Attach the extension cable [E] to the 2 clamps. B234/B235/B236/D101/D102/D103 1-122... - Page 161 7. Route the cable [B] as shown. 8. On the left side of the LCT, attach 2 clamps [C]. 9. Route the cable [D] as shown. 10. If the cable from the right cover is too long, loop it [E] to make it shorter. 1-123 B234/B235/B236/D101/D102/D103...

- Page 162 14. Fit the keyhole of the key counter bracket [C] over the head of the shoulder screw, then slide it back. 15. Fasten the key counter assembly [D] to the LCT ( x 1). 16. On the right side of the copier, remove the small cover [E]. 17. Remove the jumper connector [F]. B234/B235/B236/D101/D102/D103 1-124...

-

Page 163: User Tool And Sp Mode Settings

2. Enter the SP mode • Confirm that the setting for SP5121 is “0” (Default: Paper Feed Count). This sets the counter for paper feed ("1" sets for paper exit). • Confirm that the setting for SP5113 is "0". 1-125 B234/B235/B236/D101/D102/D103... -

Page 164: Installation Of Mfp Controller Options

SD card. SD card for machine firmware update by the customer engineer. • Also for Browser Unit B828 Service • Also for VM Card B861 B234/B235/B236/D101/D102/D103 1-126... -

Page 165: Overview

• Never remove the System SD Card from Slot C1. • Before uploading to an SD card, always make sure that the write-protect switch is OFF. (It is very easy to accidentally turn on the write-protect switch when inserting or removing an SD card.) 1-127 B234/B235/B236/D101/D102/D103... -

Page 166: Merging Applications

• The original card can also be used to perform an undo procedure (SP 5873 002). Before you store an SD card, label it carefully so it can be identified easily if you need to do the undo procedure (see the next page). B234/B235/B236/D101/D102/D103 1-128... -

Page 167: Undo Exec

5. Go into the SP mode and do SP5873-002 (Undo Exec) 6. Follow the messages on the operation panel to complete the procedure. 7. Turn the main switch off. 8. Remove the SD cards from the slots. 9. Turn the main switch on. 1-129 B234/B235/B236/D101/D102/D103... -

Page 168: Common Procedures For Mfp Options

1. Open both front doors of the copier. 2. Remove the emblem cover [A] ( 3. Set the copied SD card [B] in one of the compartments. 4. Reattach the emblem cover and close the front doors. B234I501.WMF B234/B235/B236/D101/D102/D103 1-130... -

Page 169: Removing Slot Covers

1. Remove the SD card slot cover screw [A] ( 2. Lift the cover [B] and pull it away to remove it. To remove a board slot cover B234I207.BMP B234I208.BMP 1. Remove the board slot cover screws [A] ( 2. Pull out the cover and bracket [B]. 1-131 B234/B235/B236/D101/D102/D103... -

Page 170: Printer/Scanner Kit (B840)

8. Memory Chip 256 MB ............1 Important • Only one slot (C2) is available for applications on SD cards. If more than one application will be used, the applications must be merged onto one SD card with SP5873 001. ( 1.15.2) B234/B235/B236/D101/D102/D103 1-132... -

Page 171: Installation

• Only one slot (C2) is available for applications on SD cards. If more than one application will be used, the applications must be merged onto one SD card with SP5873 001. ( 1.15.2) B840I201.WMF 1-133 B234/B235/B236/D101/D102/D103... - Page 172 10. Plug in the power cable and turn the main power switch on. 11. Change SP 5985 001 and 002 from ‘0’ to ‘1’. 12. Turn the main power switch off and on. 13. Follow the instructions in the Operation Instructions to complete the installation for the printer/scanner option. B234/B235/B236/D101/D102/D103 1-134...

-

Page 173: Ieee 1284 Interface Board (B679)

Q’ty 1. IEEE 1284 Centronics Board ..........1 1. Switch the machine off. 2. Remove the cover [A] of Slot B2 ( 3. Insert the 1284 Centronics board [B] into Slot B2 and fasten it with the screws. B679I201.WMF 1-135 B234/B235/B236/D101/D102/D103... -

Page 174: Accessories

Make sure the SD Card is inserted and locked in place. If it is partially out of the slot, push it in gently until it locks in place. 4. Switch the machine on. B613I201.WMF B234/B235/B236/D101/D102/D103 1-136... -

Page 175: Data Overwrite Security Unit F (B735)

