Agilent Technologies 4294A Programming Manual

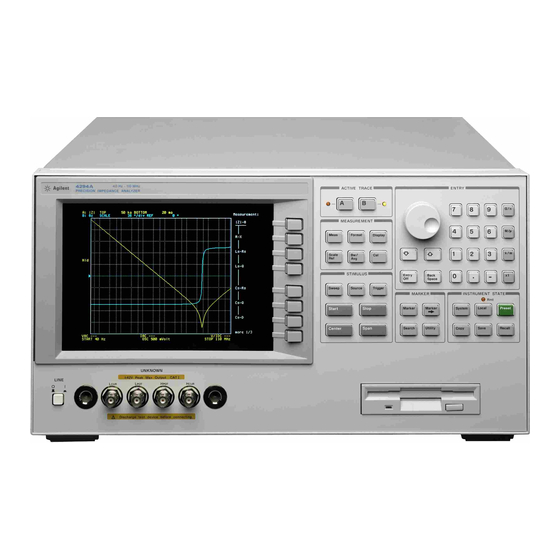

Precision impedance analyzer

Hide thumbs

Also See for 4294A:

- Operation manual (10 pages) ,

- Operating manual (469 pages) ,

- Configuration manual (8 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Agilent Technologies 4294A

- Page 1 Agilent 4294A Precision Impedance Analyzer Programming Manual Eighth Edition FIRMWARE REVISIONS This manual applies directly to instruments that have the firmware revision 1.11. For additional information about firmware revisions, see Appendix A. Part No. 04294-90061 August 2012 Printed in Japan...

- Page 2 This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Agilent Technologies. Agilent Technologies Japan, Ltd.

- Page 3 Sample Program Disk A sample program disk (Agilent Part Number 04294-18020) is supplied with this manual. The disk contains the sample programs listed in this manual. The customer shall have the personal, nontransferable rights to use, copy, or modify SAMPLE PROGRAMS in this manual for the Customer’s internal operations.

-

Page 5: Table Of Contents

Contents 1. To make effective use of this manual Contents of this manual ..............20 How To Use This Manual . - Page 6 Contents Deleting a segment ..............47 Moving offset ranges .

- Page 7 Controlling the Agilent 4294A ........

- Page 8 Instrument BASIC Commands Specific to the Agilent 4294A ....... . .

- Page 9 Printing onto a Printer Directly Connected to Agilent 4294A ....... .

- Page 10 Contents ANARANG ..............267 ANARFULL .

- Page 11 Contents DCOMLOAD{R|L} ..............292 DCOMOPEN{G|C} .

- Page 12 Contents FSIZE? ................318 HIDI .

- Page 13 Contents MKRAUV? ............... 351 MKRCENT .

- Page 14 Contents OUTFIO ............... . . 371 OUTGIO .

- Page 15 Contents PKPOL ................400 POIN .

- Page 16 Contents SEAL ................426 SEAM .

- Page 17 Contents WIDFVAL ............... . 460 WIDSIN .

- Page 18 Contents...

-

Page 19: To Make Effective Use Of This Manual

To make effective use of this manual This chapter describes the contents and the use of this manual and makes references to various other manuals. -

Page 20: Contents Of This Manual

To make effective use of this manual Contents of this manual Contents of this manual This manual is a guide to writing BASIC programs for the Agilent 4294A precision impedance analyzer. Chapter 1 , “To make effective use of this manual.”... - Page 21 Agilent 4294A than the current printing date of this manual. The information in this manual applies directly to a 4294A model that has a serial number prefix listed on the title page of this manual.

-

Page 22: How To Use This Manual

For descriptions of GPIB commands in detail, see Chapter 16 , “GPIB Command Reference.” 4. You can also use HP Instrument BASIC functions with the Agilent 4294A. Chapter 11 , “Using HP Instrument BASIC,” describes how to use Instrument BASIC. Read this chapter if you are a novice in Instrument BASIC. -

Page 23: Other Manuals Attached To This Unit

BASIC Interface Technique,” and “HP Instrument BASIC Language Reference.” Service Manual (option 0BW only) (part number: 04294-901x0) This manual describes how to adjust and repair the Agilent 4294A and how to carry out performance tests. This manual will be attached if you choose option 0BW. Chapter 1... - Page 24 To make effective use of this manual Other manuals attached to this unit Chapter 1...

-

Page 25: Remote Control, Overview

Remote Control, Overview This chapter describes how to set up a GPIB remote control system and the basic use of GPIB commands. -

Page 26: Gpib Remote Control System, Overview

JIS-C1901, which are worldwide standards. Using the GPIB interface allows you to control the Agilent 4294A from an external computer. The computer sends commands and instructions through the GPIB to the 4294A and receives data sent from the 4294A. Chapter 2... - Page 27 2. GPIB system controller You can use the Agilent 4294A as a system controller. To use HP Instrument BASIC without an external computer, set the 4294A to system controller mode. For details, see Chapter 11 , “Using HP Instrument BASIC.”...

-

Page 28: Controller

HP Instrument BASIC is connected to the Agilent 4294A by its interface installed in the 4294A. The interface select code of the built-in interface is set to 8 so as to distinguish it from the external select code 7. -

Page 29: Sending Gpib Command Messages

IEEE common commands Commands defined by IEEE488.2 Agilent 4294A commands Commands specific to the Agilent 4294A. These include all of the measurement functions and some of the general-purpose functions. Message syntax Descriptions of the syntax used in sending program messages from the GPIB are given below. -

Page 30: The Basics Of Writing/Running Programs

The following describes a procedure for writing an Instrument BASIC program as an example of simple programming. For more on how to use Instrument BASIC, see Chapter 11 , “Using HP Instrument BASIC.” This example sets the Agilent 4294A as shown below. ACTIVE TRACE block Trace A (default setting) - Page 31 Remote Control, Overview The Basics of Writing/Running Programs Step 6. Press the following instrument state key to enter the preset command. [Preset] The GPIB command “;PRES” to be used for presetting the equipment automatically appears at the cursor position. 10 ASSIGN @Hp4294 TO 800 20 OUTPUT @Hp4294;";PRES"...

-

Page 32: Running The Program

Remote Control, Overview The Basics of Writing/Running Programs Step 10. Enter the END command to quit the program. [System] IBASIC [×1] 10 ASSIGN @Hp4294 TO 800 20 OUTPUT @Hp4294;";PRES" 30 OUTPUT @Hp4294;";MEAS CSR" 40 OUTPUT @Hp4294;";CENT 70E6;SPAN 100E3" 50 OUTPUT @Hp4294;";AUTO" 60 END 70 _ Step 11. -

Page 33: Saving And Reading The Program

Remote Control, Overview Saving and Reading the Program Saving and Reading the Program Saving the program generated A simple saving procedure is given here. For details see “Saving a Program (SAVE)” on page 145. Step 1. First, connect the keyboard. Step 2. -

Page 34: Remote Control Using A Lan

Remote Control using a LAN The Agilent 4294A can be connected to a local area network (LAN). Connecting the 4294A to its external controller via a LAN allows you to efficiently send GPIB commands to and read data from the external controller. -

Page 35: Setting Measurement Conditions

Setting Measurement Conditions This chapter describes how to set measurement conditions. -

Page 36: Setting Measurement Parameters

Setting Measurement Conditions Setting Measurement Parameters Setting Measurement Parameters To set measurement parameters, use the command given below. This command sets measurement parameters for both trace A and trace B at the same time. • “MEAS” on page 348 You can set measurement parameters in the combinations shown in Table 3-1 depending on the parameters used at the time of sending a command. - Page 37 Setting Measurement Conditions Setting Measurement Parameters The following gives brief descriptions of the measurement parameters in Table 3-1: Impedance amplitude (absolute value) Admittance amplitude (absolute value) θ Impedance phase (for |Z|-θ), Admittance phase (for |Y|-θ) Impedance (complex number (R+jX)) Admittance (complex number (G+jB)) R, Rs Equivalent series resistance Equivalent series reactance...

-

Page 38: Setting Measurement Signals

Setting Measurement Conditions Setting Measurement Signals Setting Measurement Signals Setting the oscillator To set an oscillator level, use the commands given below. • “POWMOD” on page 404 • “POWE” on page 403 Either a voltage or a current can be used to set the oscillator level. First, specify whether you use voltage or a current with the “POWMOD”... -

Page 39: Setting A Sweep Condition

Setting Measurement Conditions Setting a Sweep Condition Setting a Sweep Condition Setting a sweep parameter Choose a sweep parameter from among the oscillator frequency, oscillator level, and dc bias level. To set the parameter, use the command given below. • “SWPP”... -

Page 40: Setting The On-Screen Arrangement

Setting Measurement Conditions Setting the On-screen Arrangement Setting the On-screen Arrangement You carry out most of the on-screen arrangement settings independently for trace A and trace B. After made, these will take effect on the active trace. Thus you need to use the command given below to properly switch the active trace settings from one trace to the other. -

Page 41: Setting A Display Scale

Setting Measurement Conditions Setting the On-screen Arrangement Setting a display scale If both a data trace and a memory trace are concurrently displayed, you can separately set different scales to these traces. Use the commands given below to specify whether to use the same scale for both data and memory traces or to specify which trace to set a scale to when not using the same scale. - Page 42 Setting Measurement Conditions Setting the On-screen Arrangement Figure 3-1 Commands for setting display scale parameters Polar chart format Make the settings by using the full-scale value (the value of the outermost circle) only. To make the settings, use the command given below. •...