[User Tools]> "System Settings"> "Administrator Tools"> "Administrator Authentication Management"> "Available Settings NOTE: "Available Settings" is not displayed until Step 2 is done. If this setting is not selected tell the customer that this setting must be selected before you can do the installation procedure. 1-137 B234/B235/B236/D101/D102/D103... -

Page 176: Seal Check And Removal

2. If the surfaces of the tapes do not show “VOID”, remove them from the corners of the box. 3. After you remove each seal, the “VOID” marks [B] become visible. This prevents them from being reattached to the box. B234/B235/B236/D101/D102/D103 1-138... -

Page 177: Installation

If the numbers are not identical, this means the option was not installed correctly. • Confirm that the label on the box of the DOS option says "F". • If you have installed the incorrect type, replace the NVRAM. • Do the Data Overwrite Security unit installation again. 1-139 B234/B235/B236/D101/D102/D103... - Page 178 • The icon [A] changes to [B] when job data is stored in the hard disk. • The icon goes back to its usual shape [A] after this function has completed the data overwrite operation on the hard disk. B234/B235/B236/D101/D102/D103 1-140...

-

Page 179: Browser Unit (B828)

12. When you see "Ready to Install" check the information on the screen to confirm you previous selection. 13. Touch "OK". You will see "Installing…" then "Completed". 14. Touch "Exit" twice to return to the copy screen. 15. Remove the SD card from slot C3. 1-141 B234/B235/B236/D101/D102/D103... -

Page 180: Accessories

6. Set the heap size and stack size for the application. (In User Tools/Extended Features setting, see the Administrator Tools tab.) 7. Install the application using the installation procedure provided with the application. B234/B235/B236/D101/D102/D103 1-142... -

Page 181: Accessories

Installation 1. Switch the machine off. 2. Remove the cover [A] of Slot A3 ( 3. Insert the file format converter board [B] into Slot A3 and fasten it with the screws. 4. Switch the machine on. B609I100.WMF 1-143 B234/B235/B236/D101/D102/D103... - Page 182 Does not apply the features of the “1” setting when files are copied to Palm2. Note: This setting preserves the quality of the original image, especially with J2K files, but also requires more time for copying and requires more disk space to store the larger files. B234/B235/B236/D101/D102/D103 1-144...

-

Page 183: Accessories

3. Insert the USB 2.0 board [B] into Slot B1 and fasten it with the screws. 4. Print a configuration page to confirm that the machine recognizes the installed board for USB2.0: User Tools > Printer Features > List/Test Print > Configuration Page B825I100.WMF 1-145 B234/B235/B236/D101/D102/D103... -

Page 184: Accessories

4. Insert the wireless LAN board [C] into Slot B2 and fasten it with the screws. 5. Attach the cap [D]. 6. Switch the machine on and print a configuration page to confirm that the machine recognizes the installed board for IEEE 802.11b (Wireless LAN): User Tools> Printer Features> List/Test Print> Configuration Page B234/B235/B236/D101/D102/D103 1-146... -

Page 185: Accessories

B581I202.WMF and fasten it with the screws. 4. Switch the machine on and print a configuration page to confirm that the machine recognizes the installed board for IEEE 1394 (FireWire): User Tools> Printer Features> List/Test Print> Configuration Page 1-147 B234/B235/B236/D101/D102/D103... -

Page 186: Accessories

Only one PCI slot (B2) is available for one of these options: • Centronics 1284 • IEEE 1394 (FireWire) • IEEE 801.11b (Wireless LAN) • Bluetooth Interface Unit B826 • Cumin-M B818 Important • If another board is installed in B2, you must remove it before installing this card. B234/B235/B236/D101/D102/D103 1-148... - Page 187 6. Insert the interface board (with card and adapter inserted) into Slot B2. 7. Attach the card cover [E] (used to prevent static electricity). 8. Confirm that Bluetooth is installed correctly: User Tools> Printer Features> List/Test Print> Configuration Page 1-149 B234/B235/B236/D101/D102/D103...

-

Page 188: Cumin-M (B818)

B2 and fasten it with the screws x 1). B818I100.WMF 5. Enter the SP mode and note the settings of the following SP codes: SP5816 Remote Service Note Setting 150 Selection Country 153 Selection: Dial/Push 154 Outside Line/Outgoing Number 161 Telephone Number B234/B235/B236/D101/D102/D103 1-150... - Page 189 Start device registration SP5816 207 9: Under registration Show device registration result Other error 3,4,5,6: Communication error 0: Succcess Finish B246I905.WMF 7. Confirm that the Cumin-M modem is installed correctly: User Tools> Printer Features> List/Test Print> Configuration Page 1-151 B234/B235/B236/D101/D102/D103...