-

Page 43: Setting Averaging

Setting Measurement Conditions Setting Averaging Setting Averaging Setting a measurement bandwidth To set a measurement bandwidth, use the command given below. • “BWFACT” on page 274 Setting averaging Setting sweep averaging To set or control sweep averaging, use the command given below. •... -

Page 44: Combining Two Or More Sweep Conditions (List Sweep)

Setting Measurement Conditions Combining Two or More Sweep Conditions (List Sweep) Combining Two or More Sweep Conditions (List Sweep) You can carry out a sweep (list sweep) by combining the segments that set the sweep condition; these segments can provide up to 18 identical sweep parameters. To carry out a list sweep, prepare a table of segments. -

Page 45: Deleting A Segment

Setting Measurement Conditions Combining Two or More Sweep Conditions (List Sweep) Deleting a segment To delete a segment, use the commands given below. • “SDEL” on page 425 • “CLEL” on page 279 The “SDEL” command deletes a specified segment from the table (if no table is specified, then he segment to be worked on at the time of executing the command involved). -

Page 46: Setting The Limit Test Functions

Setting Measurement Conditions Setting the Limit Test Functions Setting the Limit Test Functions To turn on or off the limit test functions, use the command given below. • “LIMITEST” on page 328 To use the limit test functions, you need to make a limit line table, which includes the limits of sweep ranges (segments) defined by start points and endpoints. -

Page 47: Deleting A Segment

Setting Measurement Conditions Setting the Limit Test Functions To turn on or off the ranges for limiting individual segments, use the command given below. • “LIMSTEST” on page 335 After setting the parameters, send the command given below to finish setting segments. •... -

Page 48: Saving/Recalling Measurement Conditions

You can save the measurement conditions in a file. By saving frequently used measurement conditions, you can set the Agilent 4294A to a desired measurement condition by merely recalling the corresponding file when needed, avoiding the need to send a number of commands. -

Page 49: A Sample Program For Setting Measurement Conditions

The following is a sample program for setting measurement conditions. The program is given the file name setup.bas and stored on the sample program disk. This program resets the Agilent 4294A, then makes the settings shown below, and finally delivers the completion message when the settings are completed. - Page 50 Split$, Accumulate$, Disp_a$, Disp_b$, Fmt_a$, Fmt_b$, Top_v_a, Btm_v_a, Ref_p_b, Ref_v_b, Scal_b, Phase_unit$, and Exp_phase$. Lines 700 to 710 These lines reset the Agilent 4294A and then set the adapter selection to the variable Adapter$. Lines 750 to 900 These lines make a list sweep table.

- Page 51 Setting Measurement Conditions A Sample Program for Setting Measurement Conditions List_star(1)=1.0E+6 List_stop(1)=2.0E+7 Nop(1)=21 Osc_mode$(1)="VOLT" Osc_pow(1)=1.0 Dc_b_mode$(1)="CVOLT" Dc_bias(1)=10.0 Bw_fact$(1)="1" P_ave(1)=1 ! -- Segment 2 -- List_star(2)=2.0E+7 List_stop(2)=4.0E+7 Nop(2)=51 Osc_mode$(2)="VOLT" Osc_pow(2)=1.0 Dc_b_mode$(2)="CVOLT" Dc_bias(2)=10.0 Bw_fact$(2)="5" P_ave(2)=4 ! -- Segment 3 -- List_star(3)=4.0E+7 List_stop(3)=1.0E+8 Nop(3)=21 Osc_mode$(3)="VOLT"...

- Page 52 Setting Measurement Conditions A Sample Program for Setting Measurement Conditions OUTPUT @Hp4294a;"POIN ";Nop(I) OUTPUT @Hp4294a;"POWMOD "&Osc_mode$(I) OUTPUT @Hp4294a;"POWE ";Osc_pow(I) OUTPUT @Hp4294a;"DCMOD "&Dc_b_mode$(I) OUTPUT @Hp4294a;"DCV ";Dc_bias(I) OUTPUT @Hp4294a;"BWFACT "&Bw_fact$(I) OUTPUT @Hp4294a;"PAVERFACT ";P_ave(I) OUTPUT @Hp4294a;"SDON" OUTPUT @Hp4294a;"SCOL ";((I-1) MOD 6)+1 NEXT I OUTPUT @Hp4294a;"EDITDONE"...

-

Page 53: Preparing For Accurate Measurement

Preparing For Accurate Measurement This chapter describes how to apply adapter setting, user calibration, fixture compensation, and port extension compensation. -

Page 54: Adapter Setting

Line 110 This line substitutes the adapter selection to the variable Adapter$. Lines 130 to 160 These lines reset the Agilent 4294A and then set the adapter selection to the variable Adapter$. Lines 180 to 190 These lines set 1 to Bit 8 of the instrument event status register (the bit... - Page 55 Preparing For Accurate Measurement Adapter Setting Lines 210 to 310 These lines measure phase data, open data, short data and load data by using the subprogram FNAdap_setup. If an error is detected after any measurement, the program is terminated. Lines 330 to 350 These lines calculate setup data and store them in non-volatile memory.

- Page 56 Preparing For Accurate Measurement Adapter Setting Result=FNAdap_setup(@Hp4294a,Scode,"Phase") IF Result<>0 THEN Prog_end Result=FNAdap_setup(@Hp4294a,Scode,"Open") IF Result<>0 THEN Prog_end Result=FNAdap_setup(@Hp4294a,Scode,"Short") IF Result<>0 THEN Prog_end Result=FNAdap_setup(@Hp4294a,Scode,"Load") IF Result<>0 THEN Prog_end OUTPUT @Hp4294a;"ECALDON" OUTPUT @Hp4294a;"*OPC?" ENTER @Hp4294a;Buff$ PRINT "All Data Measurement Complete" 380 Prog_end: END ! Adapter Setup Data Measurement Function DEF FNAdap_setup(@Hp4294a,INTEGER Scode,Standard$) DIM Inp_char$[9],Err_mes$[50]...

- Page 57 Preparing For Accurate Measurement Adapter Setting RETURN -1 END IF FNEND Chapter 4...

-

Page 58: User Calibration

User calibration data and fixture compensation data are measured either at fixed points preset by the Agilent 4294A (fixed measurement points) or at sweep measurement points set at the time of command execution (user measurement points). In the former case, the compensation coefficient at a sweep measurement point is obtained by interpolation. - Page 59 This line substitutes the selection of data measurement points to the variable Cal_point$. Lines 160 to 190 These lines reset the Agilent 4294A and then set data measurement points to Cal_point$. Lines 230 to 280 These lines use the subprogram Inp_data to acquire standard values for open data, short data, and load data.

- Page 60 Preparing For Accurate Measurement User Calibration volatile memory. Lines 530 to 540 These lines indicate the message of completion and terminate the program. The following describes FNUser_cal, a data measurement subprogram for user calibration, which is shown in lines 580 to 920. Line 610 This line clears the status byte register.

- Page 61 Preparing For Accurate Measurement User Calibration Example 4-2 Data measurement for user calibration DIM Input_val$[9],Buff$[9],Adapter$[9] REAL Open_g,Open_c,Short_r,Short_l,Load_r,Load_l INTEGER Scode,Err_no CLEAR SCREEN IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 Scode=8 ELSE ASSIGN @Hp4294a TO 717 Scode=7 END IF Cal_point$="USER" ! Initial Setting OUTPUT @Hp4294a;"PRES"...

- Page 62 Preparing For Accurate Measurement User Calibration ! User Calibration Data Measurement Function DEF FNUser_cal(@Hp4294a,INTEGER Scode,Standard$) DIM Inp_char$[9],Err_mes$[50] INTEGER Err_no OUTPUT @Hp4294a;"*CLS" PRINT "Set "&Standard$&"-Connection" INPUT "OK? [Y/N]",Inp_char$ IF UPC$(Inp_char$)="Y" THEN ON INTR Scode GOTO Meas_end ENABLE INTR Scode;2 SELECT Standard$ CASE "Open"...

-

Page 63: Fixture Compensation

User calibration data and fixture compensation data are measured either at fixed points preset by the Agilent 4294A (fixed measurement points) or at sweep measurement points set at the time of command execution (user-selected measurement points). In the case of the former, the compensation coefficient at a sweep measurement point is obtained by interpolation. - Page 64 Agilent 4294A and stores the measured data and the defined standard values in a flash disk (nonvolatile memory disk) by giving the data the filenames COM_DATA and STD_VAL, respectively.

- Page 65 Preparing For Accurate Measurement Fixture Compensation Standard$ and wait for you to press the y key and the return key. Lines 1090 to 1100 These lines set the branch target for an SRQ interrupt to make the SRQ interrupt effective. Lines 1110 to 1180 These lines send the commands to execute the standard measurement specified by Standard$.

- Page 66 Preparing For Accurate Measurement Fixture Compensation OUTPUT @Hp4294a;"ESNB 256" OUTPUT @Hp4294a;"*SRE 4" Result=FNFixt_comp(@Hp4294a,Scode,"Open") IF Result<>0 THEN Prog_end Result=FNFixt_comp(@Hp4294a,Scode,"Short") IF Result<>0 THEN Prog_end Result=FNFixt_comp(@Hp4294a,Scode,"Load") IF Result<>0 THEN Prog_end ! Data Reading OUTPUT @Hp4294a;"FORM3" OUTPUT @Hp4294a;"OUTPCOMC1?" ENTER @Hp4294a USING "#,2A";Buff$ ENTER @Hp4294a USING "#,6A";Size$ ENTER @Binary;Com_o(*) ENTER @Hp4294a USING "#,1A";Buff$ OUTPUT @Hp4294a;"OUTPCOMC2?"...

- Page 67 Preparing For Accurate Measurement Fixture Compensation 1080 IF UPC$(Inp_char$)="Y" THEN 1090 ON INTR Scode GOTO Meas_end 1100 ENABLE INTR Scode;2 1110 SELECT Standard$ 1120 CASE "Open" 1130 OUTPUT @Hp4294a;"COMA" 1140 CASE "Short" 1150 OUTPUT @Hp4294a;"COMB" 1160 CASE "Load" 1170 OUTPUT @Hp4294a;"COMC" 1180 END SELECT 1190...

- Page 68 Cal_point$, Point, File$ and Std_file$, respectively. Lines 220 to 250 These lines reset the Agilent 4294A and then assign the data measurement points to Cal_point$. Lines 290 to 310...

- Page 69 Preparing For Accurate Measurement Fixture Compensation Cal_point$="FIXED" Point=100 File$="COM_DATA" Std_file$="STD_VAL" ! Initial Setting OUTPUT @Hp4294a;"PRES" OUTPUT @Hp4294a;"*OPC?" ENTER @Hp4294a;Buff$ OUTPUT @Hp4294a;"CALP ";Cal_point$ ! Load Data ASSIGN @File TO File$ ENTER @File;Com_o(*),Com_s(*),Com_l(*) ASSIGN @File TO * ASSIGN @File TO Std_file$ ENTER @File;Open_g,Open_c,Short_r,Short_l,Load_r,Load_l ASSIGN @File TO * ! Define Standard Value OUTPUT @Hp4294a;"DCOMOPENG ";Open_g...

-

Page 70: Port Extension Compensation

Preparing For Accurate Measurement Port Extension Compensation Port Extension Compensation With either 7 mm or PROBE selected as the adapter, you can compensate the delay time due to port extension by using the port extension compensation functions when connecting an extension cable to the adapter. •... -

Page 71: Starting A Measurement (Trigger) And Detecting The Completion Of A Measurement (End Of Sweeps)

Starting a Measurement (Trigger) and Detecting the Completion of a Measurement (End of Sweeps) This chapter describes how to generate a trigger to start a measurement and how to detect the completion of a measurement. -

Page 72: Triggering A Measurement (Starting A Measurement)

(End of Sweeps) Triggering a Measurement (Starting a Measurement) Triggering a Measurement (Starting a Measurement) Trigger system The trigger system of the Agilent 4294A has three states: “Idle,” “Waiting for Trigger,” and “Measurement” as shown in Figure 5-1. Figure 5-1 Trigger system The state transitions in the trigger system are described below. -

Page 73: Triggering A Measurement

Starting a Measurement (Trigger) and Detecting the Completion of a Measurement (End of Sweeps) Triggering a Measurement (Starting a Measurement) Trigger source setting Method of generating a trigger Internal trigger (INT) Automatically generates an internal trigger. External trigger (EXT) Enters a trigger signal from the EXT TRIGGER terminal on the rear panel to generate a trigger. -

Page 74: Waiting For The Completion Of One Or More Sweeps (Detecting The Completion Of A Measurement)

“ESNB” on page 314 The procedure is as follows: Step 1. Make the setting so that the Agilent 4294A generates an SRQ when the sweep completion bit in the instrument event status register is set to “1.” Step 2. Generate a trigger to start one or more sweeps. - Page 75 Starting a Measurement (Trigger) and Detecting the Completion of a Measurement (End of Sweeps) Waiting for the Completion of One or More Sweeps (Detecting the Completion of a Measurement) Lines 30 to 90 Identifies the external controller and Instrument BASIC and sets the GPIB address and the select code.

-

Page 76: Using The *Opc? Command

You can use a setting to make the controller wait for the completion of one or more sweeps performed by the Agilent 4294A (for example, using the WAIT command of HP BASIC). This method is simple, but if you set an inappropriate wait, unexpected errors could occur. -

Page 77: Reading/Writing Measurement Data

Reading/Writing Measurement Data This chapter describes how to read and write measurement data and how to obtain level monitoring and limit test results. -

Page 78: Data Transfer Format

Data Transfer Format The format applicable when you read measurement parameter settings from the Agilent 4294A (as when you read the sweep start point with “STAR?”) is the ASCII format, regardless of which data transfer format has been specified. You can select either the ASCII format (default) or one of the binary formats for reading measurement data, waveform analysis results and so on from the Agilent 4294A (as when you read a data trace array with “OUTPDTRC?”). -

Page 79: Ieee 32-Bit Floating Point Format (Form 2)

Reading/Writing Measurement Data Data Transfer Format • Floating Point Format Figure 6-2 shows this format. Numbers are expressed with floating points. For example, 1000 is expressed as “1.0E3.” Figure 6-2 Floating Point Format IEEE 32-bit floating point format (Form 2) In this format, each number is expressed by four bytes. -

Page 80: Ieee 64-Bit Floating Point Format (Form 3)

Reading/Writing Measurement Data Data Transfer Format IEEE 64-bit floating point format (Form 3) With this format, each number is expressed with eight bytes. Therefore, data containing 201 measured values is 3,216 bytes long (2 pieces of data per measurement point). Numbers are transferred in the format shown in Figure 6-4. -

Page 81: Internal Data Processing

Internal Data Processing Internal Data Processing Data processing sequence Figure 6-5 outlines the sequence of data processing performed within the Agilent 4294A. Figure 6-5 Agilent 4294A Data Processing Sequence The following describe each of the data arrays shown in Figure 6-5. - Page 82 Reading/Writing Measurement Data Internal Data Processing Data trace array The data trace array contains data that appears on the screen as data trace, that is, the result of measurement parameter conversion and arithmetic performed on the data array. Each result is stored as a complex number, regardless of whether the data is a scalar or vector. Therefore, if the data is a scalar, “0”...

- Page 83 Reading/Writing Measurement Data Internal Data Processing Compensation data array The compensation data array contains open, short and load measurement data used for calculation of the fixture compensation coefficient. These data are stored as complex numbers. Three different types of arrays are available to choose from depending on the type of measurement data (open, short, or load data).

-

Page 84: Reading/Writing Data

Reading/Writing Measurement Data Reading/Writing Data Reading/Writing Data Reading/writing measurement data Reading/writing array in ASCII format Example 6-1 shows the process of reading and writing array data in the ASCII format. This program is available under the filename of “data_b2a.bas” on the sample program disk. This program reads the data trace array for trace B in ASCII format and writes it to the data trace array for trace A. - Page 85 Reading/Writing Measurement Data Reading/Writing Data OUTPUT @Hp4294a;"TRAC A" OUTPUT @Hp4294a;"FMT "&Fmt$ OUTPUT @Hp4294a;"INPUDTRC ";Trc(*) OUTPUT @Hp4294a;"AUTO" Reading/writing data array in a binary format Example 6-2 shows the process of reading and writing array in binary format. This program is available under the filename of “mem2dat.bas” on the sample program disk. This program reads the memory trace array for trace A in the IEEE 64-bit floating point format and writes it to the data trace array.

- Page 86 Reading/Writing Measurement Data Reading/Writing Data Example 6-2 Reading/Writing Data Trace Array in a Binary Format DIM Trc(1:201,1:2),Act_trc$[9],Err_mes$[50],Header$[9],Buff$[9] INTEGER Err_no,Nop IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 ASSIGN @Binary TO 800;FORMAT OFF ELSE ASSIGN @Hp4294a TO 717 ASSIGN @Binary TO 717;FORMAT OFF END IF Act_trc$="A"...

-

Page 87: Reading Level Monitoring Results

Osc_mode$, Osc_pow, Dc_bias, Dc_b_rng$, and Mon_bias$, respectively. Lines 190 to 220 Resets the Agilent 4294A and then sets the sweep start point, the sweep stop point, and the number of measurement points to 10 MHz, 20 MHz, and 11, respectively. - Page 88 Reading/Writing Measurement Data Reading/Writing Data Lines 580 to 630 Displays the contents of “Swp_prm(*)”, “Mon_osc_v(*)”, “Mon_osc_i(*)”, and “Mon_bias(*).” Example 6-3 Reading Level Monitoring Results DIM Mon_osc_v(1:11),Mon_osc_i(1:11),Mon_bias(1:11),Swp_prm(1:11) DIM Osc_mode$[9],Mon_bias$[9],Header$[9],Buff$[9],Img$[30] REAL Osc_pow,Dc_bias CLEAR SCREEN IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 ASSIGN @Binary TO 800;FORMAT OFF ELSE ASSIGN @Hp4294a TO 717...

-

Page 89: Reading Limit Test Results

L_lim_star_b(*), Lim_stop_b(*), U_lim_stop_b(*), and L_lim_stop_b(*) respectively. Lines 620 to 670 Resets the Agilent 4294A and then sets the measurement parameters, the sweep start point, the sweep stop point, and the number of measurement points to the corresponding variables Meas_para$, Star, Stop, and Nop and enables traces A and B to be displayed on separate screens. - Page 90 Reading/Writing Measurement Data Reading/Writing Data Line 870 to 890 Specifies trace B as the active trace and sets the maximum and minimum value of the screen for trace B to Top_b and Btm_b, respectively. Lines 900 to 1030 Creates a limit line table for trace B and turns ON the limit test function.

- Page 91 Reading/Writing Measurement Data Reading/Writing Data Example 6-4 Reading Limit Test Results REAL Star,Stop,Top_a,Btm_a,Top_b,Btm_b REAL Fail_res_a(1:41,1:4),Fail_res_b(1:41,1:4) REAL Lim_star_a(1:3),U_lim_star_a(1:3),L_lim_star_a(1:3) REAL Lim_stop_a(1:3),U_lim_stop_a(1:3),L_lim_stop_a(1:3) REAL Lim_star_b(1:3),U_lim_star_b(1:3),L_lim_star_b(1:3) REAL Lim_stop_b(1:3),U_lim_stop_b(1:3),L_lim_stop_b(1:3) DIM Meas_para$[9],Buff$[9] INTEGER Nop,Fail_nop CLEAR SCREEN IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 ELSE ASSIGN @Hp4294a TO 717 END IF Meas_para$="CSD"...

- Page 92 Reading/Writing Measurement Data Reading/Writing Data OUTPUT @Hp4294a;"PRES" OUTPUT @Hp4294a;"MEAS "&Meas_para$ OUTPUT @Hp4294a;"STAR ";Star OUTPUT @Hp4294a;"STOP ";Stop OUTPUT @Hp4294a;"POIN ";Nop OUTPUT @Hp4294a;"SPLD ON" OUTPUT @Hp4294a;"TRAC A" OUTPUT @Hp4294a;"TOPV ";Top_a OUTPUT @Hp4294a;"BOTV ";Btm_a OUTPUT @Hp4294a;"EDITLIML" FOR I=1 TO 3 OUTPUT @Hp4294a;"LIMSADD" OUTPUT @Hp4294a;"LIMSTAR ";Lim_star_a(I) OUTPUT @Hp4294a;"LIMUSTAR ";U_lim_star_a(I) OUTPUT @Hp4294a;"LIMLSTAR ";L_lim_star_a(I) OUTPUT @Hp4294a;"LIMSTOP ";Lim_stop_a(I)

-

Page 93: When To Read/Write Data

Reading/Writing Measurement Data Reading/Writing Data 1250 PRINT "-- Trace A All Pass --" 1260 END IF 1270 1280 OUTPUT @Hp4294a;"TRAC B" 1290 OUTPUT @Hp4294a;"OUTPFAIP?" 1300 ENTER @Hp4294a;Fail_nop 1310 1320 IF Fail_nop>0 THEN 1330 OUTPUT @Hp4294a;"FORM4" 1340 OUTPUT @Hp4294a;"OUTPLIMF?" 1350 FOR I=1 TO Fail_nop 1360 ENTER @Hp4294a USING "#,K,K,K,K";Fail_res_b(I,1),Fail_res_b(I, 2),Fail_res_b(I,3),Fail_res_b(I,4) - Page 94 Reading/Writing Measurement Data Reading/Writing Data Chapter 6...