-

Page 190: Gigabit Ethernet (G381)

1.15.16 GIGABIT ETHERNET (G381) Accessories Description Q’ty 1. Gigabit Ethernet B381...............1 2. Ferrite Core (not used for B234/B235/B236/D101/D102/D103)..1 1. Switch the machine off. 2. Remove the cover [A] of Slot B3 ( x 2). 3. Insert the Gigabit Ethernet Board [B] into Slot B3 and fasten it with the screws. -

Page 191: Copy Data Security Unit (B829)

1.15.17 COPY DATA SECURITY UNIT (B829) Accessories Description Q’ty 1. Copy Data Security Unit B829 (Board)........1 2. Screws ..................2 Installation B829I100.WMF 1. Switch the machine off. 2. Remove the controller box cover x8). 3. Remove the bracket [B] ( x2). DSCNI901.BMP 1-153 B234/B235/B236/D101/D102/D103... - Page 192 • Before removing the ICIB-2 board, repeat the setup procedure above and set "Data Security for Copying" to "OFF". • The machine will issue an SC error if the machine is powered on with the ICIB-2 removed and the "Data Security for Copying" feature set to "ON". B234/B235/B236/D101/D102/D103 1-154...

-

Page 193: Connection Kit B328

CONNECTION KIT B328 1.16.1 INTRODUCTION The B234 (90 cpm), B235 (110 cpm) and B236 (135 cpm) machines can be connected with the new Copier Connection Kit B328. When two machines are connected, the copy speed is doubled. The copiers can be used for copy jobs only, not print jobs. However, documents stored on the document server beforehand can be printed with the connected copiers. -

Page 194: Installation

Check the quantity and condition of the accessories in the box against the following list: Description Q’ty 7. Interface Cable 1394..............3 8. Repeater Hub 1394 ...............2 9. Connection PCB..............2 10. Power Repeater Cable ............2 11. “Other Function” Keytops (NA, EU 1 ea.).......2 B234/B235/B236/D101/D102/D103 1-156... -

Page 195: Preparation

This will depend on the distance between the two connected machines. See the following table: DISTANCE POWER REPEATER HUBS INTERFACE CABLES Up to 4.5 m None (14.8 ft.) 4.5 ~ 9.0 m (14.8 ~ 29.5 ft) 9.0 ~ 13.5 m (29.5 ~ 112.5 ft. 1-157 B234/B235/B236/D101/D102/D103... -

Page 196: Installation Procedure

4. Align the PCB with the bottom groove, and push the connection PCB [B] into the slot. NOTE: Make sure that the edge of the PCB is in the groove before you push the card into the machine. 5. Fasten the PCB with the attached screws [C]. B234/B235/B236/D101/D102/D103 1-158... - Page 197 6. Connect the power repeater cable [A] to the motherboard at CN593. 7. Connect the other end of the power repeater cable to the connection PCB [B]. 8. Re-attach the controller box cover. 9. Repeat Steps 1 thru 8 to install the connection PCB on the slave machine. 1-159 B234/B235/B236/D101/D102/D103...

- Page 198 14. Attach the other end of the connection cable to the connection PCB installed in the other machine. 15. Make sure that SYSTEM Ver. 1.07 or later is installed on both machines. For details about the download procedures for this software, Section 5 (“Service Tables”) of the Service Manual. B234/B235/B236/D101/D102/D103 1-160...

-

Page 199: Preventive Maintenance

PREVENTIVE MAINTENANCE PREVENTIVE MAINTENANCE REVISION HISTORY Page Date Added/Updated/New 09/07/2006 Updated Information – PM Tables... -

Page 201: Pm Counter

Clear all PM settings. Resets all PM counter settings to "0" at the same time. PM items can be reset one by one with the [Clear] button. ( Pg.2-4) Counter list print out. Prints the PM counter on paper. B234/B235/B236/D101/D102/D103... -

Page 202: Pm Parts Screen Details

[C]: PM yield buttons. Function is the same as the "PM yield indicator settings" button. ( Pg.2-4). [D]: Current PM counter value. [E]: Target PM interval. This can be changed by pressing a number button [A]. [F]: PM counter clear button. Function is the same as the [Clear current counter] button. B234/B235/B236/D101/D102/D103... -

Page 203: Number Button Submenu

• Latest 1. The latest PM count since the unit (or part) was replaced. • Latest 2. The previous PM count since the unit (or part) was replaced. • Latest 3. The previous but one PM count since the unit (or part) was replaced. B234/B235/B236/D101/D102/D103... -

Page 204: Parts List For Pm Yield Indicator

• The # mark denotes a unit. • Items without the # (for example, 065 ITB) denote individual components. • An asterisk will appear in the Exceed column [A] to show items that that have exceeded their target PM yields. B234/B235/B236/D101/D102/D103... -

Page 205: Pm Tables

Inspect. Clean, replace, or lubricate as needed. Adjust Cleaning required. Replacement required. Lubrication required. Expected service life. WARNING Turn off the main power switch and unplug the machine before performing any procedure in this section. Laser beams can seriously damage the eyes. B234/B235/B236/D101/D102/D103... -

Page 206: Main Machine

Toner suction bottle About Replace when near end or end alert is displayed. 3000K Toner suction motor About Replace when near end or end alert is displayed. 2500K K count assumes copying and printing on A4 LEF with 6% test chart. B234/B235/B236/D101/D102/D103... - Page 207 Alcohol, when transfer belt is replaced. Belt roller Transfer bias roller Alcohol, when transfer belt is replaced. Apply conductive grease to electrical contacts. Cleaning bias roller Cleaning when Transfer belt cleaning blade is replaced Ozone filter 15000K Carrier catcher Dry cloth B234/B235/B236/D101/D102/D103...

- Page 208 Vertical Relay Roller-Duplex Vertical Relay Roller Horizontal Exit Roller Transport Roller Driven :Horizontal Guide plate Transport Roller-Driven :Entrance Guide Transport Roller-Driven :Guide Plate-Exit Cooling Transport Belt Discharge Brush :Cooling Transport Blower Brush Belt Discharge Brush :Entrance Discharge Brush :Exit Guide Plate B234/B235/B236/D101/D102/D103...

- Page 209 PM Tables FUSING UNIT 500K 700K 750K Job Time Sensor Blower Brush Exit Sensor Drive Shaft Dry Cloth Cooling pipe Exit Motor Grease Barrierta-JFE 5 5/2 B234/B235/B236/D101/D102/D103...

- Page 210 Controller filter Blower brush 500K PSU filter Blower brush Exterior 500K Heat pipe cooling fan suction duct Blower brush OTHERS 1 Year Breaker Test the operation of the two breaker switches (main body, switches z-folder) once every year. B234/B235/B236/D101/D102/D103 2-10...

-

Page 211: Adf

Lubricate with Silicone or Launa oil if noisy. Sensors Blower brush. Jogger fences Make sure screws are tight. Staple unit 500K Staple Sheets Positioning roller Shift positioning roller 2.2.4 PUNCH UNIT PU5000 B831 Punch unit B531 1 million punches 2-11 B234/B235/B236/D101/D102/D103... -

Page 212: Lcit Rt5000 B832

2.2.7 LCIT RT5010 B834 The PM interval is for the number of sheets that have been fed. 500K 1000K Note Paper feed roller x3 Pick-up rollers x3 Separation rollers x3 Transport guide plate Grip rollers (drive, idle rollers) B234/B235/B236/D101/D102/D103 2-12... -

Page 213: Cover Interposer Tray Ci5000 B835

Blower brush Booklet Stapler Replace the unit if the staple count is 200K. 2.2.10 Z-FOLDING UNIT ZF4000 B660 As Needed Note Drive Rollers Dry cloth. Idle Rollers Dry cloth. Anti-Static Brush Dry cloth. Bushings Silicone Oil Sensors Dry cloth. 2-13 B234/B235/B236/D101/D102/D103... -

Page 214: Perfect Binder/Inserter D391

Area Inserter Unit Vertical Path (Covers from Inserter) Horizontal Paper Path Signature Path Stacking Tray Main Grip Unit Gluing Unit Cover Registration Unit Signature Rotation Unit Trimming Unit Trimming Buffer Unit Trimmings Box Book Buffer Book Output B234/B235/B236/D101/D102/D103 2-14... -

Page 215: Inserter Unit

Horizontal Transport 30,000 K sheets 1,000 K Jam, skew due to Roller 4 sheets deterioration in feed capability Horizontal Transport 30,000 K sheets 1,000 K Jam, skew due to Roller 5 sheets deterioration in feed 2-15 B234/B235/B236/D101/D102/D103... -

Page 216: Signature Path

Main Grip 100 K Main grip motor error, PCB Motors signatures damaged (blown fuse) Signature 50 K Signature thickness sensor Thickness signatures error. Sensor Use the Service Board DIP switches to adjust the signature thickness for 25 mm. B234/B235/B236/D101/D102/D103 2-16... -