-

Page 95: Processing Measurement Results

Processing Measurement Results This chapter describes how to process measurement results using the marker function, the equivalent circuit analysis function, the trace bandwidth analysis function, and analysis commands. -

Page 96: Reading Measurement Data At Specific Measurement Points (Using The Marker Function)

Processing Measurement Results Reading Measurement Data at Specific Measurement Points (Using the Marker Function) Reading Measurement Data at Specific Measurement Points (Using the Marker Function) You can use the marker to read measurement data at specific points on the trace or search for the point that meets a specific condition such as the maximum value. - Page 97 Processing Measurement Results Reading Measurement Data at Specific Measurement Points (Using the Marker Function) • “SEANPK” on page 427 • “SEANPKL” on page 427 • “SEANPKR” on page 428 • “SEAL” on page 426 • “SEAR” on page 428 With the marker’s search function, you can search for measurement points, expressed as peaks, that meet the definitions given in Figure 7-1.

-

Page 98: Reading The Marker-Specified Value

*1.You can read parameter values only when you use the fixed Δ marker. You can use the following command to display a list of all marker-specified values on the Agilent 4294A LCD. Note, however, that you cannot use these commands to read these values. - Page 99 Processing Measurement Results Reading Measurement Data at Specific Measurement Points (Using the Marker Function) for the peak and moves the marker to that negative peak, and positions submarker 2 at the peak. Lines 360 to 430 Reads and displays submarker-specified measurement parameter values.

-

Page 100: Analyzing Measurement Results

Analyzing Measurement Results Analyzing Measurement Results Equivalent circuit analysis With the Agilent 4294A, five different circuit models are available for equivalent circuit analysis as shown below depending on the type of measurement results obtained. Equivalent Circuit Analysis Model Sample Types... - Page 101 Cent, Span, and model$, respectively. Lines 130 to 160 Resets the Agilent 4294A, sets impedance amplitude and phase as measurement parameters, and sets the sweep center value and the sweep span value to Cent and Span, respectively.

-

Page 102: Statistics Analysis

PRINT "L1 :";L1;"[H]" PRINT "C0 :";C0;"[F]" OUTPUT @Hp4294a;"SIMFCHAR" Statistics analysis The Agilent 4294A allows you to analyze statistics (average, standard deviation, difference between maximum and minimum). Use the following command to turn this function ON or OFF. • “MEASTAT” on page 349 NOTE The statistics analysis function is available when the marker function is ON. -

Page 103: Bandwidth Analysis

Normally, trace bandwidth analysis is made when the marker searches for peaks. Therefore, the above values appear to the right of “Peak:” on the Agilent 4294A display. However, if the marker is not positioned at any of the peaks, the above values do not represent parameter values obtained at a peak. - Page 104 Cent, Span, and Act_trc$, respectively. Lines 130 to 160 Resets the Agilent 4294A, sets impedance amplitude and phase as measurement parameters, and sets the sweep center value and the sweep span value to Cent and Span, respectively.

- Page 105 Processing Measurement Results Analyzing Measurement Results Lines 230 to 240 Turns ON the marker function, searches for a peak, and moves the marker to the peak. ⁄ Lines 250 to 260 Specifies the measurement parameter at the cut-off point to that obtained at the marker position and then turns ON the bandwidth search function.

-

Page 106: Various Analysis Methods Available With Waveform Analysis Commands

Analyzing Measurement Results Various analysis methods available with waveform analysis commands The Agilent 4294A provides waveform analysis commands that allow you, for example, to search for the maximum and minimum values on the waveform and analyze waveform ripples and resonator parameters. - Page 107 Processing Measurement Results Analyzing Measurement Results You can perform the same function by using the marker search function to move the marker to each of the peaks and reading the marker-specified value. NOTE The analysis range and the peak definition for waveform analysis commands are specified separately from those for marker search.

- Page 108 Cent, Span, Ana_trc$, and Thrr, respectively. Lines 140 to 180 Resets the Agilent 4294A, sets impedance amplitude and phase as measurement parameters, sets the sweep center value and the sweep span value, respectively, to Cent and Span, and specifies log Y-axis format as display format.

- Page 109 Processing Measurement Results Analyzing Measurement Results OUTPUT @Hp4294a;"ANARFULL" OUTPUT @Hp4294a;"ANAO"&Ana_trc$ OUTPUT @Hp4294a;"THRR ";Thrr OUTPUT @Hp4294a;"OUTPCERR?" ENTER @Hp4294a;Zr,Fr,Za,Fa,R1,R2,R3 PRINT " --- Analysis Result ---" PRINT "Resonant :";Zr;"[ohm]",Fr;"[Hz]" PRINT "Anti-Resonant:";Za;"[ohm]",Fa;"[Hz]" PRINT "Ripple L :";R1;"[ohm]" PRINT "Ripple M :";R2;"[ohm]" PRINT "Ripple R :";R3;"[ohm]" Chapter 7...

- Page 110 Processing Measurement Results Analyzing Measurement Results Chapter 7...

-

Page 111: Saving/Recalling A Measurement Result/Measurement Setup

Saving/Recalling a Measurement Result/Measurement Setup This chapter describes how to save/recall a measurement result, measurement setup, and other data into/from a file. -

Page 112: Save/Recall Of A File

Saving/Recalling a Measurement Result/Measurement Setup Save/Recall of a File Save/Recall of a File Specifying a location for save/recall You can select a mass storage for saving/recalling a file from the flash disk (non-volatile), the RAM disk (volatile), or a diskette. To select a mass storage, use the following command. -

Page 113: Recalling A File

You can recall a measurement result, calibration/compensation data (internal data arrays), and measurement setup saved in a file (whose extension is “.DAT” or “.STA”) to restore its contents on the 4294A. To recall a file, use the following command. •... -

Page 114: Copying/Deleting A File

Saving/Recalling a Measurement Result/Measurement Setup Save/Recall of a File Copying/deleting a file To copy a file, use the following command. • “FILC” on page 315 To delete a file, use the following command. • “PURG” on page 406 NOTE To copy/delete a file, specify a filename with its extension. Creating a directory To create a directory, use the following command. -

Page 115: Sample Program For Save/Recall

Clears the error queue. Line 540 Creates a program message to execute the save from the Command$ and File$ variables and sends it to the 4294A. Lines 550 to 560 Checks for the occurrence of an error. Lines 580 to 600... - Page 116 Saving/Recalling a Measurement Result/Measurement Setup Sample Program for Save/Recall Line 820 Allows the user to return to the entry start line and enter the data again if an error occurs due to, for example, a typing error. Lines 830 to 840 Prompts the user to enter a save filename (without extension) and waits for the entry of a filename.

- Page 117 Saving/Recalling a Measurement Result/Measurement Setup Sample Program for Save/Recall Example 8-1 Save/recall DIM File$[9],Inp_char$[30],Err_mes$[50],Extension$[9],Command$[9] INTEGER Content,Err_no CLEAR SCREEN IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 ELSE ASSIGN @Hp4294a TO 717 END IF OUTPUT @Hp4294a;"STOD FLASH" CALL Inp_file_name(File$) ON ERROR GOTO Data_select 140 Data_select: ! PRINT "Select Saved Content"...

- Page 118 Saving/Recalling a Measurement Result/Measurement Setup Sample Program for Save/Recall CALL Inp_file_name(File$) GOTO Save_file END IF IF UPC$(Inp_char$)="P" THEN OUTPUT @Hp4294a;"PURG """&File$&Extension$&"""" GOTO Save_file END IF PRINT "Save NOT Complete" ELSE PRINT "Save Complete" PRINT " Save File Name: "&File$&Extension$ END IF ! File Name Input Function SUB Inp_file_name(Inp_name$) DIM Inp_char$[30]...

-

Page 119: Communication With External Equipment (Using The I/O Ports)

Communication with External Equipment (Using the I/O Ports) This chapter describes how to use the 8-bit I/O port and the 24-bit I/O port of the Agilent 4294A to communicate with external equipment (for example, handlers in production lines). -

Page 120: Using The I/O Ports

Communication with External Equipment (Using the I/O Ports) Using the I/O Ports Using the I/O Ports 8-bit I/O port The 8-bit I/O port of the 4294A consists of the following TTL signal lines. • OUT0 to OUT7 (8-bit output) •... - Page 121 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports 8-bit I/O port control commands To output 8-bit data through the OUT0 to OUT7 lines, use the following command. Data is outputted as 8-bit binary, assuming that OUT0 is LSB (least significant bit) and OUT7 is MSB (most significant bit).

-

Page 122: 24-Bit I/O Port

Using the I/O Ports 24-bit I/O port The 24-bit I/O port of the 4294A consists of 4 independent data input/output parallel ports, several control signal lines, and a power line. All the signals provide TTL level. The data input/output port consists of 2 sets of 8-bit output ports and 2 sets of 4-bit bi-directional ports. - Page 123 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports Input/output port The 24-bit I/O port of the 4294A consists of 2 sets of output ports and 2 sets of bi-directional ports as shown below. • Output port...

- Page 124 This line has no fuse, but, if over-current flows, the protection circuit of the 4294A operates and the main power to the 4294A is automatically cut off. When the cause of over-current is removed, the power to the 4294A is restored, but the instrument states are reset to the power-on states.

- Page 125 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports Table 9-1 Signal assignment Pin number Signal name Signal specification TTL level, pulse input (width: 1 μs or more) INPUT1TTL OUTPUT1 TTL level, latch output OUTPUT2 TTL level, latch output Output port A0 TTL level, latch output Output port A1...

- Page 126 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports Basic input/output circuit Table 9-2 Basic input/output circuit of the 24-bit I/O port Basic Input port circuit I/O pin INPUT1 Ports C, D (input) Basic Output port Other circuit I/O pin OUTPUT1, 2...

- Page 127 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports Preset states at power-on The 24-bit I/O port is set at power-on as follows (not affected at reset). Logic Negative logic Write strobe signal HIGH SWEEP END signal HIGH Port A Negative 0 Æ...

- Page 128 Communication with External Equipment (Using the I/O Ports) Using the I/O Ports To read out data from each input port (C to E) to the controller, use the following commands. GPIB command Instrument BASIC command Description “OUTPINPCIO?” on page 381 “READIO(16,2)”...

-

Page 129: Sample Program To Use The I/O Port

Communication with External Equipment (Using the I/O Ports) Sample Program to Use the I/O Port Sample Program to Use the I/O Port Communication with external equipment shows a sample program to communicate with external equipment through the 8-bit I/O. This program is stored on the sample program disk as the io_port.bas file. - Page 130 Communication with External Equipment (Using the I/O Ports) Sample Program to Use the I/O Port Chapter 9...