Page 217: Gluing Unit

50 K signatures Motor Trimmings Catcher 40 K cuts Set the machine in Replacement Mode for replacement. Other Part Interval Predicted Deodorization Filters 1,000 K sheets Glue odor noticeable Deodorization Filters (Gluing 1,000 K sheets Glue odor noticeable Unit) 2-17 B234/B235/B236/D101/D102/D103... -

Page 218: Ring Binder D392

Drive rollers, idle rollers Damp cloth Switchback Unit Anti-static brushes Blower brush Switchback area sensors Blower brush Drive rollers, idle rollers Damp cloth Binder Unit Paddle roller Blower brush Transport path sensors Blower brush Drive rollers, idle rollers Damp cloth B234/B235/B236/D101/D102/D103 2-18... -

Page 219: Lubrication Points

LUBRICATION POINTS Types of Grease Grease – KS660 – SHIN-ETSU Grease Barrierta – JFE 5 5/2 2.3.1 TRANSFER No.1 No.2 B234P901.WMFF Lubrication Point Type of Grease Upper part of the bias roller terminal Rear end of the bias roller 2-19 B234/B235/B236/D101/D102/D103... -

Page 220: Fusing

Type of Grease Outer, inner surfaces of bushings Inner surface of both ends of the pressure roller where it contacts the ball bearing Fusing unit drive gears No. 4 Grease here B234P903.WMFF B234P902.WMFF No. 3 No. 3 B234P904.WMFF B234/B235/B236/D101/D102/D103 2-20... - Page 221 Lubrication Points No. 5 B234P906.BMPP 2-21 B234/B235/B236/D101/D102/D103...

-

Page 223: Replacement And Adjustment

REPLACEMENT AND ADJUSTMENT REPLACEMENT AND ADJUSTMENT REVISION HISTORY Page Date Added/Updated/New 114 ~ 115 10/09/2007 Updated Information – CIS Image Position Adjustment 147 ~ 192 05/19/2006 Added pages omitted from the original documentation 09/07/2006 Updated Information – PPG, CGB Power Packs... -

Page 225: General Cautions

If the drum unit is loose, poor contact of the drum connectors may cause electrical noise, resulting in unexpected malfunctions (RAM data change is the worst case). 3. To prevent drum scratches, remove the development unit before removing the drum unit. B234/B235/B236/D101/D102/D103... -

Page 226: Transfer Belt Unit

GENERAL CAUTIONS 3.1.3 TRANSFER BELT UNIT 1. Never touch the transfer belt surface with bare hands. 2. Take care not to scratch the transfer belt, because the surface is easily damaged. 3. Before installing the new transfer belt, clean all the rollers and the inner part of the transfer belt with a dry cloth to prevent the belt from slipping. -

Page 227: Charge Corona

8. When using a vacuum cleaner to clean the development unit casing, always ground the casing with your fingers to avoid damaging the toner density sensor with static electricity. 9. When replacing the TD sensor, replace the developer, then execute SP2801 (TD Sensor Initialization) and SP2962 (Auto Process Control Execution). B234/B235/B236/D101/D102/D103... -

Page 228: Cleaning

GENERAL CAUTIONS 3.1.8 CLEANING 1. When servicing the drum cleaning section, be careful not to damage the edges of the drum cleaning blade and 2nd cleaning blade. 2. Do not touch the cleaning blade with bare hands. 3. Before disassembling the cleaning section, place a sheet of paper under it to catch any toner falling from it. -

Page 229: Special Tools And Lubricants

Test Chart – S5S (10 pcs./set) A0299387 Digital Multimeter – FLUKE 87 B6455010 SD (Secure Digital) Card – 64 MB G0219350 Loop Back Connector 3.2.2 LUBRICANTS Part No. Description A2579300 Grease Barrierta – JFE 5 5/2 52039502 Silicon Grease G-501 B234/B235/B236/D101/D102/D103... -

Page 230: Common Procedures

COMMON PROCEDURES COMMON PROCEDURES 3.3.1 PULLING THE DEVELOPMENT UNIT DRAWER OUT NOTE: These illustrations show removal with the hex driver provided to the customer, but the screws can be removed with any Phillips head (+) screwdriver. 11. Open the right front door. 12. - Page 231 Important: Use a sheet of clean paper to cover the slit in the PCU where the drum is visible. This protects the photo-sensitive surface of the drum from overhead light and direct sunlight. B234R914.WMF B234/B235/B236/D101/D102/D103...