-

Page 131: Handling Errors

Handling Errors This chapter describes how to handle errors that may occur in the Agilent 4294A while running a program. -

Page 132: Using The Status Register

“*ESE” on page 258 Here described is how to work with SRQ in your program. Step 1. Set the 4294A to generate SRQ when “1” is assigned to the each error occurrence bit of the standard event status register. Step 2. Perform an interruption processing at the time SRQ is generated. -

Page 133: Using The Error Queue

Handling Errors Using the Error Queue Using the Error Queue When an error occurred, its number and message will be stored in the error queue. Thus, reading contents of the error queue will enable it to verify which error occurred. Use the command below to read contents of the error queue. -

Page 134: Sample Program For Error Handling

This program performs necessary settings for SRQ, intentionally sends a command that the 4294A does not support to cause an error, then handles the error occurred. In the error handling, the error is identified, its error number and message are displayed followed by a message showing that the program is aborted. - Page 135 Handling Errors Sample program for error handling Example 10-1 Detecting of an error via SRQ DIM Buff$[9],Err_mes$[50] INTEGER Scode,Err_no IF SYSTEM$("SYSTEM ID")="HP4294A" THEN ASSIGN @Hp4294a TO 800 Scode=8 ELSE ASSIGN @Hp4294a TO 717 Scode=7 END IF OUTPUT @Hp4294a;"*ESE 60" OUTPUT @Hp4294a;"*SRE 32" OUTPUT @Hp4294a;"*CLS"...

- Page 136 Handling Errors Sample program for error handling Chapter 10...

-

Page 137: Using Hp Instrument Basic

Using HP Instrument BASIC This chapter gives an overview of HP Instrument BASIC and explains how to use the keyboard. Read this chapter before using the HP Instrument BASIC program installed in the Agilent 4294A. -

Page 138: Hp Instrument Basic, Overview

HP Instrument BASIC User's Handbook. Controlling the Agilent 4294A HP Instrument BASIC can control the 4294A’s main unit via the internal GPIB bus. This means that 4294A has a measuring device and a controller coupled together with the GPIB bus within a case. -

Page 139: Reserving An Area For Basic On The Screen

When the 4294A is powered on, the measurement screen (ALL INSTRUMENT) shows up. The BASIC screen is made ready so as to use HP Instrument BASIC. In the 4294A, four screen layouts are available. Let's go over these four screen layouts. -

Page 140: Editing A Program

Using HP Instrument BASIC Editing a Program Editing a Program Starting up and exiting edit mode Starting up edit mode with key operation on the front panel The following key operation allows you to start up edit mode regardless of the layout displayed on the screen. - Page 141 Using HP Instrument BASIC Editing a Program Inserting characters In edit mode, character insertion mode is constantly ready. What you type on the keyboard is inserted at the cursor position (not in overwrite mode). Moving the cursor You can move the cursor either leftward or rightward by the key operation given below. Front panel operation Keyboard operation Turn the rotary knob.

-

Page 142: Re-Numbering A Line Number

Using HP Instrument BASIC Editing a Program Clearing a line Pressing the [End] key while holding down the [Shift] key on the keyboard allows you to delete characters from the current cursor position to the end of that line. Re-numbering a line number The procedure given below allows you to re-number a line number of the program. -

Page 143: Running A Program

[Enter] Running a program through the softkey interface Step 1. Carry out the following key operation on the front panel. Then the 4294A displays a menu of softkeys that correspond to available program files residing on the selected storage device. -

Page 144: Listing A Program (List)

You output a program listing on the screen as described below. Step 1. Since a program listing is output on the BASIC area of the 4294A's LCD screen, you need to reserve the BASIC area before outputting a listing. For the procedure, see “Reserving an Area for BASIC on the Screen”... -

Page 145: Saving A Program (Save)

Using HP Instrument BASIC Saving a Program (SAVE) Saving a Program (SAVE) Step 1. To use the built-in floppy disk drive, insert a 2DD disk or 2HD disk into the floppy disk drive. (If the disk is not initialized, initialize it in DOS format. For the procedure see Operation Manual.) Step 2. -

Page 146: Listing File Names (Cat)

Displaying a list of file names on the screen Step 1. Since the list of file names is output on the BASIC area of the 4294A's LCD screen, you need to reserve the BASIC area before outputting the list. For the procedure, “Reserving an Area for BASIC on the Screen”... -

Page 147: Reading A Program (Get)

Using HP Instrument BASIC Reading a Program (GET) Reading a Program (GET) Here follows the procedure of reading a program from the storage unit. Step 1. To read a program from a floppy disk, inert it into the floppy disk drive. Step 2. -

Page 148: On Key Label Functions

Using HP Instrument BASIC ON KEY LABEL Functions ON KEY LABEL Functions HP Instrument BASIC provides you with a means to define softkeys within a program. Softkeys defined in a program will be displayed in the softkey label area if you press the while holding down the key on the keyboard or if you press the keys [F10]... -

Page 149: Pass Control Involved With An External Controller

When the 4294A has the control priority, the 4294A can specify another device on the GPIB bus to freely exchange (talk/listen) data. Similarly to the system controller, the 4294A can transmit data either to a printer or to a plotter (talk) and receive (listen) responses either from the printer or from the plotter. -

Page 150: Communicating With An External Controller

Example 11-1 shows an example of communication between an external controller and the 4294A Instrument BASIC. This example shows a program executable only on the external controller. It is given a file name prg_xfer.bas and is stored in the sample program disk. -

Page 151: Usable I/O Interfaces And Select Code

Using HP Instrument BASIC Usable I/O Interfaces and Select Code Usable I/O Interfaces and Select Code Interfaces usable in the 4294A Instrument BASIC and their select codes are as follow. Select code Device Keyboard External GPIB interface Internal GPIB interface... -

Page 152: Displaying Graphics

Displaying Graphics Displaying Graphics You can draw graphics on the screen of the 4294A by use of HP Instrument BASIC. the 4294A has two screens, that is, the instrument screen and the graphics screen. These screens are both always displayed on the LCD, and you cannot choose either of them to display. -

Page 153: Hard Copy

Using HP Instrument BASIC Displaying Graphics Hard copy You can produce hard copy output of graphics by use of the printing feature. Press the START key located under the [Copy] key. Default setting The default setting when the power is turned on is as follows. •... -

Page 154: Keyboard

Using HP Instrument BASIC Keyboard Keyboard Here is the description of key bindings of the keyboard. Character entry keys The character keys are laid out the same as U.S. 101 keyboard. Additional features are as follows. [Caps] Pressing this key switches between uppercase characters (default) and lowercase characters. -

Page 155: Numeric Keys

If you carry out the key operation [System] IBASIC Continue on the front panel of the 4294A, the temporary stop is canceled. Pressing the key while holding down the key and the [F4] [Shift] [Alt] key together stops program execution. -

Page 156: System Control Keys

[F1] [F8] panel of the 4294A. The softkey labels are displayed on the right hand part of the screen. Soft control keys [F9] This key turns on or off the BASIC menu to control a program and editor. -

Page 157: Softkeys Accessed From [Shift]+[F9] Key

Using HP Instrument BASIC Keyboard Softkeys accessed from key. [Shift] [F9] Pressing the [F9] key while holding down the [Shift] key calls the BASIC menu to be used for controlling a program. Pressing this softkey allows you to run a command or to generate program source code instead of keyboard entries. -

Page 158: The [Ctrl] In Edit Mode

Using HP Instrument BASIC Keyboard in edit mode [Ctrl] Pressing a certain key while holding down the key in edit mode works equivalently [CTRL] to one of the control keys such as [↑] [↓] [Insert] . Description of how these keys work is given below. -

Page 159: Instrument Basic Commands Specific To The Agilent 4294A

Reference” in HP Instrument BASIC User's Handbook, but they are available on HP Instrument BASIC of the 4294A. They can be run both by use of the keyboard and within programs. They, if used in a program, can be used in a single IF ... THEN ..line. -

Page 160: Readio

Using HP Instrument BASIC Instrument BASIC Commands Specific to the Agilent 4294A READIO This command reads the content of I/O ports. Syntax: READIO(<numerical 1>,<numerical 2>) Parameter Description Range of setting <numeric 1> Select code One of 15, and 16 15: 8-bit I/O port 16: 24-bit I/O port <numeric 2>... -

Page 161: Time

Using HP Instrument BASIC Instrument BASIC Commands Specific to the Agilent 4294A TIME This function indicates the elapsed time from 00:00 a.m. in seconds. • Examples of use Seconds=TIME("8:37:20") ! The elapsed time expressed in seconds ! from 00:00 a.m. to 08:37:20 a.m. -

Page 162: Instrument Basic Commands That Cannot Be Run On The Agilent 4294A

Using HP Instrument BASIC Instrument BASIC Commands that Cannot be Run on the Agilent 4294A Instrument BASIC Commands that Cannot be Run on the Agilent 4294A The commands given below are carried on “HP Instrument BASIC Language Reference” in HP Instrument BASIC User's Handbook, but they cannot be run on HP Instrument BASIC of the 4294A. -

Page 163: Using Lan

Using LAN This chapter describes LAN (Local Area Network)-based file transfer and remote control. -

Page 164: Advantages Of Lan Connection

Using LAN Advantages of LAN Connection Advantages of LAN Connection You can connect the Agilent 4294A with LAN. Connecting it with LAN allows you to make use of the functions given below. • You can easily transfer files between an external computer and the 4294A. -

Page 165: Getting Ready For Using Lan

Getting Ready for Using LAN Getting ready for LAN connection Before connecting the 4294A with LAN, you set an IP address (a unique address within a single LAN assigned to a device to identify it in making LAN connection), a gateway IP address (the IP address of a routing device that connects your the 4294A’s LAN with other... -

Page 166: Connecting With Lan

LCD screen. Connecting with LAN Use a 10Base-T twisted pair (Ethertwist) cable to connect the LAN port (RJ-45 connector) located at the lower left of the 4294A's rear panel with a vacant port of the LAN in view. Chapter 12... -

Page 167: Transferring Files

Using LAN Transferring Files Transferring Files You can transfer files from the 4294A, if connected to LAN, to an external computer connected to the same LAN or vice versa by use of FTP (file transfer protocol). NOTE The description given below assumes that you are familiar with the basic operation in a Window environment, such as Windows 95, Windows NT, and so on, and that you have basic knowledge about the operation of MS-DOS. - Page 168 The chief commands used in ftp are briefly described below. Transfers (Copies) a specified file from the current directory of the ftp server (the 4294A for the example above) to the ftp client (an external computer for the example above) Transfers (Copies) a specified file from the ftp client to the ftp server's current directory.

-

Page 169: File Transfer Procedure Using A File Transfer Application

A sample screen of file transfer application (before connecting with the 4294A) Step 2. Enter the IP address of the 4294A in the Server Name field (the field labeled 1 in Figure 12-1), enter suitable character(s) (any character(s) other than blank character(s)) in the User Name field (the field labeled 2 in Figure 12-1). - Page 170 Step 4. Copy files, similarly to the usual procedure for copying files by use of Windows 95 Explorer, from the external computer side (the window labeled 1 in Figure 12-2) to the 4294Aside (the window labeled 2 in Figure 12-2), or from the 4294A side to the external computer.

-

Page 171: Saving/Recalling A File In/From An External Computer

Accessing from an external computer to files held in the dynamic data disk of the 4294A by use of ftp allows you to directly save/recall measurement data, files of equipment settings, or Instrument BASIC programs in/from an external computer. - Page 172 Saves the current memory trace arrays of 4294A in files held on an data_mt.txt external computer in ASCII form. *1.get: Transfers files from the 4294A to an external computer put: Transfers files from an external computer to the 4294A. Chapter 12...

- Page 173 *3.This operation is ignored if an Instrument BASIC program is being edited or run on the 4294A. *4.If an Instrument BASIC program is being edited or run on the 4294A, the pro- cess of editing or running is suspended, and Instrument BASIC is reset, then the programs are downloaded and run.

-

Page 174: Controlling The Agilent 4294A

Step 4. Enter a command under the welcome message and press the Return key, then the command is sent to the 4294A and run. Enter a Query command and press the Return key, then a Query response is displayed. Figure 12-3 shows the screen that appears after you reset the 4294A by use of the “PRES”... - Page 175 In line mode, pressing the Return key sends characters entered up to that time to the 4294A. That is, characters are sent line by line. Thus if you make a mistake in typing a command, you can correct it by use of the Backspace key.

- Page 176 4294A. Figure 12-4 shows an example (in which the IP address 1.10.100.50 is assigned to the 4294A). Type 5025 in the Connection Port field (1 in Figure 12-4) and type either the IP address or the host name of the 4294A in the Host Name field (2 in Figure 12-4).

- Page 177 No. In the case of Version 1.1, for example, 256 × 1 + 1 = 257. Type the IP address of the 4294A into the cell at the right to “IP address.” If any of these two entries is wrong, this VBA macro will never work.

- Page 178 Table, like the Settings Table; clicking the Query button will read the existing List Sweep Table of the 4294A. Clicking the Clear button will clear the Settings Table. A line on which the Start column has any value will be set in the table even if other columns are blank, and these blank columns will be filled with their initial value.

- Page 179 Using LAN Controlling the Agilent 4294A wHighVersion As Integer szDescription As String * WSA_DescriptionSize szSystemStatus As String * WSA_SysStatusSize iMaxSockets As Integer iMaxUdpDg As Integer lpVendorInfo As String * 200 End Type 'Define socket return codes Public Const INVALID_SOCKET = &HFFFF...

- Page 180 Using LAN Controlling the Agilent 4294A Public Declare Function recv Lib "wsock32.dll" (ByVal s As Long, ByVal buf As Any, ByVal buflen As Long, ByVal flags As Long) As Long Public Declare Function recvB Lib "wsock32.dll" Alias "recv" (ByVal s As Long, buf As Any, ByVal buflen As Long, ByVal flags As Long) As Long Public Declare Function send Lib "wsock32.dll"...

- Page 181 (big endian). In (4), the connect function of WinSock is used for connection to 4294A. If an error occurs during this operation, the function outputs a message and returns processing to the main program. Parameters for the connect function are Socket Descriptor (input), Socket Address and Socket Address Size (input).

- Page 182 Using LAN Controlling the Agilent 4294A MsgBox ("ERROR: socket = " + Str$(socketId)) '....(2) OpenSocket = COMMAND_ERROR Exit Function End If 'Open a connection to a server I_SocketAddress.sin_family = AF_INET I_SocketAddress.sin_port = htons(PortNumber) '....(3) I_SocketAddress.sin_addr = ipAddress I_SocketAddress.sin_zero = String$(8, 0)

- Page 183 Using LAN Controlling the Agilent 4294A Example 12-5 RecvAscii Function RecvAscii(dataBuf As String, ByVal maxLength As Integer) As Integer Dim c As String * 1 Dim length As Integer dataBuf = "" While length < maxLength DoEvents count = recv(socketId, c, 1, 0) If count <...

-

Page 184: Control By Making Use Of The Dynamic Data Disk

4294A, and transfer that file to the external controller after the program quits. Chapter 12... -

Page 185: Application Sample Programs

Application Sample Programs This chapter provides sample measurements (sample programs). -

Page 186: Basic Measurement

This program performs the same measurement described in “Learning basic operations” of the Agilent 4249A Operation Manual. Connect the Agilent 16047E test fixture for lead parts to the Agilent 4294A, and then start the program. When “Set Open-Connection” appears, make the connection to measure data for open compensation, and press the and the key. - Page 187 Application Sample Programs Basic Measurement Lines 600 to 630 Performs a single sweep and waits for its completion. Lines 670 to 700 Executes the auto scale on trace A and trace B to automatically set the scale parameters so that waveforms fit on the screen. Lines 740 to 760 Searches for the minimum value (self-resonant point) on trace A using the marker.

- Page 188 Application Sample Programs Basic Measurement ! Display Setting OUTPUT @Hp4294a;"TRAC A" OUTPUT @Hp4294a;"FMT "&Fmt_a$ OUTPUT @Hp4294a;"TRAC B" OUTPUT @Hp4294a;"FMT "&Fmt_b$ OUTPUT @Hp4294a;"SPLD "&Spl_disp$ 550 Meas_start: ! Single Sweep Start PRINT "Set DUT, then Push [Enter] key" INPUT "",Inp_char$ OUTPUT @Hp4294a;"SING" PRINT "Now measuring..."...

- Page 189 Application Sample Programs Basic Measurement 1100 OUTPUT @Hp4294a;"COMC" 1110 END SELECT 1120 PRINT "Now measuring..." 1130 Meas_wait: GOTO Meas_wait 1140 Meas_end: ! 1150 PRINT Standard$&" Data Measurement Complete" 1160 RETURN 0 1170 ELSE 1180 PRINT "Program Interruption" 1190 RETURN -1 1200 END IF 1210 FNEND...

-

Page 190: Measuring Dielectric Material

Application Sample Programs Measuring Dielectric Material Measuring Dielectric Material This section describes how to measure dielectric material using the 4294A and the 16451B dielectric test fixture. Measurement Procedure Figure 13-2 shows the flow of dielectric measurement. Figure 13-2 Flow of Dielectric Measurement Step 1. - Page 191 C and D NOTE The 4294A does not allow you to define the LOAD standard using the values Cp and G. Therefore, you must use the OPEN standard and the LOAD standard inversely. To be more specific, first, define the OPEN standard value as the LOAD standard and the LOAD...

- Page 192 Application Sample Programs Measuring Dielectric Material Step 7. Insert the MUT Insert the MUT between the 16451B’s electrodes. Step 8. Cp-D measurement Measure the equivalent parallel capacitance (Cp) and the dissipation factor (D). When using the non-contacting electrode method, perform the Cp-D measurement twice in this step: one with the MUT connected and the other not connected.

-

Page 193: Sample Program For Contacting Electrode Method

The steps to use the program are described below: Step 1. Connect the 16451B dielectric test fixture to the 4294A, and start this program. When the message “Which electrode of 16451B is used? 0:A, 1:B, 2:C, 3:D” is displayed, select the electrodes you want to use by specifying the corresponding number (0 to 3). - Page 194 Application Sample Programs Measuring Dielectric Material Figure 13-3 Example of the Result of Executing the Program of Example 13-2 The program is described in detail below: Line 90 Sets the GPIB address. Lines 100 to 110 Assigns the upper half of the LCD screen to measurement result display and the lower half to the HP Instrument BASIC, and terminates the sweep.

- Page 195 Application Sample Programs Measuring Dielectric Material be parallel. Line 550 Passes control to a subroutine named Compen to execute fixture compensation. Lines 570 to 580 Passes control to subroutines named Input_t and Input_d to set the MUT thickness and the electrode diameter. Line 590 Passes control to a subroutine named Sweep to perform measurement.

- Page 196 Application Sample Programs Measuring Dielectric Material air capacitor is used as the LOAD standard. Lines 2230 to 2260: Waits until you adjust the distance between the electrodes so that the limit test results display PASS (an appropriate air capacitor value is obtained) and press the Continue key.

- Page 197 Lines 4330 to 4430 Processing when the softkey labeled as “Quit” is pressed. Example 13-2 Dielectric (Relative Permittivity) Measurement (Contacting Electrode Method) !************************************************************** !* 4294A + 16451B Permittivity Measurement (Contact Method) !* Instrument BASIC Sample Program !************************************************************** DIM Cp_data(1:801,1:2),D_data(1:801,1:2),Err_data(1:801,1:2) DIM Eri_data(1:801,1:2),Erm_data(1:801,1:2),Cole_data(1:801,1:2)

- Page 198 Application Sample Programs Measuring Dielectric Material PRINT "[ ] Select the main electrode of 16451B" PRINT "[ ] Perform the adapter setup (1m cable)" PRINT "[ ] Adjust the electrodes (Parallelizing)" PRINT "[ ] Perform fixture compensation" PRINT "x: done, s: skip, n: not required." 510 Adjustment: GOSUB Select_elec GOSUB Adapter_setup...

- Page 199 Application Sample Programs Measuring Dielectric Material 1090 PAUSE 1100 DISP "Wait until the setup is finished." 1110 OUTPUT @Agt4294a;"E4TP M1" 1120 Result=FNUser_Corr(@Agt4294a,"Adapter_Phase") 1130 IF Result<>0 THEN Prog_end 1140 OUTPUT @Agt4294a;"ECALDON" 1150 DISP "" 1160 PRINT TABXY(2,5);"x] " 1170 RETURN 1180 1190 Adjust:! 1200 IF Elec$="C"...