-

Page 232: Putting The Development Unit Drawer In

COMMON PROCEDURES 3.3.2 PUTTING THE DEVELOPMENT UNIT DRAWER IN 1. Gently and firmly push the purple handle into the machine until the drawer stops and locks. B234R915.WMF 2. Mount the faceplate holes over the pegs. B234R916.WMF 3. Push in on each corner and edge of the faceplate to make sure that it is locked and mounted correctly. - Page 233 B234R918.WMF 5. Reattach the ground plate ( x1). B234I110E.WMF 6. Mount the inner cover. • Attach screw first but do not tighten. • Attach the other screws. • Tighten all the screws. 7. Close the right front door. B234R920.WMF B234/B235/B236/D101/D102/D103...

-

Page 234: Front Doors

COMMON PROCEDURES 3.3.3 FRONT DOORS B234R945.WMF CAUTION Turn off the main power switch and unplug the machine before attempting any procedure in this section. 1. Open the left door [A]. 2. Bracket [B] ( x 1). 3. Lift up the left door and remove it. 4. -

Page 235: Right Covers

Common Procedures 3.3.4 RIGHT COVERS B234R921.WMF 1. Right upper cover [A] ( x 4). 2. Right lower cover [B] ( x 4). 3-11 B234/B235/B236/D101/D102/D103... -

Page 236: Left Covers

COMMON PROCEDURES 3.3.5 LEFT COVERS B234R910.WMF 1. Disconnect the optional finisher, if it is installed. 2. If the optional finisher was installed: • Remove the front joint bracket x 2) • Remove the and rear joint bracket x 2. 3. Left upper cover [A] ( x 4) 4. -

Page 237: Rear Upper Cover

Common Procedures 3.3.6 REAR UPPER COVER B234R911.WMF 1. Disconnect the ADF connector [A]. 2. Open the PSU box [B] ( x 3) 3. Rear upper cover [C] ( x 3). 3-13 B234/B235/B236/D101/D102/D103... -

Page 238: Controller Box

COMMON PROCEDURES 3.3.7 CONTROLLER BOX B234R155B.WMF B234R155.WMF 8. Open the controller box [A] ( x 3 with washers). 9. Remove 1st connector cover [B] ( x2). 10. Remove 2nd connector cover [C] ( 11. Disconnect [D], [E] ( 12. Disconnect the ground wire [F] ( 13. -

Page 239: Psu Box

6. Disconnect [C] ( NOTE: You do not need to remove the cover as shown. B234R971A.WMF 7. Disconnect connectors [D] ( x10) 8. Remove the hinge covers (top, bottom) [E] ( x 2) 9. Remove the PSU door [A] B234R156A.WMF 3-15 B234/B235/B236/D101/D102/D103... -

Page 240: Document Feeder

DOCUMENT FEEDER DOCUMENT FEEDER 3.4.1 ADF COVERS B234R922.WMF Front cover [A] ( x 2). Rear cover [B] ( x 2). Left cover [C] ( x 2, x 2). Original exit tray. ( 3.5.6) Right cover [D] ( x 4, x 2). Upper exit cover [E] ( x 1). -

Page 241: Adf Original Tray

2. Remove the original tray [A]. 3. Original table cover [B] ( x 2). Bottom Plate 1. Remove the ADF front and rear covers. ( 3.4.1) 2. Remove the original tray [A]. 3. Bottom plate [C] ( x 1, x 1). 3-17 B234/B235/B236/D101/D102/D103... -

Page 242: Feed Unit And Separation Roller

DOCUMENT FEEDER 3.4.3 FEED UNIT AND SEPARATION ROLLER B234R924.WMF 1. Open the left cover. 2. Clip [A]. 3. Remove the feed unit [B]. Pull the feed unit to the front, release the shaft at the rear, and release the front bushing. 4. -

Page 243: Feed Belt

NOTE: The springs [C] come off the feed belt cover easily. 4. Feed belt [D]. NOTE: When reinstalling the pick-up roller unit, make sure that levers [E] and [F] on the front and rear original guides are resting on the pick-up roller unit cover. 3-19 B234/B235/B236/D101/D102/D103... -

Page 244: Pick-Up Roller

DOCUMENT FEEDER 3.4.5 PICK-UP ROLLER B234R860.WMF 1. Open the left cover. 2. Feed unit ( 3.4.3) 3. Snap rings [A] ( x 2). 4. Two bushings [B]. 5. Pick-up roller [C]. NOTE: When reinstalling the pick-up roller, make sure that the one-way clutch [D] is not on the gear side. -