- Page 200 Application Sample Programs Measuring Dielectric Material 1730 IF Ans=1 THEN 1740 PRINT TABXY(2,7);"s] " 1750 RETURN 1760 END IF 1770 END IF 1780 PRINT TABXY(4,7);"->" 1790 Input_config:! 1800 DISP "Start frequency [Hz] = ?"; 1810 INPUT "",Start 1820 DISP "Stop frequency [Hz] = ?"; 1830 INPUT "",Stop 1840...

- Page 201 Application Sample Programs Measuring Dielectric Material 2350 2360 OUTPUT @Agt4294a;"STAR ";Start 2370 OUTPUT @Agt4294a;"STOP ";Stop 2380 OUTPUT @Agt4294a;"SWPT ";Swe_type$ 2390 OUTPUT @Agt4294a;"POIN ";Nop 2400 OUTPUT @Agt4294a;"BWFACT ";Bw 2410 OUTPUT @Agt4294a;"POWMOD VOLT;POWE ";Vosc 2420 OUTPUT @Agt4294a;"DCOMOPENG ";Load_g 2430 OUTPUT @Agt4294a;"DCOMOPENC ";Load_c/1.E-15 2440 OUTPUT @Agt4294a;"DCOMSHORR ";Short_r 2450...

- Page 202 Application Sample Programs Measuring Dielectric Material 2990 OUTPUT @Agt4294a;"*OPC?" 3000 ENTER @Agt4294a;Opc 3010 DISP "Now getting data..." 3020 OUTPUT @Agt4294a;"TRAC A" 3030 OUTPUT @Agt4294a;"AUTO" 3040 OUTPUT @Agt4294a;"OUTPDTRC?" 3050 ENTER @Agt4294a USING "%,K";Cp_data(*) 3060 OUTPUT @Agt4294a;"TRAC B" 3070 OUTPUT @Agt4294a;"AUTO" 3080 OUTPUT @Agt4294a;"OUTPDTRC?"...

- Page 203 Application Sample Programs Measuring Dielectric Material 3630 OUTPUT @Agt4294a;"HIDI OFF;SPLD ON" 3640 OUTPUT @Agt4294a;"TRAC A" 3650 OUTPUT @Agt4294a;"INPUDTRC "; 3660 FOR I=1 TO Nop 3670 OUTPUT @Agt4294a;Erm_data(I,1),Erm_data(I,2); 3680 NEXT I 3690 OUTPUT @Agt4294a;"" 3700 OUTPUT @Agt4294a;"AUTO" 3710 OUTPUT @Agt4294a;"TRAC B" 3720 FOR I=1 TO Nop 3730...

- Page 204 Application Sample Programs Measuring Dielectric Material 4270 CASE 1 4280 GOTO Display 4290 CASE ELSE 4300 GOTO Re_meas 4310 END SELECT 4320 4330 Quit: 4340 DISP "Really quit the program? 0:Yes, 1:Cancel"; 4350 INPUT "",Ans 4360 SELECT Ans 4370 CASE 0 4380 DISP "Bye."...

-

Page 205: Sample Program For Non-Contacting Electrode Method

This programs is very similar to Example 13-2, and therefore only its listing is given here. Example 13-3 Dielectric (Relative Permittivity) Measurement (Non-Contacting Electrode Method) !************************************************************** !* 4294A + 16451B Permittivity Measurement (Non-Contact Method) !* Instrument BASIC Sample Program !************************************************************** DIM Cp_data(1:801,1:2),D_data(1:801,1:2) DIM Cp_data1(1:801,1:2),D_data1(1:801,1:2),Err_data(1:801,1:2) - Page 206 Application Sample Programs Measuring Dielectric Material 550 Meas: ! GOSUB Input_t GOSUB Input_d DISP "Create the electrode gap Tg. Press 'Continue' when ready" PAUSE GOSUB Input_tg DISP "Insert MUT between electrodes and press 'Continue'" PAUSE GOSUB Sweep FOR I=1 TO Nop FOR J=1 TO 2 Cp_data2(I,J)=Cp_data(I,J) D_data2(I,J)=D_data(I,J)

- Page 207 Application Sample Programs Measuring Dielectric Material 1190 PAUSE 1200 DISP "Wait until the setup is finished." 1210 OUTPUT @Agt4294a;";E4TP OFF;E4TP M1" 1220 Result=FNUser_Corr(@Agt4294a,"Adapter_Phase") 1230 IF Result<>0 THEN Prog_end 1240 OUTPUT @Agt4294a;";ECALDON" 1250 DISP "" 1260 PRINT TABXY(2,5);"x] " 1270 RETURN 1280 1290 Adjust:! 1300...

- Page 208 Application Sample Programs Measuring Dielectric Material 1830 IF Ans=1 THEN 1840 PRINT TABXY(2,7);"s] " 1850 RETURN 1860 END IF 1870 END IF 1880 PRINT TABXY(4,7);"->" 1890 Input_config:! 1900 DISP "Start frequency [Hz] = ?"; 1910 INPUT "",Start 1920 DISP "Stop frequency [Hz] = ?"; 1930 INPUT "",Stop 1940...

- Page 209 Application Sample Programs Measuring Dielectric Material 2450 2460 OUTPUT @Agt4294a;";STAR ";Start 2470 OUTPUT @Agt4294a;";STOP ";Stop 2480 OUTPUT @Agt4294a;";SWPT ";Swe_type$ 2490 OUTPUT @Agt4294a;"POIN ";Nop 2500 OUTPUT @Agt4294a;";BWFACT ";Bw 2510 OUTPUT @Agt4294a;";POWMOD VOLT;POWE ";Vosc 2520 OUTPUT @Agt4294a;"DCOMOPENG ";Load_g 2530 OUTPUT @Agt4294a;"DCOMOPENC ";Load_c/1.E-15 2540 OUTPUT @Agt4294a;"DCOMSHORR ";Short_r 2550...

- Page 210 Application Sample Programs Measuring Dielectric Material 3090 OUTPUT @Agt4294a;"TRAC A" 3100 OUTPUT @Agt4294a;"AUTO" 3110 OUTPUT @Agt4294a;"OUTPDTRC?" 3120 ENTER @Agt4294a USING "%,K";Cp_data(*) 3130 OUTPUT @Agt4294a;"TRAC B" 3140 OUTPUT @Agt4294a;"AUTO" 3150 OUTPUT @Agt4294a;"OUTPDTRC?" 3160 ENTER @Agt4294a USING "%,K";D_data(*) 3170 RETURN 3180 3190 Calc: 3200 FOR I=1 TO Nop 3210...

- Page 211 Application Sample Programs Measuring Dielectric Material 3710 OUTPUT @Agt4294a;"MEAS CPD" 3720 OUTPUT @Agt4294a;"HIDI OFF;SPLD ON" 3730 OUTPUT @Agt4294a;"TRAC A" 3740 OUTPUT @Agt4294a;"INPUDTRC "; 3750 FOR I=1 TO Nop 3760 OUTPUT @Agt4294a;Erm_data(I,1),Erm_data(I,2); 3770 NEXT I 3780 OUTPUT @Agt4294a;"" 3790 OUTPUT @Agt4294a;"AUTO" 3800 OUTPUT @Agt4294a;"TRAC B"...

- Page 212 Application Sample Programs Measuring Dielectric Material 4350 GOTO Meas 4360 CASE 1 4370 GOTO Display 4380 CASE ELSE 4390 GOTO Re_meas 4400 END SELECT 4410 4420 Quit: ! 4430 DISP "Really quit the program? 0:Yes, 1:Cancel"; 4440 INPUT "",Ans 4450 SELECT Ans 4460 CASE 0...

-

Page 213: Measuring Magnetic Materials

Application Sample Programs Measuring Magnetic Materials Measuring Magnetic Materials This section describes how to measure magnetic materials using the 4294A (and the 42942A terminal adapter) and the 16454A magnetic material test fixture. Measurement Procedure Figure 13-2 shows the flow of magnetic material measurement. - Page 214 Application Sample Programs Measuring Magnetic Materials Step 3. Connect the 16454A Connect either the small of large electrode of 16454A (whose size is suitable for the shape of the magnetic material (MUT) you want to measure) to the 42942A. NOTE For details on how to handle the 16454A (the dimensions of the MUT suitable for measurement in each size (small or large)), refer to the 16454A Operation and Service Manual.

-

Page 215: Sample Program

How to use the program is described below: Step 1. Connect the 42942A terminal adapter to the 4294A, and start this program. When the message “Perform the adapter setup? 0:Yes, 1:Skip” is displayed, enter 0 if you want to set up the adapter. - Page 216 Application Sample Programs Measuring Magnetic Materials Figure 13-5 Example of the Result of Executing the Program of Example 13-4 The program is described in detail below: Lines 100 to 110 Sets the GPIB address and select code. Lines 120 to 130 Assigns the upper half of the LCD screen to measurement result display and the lower half to the HP Instrument BASIC, and stops the sweep.

- Page 217 Application Sample Programs Measuring Magnetic Materials Lines 510 to 630: When you finish connecting OPEN and press the Continue key, measures phase and OPEN with the same connection. Lines 640 to 810: Measures SHORT and LOAD in the same way. Lines 820 to 850: Calculates the setup data and saves it into the nonvolatile memory.

- Page 218 OUTPUT @Agt4294a;"HOLD" 140 Constants: U0=1.257E-6 !########################################## Main 170 Disp_proc: ! CLEAR SCREEN PRINT "4294A + 16454A Permeability Measurement Program" PRINT "" PRINT "[ ] Perform the adapter setup (7mm)" PRINT "[ ] Perform fixture compensation" PRINT "x: done, s: skip."...

- Page 219 Application Sample Programs Measuring Magnetic Materials 560 Phase_meas_end: ! OUTPUT @Agt4294a;"*CLS" ON INTR Scode GOTO Open_meas_end ENABLE INTR Scode;2 DISP "Now measuring OPEN data..." OUTPUT @Agt4294a;"ECALA" 620 Open_meas_wait: GOTO Open_meas_wait 630 Open_meas_end: ! OUTPUT @Agt4294a;"*CLS" ON INTR Scode GOTO Short_meas_end ENABLE INTR Scode;2 DISP "Connect SHORT (0-OHM) to the 7mm port and press 'Continue'."...

- Page 220 Application Sample Programs Measuring Magnetic Materials 1190 PRINT TABXY(1,11);"Sweep Type: ";Swe_type$;" OSC Level: ";Vosc;"[V] BW: ";Bw; 1200 DISP "Measurement condition is OK? 0:OK, 1:NO"; 1210 INPUT "",Ans 1220 IF Ans<>0 THEN Input_config 1230 1240 OUTPUT @Agt4294a;"CALP USER" 1250 OUTPUT @Agt4294a;"MEAS IRIM" 1260 OUTPUT @Agt4294a;"STAR ";Start 1270...