Page 245: Adf Sensors

DOCUMENT FEEDER 3.4.6 ADF SENSORS Entrance Sensor and Length Sensor B234R861.WMF Left cover. Guide plate [A] ( x 5). Entrance sensor [B] ( x 1). Length sensor bracket [C] ( x 2). Length sensor [D] ( x 1). 3-21 B234/B235/B236/D101/D102/D103... -

Page 246: Registration Sensor

DOCUMENT FEEDER Registration Sensor B234R950A.WMF B234R928.WMF 1. ADF front cover. ( 3.4.1) 2. ADF left cover. ( 3.4.1) 3. Release the entrance guide [A] ( x 2). 4. Release the transport belt unit [B] ( x 3). Sensor bracket [C] ( x 1). -

Page 247: Width Sensors

4. Guide plate [B] ( x 2). 5. Release the front end of the upper transport roller [C] (bushing x 1, x 1). 6. Sensor bracket [D] ( x 1). 7. Width sensors [E] ( x 1 each). 3-23 B234/B235/B236/D101/D102/D103... -

Page 248: Exit Sensor, Inverter Sensor

DOCUMENT FEEDER Exit Sensor, Inverter Sensor B234R927.WMF B234R930.WMF 1. Front and rear covers. ( 3.4.1) 2. Original tray. ( 3.4.2) 3. Exit guide unit [A] ( x 5, x 1). 4. Exit sensor [B] ( x 1). NOTE: When reinstalling the exit guide unit, make sure that the guide plate [C] on the exit unit is over the exit gate [D]. -

Page 249: Transport Belt

NOTE: When installing the transport belt, make sure that the belt passes under the upper and lower belt guide spacers [E]. 6. Execute SP6009 (DF Free Run) to do an ADF free run for 3 minutes. After the free run is finished, clean off any dust on the exposure glass. 3-25 B234/B235/B236/D101/D102/D103... -

Page 250: Adf Motors

DOCUMENT FEEDER 3.4.8 ADF MOTORS B234R934.WMF B234R936.WMF Bottom Plate Motor, Pick-up Motor 1. Rear cover. ( 3.4.1) 2. Bottom plate motor [A] ( x 2, x 1). 3. Pick-up motor [B] ( x 2, x 1). 3-26... -

Page 251: Feed-In, Transport, Feed-Out Motors

3. Connector [B] 4. Fins [C] 5. Transport motor [D] ( x 4, x 2). 6. Grounding wire [E] ( x 1). 7. Feed-out motor assembly [F] ( x 2, x 2). 8. Feed-out motor [G] ( x 2). 3-27 B234/B235/B236/D101/D102/D103... -

Page 252: Feed-In Clutch

DOCUMENT FEEDER 3.4.9 FEED-IN CLUTCH B234R943.WMF B234R944.WMF 1. Rear cover. ( 3.4.1) 2. Remove screw [A]. 3. Timing belt [B]. 4. Pulley [C] and bearing [D] from the feed-in drive shaft ( x 1, pin x 1). 5. Pulley [E] and bushing [F] from the pick-up roller cam shaft ( x 1, pin x 1) 6. - Page 253 8. Two bearings [A] from the feed-in clutch shaft ( x 1 each). 9. Pulley [B] ( x 1), pin and timing belt [C]. 10. Feed-in clutch [D]. NOTE: When re-installing the feed-in clutch, put the stopper screw [E] in the clutch hook. 3-29 B234/B235/B236/D101/D102/D103...

-

Page 254: Scanner Unit

SCANNER UNIT SCANNER UNIT 3.5.1 EXPOSURE GLASS B234R001.WMF 1. Left scale [A] ( x 3). 2. Rear scale [B] ( x 2). Slide in the direction of the arrow to remove. 3. Exposure glass [C]. NOTE: When positioning the exposure glass for re-installation, make sure that the white dot [D] is at the rear left corner. -

Page 255: Lens Block

• Disconnect the connectors from the relay board , then remove the lens block. 4. After reassembly, do the scanner and printer copy adjustments. ( 3.15) NOTE: There are no field adjustments for the lens block. 3-31 B234/B235/B236/D101/D102/D103... -

Page 256: Original Size Sensors

SCANNER UNIT 3.5.3 ORIGINAL SIZE SENSORS B234R052.WMF CAUTION Turn off the main switch and unplug the machine before performing this procedure. Laser beams can seriously damage the eyes. 1. Exposure glass. ( 3.5.1) 2. Lens block. ( 3.5.2) 3. Original width sensor [A] ( x 1, x 1). -

Page 257: Exposure Lamps

( 3.5.8) 3. Exposure lamp unit [A] x 2) 4. 1st exposure lamp [B] x 2, x 1, x4). 5. 2nd exposure lamp [C] x 2, x 1, x3). B234R050A.WMF 6. Exposure lamps [D] ( x1). B234R050B.WMF 3-33 B234/B235/B236/D101/D102/D103... -

Page 258: Lamp Regulators

SCANNER UNIT 3.5.5 LAMP REGULATORS B234R007A.WMF B234R007B.WMF 1. Exposure glass. ( 3.5.1) 2. Open the front door, then remove the top front cover. ( 3.5.8) 3. Remove [E]: Left inner cover ( x 2) [F]: Right inner cover ( x 2) [G]: Middle inner cover ( x 2) [H]: Lamp regulator cover (... -

Page 259: Optics Dust Filter

SCANNER UNIT 3.5.6 OPTICS DUST FILTER B234R006.WMF 1. Original exit tray [A] ( x 4). 2. Optics dust filter [B]. 3-35 B234/B235/B236/D101/D102/D103... -

Page 260: Scanner Hp Sensor

SCANNER UNIT 3.5.7 SCANNER HP SENSOR B234R017.WMF 10. Front upper cover ( 3.5.8) 11. Left lamp regulator ( 3.5.5) 12. Scanner HP sensor bracket [A] ( x 1). 13. Scanner HP sensor [B] ( x 1, Pawls x4). 3-36... -

Page 261: Scanner Motor

4. Remove the MCU [B] cover ( x 3). 5. Scanner motor assembly [C] ( x 2, x 3). 6. Scanner motor from the bracket [D] ( x 3). 7. After reassembly, do the copy image adjustments. ( 3.18) 3-37 B234/B235/B236/D101/D102/D103... -

Page 262: Scanner Drive Wires

SCANNER UNIT 3.5.9 SCANNER DRIVE WIRES Preparation B234R011.WMF B234R012.WMF 1. Remove the ADF ( x 2). 2. Original exit tray [A] ( x 4). 3. Exposure glass ( 3.5.1) 4. Top front cover [B] ( x 7). 5. Top rear cover [C] ( x 6). -

Page 263: Front, Rear Scanner Drive Wires

4. Wind the end of the wire with the ball as shown ( , , ). 5. Wind the end of the wire with the ring as shown ( , , ). 6. Install the tension spring on the tension bracket, and slightly tighten the tension bracket ( x 1). 3-39 B234/B235/B236/D101/D102/D103... - Page 264 SCANNER UNIT B234R015.WMF B234R013.WMF 7. Install the 1st scanner and adjust the position with the positioning tools [A]. 8. Secure the 1st scanner with the scanner wire bracket [B] ( x 1). 9. Tighten the tension bracket [C] and remove the tape. 10.

-

Page 265: Sib

SCANNER UNIT 3.5.10 B234R903.BMP Remove: ( 3.5.8) • Original exit tray • Top right cover • Filter • Bracket [A] SIB ( 3-41 B234/B235/B236/D101/D102/D103... -

Page 266: Laser Unit

LASER UNIT LASER UNIT WARNING • This laser unit employs 8 laser beams produced by a Class III LDA with a wavelength of 788 nm and intensity of 10 mW. Direct exposure to the eyes could cause permanent blindness. • Before any performing any replacement or adjustment of the laser unit, press the main power switch to power the machine off then unplug the machine from the power source. -

Page 267: Ld Unit

Before you remove the LD unit, take a careful note of where these spacers are. When replacing the LD unit, these spacers must be in exactly the same position. • Be sure to remove the mylar from the underside of the old LD unit and attach it to the new one. 3-43 B234/B235/B236/D101/D102/D103... - Page 268 LASER UNIT 7. After installing the LD unit, execute SP2115 001~009 to input the pitch settings for the main scan beams. NOTE: The correct settings for these SP codes are printed on a decal attached to the mounting bracket [C] of the LD unit. <LD Unit Lot No.>...

-

Page 269: Polygon Mirror Motor

NOTE: 1) When reinstalling, make sure that the polygon mirror opening faces the right. 2) Never touch the glass surface of the polygon mirror motor with bare hands. 7. After reassembly, do the scanner and printer copy adjustments. ( 3.15) 3-45 B234/B235/B236/D101/D102/D103... -