- Page 221 Application Sample Programs Measuring Magnetic Materials 1820 Urr_data(I,2)=0 1830 Uri_data(I,1)=R_data(I,1)/(Freq(I)*U0*H*LOG(C/B)) 1840 Uri_data(I,2)=0 1850 Tan_d_data(I,1)=Uri_data(I,1)/ABS(Urr_data(I,1)) 1860 Tan_d_data(I,2)=0 1870 Urm_data(I,1)=SQR(Urr_data(I,1)^2+Uri_data(I,1)^2) 1880 Urm_data(I,2)=0 1890 Cole_data(I,1)=Urr_data(I,1) 1900 Cole_data(I,2)=Uri_data(I,1) 1910 NEXT I 1920 RETURN 1930 1940 Display: ! 1950 ON KEY 1 LABEL "ur' - tan d",1 GOSUB Disp_ur_d 1960 ON KEY 2 LABEL "|ur| -...

- Page 222 Application Sample Programs Measuring Magnetic Materials 2460 OUTPUT @Agt4294a;"AUTO" 2470 OUTPUT @Agt4294a;"TRAC A" 2480 BEEP 2490 DISP "A: |ur| B: tan d " 2500 RETURN 2510 2520 Disp_ur_ui: ! 2530 DISP "Now loading data..." 2540 OUTPUT @Agt4294a;"MEAS LSR" 2550 OUTPUT @Agt4294a;"HIDI OFF;SPLD ON" 2560 OUTPUT @Agt4294a;"TRAC A"...

- Page 223 Application Sample Programs Measuring Magnetic Materials 3100 CASE ELSE 3110 GOTO Quit 3120 END SELECT 3130 Prog_end: END 3140 3150 ! Correction Data Measurement Function 3160 3170 DEF FNUser_Corr(@Agt4294a,Type$) 3180 DIM Inp_char$[9],Err_mes$[50] 3190 INTEGER Err_no 3200 3210 OUTPUT @Agt4294a;"ESNB 256" 3220 OUTPUT @Agt4294a;"*SRE 4"...

-

Page 224: Measurement Controlling Oscillator Level

DUT using the oscillator level monitor function. This program is stored on the sample program disk as the alc.bas file. Connect the Agilent 16047E test fixture for lead parts to the Agilent 4294A, and then start this program. When “Set Open-Connection” appears, make the connection to measure data... - Page 225 Application Sample Programs Measurement controlling oscillator level Lines 460 to 500 Turns on the manual sweep function and the level monitor function, and sets the oscillator level mode to Power_mode$. Lines 520 to 600 According to the oscillator level mode, substitutes the command name for reading the level monitor value, the range (lower limit and upper limit) of level setting into the variables: Command$, Range_l, and Range_u, respectively.

- Page 226 Application Sample Programs Measurement controlling oscillator level Fmt_b$="LINY" Pow_mode$="CURR" Level=.001 Err_limit=1.0 ! Osc Level Error Limit: 1[%] Iteration=10 OUTPUT @Hp4294a;"E4TP "&Adapter$ OUTPUT @Hp4294a;"PRES" OUTPUT @Hp4294a;"MEAS "&Meas_para$ OUTPUT @Hp4294a;"SWPT "&Swp_type$ OUTPUT @Hp4294a;"STAR ";Start OUTPUT @Hp4294a;"STOP ";Stop OUTPUT @Hp4294a;"POIN ";Nop ! Fixture Compensation (Open/Short) OUTPUT @Hp4294a;"ESNB 256"...

- Page 227 Application Sample Programs Measurement controlling oscillator level Count=Count+1 END WHILE OUTPUT @Hp4294a;"TRAC A" OUTPUT @Hp4294a;"OUTPDTRCP? ";I ENTER @Hp4294a;Data_a(1),Data_a(2) OUTPUT @Hp4294a;"TRAC B" OUTPUT @Hp4294a;"OUTPDTRCP? ";I ENTER @Hp4294a;Data_b(1),Data_b(2) OUTPUT @Hp4294a;"OUTPSWPRMP? ";I ENTER @Hp4294a;Swp_para PRINT USING Img$;Swp_para,Mon_lvl,Data_a(1),Data_b(1) NEXT I OUTPUT @Hp4294a;"TRAC A" 1000 OUTPUT @Hp4294a;"FMT "&Fmt_a$ 1010 OUTPUT @Hp4294a;"AUTO"...

- Page 228 Application Sample Programs Measurement controlling oscillator level Figure 13-6 An example of the output at the execution of the program in Example 13-5 ############# Measurement Result ############# Frequency Monitor: CURR Trace A Trace B 1.00000E+03 1.0051E-03 5.7868E-01 1.7915E+02 1.58489E+03 1.0021E-03 5.7978E-01 1.7871E+02 2.51189E+03...

-

Page 229: Measurement Using Scanner

Measurement using scanner To perform measurement using the scanner while switching differnet channels, compensation for each channel must have been done. The 4294A lets you perform measurement while scanning channels, by making the connection as shown in 4294A and using functions including the list sweep, reading/writing compensation coefficients, and the manual sweep. - Page 230 Scanning measurement flow Step 1. Connecting the instruments Connect the instruments as shown in Figure 13-9. Figure 13-9 Connection between 4294A and 3499A Step 2. Setting up the adapter Select 4TP 2M as the adapter and perform setup. Only the phase compensation is...

-

Page 231: Sample Program

Application Sample Programs Measurement using scanner performed here. Because the phase compensation is common to all the channels, perform it for one channel. For the phase compensation, you need to bring the measurement terminal into the open state as shown in Figure 13-10. Figure 13-10 Open state Step 3. - Page 232 Lines 890 to 920 Reads out the open compensation coefficient calculated from the measurement data from the 4294A and enters it to the variable Temp. Lines 930 to 960 Enters the sweep range for the channel from the variable Temp to Open.

- Page 233 Lines 1380 to 1430 Enters the created compensation coefficient to the 4294A. Lines 1470 to 1480 Sets the trigger source to the internal trigger and stops the sweep. Lines 1520 to 1530 In order to use SRQ, enables the instrument event status register's bit 1 (sweep completion) and sets the service request enable register's bit 2 to 1.

- Page 234 OUTPUT @Agt4294a;"PRES" OUTPUT @Agt4294a;"ESNB 256" OUTPUT @Agt4294a;"*SRE 4" OUTPUT @Agt4294a;"E4TP "&Adapter$ PRINT "##### Adapter Setup #####" PRINT "Channel 0 is activated." Result=FNSetup_4tp(@Agt4294a,Scode,"Open") IF Result<>0 THEN Prog_end OUTPUT @Agt4294a;"ECALDON" ! 4294A Setting OUTPUT @Agt4294a;"MEAS "&Meas_para$ OUTPUT @Agt4294a;"POWMOD "&Pow_mod$ OUTPUT @Agt4294a;"DCMOD "&Dc_mod$...

- Page 235 Application Sample Programs Measurement using scanner OUTPUT @Agt4294a;"EDITLIST" Point(0)=0 FOR I=0 TO Max_chan READ Start$,Stop$,Nop$,Osc$,Bias$,Bw$,Avg$ Point(I+1)=Point(I)+IVAL(Nop$,10) OUTPUT @Agt4294a;"SADD" OUTPUT @Agt4294a;"MEAS "&Meas_para$ OUTPUT @Agt4294a;"STAR "&Start$ OUTPUT @Agt4294a;"STOP "&Stop$ OUTPUT @Agt4294a;"POIN "&Nop$ OUTPUT @Agt4294a;"BWFACT "&Bw$ OUTPUT @Agt4294a;"POWE "&Osc$ OUTPUT @Agt4294a;"DCV "&Bias$ OUTPUT @Agt4294a;"PAVERFACT "&Avg$ OUTPUT @Agt4294a;"SDON"...

- Page 236 Application Sample Programs Measurement using scanner 1130 NEXT J 1140 PRINT 1150 NEXT I 1160 CLEAR SCREEN 1170 PRINT "##### Load Compensation #####" 1180 OUTPUT @Agt4294a;"DCOMLOADR 100OHM" 1190 OUTPUT @Agt4294a;"DCOMLOADL 0H" 1200 FOR I=0 TO Max_chan 1210 OUTPUT @Agt3499a;"CLOSE 10"&VAL$(I)&",11"&VAL$(I) 1220 PRINT "Channel "&VAL$(I)&"...

- Page 237 Application Sample Programs Measurement using scanner 1710 WAIT .2 1720 OUTPUT @Agt4294a;"*CLS" 1730 OUTPUT @Agt4294a;"*OPC?" 1740 ENTER @Agt4294a;Opc 1750 ON INTR 7 GOTO Sweep_end 1760 ENABLE INTR 7;2 1770 OUTPUT @Agt4294a;"MANR "&VAL$(Point(I)+1)&","&VAL$(Point(I+1)) 1780 OUTPUT @Agt4294a;"SING" 1790 PRINT "Measuring Channel ";VAL$(I) 1800 Sweep_wait: GOTO Sweep_wait 1810 Sweep_end: OFF INTR 7 1820...

- Page 238 Application Sample Programs Measurement using scanner 2280 Setup_start: 2290 PRINT "Set "&Standard$&"-Connection" 2300 INPUT "OK? [Y/N]",Inp_char$ 2310 OFF ERROR 2320 IF UPC$(Inp_char$)="Y" THEN 2330 ON INTR Scode GOTO Meas_end 2340 ENABLE INTR Scode;2 2350 PRINT "Now measuring..." 2360 SELECT Standard$ 2370 CASE "Open"...

-

Page 239: File Transfer Function

Then, recall the file to set the 4294A for the measurement and perform the measurement using the GPIB commands. The storage device of the 4294A allows you to handle files listed below in the DOS format. Both binary files and ASCII files can be transferred. -

Page 240: File Transfer From 4294A To External Controller

This program transfers a specified file in the current directory (RAM disk in the sample program of Example 13-7 ) of the 4294A to the current directory of the storage device (A drive in the sample program of Example 13-7 ) connected to the external controller, giving a file name you desire. - Page 241 Lines 80 to 90 Set the current directory of the external controller to A drive and sets the current directory of the 4294A to the RAM disk. You can set the current directory of the 4294A to the internal flexible disk using the STODDISK command.

-

Page 242: File Transfer From External Controller To 4294A